If you are looking for a way to improve the performance of your CNC machines, then grooving inserts may be the answer. Grooving inserts are designed to help remove material quickly and efficiently, which can result in improved cycle times and reduced manufacturing costs. This article will talk about how to choose the right grooving insert for your CNC machine.

What Are Grooving Inserts?

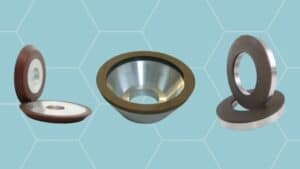

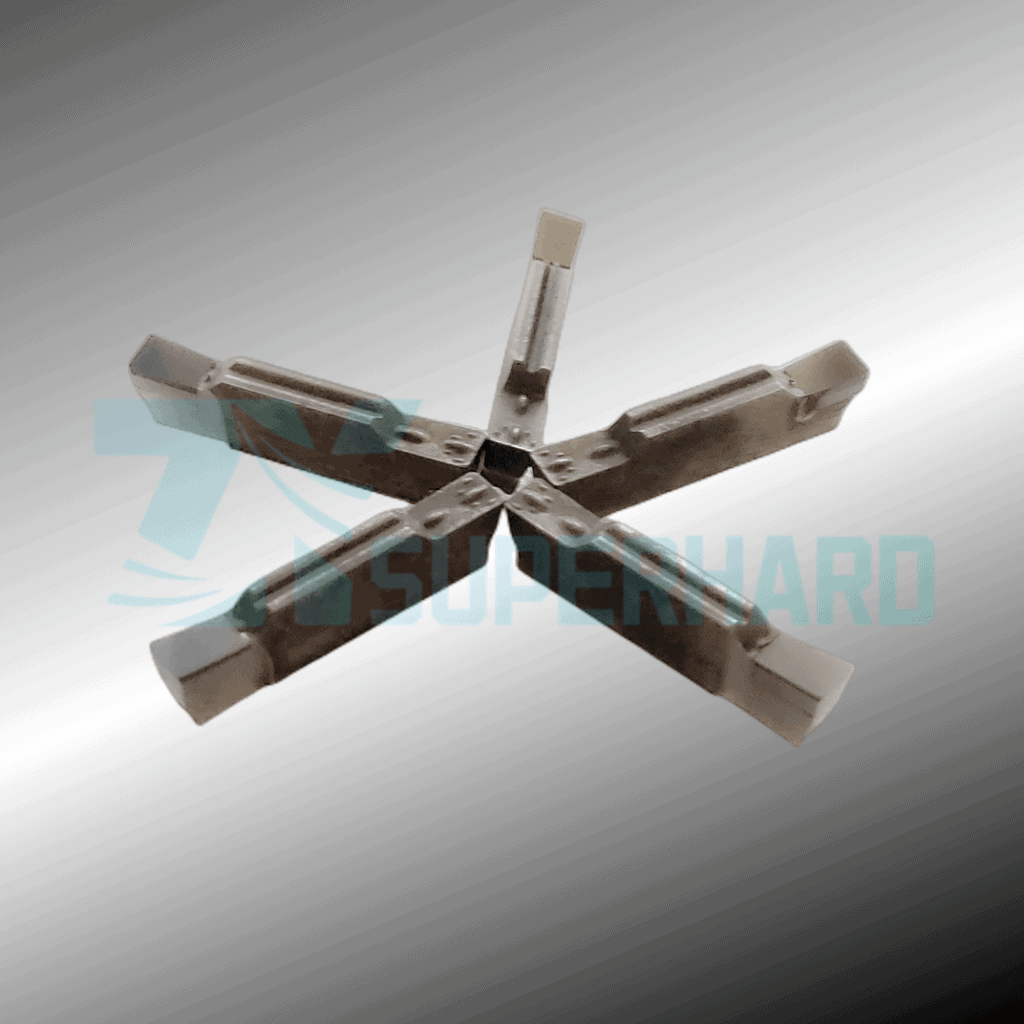

Grooving inserts are specially designed to cut grooves and other features into all materials, including hard-to-machine metals. They feature a unique shape that helps distribute cutting forces evenly, allowing them to create intricate shapes easily. The inserts also provide improved chip evacuation due to their geometry and sharp edges. This can lead to increased throughput and improved machining accuracy. Grooving inserts also come in a variety of sizes, shapes, and materials to suit your specific needs.

How To Buy The Right Grooving Inserts For Your Machine?

1. Determine the size of the insert you need based on the size of your machine. Ensure the insert will fit into the working space of your machine. Check the shape, size, and threading compatibility of the insert. Ensure it can be securely and accurately installed in your machine’s holding device.

2. Consider the type of material you will be machining – aluminum, steel, or stainless steel.

Different materials require different types of grooving inserts. Those made from carbide are great for machining aluminum, while steel and stainless steel may need ceramic or diamond-tipped inserts.

3. Choose a style of grooving insert that is compatible with your machine. Some inserts are designed to be used on milling machines, lathes, or boring machines. Ensure that the insert you select is compatible with your machine’s specifications.

4. Select an appropriate insert grade for the material you will be machining. The grade of the insert should be based on the hardness and toughness of the material, as well as its cutting speed, feed rate, and depth.

5. Purchase inserts from a reputable manufacturer to ensure quality and durability. Ensure the inserts are properly coated to protect against wear and tear.

Conclusion

When purchasing the right grooving inserts for your machine, it’s important to consider the size, shape, type of material, and style of insert that is compatible with your machine. Additionally, make sure to purchase inserts from a reputable manufacturer to ensure quality and durability. These tips will help you find the right grooving inserts for your machine.

If you still have questions about how to choose, you can also contact us; we will provide you with professional advice.