-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

Which Diamond Grinding Wheel is Best for Your Tungsten Carbide Project?

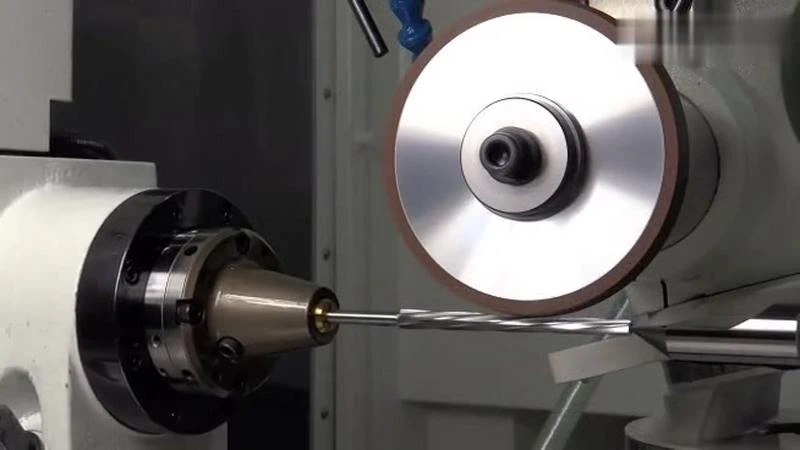

When facing a tungsten carbide grinding task, are you wondering which diamond wheel will truly deliver the best results for your specific project?

The best diamond grinding wheel for your tungsten carbide project depends on several factors, including the specific grinding application, the desired surface finish, the amount of material to be removed, and your machine capabilities. Generally, you’ll need to select an appropriate diamond grit size, bond type (resin, vitrified, metal, or electroplated), diamond concentration, and wheel shape that collectively match your project’s requirements for optimal performance, efficiency, and wheel longevity.

Why Are Diamond Wheels the Superior Choice for Grinding Tungsten Carbide?

So, why exactly are diamond grinding wheels considered the best option when you need to shape or sharpen tungsten carbide?

Diamond grinding wheels are the superior choice for tungsten carbide primarily because diamond is significantly harder than tungsten carbide, allowing for efficient material removal and precision. This exceptional hardness ensures effective grinding, helps maintain the integrity of the carbide tool, and typically provides a better surface finish compared to other abrasives, which often struggle against carbide’s extreme toughness and wear resistance.

Now, let’s delve deeper into the reasons behind this superiority.

Understanding the Unique Hardness of Tungsten Carbide

Tungsten Carbide1, often just called carbide, isn’t a simple metal. Instead, it’s a composite material made by chemically combining tungsten metal with carbon atoms. This combination creates a material that is incredibly hard and resistant to wear. Tungsten carbide is even harder than most common steels and many other hard materials.

On the Mohs scale of mineral hardness2, where talc is a 1 (very soft) and diamond is a 10 (the hardest), tungsten carbide typically ranks around 9 to 9.5. This puts it very close to the top, making it an excellent material for things that need to stay sharp or resist wear, such as:

- Cutting tools: Drill bits, end mills, and lathe inserts used in machining.

- Wear parts: Nozzles for abrasive blasting, dies for drawing wire, and seals in pumps.

- Mining and construction tools: Tips for drill bits used to cut through rock.

Because tungsten carbide is so hard, trying to grind it or shape it with a material that is not significantly harder is like trying to cut a very hard material with a much softer tool – it’s highly inefficient and can damage both the tool and the material. This is where diamond grinding wheels3 step in.

The Abrasive Power of Diamond: A Perfect Match

Diamond is, famously, the hardest known natural substance on Earth, scoring a perfect 10 on the Mohs scale. This exceptional hardness is the primary reason diamond grinding wheels are perfectly matched for working with tungsten carbide.

Think of the diamond particles embedded in a grinding wheel as millions of microscopic, super-sharp cutting edges. When the diamond wheel spins against the tungsten carbide workpiece:

- Penetration: These diamond edges are hard enough to penetrate the tough surface of the carbide.

- Material Removal: As they penetrate, they effectively chip away or “plough” tiny particles of carbide material. This process is known as abrasion.

- Maintaining Sharpness: Because diamond is so much harder than tungsten carbide, its cutting edges stay sharper for longer, continuing to remove material efficiently.

This ability to cleanly and effectively cut through such a hard material without quickly becoming dull is what sets diamond abrasives apart. It’s a bit like using an extremely sharp and durable chisel on very hard wood; a lesser tool would dull almost immediately.

Key Advantages Over Other Abrasive Types (e.g., Silicon Carbide)

While other abrasive materials exist, such as silicon carbide (SiC)4 or aluminum oxide, diamond offers distinct advantages when it comes to grinding tungsten carbide. Let’s compare diamond primarily with silicon carbide, which is another very hard abrasive often considered for tough materials.

| Feature | Diamond Abrasive | Silicon Carbide (SiC) Abrasive |

|---|---|---|

| Relative Hardness (Mohs) | 10 (Significantly harder than WC) | ~9 to 9.5 (Similar to, or only slightly harder than WC) |

| Grinding Efficiency on WC | High; removes material quickly. | Moderate to Low; much slower material removal. |

| Wheel Wear Rate on WC | Low; wheel maintains its shape and size for longer. | High; wheel wears down rapidly, losing its profile. |

| Heat Generation | Can be effectively managed with proper bond & coolant. | Can be higher if not managed well. |

| Achievable Surface Finish | Generally Good to Excellent. | Often Fair to Good; may struggle with fine finishes. |

| Dimensional Accuracy | Easier to maintain tight tolerances. | Difficult to maintain tolerances due to rapid wear. |

| Overall Cost-Effectiveness | Often lower in production due to longevity and speed. | Can be higher due to frequent wheel replacement and slower cycle times. |

Here’s a more detailed look at these advantages:

- Superior Hardness and Efficiency: As noted, diamond’s top-tier hardness means it cuts tungsten carbide much more effectively than silicon carbide. SiC, being only marginally harder or sometimes even similar in hardness to certain grades of tungsten carbide, tends to dull quickly. This results in slower grinding and more effort required. For instance, in manufacturing precision carbide end mills, using SiC would lead to unacceptably slow production and an inability to hold the sharp cutting edges required.

- Longer Wheel Life: Because diamond is so resilient against tungsten carbide, diamond grinding wheels last significantly longer. A silicon carbide wheel attempting to grind carbide will wear down very quickly, meaning more frequent stops to replace or “dress” the wheel (reshape it). In an industrial setting, this downtime adds up, reducing productivity.

- Better Surface Finish and Accuracy: The clean, efficient cutting action of diamond particles generally results in a smoother surface finish on the tungsten carbide workpiece. Furthermore, because the diamond wheel retains its shape and sharpness longer, it’s much easier to achieve and maintain precise dimensions and complex profiles, which is critical for high-performance tools and components.

- Reduced Thermal Damage Risk: While all grinding generates heat, efficient cutting (as with diamond) can sometimes lead to less overall heat buildup in the workpiece compared to an abrasive that is rubbing and struggling more than cutting. Coupled with appropriate coolant and grinding parameters (which we’ll discuss in a later section), diamond grinding can minimize the risk of thermal damage to the heat-sensitive tungsten carbide.

- Cost-Effectiveness in the Long Run: Although diamond grinding wheels usually have a higher initial purchase price than silicon carbide wheels, their extended lifespan, faster cutting speeds, and the reduced need for wheel changes often lead to a lower total cost per part ground. This is especially true in production environments where efficiency and consistency are paramount. For example, a facility producing hundreds of carbide inserts daily would find the operational efficiencies of diamond far outweigh its initial cost compared to the constant replacement and slower output associated with SiC.

In essence, while other abrasives might technically be able to remove some tungsten carbide material, diamond does it far more effectively, efficiently, and economically, making it the undisputed champion for this challenging application.

What Critical Specifications Must You Consider for Optimal Carbide Grinding?

So, you know diamond is the way to go for tungsten carbide, but how do you pick the right diamond wheel from all the options out there? What details truly matter?

To choose the best diamond grinding wheel for tungsten carbide, you must critically consider four key specifications: the diamond grit size, the bond type holding the diamonds, the diamond concentration within the bond, and the overall wheel shape and dimensions. Each of these factors significantly impacts grinding speed, surface finish, wheel lifespan, and suitability for your specific task and machinery.

Let’s break down each of these important specifications.

Selecting the Right Diamond Grit Size: From Rapid Removal to Precision Finishing

Think of diamond grit size like sandpaper grit. It refers to the size of the individual diamond particles embedded in the grinding wheel. These particles do the actual cutting. Choosing the right grit size is crucial because it directly affects how quickly you can remove material and the kind of surface finish you’ll achieve on your tungsten carbide part.

Grit sizes are typically indicated by numbers (mesh size) – a smaller number means larger, coarser diamond particles, while a larger number indicates smaller, finer particles. Sometimes, very fine grits are measured in microns.

Here’s a general guide:

- Coarse Grits (e.g., 40/60, 60/80, 80/100 mesh):

- Use: Best for rapid stock removal, rough grinding, or when you need to remove a lot of carbide material quickly. The surface finish will be rougher.

- Example: Quickly reshaping a significantly chipped or damaged carbide cutting tool before moving to finer sharpening, or rough grinding large carbide wear parts to near net shape.

- Medium Grits (e.g., 100/120, 120/150, 150/180, 200/230 mesh):

- Use: Offer a good balance between material removal rate and surface finish. Suitable for general-purpose grinding and sharpening.

- Example: Sharpening standard carbide end mills, drill bits, or saw blades where a reasonably good finish and sharp edge are needed. This range is very common in tool and cutter grinding.

- Fine Grits (e.g., 230/270, 270/325, 325/400 mesh, or finer micron sizes like 40/60µm down to 0/1µm for lapping):

- Use: Designed for precision finishing, achieving very smooth surfaces, creating keen cutting edges, or lapping operations. Material removal is slow.

- Example: Finish grinding on carbide dies for high-precision stamping operations, achieving a mirror-like polish on a carbide wear surface, or creating an ultra-sharp cutting edge on a precision surgical blade.

For instance, a workshop re-sharpening carbide router bits might first use a 100/120 grit wheel to restore the primary geometry if there’s significant wear, then switch to a 230/270 or finer grit wheel to create the final sharp cutting edge and smooth finish.

Important Note: While these grit ranges are typical, the exact performance and resulting finish can also depend on the specific grade of tungsten carbide you are grinding and the other grinding parameters used. It’s always a good idea to consult your supplier’s recommendations or data sheets for specific grit sizes suited to your exact application, as performance characteristics can vary.

Choosing the Appropriate Bond Type: Resin, Vitrified, Metal, or Electroplated?

The “bond” in a grinding wheel is the material that holds the diamond abrasive particles together. The type of bond significantly influences the wheel’s grinding characteristics, its durability, and its suitability for different applications on tungsten carbide. There are four main types, and understanding grinding wheel bond types5 is key:

- Resin Bond:

- Characteristics: Resin bonds are generally softer, offering a smoother grinding action and generating less heat. This makes them excellent for achieving fine surface finishes and for grinding heat-sensitive grades of tungsten carbide or delicate parts. They provide some shock absorption, which can be beneficial.

- Typical Use on Carbide: Widely used for tool and cutter grinding (e.g., sharpening end mills, reamers, carbide inserts), and for applications requiring a high-quality surface finish.

- Vitrified Bond (Ceramic Bond):

- Characteristics: Vitrified bonds are very hard, strong, and porous. This porosity aids in coolant delivery and chip clearance. They hold their form exceptionally well, making them ideal for precision grinding and applications requiring high dimensional accuracy. They can be used at higher speeds.

- Typical Use on Carbide: Precision grinding of carbide components like punches, dies, and wear parts where maintaining tight tolerances and intricate profiles is critical.

- Metal Bond:

- Characteristics: Metal bonds are the most durable and wear-resistant. They offer excellent wheel life and can withstand high grinding forces, making them suitable for aggressive stock removal and demanding applications. However, they may cut slower than other bonds initially and require more dressing.

- Typical Use on Carbide: Heavy-duty grinding of large carbide wear parts, cut-off applications (e.g., slicing carbide rods), or in high-volume production where wheel longevity is paramount.

- Electroplated Bond:

- Characteristics: In electroplated wheels, a single layer of diamond particles is bonded to the wheel’s surface using a nickel (or other metal) coating. This creates a very aggressive, free-cutting wheel ideal for rapid stock removal and grinding complex profiles. However, they generally have a shorter lifespan as there’s only one layer of abrasive.

- Typical Use on Carbide: Grinding intricate forms, specialized profile grinding, and applications where a very high initial material removal rate is needed.

The choice of bond will depend heavily on your specific grinding operation, the type of carbide, the machine you are using, and your desired outcome (e.g., speed vs. finish). For example, when manufacturing high-precision carbide stamping dies, a vitrified bond wheel might be preferred for its form-holding ability. Conversely, for sharpening carbide-tipped saw blades in a production setting, resin bond wheels are a common choice due to their good balance of finish and cutting efficiency. The optimal bond type can also depend on the specific formulation from the manufacturer, so discussing your application with your supplier is beneficial.

Understanding Diamond Concentration: Impact on Cutting Speed and Wheel Lifespan

Diamond concentration refers to the amount of diamond abrasive contained within a given volume of the bond material. It’s often expressed as a number, such as C25, C50, C75, C100, or C125. It’s important to understand that C100 does not mean the wheel is 100% diamond; rather, it’s a standard reference point (for example, C100 often corresponds to 4.4 carats of diamond per cubic centimeter of bond material, though this standard can vary slightly).

Diamond concentration plays a crucial role in:

- Cutting Speed and Material Removal Rate:

- Generally, a higher concentration means more diamond particles are actively cutting, which can lead to faster material removal. However, if the concentration is too high for the application or bond type, it can sometimes lead to increased grinding forces or “rubbing” rather than efficient cutting, especially with finer grit sizes.

- Wheel Lifespan:

- Higher diamond concentration typically results in longer wheel life because there’s more abrasive material available to do the work. However, wheels with higher concentrations also have a higher initial cost.

- Grinding Pressure and Finish:

- Lower concentration wheels may require less grinding pressure and can sometimes produce a finer finish because there’s more space between the cutting particles, which can aid in chip clearance. Higher concentration wheels can often handle higher grinding pressures.

- Cost:

- The amount of diamond is a primary driver of the wheel’s cost. Higher concentration means a more expensive wheel.

Choosing the right concentration involves balancing performance requirements (speed, finish) with economic considerations (wheel cost, wheel life). For example:

- In a high-volume production environment grinding carbide rods, a metal bond wheel with a higher concentration (e.g., C75 or C100) might be selected for its long life, even if the initial cost is higher.

- For precision finishing of intricate carbide tools, a resin bond wheel with a moderate or even lower concentration (e.g., C50 or C75) might be preferred to achieve a superior surface finish and better control, especially when combined with fine grit sizes.

Diamond concentration directly impacts wheel cost and performance. Therefore, it’s wise to consult your supplier for recommendations based on your specific carbide grade, machine capabilities, coolant use, and desired grinding results, as the ‘ideal’ concentration isn’t universal and can vary significantly based on the manufacturer’s design and the application’s demands.

Matching Wheel Shape and Dimensions to Your Grinder and Task

Finally, the physical shape and dimensions of the diamond grinding wheel must be compatible with your grinding machine and appropriate for the specific grinding task on your tungsten carbide workpiece.

Key dimensional aspects include:

- Overall Diameter (D): Must match your grinder’s specifications and provide adequate surface speed.

- Thickness (T or W): The width of the grinding face, chosen based on the area to be ground.

- Hole Diameter (H) or Arbor Hole: Must precisely fit your grinder’s spindle for secure and safe mounting.

- Diamond Layer Depth (X) and Width (W or U): For wheels where the diamond isn’t through the entire thickness (e.g., on the rim of cup wheels).

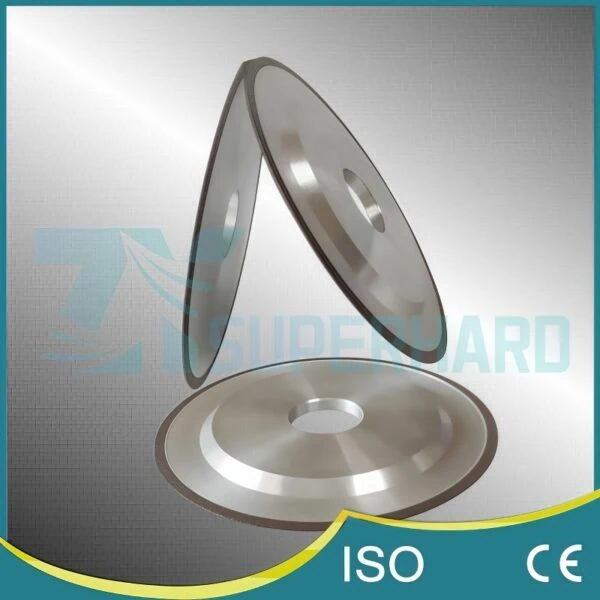

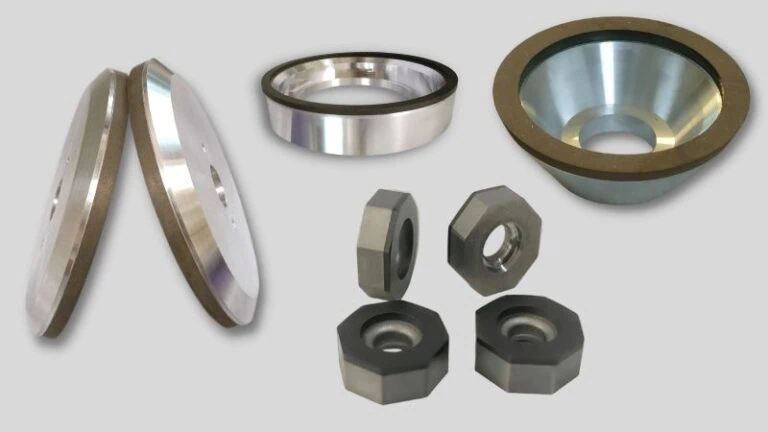

Common wheel shapes (designated by FEPA or ANSI standards) used for tungsten carbide include:

- Type 1 (Straight Wheels):

- Description: Simple, flat cylindrical wheels.

- Use on Carbide: Surface grinding flat carbide components, cylindrical grinding6 of carbide rods or shafts.

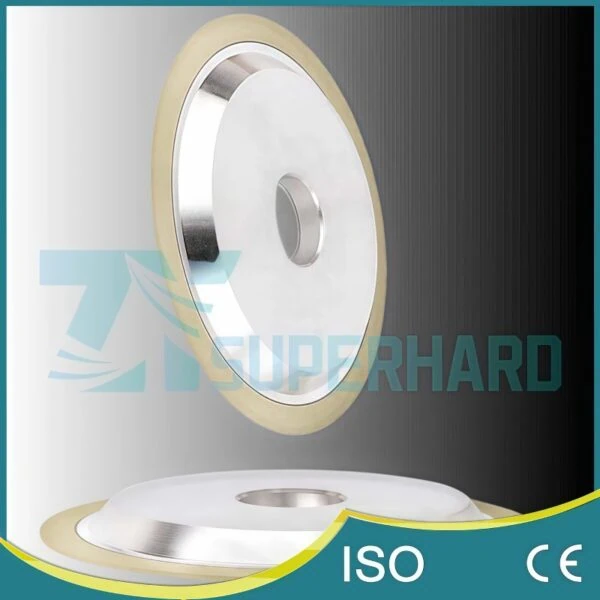

- Type 6 (Straight Cup Wheels) & Type 12 (Dish Wheels):

- Description: Cup-shaped or dish-shaped with the grinding face on the rim.

- Use on Carbide: Commonly used in tool and cutter grinding for sharpening the faces and flutes of carbide end mills, reamers, and other cutting tools.

- Type 11 (Flaring Cup Wheels):

- Description: Cup-shaped with angled sides, providing clearance.

- Use on Carbide: Excellent for sharpening carbide tools, especially for getting into tighter areas like the gullets of saw blades or complex tool geometries.

- Type 1A1 (Cut-off Wheels):

- Description: Thin, straight wheels designed for parting or slotting.

- Use on Carbide: Slicing carbide rods, cutting wear-resistant carbide strips.

The shape of the wheel determines how it can access the area on the tungsten carbide part that needs grinding. For instance, when sharpening the intricate flutes of a small carbide drill bit, a small diameter, specially shaped wheel like a Type 12V9 dish wheel or a Type 11V9 flaring cup wheel is necessary to reach into the confined geometry. In contrast, for grinding a large, flat carbide wear plate on a surface grinder, a larger diameter Type 1 straight wheel would be the appropriate choice.

Crucial Safety Note: Always ensure that the wheel’s maximum rated operating speed (RPM) is higher than or equal to your grinder’s maximum spindle speed. Additionally, carefully verify all wheel dimensions (diameter, arbor hole, thickness) with your supplier or the manufacturer’s catalog before ordering to guarantee a proper, secure fit and ensure safe operation. Using an incorrectly sized or rated wheel can be extremely dangerous.

Which Common Types of Diamond Wheels Excel for Different Carbide Applications?

Now that you understand the key specifications, you might be wondering: which specific type of diamond wheel, based on its bond, is actually best suited for my particular job on tungsten carbide?

The most suitable type of diamond wheel for tungsten carbide depends heavily on your application: resin bond wheels offer versatility and fine finishes for general tool grinding; vitrified bond wheels provide high efficiency and form-holding for precision work; metal bond wheels deliver durability for high-volume or demanding operations; and electroplated wheels are ideal for aggressive stock removal and complex profiles, especially in shorter runs.

Let’s explore how these common types of diamond wheels, primarily defined by their bond material, are applied to various tungsten carbide grinding tasks.

Resin Bond Wheels: Versatility for General Purpose Grinding and Fine Finishes

Resin bond diamond wheels7 use a phenolic or polyimide resin to hold the diamond particles. This bond is generally softer and more forgiving than other types.

Common Applications for Carbide:

- Tool and Cutter Grinding: This is a primary area for resin bond wheels. They are excellent for sharpening a wide array of tungsten carbide cutting tools, such as:

- End mills

- Drills

- Reamers

- Lathe tools

- Carbide inserts

- Router bits

The relatively cool cutting action and ability to produce sharp edges with good surface finishes make them ideal. For instance, resharpening the intricate flutes of a carbide spiral end mill to restore its cutting performance is a typical job for a resin bond diamond wheel.

- Off-Hand Grinding: When sharpening tools by hand on a bench grinder, the slightly softer nature of resin bond wheels provides a better feel and can be more forgiving of minor inconsistencies in pressure or angle.

- Fine Finishing: When a smooth surface finish is a key requirement on a carbide part, resin bond wheels combined with finer diamond grits excel.

- Heat-Sensitive Applications: Because they tend to generate less heat than metal or vitrified bonds, resin bonds are preferred for grinding heat-sensitive grades of tungsten carbide or tools where excessive heat could damage brazed joints (like carbide-tipped saw blades).

Strengths:

- Produces excellent surface finishes.

- Offers a relatively cool grinding action, reducing thermal stress on the workpiece.

- Versatile for a wide range of common carbide tools and general-purpose grinding.

- Often more economical for general tool room use.

Limitations:

- May wear more quickly than metal or vitrified bond wheels, especially in high-volume or aggressive material removal applications.

- May not hold intricate profiles as rigidly as vitrified bonds under heavy grinding loads.

Industry Example: A woodworking shop that frequently resharpens its own carbide-tipped saw blades and router bits would likely use various shapes and grit sizes of resin bond diamond wheels. Their ability to achieve a keen edge without overheating the brazed carbide tip is crucial.

A reminder that while resin bond wheels are broadly versatile, specific formulations (e.g., phenolic, polyimide, or filled resins) vary between manufacturers. Discussing your particular carbide grade, machine type, and desired finish with your supplier can help you select the most effective resin bond wheel for your needs.

Vitrified Bond Wheels: For High-Efficiency Grinding and Superior Form Holding

Vitrified bond diamond wheels8, also known as ceramic bond wheels, use a glass-like ceramic material to hold the diamond particles. This bond is very hard, strong, and often porous.

Common Applications for Carbide:

- Precision Grinding: Vitrified wheels are champions when dimensional accuracy, tight tolerances, and holding complex forms are critical. This includes:

- Grinding precise profiles on carbide tools.

- Creating accurate slots or flat surfaces.

- Manufacturing precision carbide components like punches, dies, and bushings.

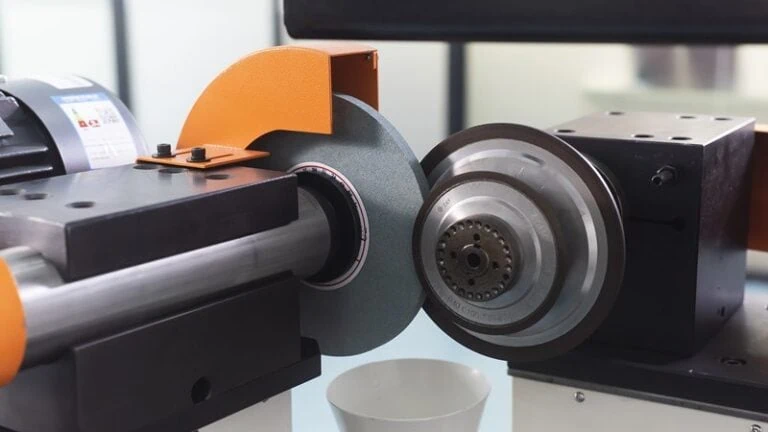

- High-Efficiency Production Grinding: Their rigidity and ability to maintain their shape allow for higher material removal rates and use at higher speeds, especially in CNC grinding operations with effective coolant systems.

- Grinding Harder/Tougher Carbide Grades: For particularly wear-resistant grades of tungsten carbide, the aggressive nature of vitrified bonds can be advantageous.

- Creep Feed Grinding: This technique, which involves taking deep cuts at slow traverse rates, often utilizes vitrified bond wheels due to their durability and form-holding ability.

Strengths:

- Excellent form-holding capability, crucial for profile grinding.

- Can be very aggressive and efficient in material removal.

- Porous structure can improve coolant delivery and chip clearance.

- Long-lasting in suitable high-precision, high-volume applications.

- Suitable for automation and CNC grinding processes.

Limitations:

- Can be more brittle than resin bonds, requiring rigid machines and stable setups.

- Dressing (reshaping and re-sharpening the wheel) can be more involved than with resin bonds.

- May have a higher initial cost compared to resin bond wheels.

Industry Example: In the automotive or electronics industries, the manufacturing of high-precision tungsten carbide stamping dies and punches relies heavily on vitrified bond diamond wheels. These wheels ensure that the intricate profiles of the dies, which might produce millions of parts, are ground to exceptionally tight tolerances (e.g., within a few microns).

It’s important to note that the performance characteristics of vitrified bond wheels, such as their friability (the ability of dull grains to break away and expose new sharp ones) and cutting action, are highly dependent on the specific ceramic bond formulation. Always consult with your supplier to accurately match the wheel to your machine’s rigidity, coolant system capabilities, and the specific requirements of your carbide application.

Metal Bond Wheels: Durability for High-Volume or Demanding Operations

Metal bond diamond wheels9 use various metal alloys (such as bronze, steel, or other sintered metals) to hold the diamond particles. This creates an extremely strong and wear-resistant bond.

Common Applications for Carbide:

- High-Volume Stock Removal: Ideal when large amounts of tungsten carbide need to be removed, such as in the initial shaping of carbide blanks or grinding large wear components.

- Cut-Off Applications: Thin metal bond diamond wheels are widely used for slicing or parting tungsten carbide rods, bars, and plates efficiently.

- Demanding and Abrasive Environments: Suitable for grinding carbide components used in highly abrasive environments, like mining tools or agricultural wear parts, where wheel durability is paramount.

- Applications Prioritizing Wheel Life: When the longest possible wheel life is more critical than achieving the finest surface finish, metal bonds excel.

Strengths:

- Extremely durable and offer the longest lifespan among bond types.

- Can withstand high grinding forces and harsh operating conditions.

- Excellent for maintaining size and form in very long production runs.

Limitations:

- Can generate more heat if not used with adequate coolant and proper parameters.

- May require higher grinding pressures to achieve optimal cutting action.

- Dressing metal bond wheels to expose new diamond particles can be more difficult and time-consuming.

- Often provides a rougher surface finish compared to resin or vitrified bonds.

- May have a slower cutting rate initially until the bond “opens up” to expose the diamonds.

Industry Example: A manufacturer producing tungsten carbide rods for various industrial uses would likely employ metal bond diamond cut-off wheels for efficiently slicing these rods to precise lengths in a high-volume setting. Similarly, refurbishing large carbide wear blocks from rock crushing equipment, where significant material removal is needed and toughness is key, would benefit from metal bond wheels.

Metal bond diamond wheels are available in various specific metal matrix formulations. The choice of the metal bond (e.g., bronze, steel alloy) significantly impacts the wheel’s wear characteristics and its suitability for wet versus dry grinding conditions, as well as for different grades of tungsten carbide. This choice should be discussed with your grinding wheel supplier.

Electroplated Wheels: Ideal for Aggressive Stock Removal and Complex Profiles

Electroplated diamond wheels10 feature a single layer of diamond particles bonded to the wheel’s core (often steel) by a layer of nickel or another metal applied through an electroplating process.

Common Applications for Carbide:

- Aggressive Stock Removal (Short Runs): When a very high initial cutting rate is needed for a specific task or for short production runs, electroplated wheels can be effective.

- Grinding Complex Forms and Profiles: Because the diamond can be plated onto pre-formed wheel cores, this method is excellent for creating wheels with intricate or custom profiles for special carbide grinding tasks.

- Hand-Held Grinding Operations: The free-cutting nature of electroplated tools can be beneficial for manual operations with grinders or flexible shaft tools, such as deburring or shaping small carbide parts.

- Internal Grinding: Small electroplated diamond points or internal grinding wheels are used for grinding the inside diameters of small carbide bores or bushings.

Strengths:

- Very free-cutting with a high initial material removal rate due to maximum diamond exposure.

- Excellent for producing and maintaining complex profiles.

- Often lower initial cost, especially for custom-shaped wheels, as no complex molding or sintering is required for the abrasive layer.

Limitations:

- Generally have the shortest wheel life because there is only a single layer of diamond. Once this layer is worn, the wheel is usually no longer effective (unless it’s a core designed for re-plating).

- The surface finish might not be as fine as that achievable with resin or fine-grit vitrified wheels.

- Performance can drop off significantly once the initial sharpness of the exposed diamonds diminishes.

Industry Example: A toolmaker needing to create a specific non-standard radius or chamfer on a small batch of prototype tungsten carbide components might opt for a custom-profiled electroplated diamond wheel due to its quick turnaround and lower cost for a unique shape. Another common use is small, mounted electroplated diamond burrs used by hand to deburr or modify intricate features on carbide die components.

The quality and operational lifespan of an electroplated diamond wheel are heavily influenced by the precision of the plating process and the quality of the diamond used. For applications involving larger batch sizes or requiring highly consistent long-term performance, it’s worth discussing with your supplier whether re-platable cores are a viable option or if other bond types might prove more economical in the long run.

How Can You Maximize Performance and Extend the Life of Your Diamond Wheel on Carbide?

So, you’ve chosen your diamond wheel, but how do you make sure you get the absolute best performance from it and ensure it lasts as long as possible when grinding tough tungsten carbide?

To maximize performance and extend the life of your diamond wheel on tungsten carbide, you must focus on three critical areas: employing essential wheel mounting, truing, and dressing practices; optimizing grinding parameters like speeds, feeds, and coolant application; and recognizing and avoiding common grinding mistakes. Proper care and correct usage are key to achieving both efficiency and longevity.

Let’s explore these practices in more detail.

Essential Wheel Mounting, Truing, and Dressing Practices

Getting the setup right before you even start grinding is fundamental. Think of it like ensuring a car’s tires are properly fitted and balanced before a long race.

1. Wheel Mounting:

Proper mounting is crucial for safety and performance.

- Cleanliness is Key: Always ensure the grinder’s spindle, flanges (the circular plates that hold the wheel), and the wheel’s arbor hole are perfectly clean and free from burrs or old debris.

- Use Blotters: If recommended for your wheel type (often for vitrified or larger resinoid wheels), use clean, undamaged blotters (paper or compressible washers) between the wheel and the flanges. These help distribute clamping pressure evenly.

- Correct Tightening: Tighten flange screws or the spindle nut just enough to hold the wheel securely. Use a star pattern for multiple screws to ensure even pressure and prevent wheel distortion or cracking. Do not over-tighten.

- Check for Runout: After mounting, it’s good practice to check the wheel for radial (up and down) and axial (side to side) runout using a dial indicator. Excessive runout will cause vibration, poor finish, and uneven wheel wear. Aim for minimal runout, often within 0.0005 inches (0.013 mm) or less for precision work.

- Safety First: Never force a wheel onto a spindle if it doesn’t fit easily. Inspect every wheel for cracks or damage before mounting.

2. Truing the Wheel:

Truing makes the grinding wheel periphery perfectly round and concentric with the spindle axis. It also ensures the wheel face is flat and true.

- Why Truing is Essential: A true wheel ensures even contact with the workpiece, prevents vibration, improves surface finish, allows for accurate form grinding, and significantly extends the wheel’s effective life. It’s especially important for new wheels or wheels that have been remounted.

- How It’s Done: Truing is often done using a brake-controlled truing device that feeds a silicon carbide or aluminum oxide wheel across the diamond wheel’s face. Specialized diamond truing tools or rotary dressers can also be used, particularly for vitrified bond wheels. The process gently grinds the diamond wheel to achieve the desired geometry.

- Example: For precision surface grinding of carbide blocks, truing a newly mounted diamond wheel to within a few ten-thousandths of an inch (or a few microns) of runout is critical for achieving the required flatness and parallelism on the finished parts.

3. Dressing the Wheel:

Dressing is the process of reconditioning the cutting face of the diamond wheel. Its main purposes are:

- Exposing New Diamond Particles: Over time, the bond material can wear down flush with the diamond particles, or the diamonds themselves can become dull or flattened. Dressing removes a small amount of bond material to expose fresh, sharp diamond cutting edges.

- Removing “Loading”: Swarf (tiny particles of the ground material – in this case, carbide) and worn bond material can clog the spaces between diamond particles. This is called “loading,” and it makes the wheel cut inefficiently. Dressing cleans this loaded material away.

For a practical guide, see this article on diamond wheel dressing11. - When to Dress: You’ll know your wheel needs dressing when it starts to cut slowly, generates more heat, produces a poor surface finish, or makes a different sound (often a high-pitched squeal if glazed).

- Dressing Methods (vary by bond type):

- Resin Bond Wheels: Often dressed by lightly applying a soft-grade abrasive stick (e.g., white aluminum oxide or green silicon carbide of an appropriate grit) to the rotating wheel face.

- Vitrified Bond Wheels: May require more robust dressing, sometimes with harder abrasive sticks, specialized rotary diamond dressers, or by grinding a piece of sacrificial material.

- Metal Bond Wheels: These can be the most challenging to dress due to the bond’s toughness. Specialized techniques, very hard abrasive sticks, or even controlled “abrading” against a softer steel block might be used.

- Electroplated Wheels: Generally, these are not dressed. Since they have only a single layer of diamond, dressing would remove the abrasive and shorten their already limited life. They are used until the diamond layer is worn out.

- Example: After sharpening many carbide end mills, a resin bond diamond wheel might start to “glaze” (become smooth and shiny). The operator would then gently press a soft aluminum oxide dressing stick against the rotating wheel for a few seconds. This action abrades away a tiny amount of the loaded resin bond, exposing fresh diamond particles and restoring the wheel’s cutting ability.

A crucial point: Truing and dressing procedures, especially the choice of dressing stick material, grit, and the technique used, can vary significantly based on the diamond wheel’s specific bond type, diamond grit size, concentration, and the manufacturer’s detailed recommendations. Always consult your wheel supplier’s guidelines or technical support for the best practices for your particular wheel.

Optimizing Grinding Parameters: Speeds, Feeds, and Coolant Application

Once your wheel is perfectly mounted and prepared, using the right grinding settings is the next step to achieving top performance and long life.

1. Wheel Speed (Surface Speed):

This isn’t just about how fast the grinder’s spindle rotates (RPM – Revolutions Per Minute), but more importantly, the speed at which the wheel’s cutting surface travels (often measured in Surface Feet Per Minute – SFPM, or meters per second – m/s).

- Manufacturer’s Recommendation is Key: Diamond wheel manufacturers provide recommended surface speed ranges for their wheels based on the bond type, diameter, and intended application.

- Too Slow: Can lead to inefficient cutting, increased wheel wear, and a poor finish.

- Too Fast: Can be dangerous (risk of wheel breakage!), generate excessive heat, cause the wheel to glaze (lose its cutting ability), or even damage the bond.

- Typical Ranges: These are very general and can vary widely. For example, resin bond diamond wheels for carbide might operate in the 3,000-6,000 SFPM (15-30 m/s) range, while some vitrified bonds might be designed for higher speeds. Always check the specific wheel.

2. Feed Rates (Infeed/Depth of Cut & Traverse Speed):

- Infeed/Depth of Cut: This is how much material the wheel removes in a single pass.

- Too Aggressive: Can overload the wheel and machine, cause excessive heat, damage the diamond particles or bond, lead to workpiece burning or cracking, and result in poor dimensional accuracy.

- Too Light: Can be inefficient, leading to long cycle times, and may cause the wheel to rub rather than cut, leading to glazing.

- Traverse Speed: This is how quickly the workpiece moves past the wheel (or the wheel across the workpiece).

- Finding the Balance: The traverse speed must be balanced with the depth of cut and wheel speed to allow the diamond particles to cut effectively without being overloaded or, conversely, without “skipping” over the surface.

- Example: When rough grinding a tungsten carbide component with a resin bond wheel, an infeed of 0.0005″ to 0.001″ (0.013 mm to 0.025 mm) per pass might be appropriate. For a fine finishing pass, the infeed might be reduced to just 0.0001″ to 0.0002″ (0.0025 mm to 0.005 mm). Traverse speeds would be adjusted to ensure a consistent cutting action.

3. Coolant Application:

Using coolant (also called grinding fluid) is almost always essential when grinding tungsten carbide with diamond wheels.

- Why Coolant is Critical:

- Heat Dissipation: Grinding generates significant heat. Coolant carries this heat away, preventing thermal damage to the sensitive tungsten carbide (which can cause micro-cracks) and protecting the diamond wheel’s bond material from overheating and degrading.

- Lubrication: It reduces friction between the wheel, the workpiece, and the grinding chips.

- Chip Removal: Coolant flushes away the tiny grinding chips (swarf), preventing them from clogging or “loading” the wheel’s surface, which maintains cutting efficiency.

- Types of Coolant: Synthetic coolants are very common for grinding carbide with diamond wheels due to their excellent cooling and cleaning properties. Semi-synthetics and some soluble oils may also be used. The choice can depend on the specific carbide grade, wheel bond, and machine.

- Proper Application: It’s not enough to just have coolant; it must be applied generously and effectively. This means using nozzles that direct a strong, consistent flow of clean, filtered coolant precisely to the grinding zone – where the wheel meets the workpiece.

- Example: On a CNC tool grinding machine producing carbide end mills, multiple high-pressure coolant nozzles are precisely aimed at the grinding interface. This ensures that the vitrified diamond wheel and the carbide flute being ground are constantly flooded with clean synthetic coolant, allowing for aggressive material removal while maintaining dimensional accuracy and preventing thermal damage.

Important Consideration: Optimal grinding parameters—including wheel speed, feed rates, and depth of cut—are highly dependent on many factors: the specific diamond wheel (its bond, grit, concentration, and diameter), the particular grade of tungsten carbide being ground, the rigidity and power of the grinding machine, and the type and application of the coolant system. It is always best to start with the wheel manufacturer’s or machine tool builder’s baseline recommendations and then make small, incremental adjustments while carefully observing the grinding process (sparks, sound, surface finish, wheel wear, and part temperature) to fine-tune for your specific setup.

Recognizing and Avoiding Common Grinding Mistakes with Tungsten Carbide

Even with the best wheel and machine, mistakes can happen. Being aware of common pitfalls can save you time, money, and frustration.

- Using the Wrong Wheel Specifications:

- Mistake: Not matching the diamond grit size, bond type, or concentration to the specific carbide grade, desired finish, or material removal requirements. (This links back to the importance of the choices discussed earlier).

- Result: Inefficient grinding, poor surface finish, rapid wheel wear, or even damage to the workpiece.

- Improper Wheel Preparation:

- Mistake: Skipping or incorrectly performing truing or dressing operations.

- Result: Vibration, chatter marks on the workpiece, poor dimensional accuracy, rapid or uneven wheel wear, and potential damage to the workpiece from an untrue or loaded wheel.

- Excessive Grinding Pressure or Aggressive Feeds:

- Mistake: Trying to remove too much material too quickly by applying excessive force or taking too deep a cut.

- Result: Can chip or crack the diamond wheel, overheat and burn the tungsten carbide workpiece (leading to micro-cracks), cause dimensional inaccuracies, or even stall or damage the grinding machine.

- Insufficient or Improper Coolant Application:

- Mistake: Using too little coolant, applying it ineffectively (e.g., nozzle aimed incorrectly), or using dirty/contaminated coolant.

- Result: Overheating of both the workpiece and the wheel bond, leading to thermal cracks in the carbide, wheel glazing (diamonds get covered by molten bond or loaded material), significantly shortened wheel life, and poor surface finish.

- Ignoring Machine Condition:

- Mistake: Using a grinding machine that has worn spindle bearings, loose components, a lack of rigidity, or insufficient power.

- Result: Leads to vibrations (causing chatter marks on the workpiece), difficulty in holding tight tolerances, premature or uneven diamond wheel wear, and can be a safety hazard.

- Allowing the Wheel to Glaze or Load Excessively:

- Mistake: Not recognizing the signs of a glazed (shiny, smooth wheel face) or loaded (clogged with material) wheel and failing to dress it promptly.

- Result: The wheel stops cutting efficiently and starts to rub, generating excessive heat, producing a poor surface finish, and potentially damaging the workpiece.

- “Pushing” a Dull or Worn-Out Wheel:

- Mistake: Continuing to use a diamond wheel that is clearly dull, needs dressing, or has reached the end of its usable life.

- Result: Extremely inefficient grinding, excessive heat generation, high risk of workpiece damage, operator fatigue, and ultimately higher costs due to wasted time and materials.

- Overlooking Safety Precautions:

- Mistake: Not using appropriate personal protective equipment (PPE) like safety glasses or face shields, or operating the grinder with machine guards removed or improperly adjusted.

- Result: Increased risk of serious injury from flying debris or wheel breakage.

Industry Example: A common error observed in workshops, especially where operators may not be fully trained in diamond grinding, is to continue forcing a glazed resin bond wheel to cut when sharpening carbide tools. This often results in the carbide tips overheating, turning blue or brown (a sign of thermal damage), which can soften the carbide or damage the braze joint. Recognizing the subtle change in grinding sound or the increased effort needed, and then correctly dressing the wheel, could prevent this damage and restore efficient cutting. Taking a moment to dress the wheel is far more productive than struggling with a dull one.

By understanding and implementing these best practices, you can significantly improve your tungsten carbide grinding operations, achieving better quality parts, faster cycle times, and getting the most value from your investment in diamond grinding wheels.

Conclusion

Selecting and correctly using the right diamond grinding wheel for tungsten carbide is a critical skill that blends understanding material properties, wheel specifications, and operational best practices. By carefully considering why diamond is superior, what specifications to look for, which wheel types suit different applications, and how to optimize their use while avoiding common mistakes, you can transform your carbide grinding from a challenging task into an efficient and precise manufacturing process. Remember that consulting with your wheel supplier for specific recommendations tailored to your unique needs can further enhance your results and ensure you achieve the desired quality and productivity in all your tungsten carbide projects.

References

- Tungsten Carbide1 – Britannica article explaining the properties and uses of tungsten carbide.

- Mohs scale of mineral hardness2 – National Park Service (USA) page detailing the Mohs Hardness Scale.

- diamond grinding wheels3 – ZYDiamondTools blog post providing a general introduction to diamond grinding wheels.

- silicon carbide (SiC)4 – Britannica article explaining the properties and applications of silicon carbide.

- grinding wheel bond types5 – ZYDiamondTools blog post explaining different grinding wheel bond types and their selection.

- cylindrical grinding6 – ZYDiamondTools blog post on diamond cylindrical grinding wheels and their selection.

- Resin bond diamond wheels7 – ZYDiamondTools comprehensive guide to selecting and applying resin bond diamond and CBN grinding wheels.

- Vitrified bond diamond wheels8 – ZYDiamondTools comprehensive guide to vitrified bond diamond and CBN grinding wheels for selection and high-performance grinding.

- Metal bond diamond wheels9 – ZYDiamondTools article explaining why metal bond diamond/CBN wheels excel and how to select them.

- Electroplated diamond wheels10 – ZYDiamondTools ultimate guide to electroplated diamond and CBN grinding wheels.

- diamond wheel dressing11 – ZYDiamondTools practical how-to guide on mastering diamond wheel dressing.