-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

What Is Honing and How Does It Achieve a Perfect Surface Finish?

So, what exactly is honing, and what makes it so special for creating perfect surfaces?

Honing is a precision machining process that uses abrasive stones to correct the geometry and improve the surface finish of internal bores. It achieves a perfect finish through a unique combination of low-speed rotation and reciprocation, which allows the tool to correct errors in roundness and straightness while creating a specific, functional surface texture like a cross-hatch pattern.

How Does the Honing Process Correct Geometric Errors?

So, how exactly does a honing tool fix a hole that isn’t perfectly round or straight?

The honing process corrects geometric errors through the combined action of a rotating and reciprocating abrasive tool that operates under low, controlled pressure. This unique motion, guided by the workpiece’s centerline rather than the machine’s spindle, allows the abrasive stones to consistently remove material from high spots inside the bore, progressively averaging out imperfections to create a true, geometrically perfect cylinder.

The Combined Rotation and Reciprocation Motion

Imagine trying to flatten a bumpy wooden board with a spinning sander. If you only spin the sander in one place, you will dig a circular trench. On the other hand, if you only push it back and forth without spinning, you will create a long groove. To flatten the entire board, you must do both at the same time: spin the sander while moving it back and forth across the entire surface.

The honing process works on this exact principle, but inside a cylindrical hole. This combined motion is the secret to its precision.

The Role of Rotation: Ensuring Roundness

The rotation of the honing tool ensures that the abrasive stones apply even cutting pressure around the entire 360-degree inner surface of the hole. As the tool spins, the rigid honing stones act like a bridge. They span across any low spots or valleys and focus their cutting action exclusively on the high spots—the parts of the bore that are out-of-round.

Because this happens continuously as the tool rotates, it shaves down every high point from every angle, gradually making the bore perfectly circular.

The Role of Reciprocation: Ensuring Straightness and Cylindricity

Simultaneously, the tool moves back and forth along the length of the hole in a controlled stroke. This is reciprocation. This motion guarantees that the error correction isn’t just happening at one point along the bore but is distributed evenly from end to end.

This action corrects issues like:

- Taper: Where the hole is wider at one end than the other.

- Bellmouth: Where the very end of the hole flares out.

- Waviness: Undulations or ripples along the length of the bore wall.

By combining rotation for roundness with reciprocation for straightness, the honing process averages out all geometric flaws, resulting in a true, straight, and uniform cylinder.

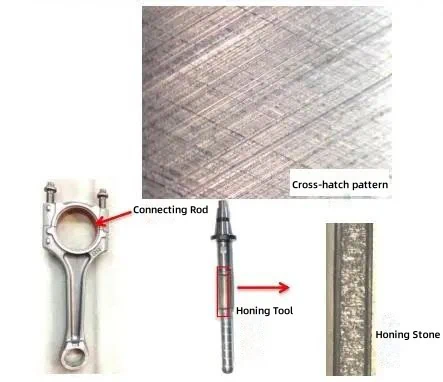

Creating the Signature Cross-Hatch Pattern

Have you ever looked inside a high-performance engine cylinder and seen a distinct pattern of fine lines crossing each other? This isn’t a random texture; it’s the cross-hatch pattern1, and it’s a direct and intentional result of the honing process.

This pattern is formed by the path of the abrasive grains as the honing tool simultaneously rotates and reciprocates.

- On the outward stroke, the grains cut a helical path in one direction.

- On the inward stroke, they cut another helical path in the opposite direction.

The intersection of these two paths creates a diamond-shaped pattern on the surface of the bore. This is more than just a visual byproduct; it serves a critical engineering purpose.

The cross-hatch pattern creates thousands of tiny pockets or reservoirs. In applications like engine cylinders or hydraulic components, these reservoirs hold lubricating oil, ensuring a consistent oil film is maintained between moving parts. This dramatically reduces friction and wear, extending the life of the component.

The angle of this pattern is a crucial specification. For instance, many engine manufacturers require a cross-hatch angle in the range of 40 to 60 degrees for optimal lubrication. It’s important to remember that the ideal angle is application-specific, so it’s always best to consult the component’s engineering specifications to configure the machine’s rotation and reciprocation speeds correctly.

The Critical Role of Honing Fluid

The honing process simply cannot work without a constant flow of specialized honing fluid. This fluid is not just a simple lubricant; it performs three essential jobs that are fundamental to correcting geometric errors.

| Function of Honing Fluid | Impact on Geometric Correction |

|---|---|

| Flushing Away Debris | This is the most critical role. Honing creates fine particles of metal and abrasive, called swarf. The fluid must continuously wash this swarf out of the bore. If it doesn’t, the honing stones become clogged, stop cutting the high spots, and the error-correction process halts. Trapped swarf can also scratch the surface, creating new geometric flaws. |

| Maintaining Thermal Stability | The friction from honing generates heat. The fluid absorbs this heat and carries it away, keeping the workpiece at a stable temperature. Without this cooling, the part would expand and distort during the process, making it impossible to achieve true geometric accuracy since you would be working on a moving target. |

| Providing Lubrication | The fluid creates a high-pressure lubricating film between the stones and the workpiece. This ensures the abrasive grains cut cleanly and efficiently, rather than plowing or smearing the metal. A clean, sharp cut on the high spots is essential for a predictable and controlled finishing process. |

Ultimately, the fluid creates a stable environment where the mechanical action of the honing tool can do its job precisely and predictably. Without it, the process would be uncontrolled and chaotic, failing to achieve any measure of geometric improvement.

What Are the Essential Components of a Honing System?

So, what are the main pieces of hardware that work together to make a honing system function?

A complete honing system consists of three essential components: the honing machine, which provides the power and controlled motion; the honing tool or mandrel, which holds and expands the abrasives inside the bore; and the honing stones, which are the consumable abrasive elements that perform the actual cutting.

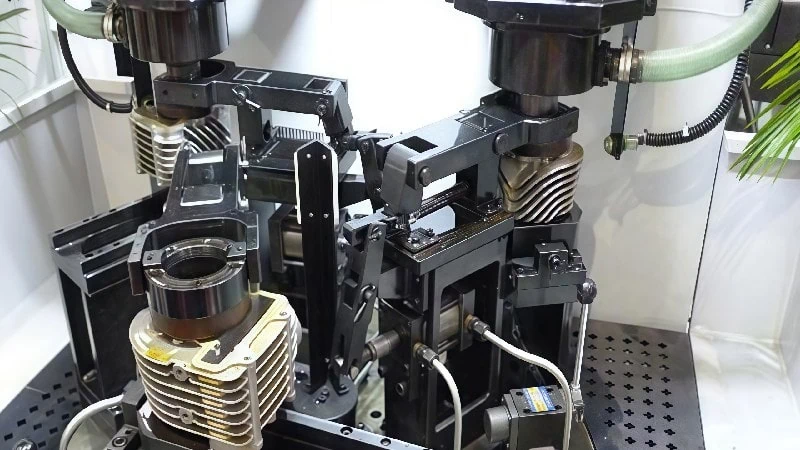

The Honing Machine: Vertical vs. Horizontal

Think of the honing machine as the “body” of the entire system. It provides the structural support, the power, and the intelligent control needed to perform the honing operation precisely. Its primary job is to deliver the smooth rotational motion and the consistent back-and-forth stroking motion to the honing tool.

Furthermore, the machine houses the advanced systems that control the cutting pressure of the abrasives and circulates the critical honing fluid. Honing machines are generally built in two primary configurations: vertical and horizontal. The choice between them depends entirely on the workpiece.

| Feature | Vertical Honing Machine | Horizontal Honing Machine |

|---|---|---|

| Workpiece Orientation | Part stands upright; tool strokes up and down. | Part lies flat; tool strokes in and out. |

| Typical Applications | High-volume parts like engine blocks, cylinder liners, and gears. Gravity helps with fluid flow and swarf removal. | Extremely long parts like hydraulic cylinders, oil and gas piping, and gun barrels, which are too long to stand vertically. |

| Factory Footprint | Taller, but takes up less floor space. | Shorter, but requires a much longer floor space to accommodate the part and machine length. |

| Fluid Containment | Generally easier, as gravity helps fluid drain back into the reservoir. | Can be more complex, requiring careful guarding to contain the fluid along the entire machine length. |

The size, power, and specific features of a honing machine can vary significantly. Therefore, selecting the right machine always involves a detailed discussion with the supplier to match its capabilities to the size and production demands of your parts.

The Honing Tool (Mandrel)

If the machine is the body, the honing tool (often called a mandrel) is the system’s sophisticated “arm and hand.” It is the crucial link between the machine and the workpiece, transmitting the machine’s motion and control directly into the bore.

The honing tool has two primary functions:

- To Hold the Honing Stones: It has precision-machined slots or pockets that securely hold the abrasive honing stones in the correct orientation.

- To Expand the Honing Stones: Inside the tool is a mechanism, typically a tapered cone, that is pushed forward by the machine. As the cone moves, it forces the honing stones outward, pressing them against the wall of the bore with a very precise and controlled amount of pressure. This expansion is what enables the stones to cut.

A key feature of a professional honing tool is its “floating” design. It connects to the machine via a universal joint, which allows the tool to center itself perfectly within the true centerline of the bore, rather than being forced into the position of the machine’s spindle. This capability is fundamental to honing’s ability to correct geometric errors.

Tools are designed for specific diameter ranges and applications. For instance, a small-diameter tool for a fuel injector will be vastly different from a large tool used for a marine diesel cylinder liner.

The Honing Stone: The Core Abrasive Element

Finally, we have the honing stone, also called an abrasive stick. This is the part of the system that does the actual work. It is the consumable component, engineered to wear down slowly as it cuts the workpiece material.

A honing stone is a composite block made of two key ingredients:

- Abrasive Grains: These are microscopic, extremely hard particles that act as the cutting teeth. They shear away tiny chips of material from the workpiece.

- Bonding Agent: This is the “glue” that holds millions of abrasive grains together in a solid, rectangular stick. The bond erodes over time to expose new, sharp abrasive grains.

The specific type of abrasive grain and the characteristics of the bonding agent are carefully selected to optimize performance on different materials, from cast iron to hardened steel to ceramics. This selection process is a critical topic that dictates the success of any honing operation.

When Should You Choose Honing Over Grinding or Boring?

With other options like grinding and boring available, when is honing the absolute best choice for finishing a hole?

You should choose honing over grinding or boring when your primary goals are to achieve the highest degree of geometric accuracy in roundness and straightness, to create a specific functional surface texture like a cross-hatch pattern, or to finish long, small-diameter bores without inducing thermal damage or stress.

To understand why honing excels in these areas, it helps to know what the other processes do. Boring uses a single-point cutting tool to generate a hole’s size and location, while internal grinding uses a high-speed abrasive wheel to achieve very tight size tolerances, especially in hardened materials.

Honing is not a replacement for these processes; it is the final, corrective step that takes a good hole and makes it nearly perfect. Here is how they compare at a glance:

| Feature / Goal | Boring | Internal Grinding | Honing (The Superior Choice) |

|---|---|---|---|

| Geometric Correction | Good for position, moderate for form. | Good, but follows the machine’s path. | Excellent, follows the part’s centerline. |

| Surface Finish Control | Creates a spiral groove. | Creates a random, ground pattern. | Excellent, creates a specific cross-hatch. |

| Heat & Stress Induced | Low heat, moderate stress. | High heat, high stress. | Very low heat, very low stress. |

| Long Bores | Difficult due to tool deflection. | Very difficult due to long, thin spindle. | Ideal, tool is self-supporting. |

For Superior Hole Geometry and Accuracy

When the absolute truth of a cylinder’s geometry is the most important factor, honing is the clear winner. This is because of one fundamental difference in how the tools are guided.

- In boring and internal grinding, the tool’s path is rigidly dictated by the machine’s spindle and slides. Any microscopic error in the machine’s alignment or straightness is directly copied onto the workpiece.

- In honing, the tool “floats” and is guided by the centerline of the workpiece itself.

This self-aligning nature allows honing to correct errors that other processes cannot. For instance, a hydraulic valve body requires a bore that is straight to within a few micrometers to prevent high-pressure fluid leakage. Honing is routinely used to achieve this level of precision, a feat that is extremely challenging for grinding, especially in a production environment.

For a Controlled, Functional Surface Texture

The surface finish left behind by a machining process has a huge impact on how a part performs. This is another area where honing provides a unique and vital advantage.

- Boring leaves a single, continuous spiral groove, similar to the thread on a screw. This is generally undesirable for sealing or bearing surfaces.

- Internal Grinding creates a surface with a random, non-directional pattern. While it can be made very smooth, it lacks any structure to hold oil.

- Honing is the only process that produces the signature cross-hatch pattern.

This pattern is non-negotiable in many high-performance applications.

Case Study: The Engine Cylinder

The inside of an engine cylinder is a perfect example. A honed cross-hatch pattern is required to hold oil to lubricate the piston rings, ensuring a proper gas seal, low friction, and long engine life. No other process can create this specific, functional texture as effectively and consistently.

For Finishing Long Bores with High Precision

What happens when you need to finish a hole that is very long relative to its diameter? This is where the physical limitations of boring and grinding become clear, and honing shines.

Imagine trying to write your name with a very long, thin, and flimsy pencil. It would bend and vibrate, making your signature nearly unreadable. The same thing happens to boring bars and grinding spindles.

- Boring & Grinding Limitation: To machine deep inside a hole, these processes require a long, skinny tool (a boring bar or grinding spindle). These tools are prone to deflection, bending, and vibration, which leads to errors like taper (the hole getting wider or narrower at the end) and chatter (a poor, wavy surface finish).

- Honing’s Advantage: The honing tool is supported by the walls of the workpiece along its entire length. It doesn’t hang out in free space. This self-supporting design means the tool remains rigid and stable, regardless of how long the bore is.

A prime industry example is the manufacturing of firearm barrels. A rifle barrel must be incredibly straight with a uniform diameter to be accurate. After the initial hole is drilled, honing is the preferred method to achieve the final precision finish over lengths of 20-30 inches or more, a task nearly impossible for traditional internal grinding.

How Do You Select the Right Honing Stone for Your Material?

With so many options available, how do you choose the one perfect honing stone for your specific job?

Selecting the right honing stone involves a three-step process: first, you must match the abrasive type (like Diamond or CBN) to the hardness of your workpiece material. Second, you choose the grit size based on your desired stock removal rate and final surface finish. Finally, you select the bonding agent that best balances cutting efficiency and tool life for your application.

Making the right choice in these three areas is the difference between an efficient, precise operation and a frustrating process that produces scrap parts. Let’s break down each decision.

Abrasive Type: Diamond vs. CBN vs. Conventional Abrasives

The first and most important rule in honing is that your abrasive must be significantly harder than the material you are cutting. You can’t cut a diamond with a steel knife, and the same principle applies here.

This choice is primarily dictated by the workpiece material and its hardness, typically measured on the Rockwell C scale (HRC)2.

| Abrasive Type | Best For Cutting… | Key Industry Applications | Important Consideration |

|---|---|---|---|

| Conventional3 (Aluminum Oxide & Silicon Carbide) | Softer, non-hardened materials (< 40 HRC). Aluminum, bronze, brass, and unhardened steels. | General machine shop work, low-volume repairs, and applications where cost is the primary driver. | The most economical option, but they wear out quickly and cannot handle hard materials effectively. |

| CBN4 (Cubic Boron Nitride) | Hardened ferrous (iron-based) metals (> 45 HRC). Hardened steel, tool steel, cast iron, and superalloys. | Automotive engine cylinders, gears, bearings, and hydraulic components made of steel. | The go-to choice for hard steel. CBN is thermally stable and does not chemically react with iron. |

| Diamond5 | Extremely hard or abrasive non-ferrous and non-metallic materials. Ceramics, carbide, glass, and high-silicon aluminum. | Finishing carbide wear parts, ceramic pump components, and honing aluminum engine blocks with Alusil or Lokasil liners. | Do not use on steel. At the high temperatures of cutting, the carbon in the diamond has a chemical affinity for the iron in steel, causing the abrasive to degrade rapidly. |

Grit Size: From Rapid Stock Removal to Fine Polishing

Once you’ve chosen the right abrasive type, the next step is to select the grit size. Grit size refers to the size of the individual abrasive particles in the stone. The concept is identical to sandpaper: a lower number means larger, coarser particles, while a higher number means smaller, finer particles.

Your choice of grit size is a trade-off between speed and smoothness.

Roughing and Semi-Finishing (e.g., 80 – 280 Grit)

Coarse grit stones are used for the initial honing steps. Their large abrasive particles can remove material quickly, making them ideal for correcting significant geometric errors or for applications where a fine finish is not required.

Finishing (e.g., 320 – 800 Grit)

Medium-fine grits are the workhorses for most standard finishing applications. They provide a good balance, refining the surface to a smooth texture while still removing a small amount of material to hit the final size tolerance. This is the range often used to produce the functional cross-hatch pattern on engine cylinders.

Polishing (e.g., 1000+ Grit or Micron-Graded)

For applications demanding a mirror-like finish, you must use ultra-fine, or “micron-graded,” honing stones. At this stage, the grit is so fine it’s measured in microns (µm) instead of a grit number.

It is important to note that grit size standards, such as the US ANSI mesh system, can vary between suppliers. For polishing applications, always refer to the micron size (e.g., 15 µm, 9 µm, 3 µm) for accuracy. Consulting your supplier’s grit chart is the best way to match a specific stone to your target surface roughness (Ra) value.

Bonding Agent: Metal, Vitrified, and Resin Bonds Explained

The final piece of the puzzle is the bonding agent6, which is the “glue” that holds the abrasive grains together. The bond’s job is to hold onto the grains tightly enough to let them cut, but to also erode just enough to expose new, sharp grains as the old ones become dull. The type of bond dramatically affects the stone’s performance.

| Bond Type | Key Characteristic | Best For… | The Trade-Off |

|---|---|---|---|

| Metal | Maximum Durability. The strongest and most wear-resistant bond. | Heavy stock removal and roughing operations, especially in cast iron. Its longevity makes it excellent for high-volume production where tool changes are infrequent. | Poor self-sharpening. The bond is so strong that it can fail to expose new grains, causing the stone to “glaze over” and stop cutting. |

| Vitrified (Ceramic) | The All-Rounder. A hard, strong, porous structure. | The widest range of applications, from roughing to fine finishing. The pores help with cooling and swarf removal, making it a very efficient and versatile choice, especially for production CBN honing. | Can be brittle and sensitive to chipping or shock compared to a metal bond. |

| Resin | The Finishing Touch. The softest and most flexible bond. | Final polishing steps where surface finish is the absolute priority. Its elasticity provides a gentle, smooth cutting action that produces the best mirror finishes. | The shortest tool life. The bond wears away relatively quickly, making it unsuitable for heavy material removal. |

Ultimately, the bond must be matched to the application. For instance, you would use a hard-grade bond for honing soft materials like aluminum, and a softer-grade bond for honing very hard materials like hardened tool steel. Since bond formulations are often proprietary, discussing your specific material and process goals with your tooling supplier is crucial for optimal performance.

Can Honing Be Used for Polishing to a Mirror Finish?

Can the same honing process used to finish an engine cylinder also be used to create a true, mirror-like polish?

Yes, honing can absolutely be used for polishing to a mirror finish. This advanced process, known as mirror honing or superfinishing, is achieved by using a sequence of progressively finer, micron-graded abrasive stones to systematically reduce surface roughness until a highly reflective, low-friction surface is created.

This isn’t a different type of machining, but rather the highest level of refinement that the honing process can achieve. It takes a precisely honed hole and elevates the surface quality to its peak.

The Multi-Step Process for Mirror Honing

Achieving a mirror finish is not a single action, but the final result of a disciplined, multi-step sequence. You cannot simply jump from a coarse stone to a polishing stone. This is much like polishing a raw gemstone, where a gem cutter uses progressively finer abrasives to achieve a brilliant shine.

A typical sequence includes:

- Rough Honing: This initial step uses a coarse grit stone (e.g., 150 grit) to quickly establish the correct size and geometry.

- Semi-Finish Honing: A medium grit stone (e.g., 400 grit) is then used to remove the deep scratch pattern left by the roughing stone.

- Fine Honing: A fine grit stone (e.g., 800-1200 grit) creates a very smooth, pre-polish surface, ready for the final step.

- Polishing: The final stage uses one or more ultra-fine, micron-graded stones to erase the fine marks from the finishing step, producing the final mirror surface.

The core principle is that each step must completely remove the surface texture left by the step before it. Skipping a step will leave deeper scratches behind that the final polishing stone cannot remove, making a true mirror finish impossible.

Using Micron-Grade Abrasives for the Final Polish

The tools that make mirror honing possible are micron-grade abrasive stones. Unlike standard honing stones measured by a grit number, these are so fine that their abrasive particle size is measured in microns (µm). For perspective, a human hair is about 70 microns thick. Polishing stones often use abrasives that are 15, 9, 3, or even as small as 1 micron.

Instead of aggressively cutting material, these ultra-fine particles perform a lapping or burnishing action. They gently smooth over the microscopic peaks left on the surface from the final finishing step. This action dramatically lowers the surface roughness, which is measured by a value called Ra7.

- A standard finished part might have a surface roughness of Ra 0.2 µm.

- A mirror-honed part aims for a surface roughness of Ra 0.05 µm or lower.

Achieving this level of finish requires absolute process control. The honing fluid must be exceptionally clean, as a single rogue particle could scratch the mirror surface. Furthermore, resin bond honing stones are often the preferred choice for this final step, as their inherent flexibility allows for a gentler action that is perfect for polishing.

Key Applications for Honed and Polished Surfaces

Why would a manufacturer invest in achieving such a perfect finish? A mirror-honed surface provides critical performance advantages that are non-negotiable in many high-tech industries.

- Hydraulic and Pneumatic Systems: Components like valve spools and cylinders require a near-perfect seal to prevent leakage of high-pressure fluid or air. The ultra-smooth, polished surface allows for a tight clearance with minimal friction, ensuring efficient and responsive operation.

- High-Pressure Fuel Injection Systems: In modern diesel and gasoline engines, fuel injector bodies and plungers operate under extreme pressures. A mirror finish is essential for creating a perfect seal, preventing internal leaks, and ensuring precise fuel delivery and engine efficiency.

- Bearing Races and Roller Surfaces: For high-performance bearings, a smoother surface finish on the races and rollers directly translates to lower friction, reduced operating temperatures, and a significant increase in the component’s fatigue life and reliability.

- Medical Devices and Implants: Surgical tools and artificial joints, such as hip or knee replacements, require polished surfaces. This minimizes friction between moving parts, reduces wear over the long term, and ensures biocompatibility by creating a surface that is less prone to bacterial adhesion.

- Precision Molds and Dies: In the injection molding industry, the surface finish of the mold cavity is directly mirrored onto the final plastic product. A mirror-honed mold cavity produces a glossy, high-quality part straight out of the mold, eliminating the need for secondary polishing operations.

Conclusion

In conclusion, honing is a uniquely capable and versatile finishing process. It stands apart from other machining methods through its ability to simultaneously correct a hole’s geometry to exacting tolerances while creating a highly specialized, functional surface finish. From producing the critical oil-retaining cross-hatch pattern in an engine cylinder to achieving a flawless mirror polish on a hydraulic valve, the success of any honing operation depends on a systematic approach. By understanding the core principles of the process and carefully selecting the right combination of machine, tool, and honing stone for the specific application, manufacturers can unlock the highest levels of precision, performance, and reliability in their finished components.

References

- cross-hatch pattern1 – A page from Precision Surface showcasing images of the honing cross-hatch pattern.

- Rockwell C scale (HRC)2 – The Wikipedia entry detailing the Rockwell hardness test method and scales.

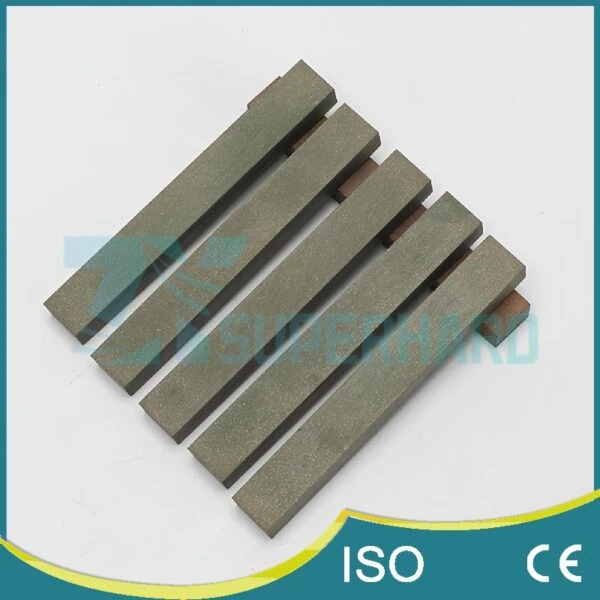

- Conventional3 – ZYDiamondTools product page for conventional abrasive oil stones suitable for general purpose honing, polishing, and finishing.

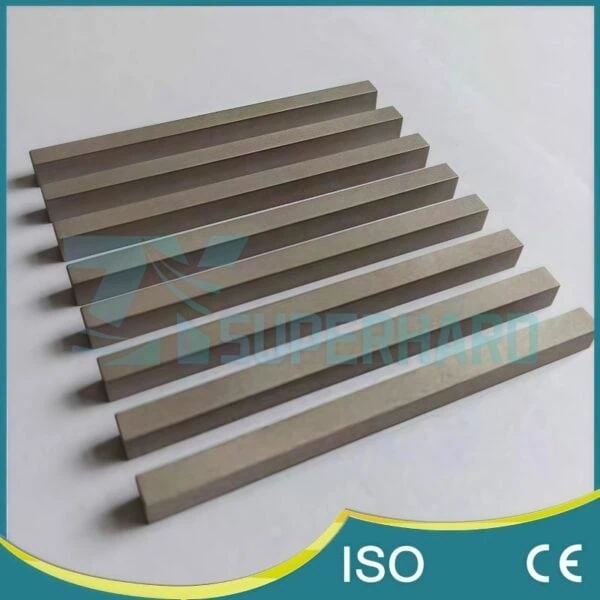

- CBN4 – ZYDiamondTools product page for high-performance CBN oil honing stones designed for machining hardened steels and ferrous metals.

- Diamond5 – ZYDiamondTools product page for premium diamond oil honing stones used for honing ceramics, carbide, and other hard non-metallic materials.

- bonding agent6 – ZYDiamondTools article detailing different grinding wheel bond types and their impact on performance.

- surface roughness, which is measured by a value called Ra7 – A guide from Get It Made explaining surface roughness and the meaning of Ra.