-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

Why Choose PCD Reamers? Your Guide to Performance, Applications, and Making the Right Selection

- Knowledge, PCD & CBN Tools Knowledge

- -2025-05-09

- - byKevin Ray

So, when you’re faced with making lots of very precise holes, especially in tricky materials, why should you consider choosing PCD reamers?

PCD (Polycrystalline Diamond)1 reamers are chosen for their exceptional performance in specific machining applications, primarily offering dramatically longer tool life, the ability to achieve much higher cutting speeds and produce superior surface finishes, particularly when working with non-ferrous metals and abrasive non-metallic materials. This leads to increased productivity and lower overall costs per hole in high-volume scenarios, making them a smart investment despite a higher initial price, provided they are selected carefully to match the application.

Table of Contents

ToggleCore Benefits of Using PCD Reamers in Demanding Applications

When you’re facing tough machining jobs that demand high precision, it’s important to understand what makes PCD reamers stand out.

PCD (Polycrystalline Diamond) reamers offer significant advantages in demanding applications primarily due to their exceptional hardness. This results in dramatically extended tool life, the capability for much faster cutting speeds and feeds, consistently superior surface finishes, and ultimately, reduced overall machining costs, especially in high-volume production scenarios involving non-ferrous and abrasive non-metallic materials.

Unlocking Exceptional Tool Life and Wear Resistance

One of the most impressive benefits of using PCD reamers is how incredibly long they last. The secret lies in their construction. PCD tools are made from tiny, man-made diamond particles that are fused together under very high heat and pressure. Since diamond is one of the hardest materials on Earth, PCD reamers inherit this amazing toughness.

Now, why is this hardness so important?

- Battling Abrasive Materials: When you’re machining materials that are very gritty or abrasive, like aluminum with a high silicon content or composite materials, these materials act like sandpaper, wearing down ordinary tools very quickly. PCD reamers, with their diamond edges, resist this abrasive wear exceptionally well.

- Massive Gains in Longevity: Because of this wear resistance, PCD reamers can often last 10 to 50 times longer, or even more, than traditional carbide tools in the right applications. For instance, in the automotive industry, when reaming holes in aluminum alloy engine components, a PCD reamer might accurately machine tens of thousands, sometimes even over 100,000 holes before needing replacement. In contrast, a standard carbide reamer might only last for a few thousand holes in the same job.

- More Uptime, Less Downtime: This extended life isn’t just about saving on the cost of new tools. Critically, it means machines don’t have to be stopped as often for tool changes. This significantly boosts the overall machine uptime and production efficiency.

It’s important to remember that the exact increase in tool life can depend on several factors. These include the specific grade of PCD used, the exact material being machined, the stability and condition of the machine tool, and the proper application of coolant. Therefore, discussing your specific application with your tooling supplier to get the best estimates and recommendations is always a good idea.

Achieving Higher Cutting Speeds and Feed Rates for Increased Productivity

Another key advantage of PCD reamers is their ability to work much faster than other types of reamers. This means you can produce more parts in less time, which is a huge boost for productivity. How is this possible?

- Staying Sharp Under Pressure: The exceptional hardness of PCD means the cutting edges stay sharp even when they get very hot, which often happens during high-speed machining. Unlike some other tool materials that might soften or wear quickly at high temperatures, PCD maintains its integrity.

- Efficient Heat Dissipation: Diamond is also a very good conductor of heat. This means that the heat generated at the cutting edge is quickly drawn away from the cutting zone. This helps to protect both the PCD reamer itself and the part being machined from heat-related damage, allowing for higher operational speeds.

- Faster Material Removal: Because PCD reamers can cut faster and also be fed into the material more quickly (higher feed rates), they achieve a much higher Material Removal Rate (MRR).

- Shorter Cycle Times: The direct result of faster cutting speeds and feeds is a reduction in the time it takes to machine each part, known as the cycle time. For example, when finishing bores in aluminum automotive transmission cases, PCD reamers can often operate at cutting speeds between 300 to 1000 meters per minute (approximately 1000 to 3300 surface feet per minute). In comparison, carbide reamers might be limited to speeds of 100 to 300 m/min (approx. 330-1000 sfm) for similar operations to maintain tool life and quality. Naturally, these speed ranges are general guidelines, and the optimal parameters can vary significantly based on the specific aluminum alloy, hole depth, and the reamer’s design. Consulting your tooling supplier for tailored recommendations is crucial.

Ultimately, these faster operations mean more finished components roll off the production line each day, directly impacting output and profitability.

Ensuring Superior Surface Finish and Tight Dimensional Tolerances

When making precise parts, the smoothness of the hole (surface finish) and how accurately it’s sized (dimensional tolerance) are incredibly important. PCD reamers excel in delivering both.

- Ultra-Sharp Cutting Edges: Thanks to diamond’s hardness, PCD cutting edges can be ground to an exceptionally sharp and fine finish. More importantly, they stay sharp for a very long time due to their excellent wear resistance. A consistently sharp edge is key to producing a smooth cut.

- Reduced Material Adhesion: PCD has a lower tendency for the material being cut (especially non-ferrous metals like aluminum) to stick to the cutting edge. This sticking, known as a “built-up edge” or BUE, is a common problem with other tool materials and often leads to a rougher surface finish and inaccuracies. With less BUE, PCD reamers produce cleaner cuts.

- Achieving Mirror-Like Finishes: As a result, PCD reamers can often produce hole surfaces with very low roughness values, sometimes described as mirror-like. It’s common to achieve surface finishes (Ra values2) below 0.4 micrometers (which is about 16 microinches). In many cases, this exceptional finish quality can eliminate the need for further, time-consuming finishing processes like honing or grinding, saving both time and money.

- Consistency is Key for Tolerances: Because PCD reamers wear so slowly, the size and shape (like roundness and straightness) of the holes they produce remain consistent over very long production runs. If a reamer wears quickly, the first hole it makes might be a different size than the thousandth hole. PCD minimizes this variation. This consistency is vital for parts that need to fit together perfectly, such as the bores for bearings or valve spools in hydraulic systems. For instance, in manufacturing hydraulic valve bodies, maintaining tight bore tolerances (e.g., ISO tolerance grades like H6 or H7) is critical for the valve’s sealing and performance. PCD reamers are instrumental in holding these tolerances across thousands of parts, significantly reducing part rejection rates.

Could you imagine the precision needed for components in an anti-lock braking system (ABS) manifold? PCD reamers are often the tool of choice here to ensure every bore meets the stringent specifications for safety and reliability.

Reducing Overall Machining Costs in High-Volume Production

While it’s true that a new PCD reamer usually costs more to buy than a comparable carbide reamer, looking only at the initial purchase price can be misleading. When you consider the bigger picture, especially in high-volume manufacturing, PCD reamers can actually save a lot of money.

The “Total Cost of Ownership3” (TCO) or ‘cost per hole’ is often much lower with PCD. Here’s a breakdown of how these savings add up:

- Fewer Tools Needed: Because PCD reamers last so much longer, you simply don’t need to buy as many of them over time.

- Less Machine Downtime: Every time a tool needs to be changed, the machine has to be stopped. This is unproductive “downtime.” Since PCD reamers are changed far less frequently, machines spend more time making parts and less time idle.

- Lower Labor Costs: Less frequent tool changes also mean that machine operators or tool setters spend less time on this task.

- Reduced or Eliminated Secondary Operations: The excellent surface finish produced by PCD reamers can often eliminate the need for additional processes like grinding or honing.

- Higher Productivity: Faster cutting speeds and feeds mean more parts are made per hour.

- Lower Scrap Rates: When tools maintain their size and produce consistent quality, fewer parts are rejected for being out of specification.

Consider a simplified example: An automotive supplier is making 500,000 aluminum components a year, each requiring a critical reamed bore.

| Cost Factor | Carbide Reamer Scenario | PCD Reamer Scenario | Potential Impact with PCD |

|---|---|---|---|

| Initial Tool Cost | Lower ($50) | Higher ($300) | Initial outlay is more |

| Holes per Reamer | 2,000 | 60,000 | 30x more holes per tool |

| Reamers Needed/Year | 250 | Approx. 9 | Drastic reduction in tool units |

| Tool Cost/Year | $12,500 | $2,700 | Significant savings on tools |

| Tool Change Time | High (many changes) | Low (few changes) | Increased machine uptime |

| Cost Per Hole | Higher | Lower | Better long-term economics |

Note: The costs and tool life figures in this table are purely illustrative examples to demonstrate the concept.

This type of analysis, focusing on the cost per finished, good part, often reveals that the initial investment in PCD technology pays off handsomely, particularly when machining large volumes of non-ferrous metals or abrasive non-metallic materials.

Materials and Machining Tasks Best Suited for PCD Reamers

Now that we know PCD reamers offer great benefits, understanding where they perform best—in terms of materials and the jobs they do—is key.

PCD reamers are exceptionally well-suited for precision reaming of non-ferrous metals4 like aluminum, copper, and brass alloys, and they truly excel when machining highly abrasive non-metallic materials such as composites, carbon fiber, and high-silicon aluminum5. Their primary tasks involve creating highly accurate and smooth bores in components for industries like automotive, aerospace, and electronics, though they are generally not recommended for ferrous metals like steel or iron.

Excelling in Non-Ferrous Metals (Aluminum, Copper, Brass Alloys)

PCD reamers are fantastic tools when you need to make very precise holes in metals that don’t contain much iron (non-ferrous metals).

- Aluminum Alloys: This is a prime application.

- Why PCD works well: Aluminum can sometimes be “sticky,” leading to built-up edge (BUE) on tools, which harms finish and accuracy. PCD’s low friction with aluminum reduces BUE. Also, PCD handles heat well.

- Typical jobs: Engine blocks, cylinder heads, intake manifolds, transmission cases, pump housings, using various cast (e.g., A3xx series) and wrought (e.g., 6xxx series) aluminum alloys.

- Copper and Brass Alloys:

- Why PCD works well: Copper’s softness can cause BUE. Brass is easier but still benefits from a sharp, durable tool. PCD’s ability to maintain a sharp edge ensures clean cuts and avoids smearing.

- Typical jobs: Precise holes in copper electrical connectors or brass fittings for plumbing or hydraulic systems.

For all these non-ferrous metals, the major advantage of PCD reamers is producing accurate holes with extremely smooth surfaces, consistently over thousands of parts.

Tackling Abrasive Non-Metallic Materials (Composites, Carbon Fiber, High-Silicon Aluminum)

This is where PCD reamers truly demonstrate their toughness, as some materials are incredibly abrasive.

- High-Silicon Aluminum:

- The challenge: Aluminum alloys with high silicon content (e.g., >10-12%) contain very hard, abrasive silicon particles that rapidly wear down conventional tools.

- Why PCD is the solution: PCD, being much harder than silicon particles, cuts through them effectively, ensuring long tool life and consistent quality in alloys like A390 used for pistons or engine blocks.

- Composite Materials (like Carbon Fiber and Fiberglass):

- The challenge: Materials like Carbon Fiber Reinforced Polymers (CFRP) or Glass Fiber Reinforced Polymers (GFRP) contain extremely strong and abrasive fibers. Standard tools dull quickly, causing delamination, fiber pull-out, and poor hole quality.

- Why PCD is the solution: PCD reamers maintain sharp cutting edges, producing clean, precise holes with minimal damage. This is vital in aerospace for aircraft parts and in high-performance automotive components.

- Other Abrasive Materials: PCD also performs well in other tough-to-machine non-metallics, including:

- Metal Matrix Composites (MMCs).

- Green or pre-sintered ceramics.

- Some engineered plastics and wood composites with abrasive fillers.

In all these abrasive materials, PCD reamers are used to finish holes to exact sizes with smooth internal surfaces, ensuring part integrity and proper fit.

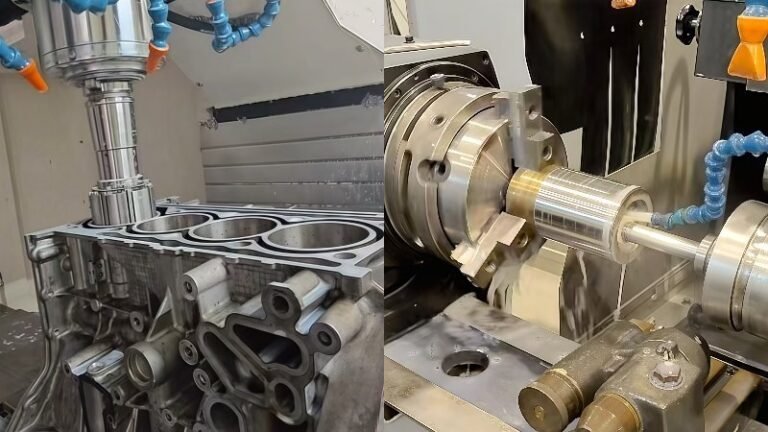

Key Industries and Specific Applications (Automotive, Aerospace, Electronics)

Because PCD reamers excel in certain areas, several major industries rely on them.

- Automotive Industry: A primary user.

- Why here? High-volume production of aluminum and high-silicon aluminum parts requires precision and cost-efficiency. PCD offers the necessary tool life and productivity.

- Specific examples: Engine blocks (cylinder, camshaft bores), cylinder heads (valve guide/seat bores), transmission casings, steering knuckles, ABS components, turbocharger housings.

- Aerospace Industry:

- Why here? Extensive use of lightweight aluminum alloys and advanced composites (CFRP, GFRP). Stringent precision and quality standards for safety.

- Specific examples: Airframe components (fastener holes in composite panels), landing gear parts, hydraulic system components, engine parts.

- Electronics Industry:

- Why here? Manufacturing of aluminum housings, heat sinks, and connectors where precision and good surface finish are important.

- Specific examples: Precise bores in computer or smartphone housings, machining heat sinks, reaming holes in copper or brass electrical connectors.

- Other Industries: Also found in heavy equipment manufacturing, hydraulics, and some specialized woodworking for abrasive wood composites.

The common thread is the need for high-precision hole finishing, often in challenging materials or high-volume production where consistency and tool life are paramount.

Understanding Limitations: When to Avoid PCD Reamers (e.g., Ferrous Metals)

While PCD reamers are excellent for specific jobs, they are not suitable for every material. Knowing when not to use them is crucial.

- The Main Limitation: Ferrous Metals (Steel, Stainless Steel, Cast Iron)

- Why not? PCD is diamond (carbon). Iron (Fe) has a strong chemical affinity for carbon at machining temperatures. This reaction causes the diamond in PCD to break down rapidly. It’s a chemical incompatibility, not just a hardness issue.

- The result: Extremely poor tool life, making PCD uneconomical for these materials. Coated carbides or Cubic Boron Nitride (CBN) are preferred for steels and cast irons.

- Titanium Alloys (especially high titanium content):

- The challenge: Pure titanium or alloys with very high titanium content can also react chemically with diamond at machining temperatures, leading to rapid wear. Chip formation can also be problematic. Specialized carbide grades or CBN tools are usually better.

- Very Severe Interrupted Cuts or Highly Unstable Machining Setups:

- The concern: PCD is extremely hard but also more brittle than some tougher materials like certain carbide grades. Heavy shocks from large interruptions or excessive vibration can chip the PCD edge. While modern PCD tools are designed for toughness, very rough conditions require special tool designs or are best avoided.

Knowing these limitations helps select the right tool, ensuring optimal performance and preventing damage to expensive PCD tools.

Application Sweet Spots: Deciding Between PCD and Carbide

Understanding the key differences between PCD and carbide tools6 is foundational to selecting the right reamer. Based on the materials and typical machining tasks discussed, here’s a summary to help you decide when PCD or traditional carbide reamers might be the more appropriate choice:

- Choose PCD Reamers when:

- Your primary workpiece materials are non-ferrous metals (especially aluminum alloys, copper, brass) and you’re running high production volumes.

- You are machining highly abrasive non-metallic materials like carbon fiber composites (CFRP), glass fiber composites (GFRP), high-silicon aluminum, or green ceramics, where carbide wears out too quickly.

- Achieving the longest possible tool life, highest productivity through speed, and minimal machine downtime are your top operational priorities (as detailed in the “Core Benefits” section).

- The application demands the best possible surface finish and tight, consistent dimensional tolerances over many parts, potentially allowing you to skip secondary finishing steps.

- The overall cost per hole, considering all factors including tool life and productivity, is your main economic driver.

- Opt for Carbide Reamers when:

- You need to machine ferrous materials such as steels, stainless steels, or cast iron (where PCD is chemically unsuitable).

- You are working with a broad range of different materials in smaller quantities or in job shop settings where the higher initial cost and specialization of PCD might not be justified for each job.

- The initial tooling budget is a significant constraint, and lower production volumes don’t allow for PCD’s long-term cost benefits to be fully realized.

- The application involves very severe interruptions or particularly unstable machining conditions where the higher toughness of some carbide grades might be preferred (though optimal conditions are best for any precision tool).

- A versatile, lower-cost, general-purpose reamer is needed for less demanding tasks or a wider array of infrequent jobs.

Making an informed decision requires weighing these factors against your specific operational needs and economic goals.

Critical Factors in Your PCD Reamer Selection Process

If you’ve determined PCD reamers are a potential fit, how do you navigate the selection process to choose the ideal tool for your specific job?

Selecting the right PCD reamer involves carefully matching the PCD grade7 and tool geometry to your specific workpiece material and application requirements. You’ll also need to consider different reamer designs (like solid, brazed, or expandable), evaluate coolant delivery options for optimal performance and chip evacuation, and finally, identify reliable manufacturers or suppliers who can provide quality tools and expert support.

Matching PCD Grade and Tool Geometry to Your Specific Material and Application

Choosing the right PCD reamer begins with two fundamental technical aspects: the PCD material grade and the tool’s cutting geometry. These must align perfectly with the workpiece material and the desired hole characteristics.

- Understanding PCD Grades: Not All Diamond is the Same

PCD is available in various grades, primarily differentiated by the diamond grain size. These particles are fused together using a high-temperature, high-pressure sintering8 process.- Fine Grain PCD: Often yields the best edge quality and surface finish, suitable for finishing less abrasive non-ferrous metals.

- Medium Grain PCD: A versatile option, balancing wear resistance and toughness, commonly used for general-purpose reaming in aluminum alloys.

- Coarse Grain PCD (or Mixed Grades): Offers higher toughness and wear resistance, preferable for highly abrasive materials (e.g., high-silicon aluminum, composites) or applications with interrupted cuts. The surface finish might be slightly less fine than that from fine grades.

- Binder materials and diamond concentration can also vary between grades, affecting properties.

- Tool Geometry: The Shape That Cuts

The reamer’s cutting edge geometry is vital for performance.- Number of Flutes (Cutting Edges): Typically 2 to 8 or more. More flutes can allow higher feed rates and improve stability but reduce chip space. Fewer flutes provide more room for chips, beneficial for gummier materials.

- Flute Type: Straight or Spiral?

- Straight Flutes: Simpler to manufacture, suitable for through-holes or materials producing short chips.

- Helical (Spiral) Flutes: Enhance chip evacuation (lifting chips in blind holes or pushing them forward in through-holes, depending on helix direction). Can provide a smoother cutting action.

- Rake and Relief Angles: Optimized by manufacturers for specific material groups. Positive rake angles generally reduce cutting forces, suitable for non-ferrous metals.

- Chamfer or Lead Angle: The angle at the reamer’s entry point; influences engagement, hole quality, and tool life.

Considering Different Reamer Designs (Solid, Brazed, Monoblock, Expandable)

PCD reamers are constructed in various ways, and the design impacts performance and cost.

- Solid PCD Reamers (Vein-type or Full-nib):

- The PCD cutting edges are an integral part of the reamer tip (e.g., a PCD “vein” in a carbide body or a full PCD nib).

- Pros: Maximum rigidity, potentially better accuracy and life for smaller diameters.

- Cons: Can be more expensive, especially for larger diameters; resharpening is complex.

- Brazed Tip PCD Reamers:

- Individual PCD segments are brazed onto a steel or carbide tool body.

- Pros: More economical for larger diameters; tips can sometimes be replaced/re-brazed by specialized services. A common design.

- Cons: Braze joint quality is critical.

- Monoblock Reamers:

- Typically a one-piece design (e.g., brazed PCD tips or integrated PCD head on a carbide shank) offering good rigidity and precision.

- Expandable Reamers (Adjustable Reamers):

- The cutting diameter can be slightly adjusted to compensate for wear, maintaining tight tolerances.

- Pros: Extends useful life within a tolerance band; excellent for ultra-high precision.

- Cons: More complex design, often higher initial cost; requires careful adjustment.

- Example: Used in critical automotive applications like engine cylinder bores where consistent size is essential.

Here’s a quick comparison of these designs:

| Reamer Design Type | Common Advantages | Common Considerations | Often Good For… |

|---|---|---|---|

| Solid/Vein PCD | Very rigid, excellent for small diameter precision | Higher cost, complex to resharpen | Small, ultra-precise holes where maximum stiffness is needed. |

| Brazed Tip PCD | Cost-effective for many diameters, repairable tips | Braze joint integrity is critical | General-purpose PCD reaming across a wide range of sizes. |

| Monoblock PCD | High rigidity and overall precision | Can be more expensive, often application-tuned | Demanding, high-performance reaming tasks. |

| Expandable PCD | Compensates for wear, maintains very tight tolerances | More complex, higher initial cost, needs skill to adjust | Critical high-precision bores in mass production, extending tool life at exact size. |

This table offers general characteristics. The best design for you will depend on hole diameter, tolerance, production volume, and budget. Discussing these with a knowledgeable supplier is important.

Evaluating Coolant Delivery Options for Optimal Performance

Coolant plays a vital role in PCD reaming.

- Why is Coolant So Important?

- Heat Dissipation: Manages overall temperature, protecting the workpiece and tool (especially braze joints).

- Chip Evacuation: Flushes chips from the cutting zone, preventing damage to surface finish or tool jamming. Critical in deep or blind holes.

- Lubrication: Reduces friction, can improve surface finish and tool life.

- Common Ways to Get Coolant to the Cut:

- External (Flood) Coolant: Basic method; coolant sprayed externally. May be less effective for deep holes.

- Internal Coolant (Through-Tool Coolant): Coolant supplied through channels within the reamer, exiting near the cutting edges (axially at the tip or radially along flutes). Generally more effective.

- MQL (Minimum Quantity Lubrication): Uses a small amount of oil in an aerosol form. Environmentally friendly but requires compatible tooling and machine.

- Choosing the Right Coolant Method for Your Job:

- Through-holes: External coolant might suffice for shallow holes, but internal is often better.

- Blind holes: Internal coolant is usually essential for chip evacuation.

- The material you’re cutting also influences chip characteristics and the need for effective flushing.

The effectiveness of coolant depends on its type, pressure, flow rate, and direction. Ensure your machine tool supports the chosen method, and discuss with your tool supplier how their reamer designs integrate with coolant systems for your specific hole depth and type.

Tips for Identifying Reliable PCD Reamer Manufacturers and Suppliers

Partnering with the right supplier is as important as choosing the right tool.

- Look for Real Experience and Specialization in PCD:

- Prioritize companies with a proven track record in PCD tooling and experience in your specific industry or with your machining materials.

- Check Their Technical Support and Expertise:

- A good supplier provides technical support, helping select the right grade, geometry, and design, and offering application advice.

- Ask About Manufacturing Quality and Consistency:

- Consistent quality is vital. Inquire about their manufacturing processes, quality control, and the source of their PCD material.

- Consider Their Range of Products and Customization Capabilities:

- A good range of standard reamers is helpful, but the ability to provide custom PCD reamer9 solutions for unique applications is often critical for demanding PCD tasks.

- Inquire About Resharpening or Relapping Services:

- PCD reamers can often be resharpened or “relapped10,” extending life and reducing long-term costs. Check if the supplier offers this or can recommend a reputable service.

- Look at Their Reputation and Ask for References:

- Seek reviews, testimonials, or case studies.

- Don’t Make Your Decision Based on Price Alone:

- The cheapest tool isn’t always the best value. Consider overall value, including performance, life, and supplier support.

Finding a reliable supplier who acts as a partner can significantly impact your success with PCD reaming.

Conclusion

In conclusion, choosing PCD reamers can be a highly effective strategy for achieving superior performance in precision hole finishing, particularly when dealing with non-ferrous metals and abrasive non-metallic materials in high-volume production. The significant benefits – including exceptional tool life, faster machining capabilities, excellent surface finishes, and ultimately, lower cost per hole – make them a compelling option for demanding applications in industries like automotive, aerospace, and electronics.

However, the journey to successful PCD reaming doesn’t end with just acknowledging these benefits. It requires a careful understanding of their ideal application niches compared to alternatives like carbide, and most importantly, a diligent selection process. By matching the right PCD grade and tool geometry to your specific material, considering the optimal reamer design and coolant strategy, and partnering with knowledgeable and reliable suppliers, you can truly unlock the full potential of PCD technology. Making an informed choice will ensure that your investment in PCD reamers translates into enhanced productivity, improved part quality, and significant long-term economic advantages.

References

- PCD (Polycrystalline Diamond)1 – ZYDiamondTools blog post providing a comprehensive overview of Polycrystalline Diamond tools.

- Ra values2 – Get It Made resource page explaining surface roughness, including Ra parameters.

- Total Cost of Ownership3 – ZYDiamondTools blog post explaining the concept of Total Cost of Ownership (TCO) for superhard tooling.

- non-ferrous metals4 – ScienceDirect topic page defining and discussing non-ferrous metals in materials science.

- high-silicon aluminum5 – ZYDiamondTools blog post discussing the challenges and solutions for machining high-silicon aluminum with PCD tools.

- key differences between PCD and carbide tools6 – ZYDiamondTools blog post detailing the comparison between PCD and Carbide cutting tools.

- PCD grade7 – ZYDiamondTools blog post explaining the key properties of PCD, relevant to understanding grades.

- sintering8 – ScienceDirect topic page explaining the sintering process in engineering and materials science.

- custom PCD reamer9 – ZYDiamondTools product page for non-standard custom PCD forming reamers.

- relapped10 – ZYDiamondTools blog post on PCD and PCBN tool sharpening and relapping techniques.

ZY Superhard Tools Co., Ltd.

Do you have any needs for PCD tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Do you have any needs for PCD & CBN tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Do you have any needs for PCD & CBN tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Post Categories

Product Categories

About Company

Related Posts

What is a Wire Drawing Die and How Does it Actually Work?

Discover what a wire drawing die is and how it works. This guide covers die materials like PCD and carbide,

Why Is My Solid CBN Insert Chipping or Wearing Out Fast on Cast Iron Rolls?

Diagnose and fix the two main failures of solid CBN inserts: chipping and rapid wear. Learn why it happens on

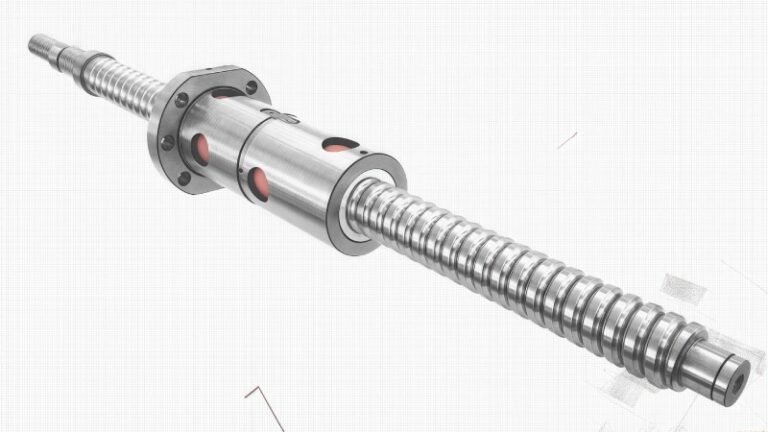

How Do You Machine a Ball Screw for a Perfect Fit? A Step-by-Step Guide

Learn how to machine a ball screw with our step-by-step guide. Covers proper clamping, hard turning with CBN tools, and

Honing vs. Internal Grinding: Which Precision Finishing Process Is Right for Your Application?

Learn the key differences between honing and internal grinding. This guide covers mechanics, surface finish, and accuracy to help you

Subscribe

Simply enter your email below and click “Subscribe” to stay connected with everything new and exciting.