-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

What Are The Different Types Of Cutting Tool Materials?

What are the different types of cutting tool materials used in machining?

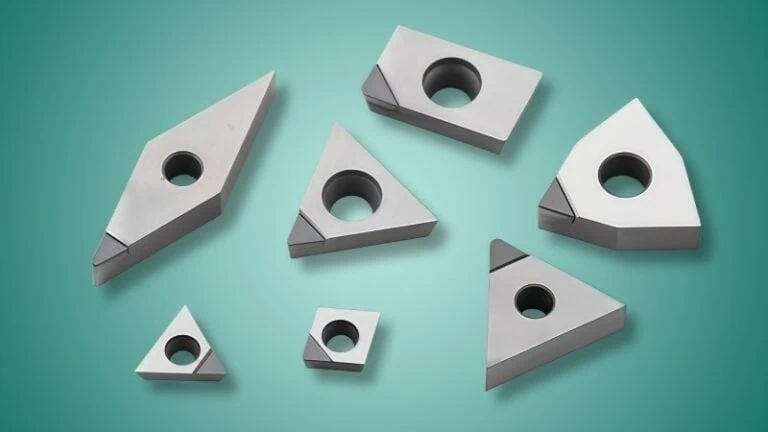

The primary types of cutting tool materials are High-Speed Steel (HSS), Tungsten Carbide, Ceramics, Cubic Boron Nitride (CBN), and Polycrystalline Diamond (PCD). Each material offers a unique combination of hardness, toughness, and heat resistance, making them suitable for different workpiece materials and machining operations, from general-purpose drilling to high-speed hard turning.

How Do The Core Properties Of These Materials Compare?

What truly separates one cutting tool material from another?

The primary differences lie in three core properties: hardness (resistance to wear), toughness (resistance to chipping or breaking), and hot hardness (the ability to maintain hardness at high temperatures). High-Speed Steel (HSS) is the toughest, while Polycrystalline Diamond (PCD) is the hardest. Materials like Carbide, Ceramics, and Cubic Boron Nitride (CBN) offer various balances of these properties to handle specific high-performance tasks.

High-Speed Steel (HSS): The Benchmark For Toughness

High-Speed Steel is the foundation of modern cutting tools. Its most important characteristic is its exceptional toughness. Think of toughness as the ability to bend without breaking. In machining, this means HSS tools can absorb the shock and vibration from an uneven cut or an old machine without chipping.

While it is not as hard as carbide, HSS maintains its hardness at moderate cutting temperatures, which is why it earned the name “high-speed” steel compared to older carbon steels.

- Core Property: Highest toughness among all major tool materials.

- Composition: It’s an iron-based alloy containing key elements like tungsten and molybdenum, which provide its heat and wear resistance.

- Practical Impact: Because of its toughness, HSS is extremely reliable for operations with a high risk of tool fracture, such as drilling holes with a hand drill or milling on less rigid machinery. It gives way gradually rather than failing catastrophically.

Tungsten Carbide: The Standard For Versatility And Hardness

Tungsten Carbide (Cemented Carbide) is the workhorse of the modern manufacturing industry. It strikes a crucial balance between hardness and toughness, making it incredibly versatile. It is significantly harder than HSS and can operate at 3-5 times the cutting speed.

Imagine carbide as a composite material like reinforced concrete. It is made of extremely hard particles of tungsten carbide (WC) suspended in a tougher, metallic binder, usually cobalt (Co).

By changing the amount of cobalt binder and the size of the tungsten carbide grains, manufacturers can create dozens of different carbide grades. A higher cobalt percentage increases toughness but reduces wear resistance, while a smaller grain size generally increases hardness. Because of this, it’s always wise to consult your supplier’s technical data for the specific performance characteristics of any given carbide grade.

Ceramics: Excelling In High-Heat And High-Speed Applications

Ceramic tools take performance to the next level, but with a specific focus on hot hardness. They can maintain their incredible hardness even when glowing red-hot. This unique ability allows them to cut at speeds far beyond what is possible with even the best-coated carbides.

However, this extreme heat resistance comes with a trade-off: ceramics have very low toughness and are quite brittle. They demand very stable machines and continuous cuts, as any vibration or shock could cause the tool to instantly shatter.

- Core Property: Extreme hot hardness and chemical stability.

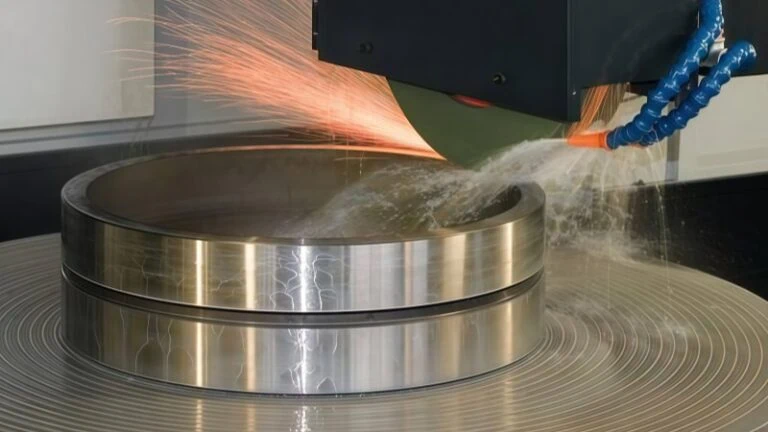

- Industry Example: When finish-turning a cast iron brake rotor, a ceramic insert can operate at speeds over 800 m/min (meters per minute). A carbide tool would likely fail quickly at these temperatures, but the ceramic insert thrives, leading to massive productivity gains in mass production.

Cubic Boron Nitride (CBN): The Specialist For Hardened Ferrous Metals

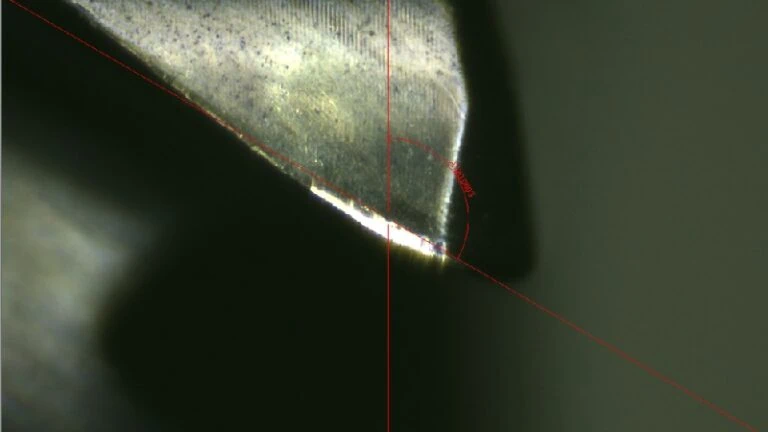

Cubic Boron Nitride1 is the second hardest material known to science, right behind diamond. Its specialty is maintaining this extreme hardness when machining hardened ferrous metals (steels and cast irons) with a hardness value typically above 45 HRC.

Why not just use diamond, the hardest material of all? At the high temperatures generated when cutting steel, diamond (which is pure carbon) undergoes a chemical reaction with the iron, causing the tool to wear out almost instantly. CBN is chemically stable against iron, making it the perfect tool for the job.

This process, known as hard turning2, is often an effective replacement for grinding operations. For instance, finishing a hardened steel gear (58-62 HRC) can be done faster and in a single machine setup with a CBN insert, compared to the separate, slower grinding process.

Polycrystalline Diamond (PCD): The Ultimate Choice For Abrasive & Non-Ferrous Materials

Polycrystalline Diamond3 is the absolute peak of hardness and wear resistance. A PCD tool consists of diamond particles sintered4 together onto a carbide substrate, combining diamond’s properties with carbide’s support.

As noted before, PCD cannot be used on steel or other ferrous metals because the carbon in the diamond reacts with iron at high cutting temperatures, causing rapid tool failure (diffusion wear). Its domain is abrasive, non-ferrous materials.

- Key Application: Machining an aluminum engine block with high silicon content. A carbide tool would wear out quickly due to the abrasive silicon particles. A PCD tool can last 50 to 100 times longer, maintaining consistent part dimensions and reducing tool change downtime in a high-production environment.

Quick Comparison Chart: Hardness vs. Toughness

To make these differences clear, here is a simple comparison.

| Material | Relative Hardness | Relative Toughness | Primary Characteristic |

|---|---|---|---|

| High-Speed Steel (HSS) | Low | Very High | Resists chipping and breaking |

| Tungsten Carbide | High | Medium | A versatile balance of hardness and toughness |

| Ceramics | Very High | Very Low | Retains hardness at extreme heat |

| Cubic Boron Nitride (CBN) | Extremely High | Low | Extreme hardness for cutting hardened ferrous metals |

| Polycrystalline Diamond (PCD) | Highest | Very Low | The ultimate hardness for non-ferrous and abrasives |

When Should You Use Each Type Of Cutting Material?

Knowing the options is one thing, but how do you match the right material to your specific job?

The choice depends almost entirely on the workpiece. Use High-Speed Steel (HSS) for general-purpose jobs and softer materials. Choose Tungsten Carbide for most steels, cast irons, and stainless steels. For hardened steels and superalloys, Cubic Boron Nitride (CBN) is the best option. Finally, use Polycrystalline Diamond (PCD) for abrasive, non-ferrous materials like aluminum, composites, and wood.

For General-Purpose Jobs And Softer Metals

For many everyday tasks, especially in maintenance shops or for one-off projects, High-Speed Steel (HSS) is the perfect choice. Its main advantage here is its excellent toughness.

Think about drilling a hole in a piece of mild steel with a power drill. The process isn’t perfectly rigid, and the tool might face some vibration. An HSS drill bit can handle this stress without chipping. It’s forgiving and reliable. Because it’s less expensive than carbide, it’s also a cost-effective solution for jobs where extreme cutting speed isn’t the primary goal.

- Best For: Low-to-medium carbon steels, aluminum, and other soft, non-ferrous metals.

- Common Tools: Drill bits, hand taps, and general-purpose end mills.

For Steels, Cast Iron, And Stainless Steels

This is where Tungsten Carbide truly shines. The vast majority of industrial machining involves cutting various grades of steel, stainless steel, and cast iron. Carbide’s combination of high hardness and good hot hardness allows it to cut these materials much faster and for much longer than HSS.

For example, when milling a block of 4140 alloy steel, a coated carbide end mill can run efficiently for hours, creating precise parts with a good surface finish. The specific grade of carbide is critical here.

- A tougher carbide grade (with more cobalt) is better for milling stainless steel, which is gummy and can cause chipping.

- A harder, more wear-resistant grade is ideal for the abrasive nature of cast iron.

In a production setting, a typical coated carbide insert might machine medium steel at speeds of 150-250 m/min. However, the optimal speed depends heavily on the exact carbide grade and coating, so always consult the tool manufacturer’s recommendations for best results.

For Hardened Steels And Superalloys

When a workpiece is heat-treated to become extremely hard (typically above 45 HRC), standard carbide tools may no longer be effective. This is the specialized domain for Cubic Boron Nitride (CBN).

Hard turning is a perfect industry example. Imagine a gear for a car’s transmission that has been case-hardened to 60 HRC. Instead of a slow, multi-step grinding process, a machine can use a CBN insert to cut the hardened surface directly. This is often faster and can be done on a single machine, dramatically improving efficiency.

What about tough, high-temperature materials like Inconel or Titanium, known as superalloys? These materials present a huge challenge because they generate extreme heat and pressure at the cutting edge. For these, machinists often use:

- Specialized, tough grades of coated carbide designed to resist the intense heat.

- Ceramics, which can handle the extreme temperatures generated during high-speed finishing cuts on materials like Inconel 718.

For Aluminum, Brass, Composites, And Wood

This category is dominated by Polycrystalline Diamond (PCD) tools, especially when dealing with abrasive materials. While you can cut aluminum with carbide, PCD excels in high-volume production.

The classic case is machining automotive aluminum with high silicon content. The hard silicon particles in the aluminum act like sandpaper, wearing out a carbide tool very quickly. A PCD tool, being much harder than the silicon, cuts through these abrasive particles with minimal wear, often lasting 50 to 100 times longer.

The same applies to modern composites.

Consider a structural component for an airplane made from carbon fiber reinforced polymer (CFRP)5. The carbon fibers are incredibly abrasive and would shred a carbide tool in minutes. A PCD-tipped tool is essential for cleanly cutting these fibers and achieving the long tool life required for cost-effective manufacturing.

For softer materials in this group, like brass or standard wood, HSS and uncoated carbide are also very effective and more economical choices.

What Are Coatings And How Do They Enhance Tool Performance?

How can a tool coating that’s thinner than a human hair make such a monumental difference in performance?

Coatings are micro-thin layers of extremely hard ceramic material applied to a tool’s surface. They act as a shield, dramatically improving performance by providing three key benefits: increased surface hardness for superior wear resistance, improved hot hardness by creating a thermal barrier, and better lubricity to reduce friction and prevent material from sticking to the tool.

Common Coating Types: TiN, TiAlN, And AlCrN

While dozens of specialized coatings exist, most fall into a few main families. Think of them as different tiers of performance. These coatings are typically applied using a process called Physical Vapor Deposition (PVD), which bonds the ceramic layer to the tool at a molecular level.

- TiN (Titanium Nitride): This is the classic, recognizable gold-colored coating. It was one of the first PVD coatings to become widely used and remains a great, all-purpose choice, especially for HSS tools like drills and taps. It provides a solid boost in hardness and wear resistance for general-purpose machining.

- TiAlN (Titanium Aluminum Nitride): This versatile, dark violet or black-colored coating is a significant step up from TiN. When it gets hot, the aluminum in the coating forms a microscopic layer of aluminum oxide—much like high-tech rust—that acts as an excellent thermal barrier. This protects the carbide or HSS underneath, making TiAlN a fantastic choice for milling steels and stainless steels at higher speeds.

- AlCrN (Aluminum Chromium Nitride): This is a newer, high-performance coating known for its exceptional hot hardness and toughness. Its slick surface provides excellent lubricity, making it ideal for demanding jobs like deep slot milling or machining tough materials where heat and chip evacuation are major challenges.

Many tool manufacturers have their own proprietary versions of these coatings with unique additives. A coating from one brand may offer different performance than a similarly named one from another, so it’s always smart to review the supplier’s specific application data.

The Key Benefits: Better Wear Resistance, Hardness, And Lubricity

Coatings don’t just look cool; they provide tangible benefits that allow you to run machines faster and make tools last longer.

🛡️ Better Wear Resistance

The coating itself is often significantly harder than the tool material it covers. This hard outer shell acts as a shield, directly resisting the abrasive wear that occurs as the tool cuts through the workpiece. This means the sharp cutting edge stays sharp for much longer.

🔥 Improved Hot Hardness

This is perhaps the most important benefit. The coating acts as an insulator, slowing the transfer of heat from the cutting zone into the tool itself. By keeping the underlying HSS or carbide cooler, the coating allows the tool to maintain its hardness at much higher cutting speeds—speeds that would quickly soften and destroy an uncoated tool.

✨ Enhanced Lubricity

Lubricity is just another word for “slipperiness.” A low-friction coating prevents the hot, sticky metal chips from welding themselves to the cutting edge. This condition, known as a built-up edge6, can ruin the surface finish of a part and quickly lead to tool failure. A slick coating ensures chips flow away smoothly, protecting both the tool and the workpiece.

Coated vs. Uncoated Tools: When To Choose Each

So, should you always choose a coated tool? Almost, but not always. The choice depends entirely on the material you’re cutting.

When to Use Coated Tools

For the vast majority of machining applications, a coated tool is the superior choice. If you are cutting any type of steel, stainless steel, cast iron, or high-temperature superalloy, a coating is practically mandatory for efficient production. The increase in tool life and the ability to run at higher speeds far outweigh the small additional cost of the coating. For example, using a TiAlN-coated carbide end mill on steel might allow for a 50% increase in cutting speed compared to its uncoated counterpart.

When to Use Uncoated Tools

There are a few key situations where an uncoated tool is actually better.

- Machining Aluminum: This is the most common reason to use an uncoated tool. Aluminum is soft and sticky, and it has a chemical affinity for the aluminum in popular coatings like TiAlN. This can cause the workpiece material to stick to the tool, leading to a poor finish and tool failure. A sharp, highly polished uncoated carbide tool often provides the cleanest cut and best performance in aluminum.

- Extremely Sharp Edge Requirements: For some soft, gummy plastics or specific non-ferrous materials, the absolute sharpest edge possible is needed. The process of coating adds a very slight rounding to the cutting edge. In these niche cases, an uncoated tool with a precision-ground edge might be preferred.

How Do You Choose The Right Material For Your Project?

How do you bring all this information together to select the perfect tool for your project?

Choosing the right material is a logical, three-step process. First, identify your workpiece material to determine the correct family of cutting tools. Second, consider your machining speed and the cutting conditions to select the right grade and coating. Finally, balance the required performance with the cost of the tool to find the most economical solution.

Step 1: Identify Your Workpiece Material

This is the most important step, as it immediately eliminates most of the options. The material you are cutting is the primary factor that dictates which tool materials are even possible to use. You can think of this as the first and most powerful filter.

- If you are cutting hardened steel (typically above 45 HRC), your choice is immediately narrowed down to CBN.

- If you are cutting abrasive materials like high-silicon aluminum or carbon fiber composites, you must start with PCD.

- If you are cutting standard steels, stainless steels, or cast iron, your starting point will be Tungsten Carbide.

- If you are doing a general-purpose job in mild steel or need high toughness, HSS is your baseline.

Getting this step right prevents catastrophic failures, such as trying to use a diamond tool on steel. Once you have matched the workpiece to the correct tool family, you can then refine your choice.

Step 2: Consider Your Machining Speed And Conditions

Now that you have the right family of materials, you need to select the right grade. This depends on how you plan to make the cut.

Machining Speed

Are you aiming for maximum productivity with high cutting speeds? Speed generates heat.

- Higher Speeds: Require a tool with better hot hardness. This is why coated carbide is used over HSS for production, and why ceramics are used for extremely high-speed finishing of cast iron.

- Lower Speeds: For slower operations where heat is not the main issue, a tougher, less expensive material like HSS or a basic uncoated carbide can work perfectly well.

Cutting Conditions

The environment of the cut is just as important as the speed. Ask yourself these questions:

- Will it be an interrupted cut? Machining a part with gaps, holes, or a rough surface creates constant impacts on the cutting edge. This shock demands a tool with higher toughness. A tougher grade of carbide or even an HSS tool would be a safer choice here than a brittle ceramic or CBN tool.

- How rigid is the machine and setup? An older, less rigid machine tool will have more vibration. This vibration can instantly shatter a very hard but brittle tool. If your setup is not perfectly rigid, lean towards a tougher tool material.

Step 3: Balance Performance Requirements With Cost

Finally, you must balance the performance you need with the budget you have. The “best” tool is not always the most expensive one; it’s the one that is most economical for the job at hand.

The key is to think in terms of cost-per-part7, not cost-per-tool.

- For a Hobbyist or Repair Shop: If you are making a single part, the lowest initial tool cost is often the most important factor. An affordable HSS drill bit or a general-purpose carbide end mill is usually the smartest financial choice. The tool doesn’t need to last for thousands of parts.

- For a Production Facility: In a production environment, machine time is the most expensive variable. A tool that costs more upfront is a sound investment if it allows you to run faster or lasts significantly longer, reducing machine downtime.

Here’s a practical case study: A PCD tool for machining aluminum might cost $300, while a carbide tool costs only $30. But if the PCD tool machines 50,000 parts before wearing out and the carbide tool only machines 1,000, the tool cost-per-part for PCD is just $0.006, while for carbide it’s $0.03. In this case, the more expensive tool is actually five times more economical and results in far less downtime for tool changes.

Ultimately, the final decision comes down to weighing these factors. While a premium tool from a leading brand may promise higher performance, always check the supplier’s data and consider running tests to confirm that the added cost delivers a real-world benefit for your specific application.

Conclusion

Selecting the right cutting tool material is not about finding a single “best” option, but about conducting a logical analysis. By understanding the core properties of each material family—from the toughness of HSS to the incredible hardness of PCD—you can effectively narrow down your choices. From there, matching the tool to your specific workpiece, machine conditions, and economic goals will lead you to the most efficient and cost-effective solution for any project, big or small.

References

- Cubic Boron Nitride1 – An in-depth guide from ZYDiamondTools covering all aspects of CBN cutting tools.

- hard turning2 – A ZYDiamondTools article explaining the process of hard turning and comparing it to traditional grinding.

- Polycrystalline Diamond3 – A comprehensive guide from ZYDiamondTools on the properties and applications of PCD tools.

- sintered4 – A Wikipedia article providing a scientific explanation of the sintering process used to form solid materials.

- carbon fiber reinforced polymer (CFRP)5 – A ZYDiamondTools article discussing if PCD tools are the optimal choice for machining aerospace composites.

- built-up edge6 – A Wikipedia article providing a technical definition and explanation of the built-up edge (BUE) phenomenon.

- cost-per-part7 – A ZYDiamondTools guide explaining Total Cost of Ownership (TCO) and its importance in calculating true tooling costs.