-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

Total Cost of Ownership (TCO) Explained: A Guide for Superhard Tooling & Abrasives

When considering the costs of superhard tools and abrasives, what does looking at the Total Cost of Ownership truly reveal beyond the initial purchase price?

Total Cost of Ownership (TCO)[1] for superhard tooling and abrasives provides a comprehensive view by accounting for all direct costs (purchase, energy, consumables) and crucial indirect costs (downtime, tool life, maintenance, scrap, labor, disposal) throughout the tool’s entire lifecycle, enabling more informed decisions and revealing the true long-term economic impact.

What Really Makes Up TCO for Superhard Tools & Abrasives?

So, when thinking about the total cost for those tough, superhard tools and abrasives used in manufacturing, what expenses are truly involved besides the initial purchase?

The Total Cost of Ownership (TCO) for superhard tooling and abrasives includes not only the initial purchase price but also all direct operating costs like energy and consumables, significant indirect costs such as machine downtime, tool setup, scrap, maintenance, and training, as well as end-of-life disposal expenses.

Understanding these different cost categories is crucial for getting a true picture of your spending. Let’s break them down.

Beyond the Price Tag: Direct Purchase & Operating Costs

These are the costs you probably think of first when buying or using a tool. They are directly related to getting the tool and running the machine.

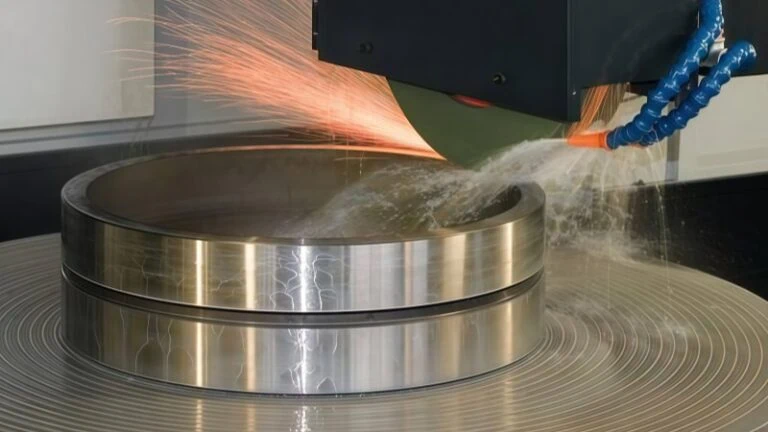

- Initial Purchase Price: This is simply the amount you pay the supplier for the new diamond wheel[2], CBN insert, or other superhard tool or abrasive. It’s the most obvious cost, but often only a small part of the total picture.

- Consumable Costs: Superhard tools and abrasives wear down with use and need replacing. This continuous replacement is a significant operating cost. Furthermore, many processes using these tools, like grinding, require coolants or cutting fluids. These fluids also cost money to purchase, maintain (filtering, treating), and eventually dispose of.

- Energy Consumption: The machines running these tools use electricity. Factors like the hardness of the material being worked on, the cutting or grinding speed, and machine efficiency all affect power consumption. Consequently, choosing a tool that allows for more efficient machining can lead to noticeable energy savings over time. Think of it like fuel for a car – the harder you drive or the less efficient the engine, the more fuel you consume.

The Hidden Iceberg: Uncovering Indirect Costs

These costs are often less obvious than direct costs, much like the hidden part of an iceberg, but they can have a massive impact on your overall TCO. Ignoring them leads to inaccurate cost assessments.

- Tool Setup & Changeover Time: Every time a machine stops so an operator can change a worn tool, replace an abrasive belt, or set up for a new job, production halts. This downtime costs money in two ways: the operator’s labor wage during the non-productive time and the value of the production lost while the machine sits idle. Faster changeovers mean lower costs.

- Machine Downtime (Unplanned & Planned): Tools can sometimes fail unexpectedly, causing unplanned machine stoppages. Additionally, routine preventive maintenance[3] is needed to keep machines running well. Both planned and unplanned downtime stop production, leading to lost output, potential delays in orders, and costs for repairs or maintenance tasks.

- Scrap & Rework Rates: A worn or incorrect tool can produce parts that don’t meet quality specifications (e.g., wrong dimensions, poor surface finish). These parts might need to be scrapped entirely, wasting materials and the machine time already invested. Alternatively, they might require rework, adding extra labor and process steps. For instance, using a degraded CBN grinding wheel on a high-value aerospace component could easily lead to scrapping the part, incurring substantial losses.

- Maintenance & Repair Costs: This includes maintaining the tools themselves (like the cost of sending a diamond dressing tool out for re-lapping or re-plating) and maintaining the machine tool. Sometimes, using inappropriate or low-quality tooling can even accelerate wear on the machine components (like spindles or guideways), leading to higher machine repair bills down the line.

- Operator Training & Skill Requirements: Effectively using advanced superhard tooling often requires specific operator skills and knowledge. The time and resources spent training operators represent another indirect cost.

- Inventory Holding Costs: Keeping a large stock of spare tools and abrasives ties up company capital that could be used elsewhere. It also requires storage space, management effort, and carries the risk of tools becoming damaged or obsolete while sitting on the shelf.

- Disposal Costs: When superhard tools or abrasives reach the end of their usable life, they need to be disposed of. Depending on the materials they contain (e.g., certain metals in binders), there might be specific environmental regulations and associated costs for proper, safe disposal.

Lifecycle Costs: From Acquisition to Disposal

Thinking about TCO means considering the entire life journey of the tool or abrasive within your operation.

This lifecycle perspective starts even before the purchase, encompassing the time and effort spent researching options, qualifying suppliers, and making the selection. It then covers all the direct operating costs and the crucial indirect costs incurred during the tool’s active use. Finally, it includes the costs associated with retiring and disposing of the tool. Therefore, TCO provides a complete view, ensuring decisions aren’t based solely on the upfront price tag but on the full economic impact over time.

Why Does Initial Price Often Mislead in Tooling & Abrasive Decisions?

When choosing superhard tools or abrasives, why can focusing just on the lowest purchase price sometimes lead you down the wrong path?

Focusing solely on initial price is misleading because it ignores critical factors like how long the tool lasts, how fast it works (performance), and the quality of the parts it produces; these factors often drive much larger costs through increased downtime, slower production, and higher scrap rates, ultimately making a “cheaper” tool more expensive overall.

It’s easy to get fixated on that upfront number, but neglecting the bigger picture can be a costly mistake in manufacturing. Let’s explore why.

The Pitfalls of Focusing Solely on Upfront Costs

Choosing the tool with the lowest price tag can feel like a smart move initially, but it often triggers a cascade of hidden expenses later on. This reflects the common saying “penny wise and pound foolish.”

Consider these common issues with seemingly cheap tools:

- Frequent Replacements: A tool might be inexpensive, but if it wears out quickly, you’ll simply end up buying more of them over the same period compared to a longer-lasting, higher-quality option. This increases your total spending on tools.

- Increased Downtime: More frequent tool wear means more frequent machine stoppages for tool changes. Each changeover takes time, during which the machine isn’t producing parts. This lost production time represents a significant hidden cost, especially in high-volume manufacturing.

- Higher Maintenance: Lower quality tools might sometimes contribute to increased vibration or put extra strain on machine components, potentially leading to higher machine maintenance needs over time.

- Risk of Unexpected Failure: Cheaper tools may be less reliable or consistent, increasing the risk of sudden failure during operation. An unexpected tool breakage can not only halt production but potentially damage the workpiece or even the machine itself, leading to major disruptions and costs.

Selecting superhard tooling based only on price often ignores these downstream consequences, leading to higher total costs in the long run.

How Tool Life & Performance Dramatically Impact TCO

This is where the limitations of price-based decisions become most apparent. Two key factors heavily influence the true cost:

Longer Life = Fewer Costs

A tool’s lifespan has a direct and substantial effect on TCO. A superhard tool, like a diamond grinding wheel or a CBN insert[4], that lasts significantly longer provides several cost benefits:

- Reduced Purchase Frequency: You simply buy fewer tools over time.

- Fewer Tool Changes: This is often the biggest saving. Less frequent changes mean significantly less machine downtime dedicated to swapping tools. This translates directly to more available production time.

- Lower Labor per Part: Less time spent changing tools means labor is focused more on production.

- Simplified Example:

- Tool A: Costs $50, lasts 1,000 parts. Cost per part (tool only) = $0.05. Requires 5 changes for 5,000 parts.

- Tool B: Costs $120, lasts 3,000 parts. Cost per part (tool only) = $0.04. Requires approximately two tool changes for 5,000 parts.

Better Performance = Faster Production

Beyond just lasting longer, higher-quality superhard tools can often enable faster and more efficient machining:

- Increased Throughput: Advanced tooling might allow for higher cutting speeds, faster feed rates, or greater depth of cuts, increasing the Material Removal Rate (MRR). This means you can produce more parts in the same amount of time.

- Lower Cost Per Part: By increasing production speed (throughput), the machine time and associated labor cost allocated to each individual part decreases. Even if the tool costs more initially, making parts significantly faster can lead to a lower overall cost per piece produced.

- Important Note: Achieving these higher performance levels often depends on machine capability and using the right parameters (speeds, feeds, coolant). Always check the tool supplier’s recommendations for your specific setup, as these parameters can vary widely.

Understanding the Cost of Quality (or Lack Thereof)

The tool you choose directly affects the quality of the parts you make. Opting for a cheaper tool that compromises on performance can introduce significant quality-related costs:

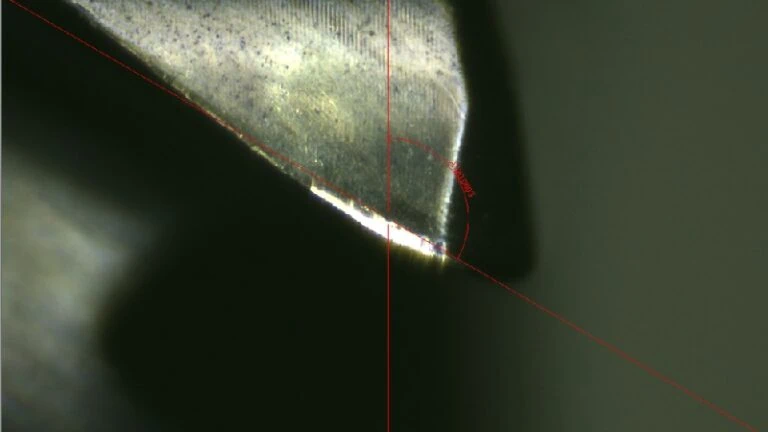

- Poor Surface Finish: Inferior abrasives or worn tools might leave undesirable surface patterns or roughness, potentially requiring secondary finishing operations (like extra polishing or grinding) which add time and cost.

- Inaccurate Dimensions: Tools that wear unevenly or deflect under pressure may struggle to maintain the tight tolerances required in precision manufacturing. This can lead to parts being produced outside of specification limits.

- Process Inconsistency: If tool performance varies significantly from one tool to the next, or even during the life of a single tool, it becomes challenging to maintain a stable and predictable manufacturing process.

What do these quality issues cost?

- Scrap: Throwing away bad parts wastes materials, labor, and machine time already invested.

- Rework: Fixing bad parts requires extra steps, labor, and inspection.

- Inspection Costs: More rigorous inspection might be needed if quality is inconsistent.

- Customer Dissatisfaction: Delivering poor quality parts can damage your reputation and lead to lost business.

Often, the hidden costs associated with scrap and rework caused by inadequate tooling far exceed any initial savings from a lower purchase price. Investing in a tool that consistently produces good parts is usually the more economical choice.

How Can You Effectively Calculate TCO for Your Specific Application?

Okay, so we know TCO is important, but how do you actually figure out the Total Cost of Ownership for the specific superhard tools and grinding wheels you use?

To effectively calculate TCO for your specific application, you need to diligently collect accurate data on all key direct and indirect costs, apply a consistent calculation framework (like cost per part or cost per hour) over a defined period, and use this analysis to objectively compare different tools or processes.

Calculating TCO might seem daunting at first, but breaking it down into manageable steps makes it achievable. It’s about gathering the right information and putting it together logically.

Key Data Points You Need to Collect

Accurate TCO calculation relies entirely on accurate data. Think of it like baking a cake – using the wrong ingredients or measurements yields poor results. Here are the essential pieces of information you’ll likely need to track:

Tool & Operating Data

- Purchase Price: The cost per unit for the specific superhard tool or abrasive. ($/tool)

- Actual Tool Life: This is critical. How many parts does one tool produce? How many hours does it last? How many linear feet can it cut or grind before needing replacement? Track this as precisely as possible in your real operating conditions. (Parts/tool, Hours/tool, etc.)

- Consumable Costs: Price and usage rate of things like coolant or cutting fluids needed for the process. ($/gallon, gallons/hour)

- Energy Use: If possible, measure the machine’s power consumption during operation. (kWh/hour)

Time & Labor Data

- Tool Changeover Time: The average time it takes to stop the machine, remove the old tool, install the new one, and get running again. (Minutes/change)

- Operator Labor Rate: The fully burdened cost of the machine operator per hour. ($/hour)

- Machine Hourly Rate: An estimated cost per hour for running the machine, often including factors like depreciation, floor space, overhead, and sometimes energy. ($/hour)

Downtime & Maintenance Data

- Unplanned Downtime: How often does the machine stop unexpectedly due to tooling issues (e.g., tool breakage), and how long does it typically take to resolve? (Frequency/month, Hours/occurrence)

- Tool Maintenance: Costs associated with maintaining the tool itself, such as sending a diamond tool out for re-lapping or re-plating, including the cost and frequency. ($/service, Frequency)

Quality Data

- Scrap Rate: The percentage of parts that must be discarded due to problems caused specifically by the tooling (e.g., poor finish, incorrect size). (%)

- Cost per Scrapped Part: The value of a scrapped part, including material cost and any processing costs already incurred before scrapping. ($/scrapped part)

- Rework Rate: The percentage of parts requiring extra steps to fix tooling-related quality issues. (%)

- Cost per Reworked Part: The additional labor and machine time needed to fix a defective part. ($/reworked part)

End-of-Life Data

- Disposal Cost: Any costs associated with properly disposing of the worn-out tool or abrasive. ($/tool)

Where to find this data? Look at machine monitoring systems, operator logs, maintenance records, purchasing department, quality reports. Start with estimates if needed, but aim for real data from your shop floor over time for the best results.

Simple Frameworks for TCO Calculation

You don’t necessarily need complex software to start calculating TCO. A structured approach using a spreadsheet can work well. Here are two common frameworks:

Calculating Cost Per Part

This is often the most useful metric in production environments. It tells you the true cost to produce one acceptable finished part.

- Basic Formula: Total Costs over a Period ÷ Total Good Parts Produced in that Period

- Breaking Down Total Costs: You need to sum up all relevant costs incurred during your chosen period (e.g., one month):

- Tooling Costs: (Number of tools used × Purchase Price per tool) + Total Tool Maintenance Costs + Total Disposal Costs

- Operating Costs: (Total operating hours × (Machine Rate + Operator Labor Rate + Energy Cost Rate + Coolant Cost Rate))

- Downtime Costs: (Total downtime hours × (Machine Rate + Operator Labor Rate))

- Quality Costs: (Number of scrapped parts × Cost per scrapped part) + (Number of reworked parts × Cost per reworked part)

- Changeover Costs: (Number of tool changes × Changeover time per change × (Machine Rate + Operator Labor Rate))

Calculating Cost Per Hour

If tracking per part is difficult, calculating the total cost to run the process for one hour can be insightful.

- Basic Formula: Total Costs over a Period ÷ Total Machine Operating Hours in that Period

- Total Costs: Calculated similarly to the Cost Per Part method, summing all expenses over the chosen period.

Define Your Scope

Before you start, decide clearly:

- What period are you measuring? (A week, month, year, specific production run?)

- What costs are you including? (Be consistent!)

Some tooling suppliers offer TCO calculators, which can be helpful starting points. However, always understand what factors they include and exclude, and use your own collected data whenever possible for accuracy.

Comparing TCO: Tool vs. Tool, Process vs. Process

The real power of calculating TCO comes from making comparisons.

Comparing Different Tools

This is the most common use. Let’s say you’re testing a new, more expensive diamond wheel (Wheel B) against your current standard wheel (Wheel A).

- Run Both: Use both tools under similar operating conditions for a defined period or number of parts.

- Collect Data: Diligently track all the key data points listed earlier for both Wheel A and Wheel B.

- Calculate TCO: Apply the exact same calculation framework (e.g., cost per part) to both sets of data.

- Compare Results: The tool with the lower calculated TCO is likely the more economical choice overall, even if its initial purchase price is higher. You might find Wheel B’s longer life and reduced downtime costs outweigh its higher price tag. This gives you solid data to justify switching.

Comparing Different Processes

You can also use TCO to compare completely different ways of making a part.

- For example, compare the TCO of using a high-speed grinding process with superhard wheels versus a slower, conventional milling process using carbide tools for a specific material removal task.

- Evaluate the TCO of dry machining versus wet machining, considering tool costs, cycle times, energy use, quality outcomes, and disposal costs for each approach.

Consistency is Key

When making any comparison, the most crucial element is consistency. Use the same data collection methods, include the same cost factors, and apply the same calculation framework to all options being evaluated. An apples-to-apples comparison is essential for the results to be meaningful.

Strategies for Lowering TCO with Superhard Tooling & Abrasives

Now that we understand and can calculate TCO, what practical steps can actually be taken to reduce the total cost of using superhard tools and abrasives?

Strategies to lower TCO for superhard tooling and abrasives involve selecting the optimal tool and fine-tuning application parameters (speeds, feeds), ensuring excellent machine maintenance for maximum uptime, utilizing supplier services like tool reconditioning and technical support, and investing in operator training alongside overall process efficiency improvements.

Lowering TCO isn’t about just one magic bullet; it’s about implementing a combination of smart choices and consistent practices across your manufacturing process. Let’s explore these key strategies.

Optimizing Tool Selection & Application Parameters

This strategy focuses on using the right tool in the right way to maximize efficiency and minimize waste.

Choosing the Right Tool for the Job

Simply buying the cheapest option is rarely the best path. Instead, focus on selecting the tool specifically engineered for your task:

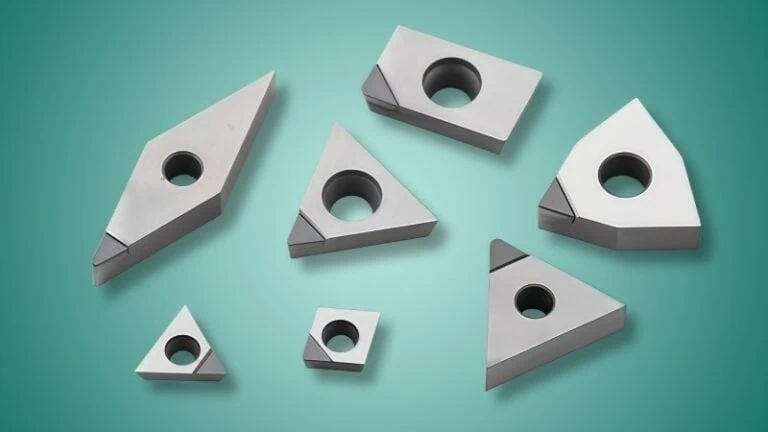

- Match Tool to Material: Use diamond tools[5] for non-ferrous materials, composites, ceramics, and carbides. Use Cubic Boron Nitride (CBN) for hardened ferrous materials like steels and cast irons. Using the wrong abrasive type leads to rapid wear and poor performance.

- Consider Bond, Grit, and Geometry: Within diamond or CBN tools, the bonding material holding the abrasive, the size of the abrasive grains (grit size), and the tool’s physical shape (geometry) all impact performance. Work with suppliers or use TCO analysis to find the combination that provides the best balance of material removal rate, surface finish, and tool life for your specific needs.

- Justify with Data: Use your TCO calculations to support choosing a tool that might cost more upfront but delivers much better performance or life, resulting in lower overall costs.

Dialing in the Parameters

Even the best tool will underperform if used incorrectly. Optimizing application parameters is crucial:

- Speeds and Feeds: Running the tool at the correct cutting speed (how fast the tool surface moves relative to the workpiece) and feed rate (how fast the tool advances into or across the workpiece) is critical. Too slow wastes time; too fast can cause premature wear or tool failure.

- Depth of Cut: How much material is removed in each pass also affects tool life and cycle time.

- Coolant Application: Proper type, concentration, pressure, and delivery of coolant are vital in many superhard tooling applications to manage heat, flush away debris, and improve tool life and surface finish.

- Optimization Process: Finding the ideal parameters often involves starting with supplier recommendations and then conducting controlled tests, monitoring tool wear, cycle times, and part quality to fine-tune settings for your specific machine and material.

- Remember: Optimal parameters vary greatly depending on the specific tool, material, machine rigidity, and coolant used. Always start with recommendations from your tooling supplier, but be prepared to fine-tune them for your unique situation.

The Role of Machine Maintenance & Uptime

Your machine tool is the platform that enables your superhard tooling to perform. Its condition directly impacts tool life, part quality, and overall TCO.

Keep Machines in Top Shape

A poorly maintained machine can undermine the benefits of even the most advanced tooling:

- Preventive Maintenance: Regularly scheduled maintenance is key. This includes checking spindle runout and balance (vibration significantly impacts tool life), verifying machine alignment, ensuring guideway lubrication, and maintaining the coolant delivery system (proper pressure, filtration, concentration).

- Addressing Issues Promptly: Don’t ignore signs of machine wear like unusual noises or vibration. These issues can rapidly degrade tool performance and even damage expensive superhard tools.

Maximize Uptime

Well-maintained machines are reliable machines. Reliability means:

- Reduced Unplanned Downtime: Fewer unexpected breakdowns mean more consistent production.

- Increased Production Hours: More available machine time allows you to produce more parts, spreading fixed costs over higher volume and lowering the TCO per part.

Leveraging Supplier Services (Regrinding, Coating, Support)

Think of your tooling suppliers as partners in cost reduction, not just vendors. Utilize the full range of services they offer:

Reconditioning Services

- Regrinding/Re-lapping/Re-plating: Many high-value superhard tools (like PCD cutting tools[6], CBN inserts, single-point diamond dressers) are designed to be reconditioned multiple times. Sending a worn tool for professional re-servicing typically costs much less than buying a new one, offering substantial savings and directly lowering TCO. Investigate if this is an option for your tools by asking your supplier.

- Tool Management Programs: Some suppliers offer programs to manage the logistics of tool reconditioning, ensuring you always have sharp tools available.

Advanced Coatings

- Performance Enhancement: Specialized coatings applied to the tool’s cutting edge or body can significantly increase hardness, reduce friction, improve heat resistance, or prevent material adhesion.

- TCO Impact: While potentially adding to the initial tool cost, the right coating, selected based on the application, can extend tool life or allow for higher machining parameters, ultimately reducing TCO. Discuss coating options with your supplier.

Technical Support & Partnership

- Expert Advice: Don’t hesitate to use your supplier’s application engineers or technical support team. They have deep knowledge about their products and can provide invaluable assistance with tool selection, parameter optimization, troubleshooting, and potentially identifying cost-saving opportunities you hadn’t considered. This expertise can save you significant time and prevent costly trial-and-error.

Improving Operator Training & Process Efficiency

Skilled people and smooth processes are key to minimizing waste and maximizing the value derived from your tooling investment.

Invest in Your Operators

- Proper Handling: Train operators on the correct procedures for handling, mounting, and setting up expensive superhard tools to avoid accidental damage.

- Wear Recognition: Teach operators to recognize the early signs of tool wear so tools can be changed proactively before causing scrap or machine damage.

- Parameter Adherence: Ensure operators understand the importance of running jobs at the specified, optimized parameters.

- Empowerment: Well-trained and engaged operators are more likely to identify potential process improvements.

Streamline the Workflow

- Reduce Non-Value-Added Time: Analyze the entire process related to tooling. Can tool changes be made faster with preset tooling or quick-change systems? Is tool storage organized for easy access? Can part loading/unloading be improved?

- Optimize Flow: Applying lean manufacturing principles[7] to minimize wasted motion, waiting time, and unnecessary handling related to tooling can significantly improve overall efficiency and reduce labor costs allocated to each part, contributing to lower TCO.

Tangible Benefits of Adopting a TCO Approach

After putting in the effort to understand, calculate, and manage TCO for superhard tools, what real, measurable advantages can a business expect to see?

Adopting a Total Cost of Ownership approach for superhard tooling delivers tangible benefits including significant long-term cost reductions by revealing hidden expenses, boosted manufacturing productivity and throughput via optimized tool performance and less downtime, smarter data-driven procurement decisions, and ultimately, a stronger competitive advantage through improved overall operational efficiency.

Moving beyond just the initial purchase price to embrace a TCO mindset isn’t just an accounting exercise; it drives real improvements on the shop floor and strengthens the bottom line. Here’s how:

Achieving Significant Long-Term Cost Reduction

Perhaps the most direct benefit of focusing on TCO is finding pathways to genuinely lower your overall manufacturing expenses over time. It achieves this by:

- Illuminating Hidden Costs: TCO forces you to look beyond the obvious price tag and identify significant “hidden” costs like excessive machine downtime, high scrap rates, frequent tool change labor, and unexpected maintenance. Once visible, these costs can be targeted for reduction.

- Justifying Value-Based Investments: It provides the financial framework to justify purchasing a higher-quality, potentially more expensive superhard tool if its superior performance or longer life significantly reduces indirect costs (like downtime or scrap) and results in a lower total cost per part.

- Optimizing Resource Allocation: By understanding the true cost drivers, you can focus cost-saving efforts and resources where they will have the greatest impact, rather than just trimming easily visible expenses that might have minor overall effect.

Boosting Manufacturing Productivity and Throughput

A thorough TCO approach naturally leads to improvements in how much you can produce and how quickly you can produce it. This happens because TCO encourages actions that:

- Minimize Interruptions: By favoring longer-lasting tools, optimizing changeover procedures, and emphasizing machine reliability (as TCO analysis encourages), you reduce interruptions like tool changes and unplanned breakdowns. More uptime = more production time.

- Enable Faster Cycle Times: Often, tools selected based on favorable TCO characteristics (not just price) allow for more aggressive, yet stable, machining parameters (higher speeds, feeds, etc.). This directly increases throughput – the number of good parts produced per hour or per shift.

- Reduce Waste: Strategies that lower TCO often simultaneously reduce scrap and rework rates. This means more of your production time and resources are spent making good parts the first time, rather than dealing with defects.

Higher productivity means better utilization of your valuable machines, skilled operators, and factory floor space, leading to greater overall operational effectiveness.

Making Smarter, Data-Driven Procurement Choices

Implementing TCO analysis fundamentally shifts procurement decisions from being purely price-focused or based on habit, to being strategic and data-driven.

- Objective Supplier & Tool Comparison: TCO provides a standardized, quantifiable method to compare different tooling options or suppliers based on their total lifecycle cost impact, enabling truly “apples-to-apples” evaluations.

- Clear Investment Justification: When proposing the purchase of a superior, perhaps more costly, tool, a TCO analysis provides the financial data (e.g., calculated savings in scrap reduction, projected decrease in cost-per-part) needed to clearly explain the benefits and gain approval from management.

- Stronger Negotiations: Armed with TCO data, discussions with suppliers can move beyond simple price haggling to focus on total value, tool life guarantees, reconditioning services, and technical support – elements critical to long-term cost efficiency.

- Strategic Procurement: This approach elevates the purchasing function from a simple cost center to a strategic partner actively contributing to operational efficiency and profitability.

Gaining a Competitive Advantage Through Efficiency

Ultimately, the combined benefits of cost reduction, productivity gains, and smarter procurement translate into a stronger competitive position in the marketplace.

- Improved Cost Structure: Lower manufacturing costs achieved through TCO optimization can enable more competitive pricing for customers or result in higher profit margins.

- Faster Response Times: Increased throughput and operational efficiency can lead to shorter lead times for customer orders, a significant competitive differentiator.

- Enhanced Reputation: Consistently delivering high-quality parts, supported by reliable tooling and processes identified through TCO analysis, builds customer trust and strengthens customer relationships.

- Greater Operational Resilience: Businesses that meticulously manage their costs and maximize efficiency are often more adaptable and better equipped to navigate market fluctuations or competitive pressures.

By truly understanding and managing the total costs associated with critical inputs like superhard tooling and abrasives, companies operate more effectively, make more informed decisions, and build a more robust and competitive manufacturing operation.

Conclusion

Understanding and actively managing the Total Cost of Ownership is essential for optimizing performance and profitability when using superhard tooling and abrasives. By looking beyond the initial price and considering the full lifecycle costs, manufacturers can make smarter decisions, enhance efficiency, and ultimately strengthen their competitive position. Embracing TCO is not just about saving money; it’s about operating smarter and more efficiently in a demanding market.

Want expert advice on selecting the right PCD/CBN tools or diamond/CBN wheels to lower your TCO? Request a free consultation with our technical team.

References

- Total Cost of Ownership (TCO)1 – Investopedia article defining and explaining the concept of Total Cost of Ownership.

- diamond wheel2 – ZYDiamondTools blog post explaining diamond grinding wheels.

- preventive maintenance3 – Reliable Plant article discussing preventive maintenance strategies in manufacturing settings.

- CBN insert4 – View the ZYDiamondTools product page for CBN & PCBN inserts.

- diamond tools5 – Encyclopedia Britannica article on industrial diamonds and their applications.

- PCD cutting tools6 – Explore the comprehensive range of standard and custom PCD & PCBN tools from ZYDiamondTools.

- lean manufacturing principles7 – Lean Enterprise Institute page explaining the core ideas behind Lean.