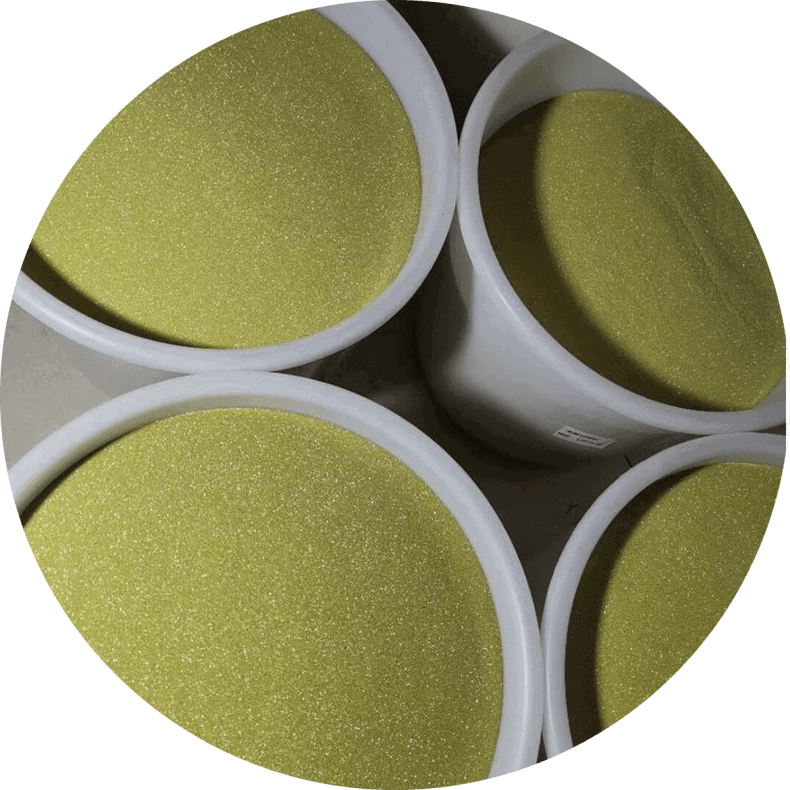

Diamond paste

1.Common Type: Water-soluble and Oil soluble

2.Grit: W0.5 – W40, also support customizing various specifications

| Choose of commonly used grit size and scope of use |

| W40 |

400-450 mesh |

Polished hard alloy, alloy steel, carbon steel, etc |

| W28/W20 |

700/1000 mesh |

Suitable for rough grinding of jade or metal with relatively rough surface |

| W14 |

1300 mesh |

Suitable for abrasive surface of relatively rough jade, jade or tungsten steel grinding tools and other metals |

| W10/W7/W5 |

2000/3000/4000 mesh |

Used for rough polishing of jade or metal |

| W3.5 |

6000 mesh |

Normally polished jade, agate,carbide.It’s one of the most used models |

| W2.5 |

10000 mesh |

Suitable for polishing the outer surface of metal such as hard alloy |

| w1.5 |

12000 mesh |

Usually Polishing jade agate or hard alloy with W3.5 or W2.5 , then W1.5, can achieve mirror effect |

| w1 |

15000 mesh |

Generally used for amber or jade fine polishing |

| w0.5 |

30000 mesh |

Suitable for high precision polishing of jade, agate, crystal and other smooth surface |

3.Material: Diamond mixed binder,

- diamond compound made of 30% concentration of diamond powders.

- also can be customized.

4.Application:

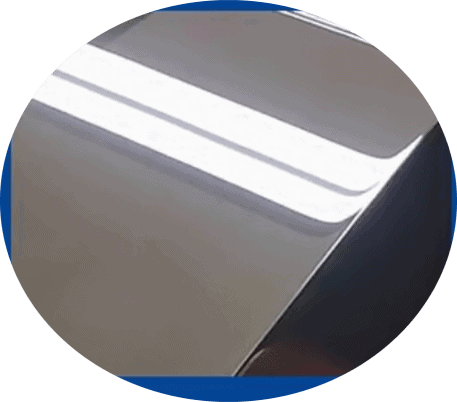

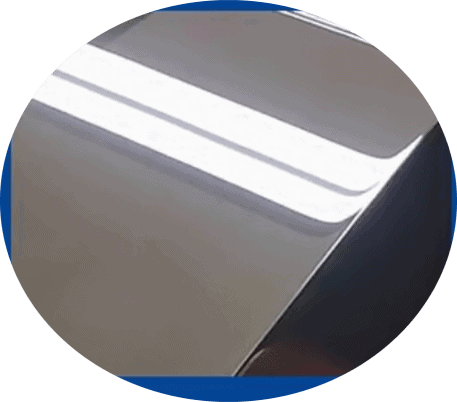

•Used for all kinds of mirror polishing

•Fast removal of workpiece surface accumulation, ultra-fine surface polishing

•Also commonly used for super grinding of various precision

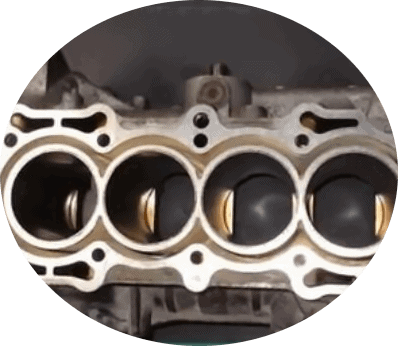

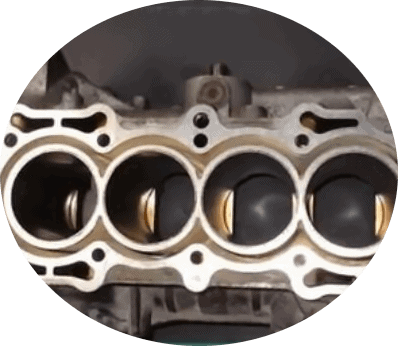

(4)work-piece:grinding and polishing hardened steels ,carbide ,tungsten steel mold, optical mold, injection mold,metallographic analysis experiments, dental materials (dentures),jewelry and jade crafts,alloy, optical lens, hard glass and crystal, super hard ceramics, polishing bore holes for l.e.d. illumination and other fields.

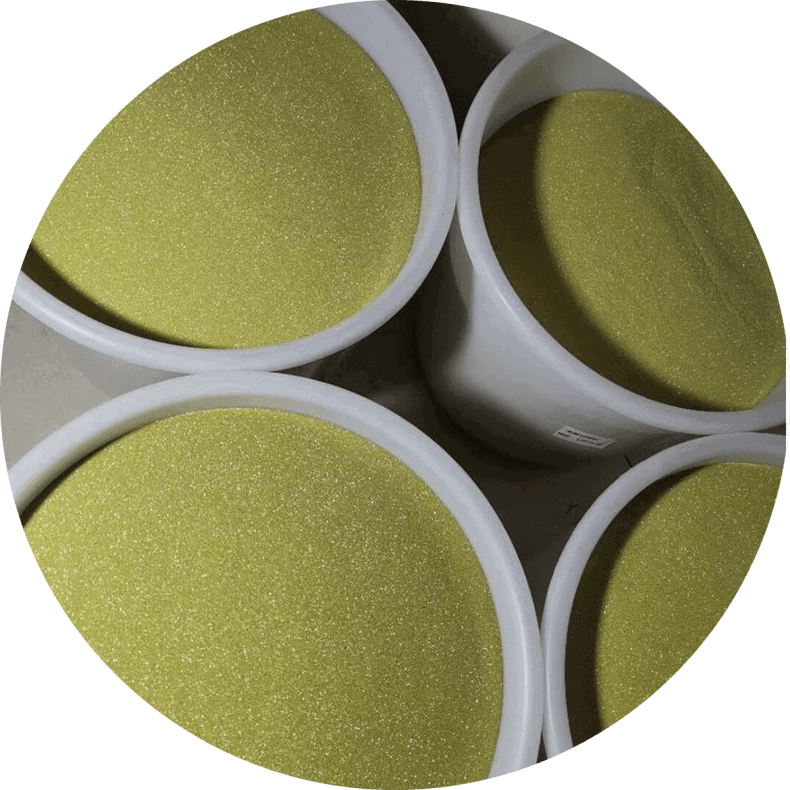

5.Packing: needle 5g/syringe( polishing paste can come in a very handy syringe) ,50g/box,100g/box, 5kg/box, etc.

6.Instructions for Use

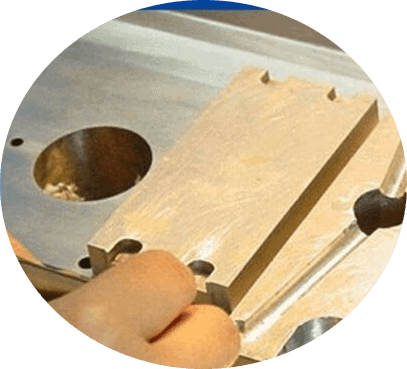

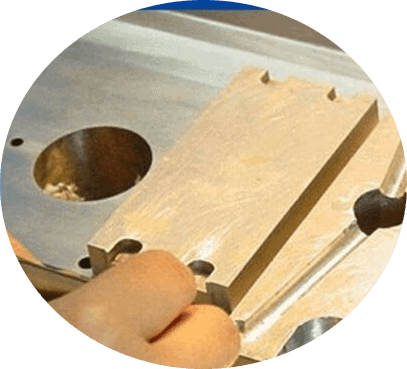

• For precision polishing, the environment and tools must be clean during processing.

• Processing, the workpiece must be cleaned before using different particle size grinding so as not to mix the coarse particles of the previous process into the fine particle grinding paste and scratch the workpiece.

•When using, squeeze a small amount of grinding paste into the container or directly squeeze on the grinding device and dilute it with water, glycerin, or kerosene. The general ratio of water paste is 1:1, which can also be according to to adjust the field use situation, so the smallest particle size only needs to add a small amount of water, as the size of the coarse adds an appropriate amount of glycerin.

(4) The workpiece should be cleaned with gasoline, kerosene, or water.

7.Note:

Diamond paste transportation and storage matters need attention

•Do not squeeze during transportation or storage.

•Storage room temperature should be below 200℃

•The storage environment should be hygienic, cool, and dry.

8.Underline :

the work-piece surface polishing, not the use of the finer, the better, but according to the actual situation of the surface to polish the model. Generally, choose 2 to 3 kinds of grit or more, first coarse and then fine-grained, and gradually polishing to achieve the required effect.