Introduction

In the realm of machining, diamond end mills have gained significant popularity due to their exceptional hardness, wear resistance, and ability to achieve high precision. Among the various types available, polycrystalline and monocrystalline diamond end mills stand out as reliable options. Understanding the characteristics, advantages, and suitable applications of each type is essential for making an informed choice.

Understanding Diamond End Mills

What is Diamond End Mills?

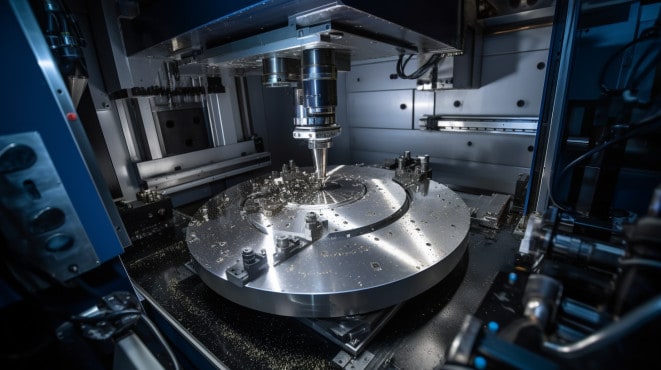

Diamond end mills are cutting tools used in milling operations, commonly employed in industries such as aerospace, automotive, and mold-making. Unlike traditional end mills made of high-speed steel or carbide, diamond end mills feature diamond as the cutting material, offering superior hardness and wear resistance.

Importance of Diamond End Mills in Machining

Diamond end mills play a crucial role in achieving precision machining results. Their exceptional hardness enables them to withstand high cutting temperatures and maintain sharp cutting edges for extended periods. Additionally, their superior wear resistance reduces the need for frequent tool changes, resulting in improved productivity and cost savings.

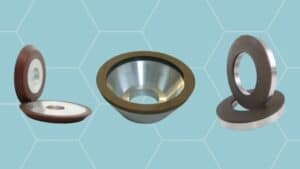

Polycrystalline Diamond (PCD) End Mills

Definition and Composition

Polycrystalline diamond (PCD) end mills are made from a composite material consisting of small diamond particles bonded together with a metallic binder. This composition results in a polycrystalline structure, giving PCD end mills their unique properties. PCD milling cutters are designed for high accuracy at high speeds, featuring various cutting edges that allow for greater control over the amount of material being removed.

Advantages and Features

PCD end mills offer several advantages in machining applications. Firstly, they exhibit exceptional hardness and wear resistance, allowing for long tool life and extended cutting performance. The polycrystalline structure of PCD end mills provides uniform wear distribution, minimizing the risk of chipping or breakage during operation.

Furthermore, PCD end mills deliver excellent surface finish, making them ideal for applications that require superior precision and smoothness. They are highly resistant to chemical reactions, making them suitable for machining abrasive materials or composites.

Another notable feature of PCD end mills is their ability to efficiently dissipate heat generated during the cutting process. This heat resistance ensures consistent performance even in high-speed machining operations.

Applications

PCD end mills find extensive use in various industries and applications. Some common areas where PCD end mills excel include:

Aerospace: PCD end mills are preferred for machining aerospace components such as aircraft engine parts, turbine blades, and composite materials.

Automotive: They are widely used in the automotive industry for machining aluminum parts, carbon fiber components, and other lightweight materials.

Mold and Die Making: PCD end mills are highly effective in producing intricate molds, dies, and tooling for industries like injection molding and die casting.

Woodworking: PCD end mills are suitable for machining wood, plywood, and laminates, providing clean cuts and reducing the need for sanding or finishing.

Monocrystalline Diamond End Mills

Definition and Composition

Monocrystalline diamond end mills, also known as single-crystal diamond end mills, are made from a single large diamond crystal. The manufacturing process involves growing a single crystal and shaping it into the desired cutting tool form. Mono Crystalline Diamond (MCD) milling cutters, also known as SCD, are a type of synthetic diamond that can enhance cutting tools for high cutting performance, enabling faster and smoother cuts.

Advantages and Features

Monocrystalline diamond end mills offer unique advantages in specific machining applications. The single-crystal structure provides exceptionally sharp cutting edges, resulting in high precision and accuracy during machining operations.

Due to their single-crystal composition, monocrystalline diamond end mills exhibit outstanding thermal conductivity. This property allows for efficient heat dissipation, reducing the risk of thermal damage to the workpiece.

Additionally, monocrystalline diamond end mills provide excellent tool rigidity and stiffness, enabling stable and vibration-free machining. This stability enhances surface finish and dimensional accuracy.

Applications

Monocrystalline diamond end mills are commonly utilized in applications that require the highest level of precision and surface quality. Some notable applications include:

Jewelry Manufacturing: Monocrystalline diamond end mills are used for machining intricate designs on precious metals and gemstones.

Optical Industry: They are employed in the production of optical lenses, prisms, and other precision components that require superior surface finish.

Electronics: Monocrystalline diamond end mills find application in the manufacturing of electronic components, such as printed circuit boards (PCBs), where precision and fine detail are essential.

Medical Industry: They are used for machining medical implants, dental prosthetics, and other critical medical devices that demand exceptional precision and biocompatibility.

Comparison between Polycrystalline and Monocrystalline Diamond End Mills

When choosing between polycrystalline and monocrystalline diamond end mills, several factors need to be considered. Let’s compare these two types based on key aspects:

Performance and Durability

Both PCD and monocrystalline diamond end mills offer excellent performance and durability. PCD end mills exhibit high wear resistance, making them suitable for extended use in abrasive materials. On the other hand, monocrystalline diamond end mills provide superior cutting sharpness and precision due to their single-crystal structure.

Cost-effectiveness

PCD end mills tend to be more cost-effective in the long run due to their extended tool life and reduced need for tool changes. However, the initial cost of PCD end mills may be higher compared to monocrystalline diamond end mills. Monocrystalline diamond end mills, while generally more expensive upfront, may offer better value for specific applications that require the highest level of precision and surface finish.

Versatility

PCD end mills are known for their versatility and can be used for a wide range of materials, including non-ferrous metals, wood, plastics, and composites. They are an excellent choice for applications that involve multiple material types. Monocrystalline diamond end mills, on the other hand, are often more specialized and excel in applications where the utmost precision and surface quality are required.

Application Specificity

Choosing the right diamond end mill depends on the specific application requirements. PCD end mills are well-suited for general-purpose machining tasks across various industries, offering a balance of performance and versatility. Monocrystalline diamond end mills, with their exceptional precision and surface finish capabilities, are ideal for industries such as jewelry manufacturing, optics, and electronics, where the highest level of accuracy is crucial.

Choosing the Right Diamond End Mill for Your Needs

Selecting the appropriate diamond end mill for your machining needs requires careful consideration. Here are some factors to keep in mind:

Material Compatibility: Consider the type of materials you will be machining. If you work with a wide range of materials, PCD end mills may provide greater versatility. For highly specialized applications involving precious metals, optics, or electronics, monocrystalline diamond end mills may be the better choice.

Precision Requirements: Assess the level of precision and surface finish required for your application. If you need the utmost accuracy, monocrystalline diamond end mills offer superior cutting sharpness and surface quality.

Budget and Cost Analysis: Consider both the upfront cost and long-term cost-effectiveness of the end mills. While monocrystalline diamond end mills may have a higher initial cost, they can provide value in precision-driven industries. PCD end mills, with their extended tool life and versatility, may be more cost-effective for general-purpose applications.

Consult with Experts: If you are unsure which diamond end mill is best suited for your specific needs, consult with industry experts or tooling suppliers. They can provide valuable insights and recommendations based on your unique requirements.

Conclusion

In the realm of machining, the choice between polycrystalline and monocrystalline diamond end mills depends on factors such as application, material compatibility, precision requirements, and budget. PCD end mills offer versatility, excellent wear resistance, and cost-effectiveness for a range of materials. Monocrystalline diamond end mills excel in applications that demand the highest level of precision and surface finish. By carefully considering these factors and consulting with experts, you can make an informed decision and achieve optimal results in your machining operations.

FAQs (Frequently Asked Questions)

What is the lifespan of a diamond end mill?

The lifespan of a diamond end mill depends on various factors, such as the material being machined, cutting conditions, and the specific type and quality of the end mill. However, diamond end mills, whether polycrystalline or monocrystalline, generally have a longer lifespan compared to traditional cutting tools made of high-speed steel or carbide.

Can I use PCD end mills for non-ferrous metals?

Yes, PCD end mills are well-suited for machining non-ferrous metals such as aluminum, brass, copper, and titanium. Their excellent wear resistance and heat dissipation properties make them effective in these applications.

Are monocrystalline diamond end mills more expensive?

Monocrystalline diamond end mills tend to have a higher initial cost compared to PCD end mills. However, their value lies in their exceptional precision and surface finish capabilities, which make them indispensable in industries such as jewelry manufacturing, optics, and electronics.

Do diamond end mills require special maintenance?

Diamond end mills generally require minimal maintenance. However, it is important to follow best practices such as proper tool handling, regular inspection for wear or damage, and using appropriate cutting parameters. Additionally, keeping the cutting edges clean and free from buildup or debris ensures optimal performance.

Can I use diamond end mills for high-speed machining?

Yes, diamond end mills, both polycrystalline and monocrystalline, are suitable for high-speed machining. Their exceptional hardness and heat resistance allow for efficient material removal and extended tool life, making them well-suited for demanding high-speed applications.