Introduction to PCD/PCBN Grooving Tools

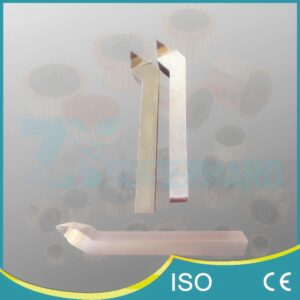

What are PCD/PCBN Grooving Tools?

Polycrystalline Diamond (PCD) and Polycrystalline Cubic Boron Nitride (PCBN) grooving tools are advanced cutting tools used in a variety of manufacturing processes. These tools are known for their superior cutting performance, long tool life, and high precision, making them a popular choice in industries such as automotive, aerospace, and electronics.

The Importance of Grooving in Manufacturing

Grooving is a critical process in manufacturing, used to cut precise, narrow grooves into workpieces. It’s a process that requires high precision and accuracy. PCD/PCBN grooving tools make it easier to meet machining requirements.

The Advantages of PCD/PCBN Grooving Tools

Superior Cutting Performance

PCD/PCBN grooving tools offer superior cutting performance compared to conventional cutting tools. They can maintain a sharp cutting edge even under high-speed cutting conditions, resulting in smoother, cleaner grooves.

Long Tool Life

Thanks to their high wear resistance, PCD/PCBN grooving tools have a significantly longer tool life than their conventional counterparts. This means fewer tool changes and less downtime, leading to increased productivity.

High Precision and Accuracy

PCD/PCBN grooving tools are known for their high precision and accuracy. They can produce grooves with tight tolerances and excellent surface finish, which is critical in industries where precision is paramount.

The Cost-Benefit Analysis of PCD/PCBN Grooving Tools

Initial Investment and Tooling Cost

While PCD/PCBN grooving tools may have a higher initial cost compared to conventional tools, they offer significant cost savings in the long run. Their long tool life means fewer tool changes, which not only reduces tooling costs but also minimizes downtime.

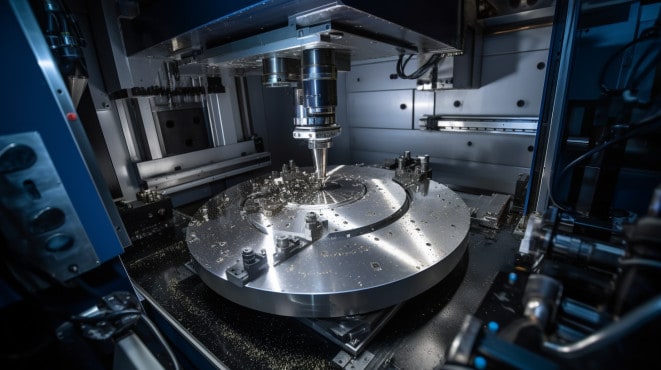

Operational Efficiency and Productivity

PCD/PCBN grooving tools can operate at higher cutting speeds without sacrificing tool life or cutting quality. This leads to increased operational efficiency and productivity, which can significantly offset the higher initial cost of these tools.

Maintenance and Replacement Costs

Due to their high wear resistance, PCD/PCBN grooving tools require less maintenance and are less likely to need replacement compared to conventional tools. This results in lower maintenance and replacement costs, further contributing to their cost-effectiveness.

Case Study: PCD/PCBN Grooving Tools in Action

I have a client, a manufacturing company in Mexico. They switches from conventional grooving tools to PCD/PCBN tools. Despite the higher initial cost, the company finds that the new tools last significantly longer, reducing the frequency of tool changes. The company also notices an improvement in the quality of their grooves, leading to fewer rejected parts. Over time, the company finds that the PCD/PCBN grooving tools have more than paid for themselves in terms of reduced tooling costs and improved productivity.

Conclusion: Are PCD/PCBN Grooving Tools Worth the Investment?

Based on their superior cutting performance, long tool life, and high precision, along with the potential for significant cost savings in the long run, it’s clear that PCD/PCBN grooving tools can be a worthwhile investment for many manufacturing operations.

FAQs

What are PCD/PCBN grooving tools?

PCD/PCBN grooving tools are advanced cutting tools made from Polycrystalline Diamond (PCD) or Polycrystalline Cubic Boron Nitride (PCBN). They are used for cutting precise, narrow grooves in a variety of materials.

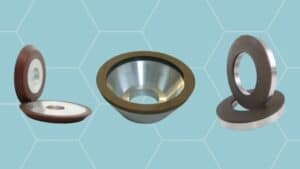

Why are PCD/PCBN grooving tools more expensive than conventional tools?

PCD/PCBN grooving tools are made from synthetic diamond or cubic boron nitride, which are more expensive materials than those used in conventional tools. However, their superior performance and longer tool life can make them more cost-effective in the long run.

What industries commonly use PCD/PCBN grooving tools?

PCD/PCBN grooving tools are commonly used in industries that require high-precision machining, such as automotive, aerospace, and electronics.

How can PCD/PCBN grooving tools increase productivity?

PCD/PCBN grooving tools can increase productivity by maintaining a sharp cutting edge even under high-speed cutting conditions, leading to smoother, cleaner grooves. Their long tool life also means fewer tool changes, reducing downtime.

Are PCD/PCBN grooving tools worth the investment?

While PCD/PCBN grooving tools have a higher initial cost, their superior performance, long tool life, and potential for cost savings in terms of reduced tooling costs and increased productivity can make them a worthwhile investment for many manufacturing operations.