-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

PCD Forming Tools: What They Are & Where to Use Them

When it comes to manufacturing complex parts with both speed and precision, what exactly are PCD forming tools and where do they provide the most value?

PCD forming tools are custom-engineered cutting tools designed to machine a complete, complex profile in a single pass. They are primarily used in high-volume industries like automotive, aerospace, and electronics to dramatically increase production speed, ensure part-to-part consistency, and effectively machine highly abrasive materials.

What is a PCD Forming Tool?

So, what exactly makes a PCD forming tool different from all the other tools in the workshop?

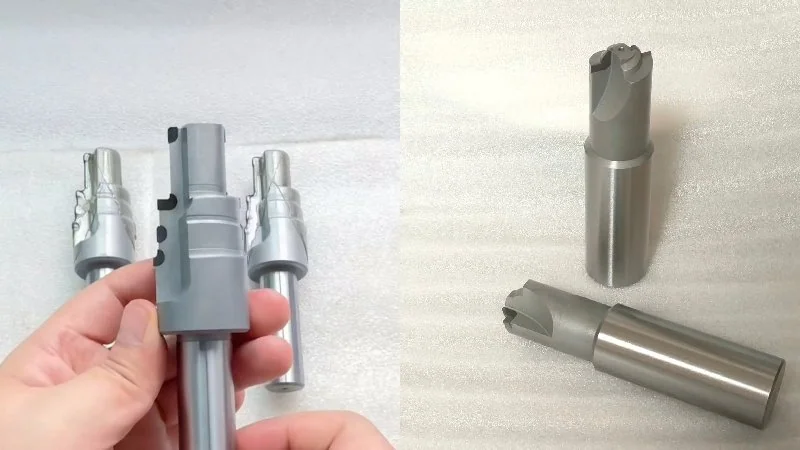

A PCD forming tool is a specialized, custom-made cutting tool1 that combines multiple cutting profiles into a single edge. Its purpose is to machine a complete, complex shape onto a workpiece in one continuous pass, drastically improving efficiency and consistency over using several standard tools in sequence.

The Core Concept: Creating a Full Profile in a Single Pass

Imagine you need to cut a specific, intricate shape on a metal part, like the groove on a piston. The traditional way involves a slow, multi-step process. First, you might use a standard turning tool for one surface. Then, you’d switch to a grooving tool. Finally, you might need a third tool to create a specific angle or chamfer. Each tool change costs time and introduces a small chance for error.

A forming tool completely changes this workflow.

To draw a parallel from within the machining world, think of it like a broaching tool2. A broach uses a series of teeth to create a complete, specific shape (like a keyway) in a single linear pass. A forming tool achieves a similar outcome on a lathe or mill: it creates the entire complex profile instantly, but through a turning or plunging motion.

But what does this mean for a busy production floor? It means a massive reduction in cycle time and a huge leap in consistency.

| Factor | Traditional Multi-Tool Process | Forming Tool Process |

|---|---|---|

| Number of Tools | 2 – 4+ different tools | 1 single tool |

| Operations | Multiple sequential cuts | 1 single pass |

| Cycle Time | Higher (due to tool changes) | Drastically Lower |

| Consistency Risk | Higher (errors can accumulate) | Extremely Low |

Key Characteristics: Custom Profiles and High-Geometric Accuracy

Two main characteristics define a forming tool and separate it from anything you can buy off the shelf. Understanding these is key to seeing their value.

- Engineered Custom Profiles: These tools are the definition of “bespoke.” They don’t exist until a specific need arises. They are engineered and manufactured based on a customer’s exact part blueprint, often from a CAD file. Every curve, angle, and radius of the tool is designed to produce one specific profile, and nothing else.

- Exceptional Geometric Accuracy: Geometric accuracy simply means the tool holds its exact shape, and therefore, the part it cuts holds its exact shape. Because a forming tool creates the entire profile at once, it ensures the geometric relationship between all features (e.g., the distance and parallelism between two grooves) is perfect every time. This is a level of precision that multi-step processes struggle to replicate consistently, and it dramatically reduces scrap rates.

Why PCD is Essential for Forming Tools

So, if the forming method is so effective, why isn’t every forming tool made from standard materials like carbide?

The answer lies in the intense physical demands of the forming process itself. When a tool machines a long, complex profile in a single continuous pass, its entire cutting edge is engaged at once. This generates immense, concentrated stress, friction, and heat.

A less durable material would fail almost immediately under these conditions. The sharp, intricate details of the profile would wear down unevenly, and the tool would lose its required accuracy. This is why the forming method necessitates a material with elite properties.

PCD (Polycrystalline Diamond)3 is the enabler for this superior method because:

- It can withstand the intense, continuous abrasion without losing its complex shape.

- It can manage the extreme heat generated by the long cutting engagement, protecting both the tool and the workpiece.

Without a material like PCD, the benefits of the single-pass forming method would be impossible to achieve in any high-volume or abrasive application.

Industries Benefiting from PCD Forming Tools

The single-pass forming method provides a decisive advantage in high-volume manufacturing sectors where efficiency and geometric precision are critical. Key industries include Automotive, Aerospace, Woodworking, and Electronics.

Automotive: High-Speed Profile Forming of Aluminum Components

The automotive industry is built on speed, volume, and consistency. The challenge isn’t just cutting metal, but creating millions of identical parts where every feature is perfectly positioned.

Consider the ring grooves on a piston. A multi-step process that cuts each groove separately risks tiny errors in spacing and parallelism. However, a forming tool machines all grooves simultaneously. This guarantees their geometric relationship is perfect on every single piston, a critical factor for engine performance and longevity. The single-pass method doesn’t just make the process faster; it makes the part fundamentally better and more consistent.

The core benefit here is the guaranteed geometric accuracy that only a single-pass forming operation can provide. This eliminates tolerance stacking issues common in multi-step machining.

Aerospace: Precision Forming of Abrasive Composite Edges and Contours

In the aerospace industry, the integrity of every component is paramount. When machining advanced composites4 like Carbon Fiber Reinforced Polymer (CFRP)5, the challenge is to create a clean, precise edge without damaging the material’s structural layers.

A multi-step process (e.g., one tool to trim, another to chamfer) increases the risk of defects like delamination6, where the material layers split apart. A forming tool solves this by applying consistent pressure and support across the entire profile during its single pass. This integrated approach trims and shapes the edge simultaneously, holding the delicate layers together and producing a perfect, damage-free finish that meets the industry’s stringent safety standards.

Woodworking & Furniture: Flawless Profile Shaping on Hardwoods and Laminates

For high-end furniture and architectural molding, the visual perfection of a decorative profile is everything. Using multiple tools to create a complex shape can result in slight mismatches between cuts, leading to an imperfect finish that requires time-consuming manual sanding.

The forming method guarantees a flawless, continuous profile because the entire shape exists on a single, solid tool. There are no transitions or potential misalignments between different cutting edges. This single-pass shaping results in a glass-smooth finish straight off the machine, ensuring every piece of molding is visually perfect and identical to the last.

Electronics & Non-Ferrous Metals: Machining Circuit Boards, Copper, and Brass

In electronics, precision is measured in microns. When machining features on Printed Circuit Boards (PCBs) or creating connectors from copper, the consistency of shapes like V-grooves is critical for functionality.

A single-pass forming operation is the most reliable way to ensure every groove or slot is identical in depth, angle, and position. This level of repeatability is difficult to achieve when features are machined one by one. The forming method provides the process stability required for high-density electronic components where even the smallest deviation can cause a failure.

Proven Results: PCD Forming Tool Case Studies

How does the forming method actually perform on the factory floor? In real-world applications, adopting this single-pass process delivers measurable improvements. Case studies consistently show significant reductions in cycle time, elimination of process steps, and a dramatic increase in part-to-part consistency.

Case Study: Forming Automotive Piston Ring Grooves

The Challenge

An automotive manufacturer’s process used three separate tools to machine the three critical ring grooves on each piston. This multi-step operation was not only slow (45 seconds) but also introduced the risk of minute errors in the spacing and parallelism between the grooves.

The Solution

The manufacturer switched to a single-pass forming process. A custom-engineered PCD forming tool was designed with the precise profile of all three grooves, allowing it to machine them all simultaneously.

The Result

The impact of the new method was profound.

- The cycle time for the grooving operation was reduced from 45 seconds to just 10 seconds by eliminating the tool-change steps.

- The quality improved significantly because the forming tool guaranteed the grooves were perfectly parallel and spaced, an outcome the previous multi-step process couldn’t ensure.

- The process became far more reliable, machining over 120,000 pistons before the tool needed service.

Case Study: Edge Forming and Chamfering on Aerospace Composite Panels

The Challenge

An aerospace supplier used a two-step process for finishing CFRP wing components: one tool for trimming the edge, and a second for applying a chamfer. This method was slow and often caused edge defects that required costly manual inspection and rework.

The Solution

They implemented a PCD forming tool designed to perform both operations at once. The tool’s profile was engineered to trim the panel and apply the chamfer in a single, continuous pass.

The Result

Adopting the forming method solved the core problems.

- The single-pass operation eliminated the edge quality issues, as the tool supported the composite material consistently throughout the entire cut.

- The need for manual rework fell by over 90%, saving significant labor costs.

- By combining two steps into one, the overall machining time was reduced by 40%.

Case Study: Creating Custom Architectural Molding Profiles

The Challenge

A woodworking company struggled with inconsistent finishes on their decorative HDF moldings. Their multi-tool shaper heads often left slight imperfections and a fuzzy finish, requiring a secondary sanding operation to meet quality standards.

The Solution

The company switched to a single-pass forming process using PCD tools ground to the exact, intricate profiles of their designs.

The Result

The forming method transformed their production.

- The tools produced a perfectly clean, sharp profile with a glass-smooth finish, completely eliminating the need for the secondary sanding operation.

- The process became incredibly reliable, with the tool maintaining its perfect profile for over six months, ensuring every piece of molding was identical.

Conclusion

In conclusion, PCD forming tools are far more than just durable cutting inserts; they represent a strategic shift in manufacturing methodology. By embracing the single-pass forming method, industries can solve critical challenges related to efficiency and geometric precision. This approach consolidates multiple operations, eliminates sources of error, and delivers a level of quality and consistency that multi-step processes cannot easily replicate. As the case studies show, its impact is most profound in applications where speed, precision, and flawless repeatability are the keys to success.

Have a complex profile that’s slowing down your production? Contact our engineering team today to discuss a custom PCD forming tool solution.

References

- custom-made cutting tool1 – ZYDiamondTools product page for custom PCD forming tools.

- broaching tool2 – Wikipedia article explaining the broaching process in metalworking.

- PCD (Polycrystalline Diamond)3 – A comprehensive guide to Polycrystalline Diamond (PCD) from ZYDiamondTools.

- machining advanced composites4 – ZYDiamondTools article on solving challenges in composite machining with PCD tools.

- Carbon Fiber Reinforced Polymer (CFRP)5 – Wikipedia’s technical page on the properties and uses of CFRP.

- delamination6 – ScienceDirect topic page defining delamination in the context of materials science.