Currently, the primary raw materials for superhard tools on the market can be divided into diamond material and cubic boron nitride material. There are many subdivided types; the most common are the following five.

1. Monocrystalline Diamond

Monocrystalline diamond is classified as natural or synthetic. It has extremely high hardness and wear resistance and is the hardest substance. Its properties make it highly sought after in various industries, including manufacturing tools used in machining and drilling. Monocrystalline diamonds can also withstand extreme temperatures and pressures, making them preferred for high-performance applications such as aerospace components. Additionally, its electrical properties make it suitable for use as a semiconductor material in the electronics industry.

However, monocrystalline diamonds are expensive. The diamond must be carefully cut and polished to achieve the desired shape, adding to its cost. Additionally, its rarity makes it more expensive to obtain than other types of industrial diamonds. Despite these drawbacks, the superior qualities of monocrystalline diamond make it a valuable material in many industries.

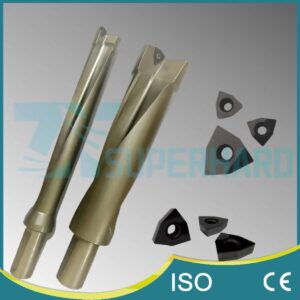

2. Polycrystalline Diamond (PCD)

Polycrystalline diamonds (PCD) are composed of multiple diamond crystals that have been sintered together under high temperatures and pressures. PCDs can be made from synthetic or natural diamonds and offer superior performance compared to monocrystalline diamonds. The resulting material is more durable and wear-resistant, making it suitable for use in applications such as tools for drilling and machining. Additionally, PCDs are less expensive than monocrystalline diamonds because they can be mass-produced.

3. CVD Diamond

Chemical vapor deposition (CVD) diamonds are a type of synthetic diamond created through a chemical reaction in which hydrocarbon gases are broken down and deposited onto a substrate. This method allows for producing extremely pure, hard, and durable diamond materials. CVD diamonds are often used in industrial applications where high wear resistance is required, such as in cutting tools and drill bits. Additionally, CVD diamonds are also used in various applications involving optics and electronics due to their optical properties.

The advantages of using CVD diamonds include their cost-effectiveness compared to other industrial diamonds and their superior performance in high-performance applications. CVD diamonds also possess excellent thermal and electrical properties, making them suitable for use in various electronic applications.

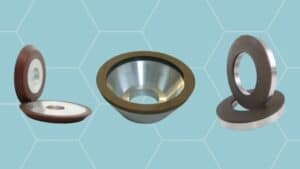

4. Polycrystalline Cubic Boron Nitride (PCBN)

Polycrystalline cubic boron nitride (PCBN) is a synthetic material composed of multiple crystals of cubic boron nitride, which are sintered together under extreme temperatures and pressures. PCBN has properties similar to diamond, including high hardness and wears resistance. However, it is also more heat-resistant than diamond, making it suitable for use in high-temperature applications such as metal cutting and grinding. Additionally, PCBN is less expensive than diamond, making it a viable alternative to monocrystalline diamonds in some industrial applications.

PCBN also has excellent thermal and electrical properties, making it a preferred material for use in electronic components such as transistors and integrated circuits. Additionally, its high wear resistance makes it a suitable material for tooling applications, particularly abrasive materials such as ceramics or glass.

5. CVD Cubic Boron Nitride Coating

Chemical vapor deposition (CVD) cubic boron nitride (CBN) coating is a synthetic material made from the chemical reaction of hydrocarbon gases with nitrogen and boron to create a layer of cubic boron nitride on a substrate. This layer of CBN provides superior wear resistance and hardness, making it an ideal choice for use in abrasive applications such as grinding and cutting tools. Additionally, CBN coatings are less expensive than diamonds and offer superior performance in terms of heat resistance, making them suitable for use in high-temperature applications such as metal processing.

Conclusion

In conclusion, industrial diamonds come in various forms and are used mainly for their wear-resistant properties. Monocrystalline diamonds, PCD diamonds, CVD diamonds, PCBN, and CBN coatings offer unique advantages to suit specific needs in various applications. Ultimately, the choice of material depends on the requirements for tool performance.