-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

Do you have any needs for PCD tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Post Categories

Product Categories

About Company

Table of Contents

This article will do a detailed introduction to diamond grinding wheels. If you want to know about grinding wheels, not diamond grinding wheels, please click here, and you will get the relevant information.

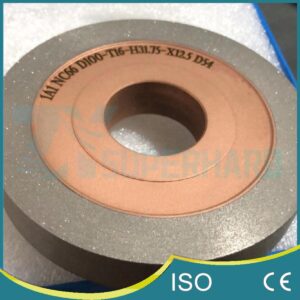

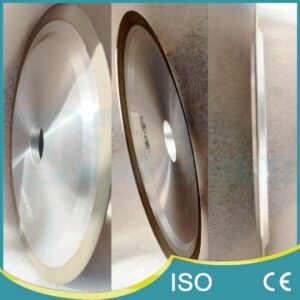

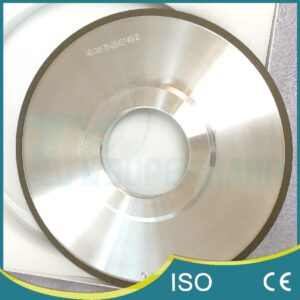

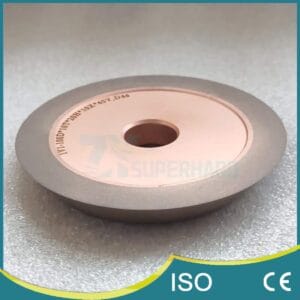

What The Diamond Grinding Wheel Is

A diamond grinding wheel is a type of abrasive wheel that is made from diamonds. The diamond is bonded to the metal alloy or resin that makes up the rest of the wheel. Diamond grinding wheels are used for grinding and polishing hard materials, such as stone, concrete, glass, and ceramic. They are also capable of sharpening carbide-tipped tools. Diamond grinding wheels are available in a variety of sizes, shapes, and grits. The size and shape of the wheel will determine the type of material it can be used on. The grit is a measure of the coarseness of the diamond particles. A higher grit means a finer finish, while a lower grit produces a rougher surface.

Structure Of Diamond Grinding Wheels

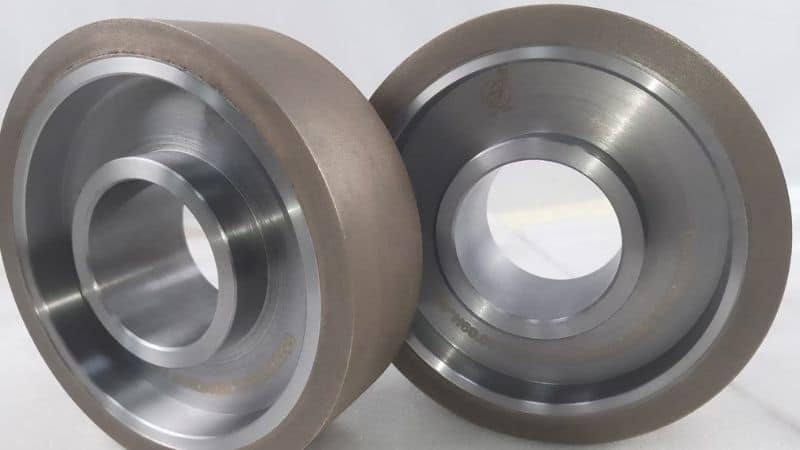

The most common type of diamond grinding wheel consists of two parts: the steel core and the diamond layer. The steel core is typically manufactured from high-strength, heat-treated alloy steel. It provides the necessary rigidity and strength to support the diamond layer.

The diamond layer is composed of abrasive grains that are evenly distributed throughout the wheel. The abrasive grains are bonded together using a specially formulated bonding agent. This bonding agent is designed to provide a strong bond between the abrasive grains while still allowing them to be removed easily during the grinding process.

Characteristics Of Diamond Grinding Wheels

The following are the characteristic of diamond grinding wheels:

1. Diamond grinding wheel has high hardness and wears resistance, which can be used for precision grinding of hard and brittle materials;

2. Diamond grinding wheel has good heat dissipation performance, which can ensure the stability of grinding temperature;

3. Diamond grinding wheel has high grinding efficiency, which can improve the production efficiency;

4. Diamond grinding wheel has good self-sharpening, which can extend the service life of the wheel;

5. Diamond grinding wheel has low noise and low vibration, which can create a good working environment.

The above is the characteristic of diamond grinding wheels, which can provide you with a reference when choosing a grinding wheel.

How Diamond Grinding Wheel Works

The diamond grinding wheel works by abrading the material it is being used on. The diamond particles in the wheel act as mini-cutting tools and wear away the material very quickly. The rate at which the diamond grinds depends on how hard the material is and how strong the bond between the diamond and the matrix is. Softer materials will be ground down more quickly than harder materials.

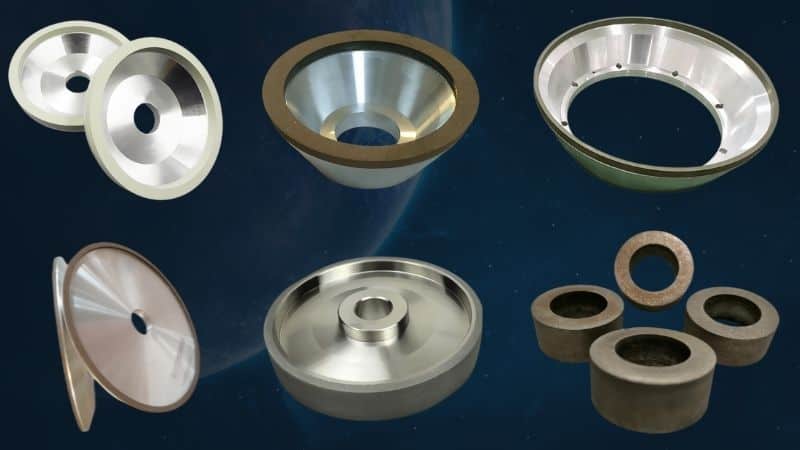

The Different Types Of Diamond Grinding Wheels

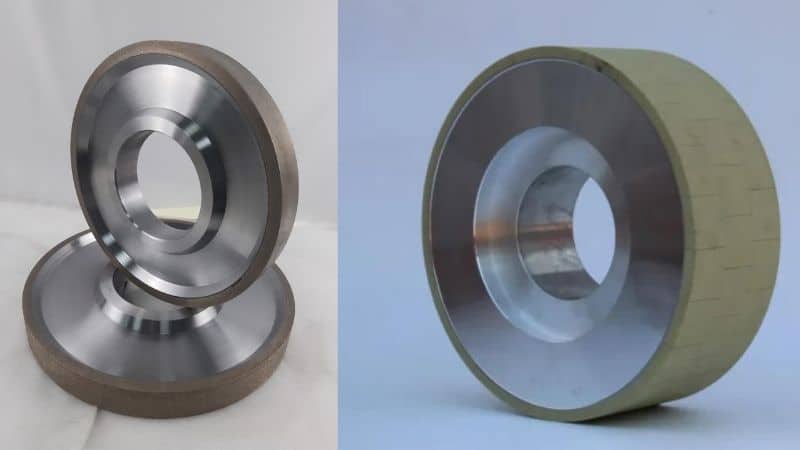

1. Resin Bond Diamond Grinding Wheel

The resin bond diamond grinding wheel is made of synthetic resin as the bonding material and has good elasticity and plasticity. It is suitable for processing brittle materials with low hardness, such as stone, glass, ceramics, and cemented carbide. The disadvantage is that it has poor heat resistance and cannot be used to process metals or other hard materials.

2. Vitrified Bond Diamond Grinding Wheel

The vitrified bond diamond grinding wheel is made of inorganic materials such as clay, silica, etc., as the bonding material and fires at a high temperature. It has good heat resistance and can be used to process metals and other hard materials. However, the disadvantage is that it is not suitable for processing stone, glass and ceramics due to its brittleness.

3. Metal Bond Diamond Grinding Wheel

The metal bond diamond grinding wheel is made of metal powder as the bonding material and has good wear resistance and high strength. It is suitable for processing hard and brittle materials, such as stone, glass, ceramics, cemented carbide, and so on. However, the disadvantage is that it has poor heat resistance and cannot be used to process metals or other hard materials.

4. Electroplated Diamond Grinding Wheel

The electroplated diamond grinding wheel is made of metal or other material as the substrate and is plated with diamond on the surface. It has good wear resistance and can be used to process hard and brittle materials, such as stone, glass, ceramics, cemented carbide, and so on. However, the disadvantage is that it has poor heat resistance and cannot be used to process metals or other hard materials.

5. Hybrid Bond Diamond Grinding Wheel

A hybrid bond diamond grinding wheel is a type of diamond grinding wheel that combines both resin and metal bonds in its construction. This results in a wheel that is much more versatile than either type of bond alone and can be used for various applications.

The main advantage of the hybrid bond is that it offers the benefits of both resin and metal bonds. The metal bond provides good durability and a long lifespan, while the resin bond offers a much more aggressive cutting action. It makes the hybrid bond ideal for hard and soft materials.

The only real downside to the hybrid bond is that it can be slightly more expensive than either type of bond alone. However, the extra cost is typically worth it for the added versatility of the hybrid bond.

How To Use A Diamond Grinding Wheel

A diamond grinding wheel is a powerful tool used to grind, cut, and shape various materials. However, it is important to use the wheel safely and correctly to avoid injuries and damage to your equipment. Here are the steps on how to properly use diamond grinding wheels:

1. Wet the material before grinding to prevent overheating.

2. Inspect the diamond grinding wheel to ensure that it is not damaged or defective.

3. Position the diamond grinding wheel on the material so it fits easily and does not require force.

4. Apply enough pressure to touch the material’s surface lightly.

5. Move the diamond grinding wheel across the material smoothly and evenly.

6. Dress the diamond grinding wheel regularly to maintain optimal performance.

7. Follow the manufacturer’s instructions for proper use and safety.

Advantages And Disadvantages Of Diamond Grinding Wheels

The advantages of diamond grinding wheels include the following:

1. Increased grinding efficiency – thanks to diamonds’ high hardness and wear resistance, they can remove material quickly and efficiently.

2. Longer wheel life – because diamond abrasive particles retain their shape well, they do not blunt as quickly as other abrasives, resulting in longer wheel life.

3. Excellent surface finish – diamond grinding wheels can produce a very fine surface finish, making them ideal for applications where precision is important.

The main disadvantage of diamond grinding wheels is their cost – they are typically the most expensive option among the different abrasive wheels. In addition, because they are so hard, they can be difficult to control and may cause more operator fatigue than other abrasive wheels.

Applications Of Diamond Grinding Wheels

Diamond grinding wheels are used for numerous applications, including:

1. Grinding and finishing of hard and brittle materials – such as concrete, stone, and glass.

2. Cutting hard and brittle materials – such as asphalt, bricks, and tile.

3. Sharpening of tools – such as saw blades and drill bits.

4. Polishing of materials – such as jewelry and optical lenses.

The Main Application Industries Of Diamond Grinding Wheels

The main application industries of diamond grinding wheels are machinery manufacturing, electronics, and semiconductors. In addition, diamond grinding wheels are also widely used in the fields of glass, ceramics, stone, and construction.

Machinery manufacturing: Diamond grinding wheels are used in various types of machinery manufacturing, such as lathes, milling machines, grinders, etc. They are mainly used for grinding and polishing various metals and non-metallic materials.

Electronics and semiconductor industries: They are mainly used for grinding and polishing various electronic components and semiconductor materials.

Glass, ceramics, stone, and construction: They are mainly used for grinding and polishing various glass, ceramic, and stone materials.

Tips For Getting The Most Out Of Your Diamond Grinding Wheel

1. Choose the right bond – the type of bond (the material that holds the abrasive particles together) will affect the performance of your diamond grinding wheel. For example, a harder bond will be better for cutting, while a softer bond will be better for finishing.

2. Select the appropriate grit size – the size of the abrasive particles will determine the aggressiveness of the grinding action. For most applications, a medium to coarse grit size is recommended.

3. Dress the wheel regularly – as the diamond abrasive particles wear down, they will become less effective at removing material. In order to maintain optimal performance of wheels, it is important to dress the wheel regularly (i.e., remove the build-up of abrasive particles).

4. Use coolant – when grinding, it is important to use coolant (water or oil) to prevent the material from overheating and becoming damaged.

5. Use the correct speed – if the diamond grinding wheel is running too slow, it will not cut effectively; running too fast may break. It is important to consult the manufacturer’s recommendations for the proper operating speed.

Tips On Choosing The Right Diamond Grinding Wheel

1. Consider the material you will be grinding – different materials require different types of diamond grinding wheels. For example, softer materials (such as concrete) will require a different wheel than harder materials (such as stone).

2. Consider the type of finish you need – if you need a very fine finish, you will need a different wheel than if you only need a rough finish.

3. Consider the cost – diamond grinding wheels are typically the most expensive abrasive wheel, so be sure to consider your budget when making a decision.

4. Consult with an expert – if you are unsure which type of diamond grinding wheel to choose, it is always best to consult an expert. They will be able to assess your specific needs and recommend the best option for you.

Precautions For Using Diamond Grinding Wheels

1. Always wear safety goggles and a dust mask when using diamond grinding wheels to protect your eyes and lungs from flying debris.

2. Inspect the diamond grinding wheel before use to ensure that it is not damaged or defective. Never use a damaged or defective wheel.

3. Never force the diamond grinding wheel onto the material – if it does not fit easily, it is the wrong size.

4. Never use a diamond grinding wheel without water – always wet the material before grinding to prevent overheating.

5. Use only enough pressure to touch the material’s surface lightly – too much pressure will cause the diamond particles to break and become embedded in the material.

6. Never use a diamond grinding wheel on aluminum – doing so will damage the wheel and potentially cause injury.

7. Always follow the manufacturer’s instructions for proper use and safety.

Dressing Of Diamond Grinding Wheels

What Is The Dressing Of Diamond Grinding Wheels?

The diamond grinding wheel dressing is the process of re-sharpening the diamond particles on the surface of the grinding wheel. It can be done using either a handheld tool or an automated machine. The process is important to keep the wheels working properly and extend their lifespan.

Why Do Diamond Grinding Wheels Need To Be Dressed?

Diamond grinding wheels need to be dressed because the diamond particles will eventually become blunt from all the grinding. When this happens, the wheel will start to slip and will not cut as well anymore. The dressing process will restore the sharpness of the diamonds and allow the wheel to cut properly again.

How Often Should Diamond Grinding Wheels Be Dressed?

It depends on how often the wheel is used. If it is used frequently, then it should be dressed more often. A good rule of thumb is to dress the wheel every 10 hours.

What Are The Methods Of Dressing Diamond Grinding Wheels?

There are many methods of dressing diamond grinding wheels. Some common methods include:

– Handheld tool: This is the most common method and is done using a handheld tool to grind away a small section of the wheel.

– Automated machine: This method is faster and more accurate than the handheld method. It uses a machine to spin the wheel and dress it.

-Lapping with a diamond: This method is used to dress very hard wheels that cannot be dressed with a handheld tool or an automated machine, but a diamond grips away a small amount of the wheel’s surface.

– Laser: This is the newest method of dressing diamond grinding wheels. A laser is used to remove a thin layer of material from the surface of the wheel. This method is precise and can dress the wheel without removing too much material.

How To Choose The Suitable Method Of Dressing The Diamond Grinding Wheel?

The dressing method choice depends on the wheel type, the amount of material to remove, and the desired finish. For most wheels, the handheld tool or automated machine methods will suffice. The laser method may be the best choice if more precision is needed. The lapping with a diamond method may be the only way to dress for very hard wheels.

When you can’t choose, it’s best to consult a professional.

What Are The Benefits Of Dressing Diamond Grinding Wheels?

There are some benefits to dressing diamond grinding wheels.

– Extending the lifespan of the wheel

– Improving the performance of the wheel

– Reducing costs associated with replacement wheels

How To Care For A Diamond Grinding Wheel

1. Store the diamond grinding wheel in a dry, safe place – moisture can damage the bond and cause the abrasive particles to break down.

2. Avoid dropping or bumping the diamond grinding wheel, as this can damage the bond and cause the abrasive particles to break down.

3. When not in use, cover the diamond grinding wheel with a cloth to protect it from dust and debris.

4. Never use a damaged or defective diamond grinding wheel. If the diamond grinding wheel is damaged, dispose of it properly – do not attempt to repair it.

5. Always follow the manufacturer’s instructions for proper care and use.

The Main Development Direction Of The Diamond Grinding Wheel Industry

1. Developing Superhard Composite Grinding Wheels

With the rapid development of science and technology, more and more industries are demanding grinding wheels with higher hardness, better wear resistance, and longer service life. Therefore, to meet market development needs, diamond grinding wheel manufacturers should further improve the hardness and wear resistance of products and develop more superhard composite grinding wheels.

2. Improving The Production Efficiency Of Diamond Grinding Wheels

With the increasing demand for diamond grinding wheels, manufacturers should improve the production efficiency of products and develop more high-efficiency diamond grinding wheels.

3. Developing New Types Of Diamond Grinding Wheels

The application range of diamond grinding wheels is becoming more and more extensive, and the market demand is getting more and more diversified. Therefore, diamond grinding wheel manufacturers should keep up with the market development trend and develop more new types of products to meet market development needs.

Conclusion

In short, a diamond grinding wheel is a type of cutting tool that is used to grind down rough surfaces or materials. The inherent properties of diamonds make them ideal for use in this application, as they can withstand high heat and friction. While there are many advantages to using a diamond grinding wheel, some disadvantages should be considered before making a purchase. Following the tips outlined in this article, you can ensure that you choose the right diamond grinding wheel for your needs and keep it in good condition with proper care. If you have more questions about diamond grinding wheels, welcome to contact us, and we will give you the answer as soon as possible.

ZY Superhard Tools Co., Ltd.

Do you have any needs for PCD tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Do you have any needs for PCD tools or diamond grinding wheels? We can customize products to meet your specific requirements. If you have any ideas or requests, feel free to reach out—we’ll respond within 24 hours!

Related Posts

Choosing Between CBN and Diamond Grinding Wheels: Which One is Right for Your Needs?

Discover how to pick CBN or diamond grinding wheels based on material, finish, and cost. Learn their differences, uses, pros,

What Are Diamond Cylindrical Grinding Wheels and How to Choose the Right One for Your Needs?

Learn what diamond cylindrical grinding wheels are, how they perform in PDC manufacturing and grinding ceramics, and how to choose,

Mastering PCD and PCBN Tool Sharpening: Essential Techniques and Best Practices

Learn essential techniques and best practices for sharpening PCD and PCBN tools. Discover how to choose grinding wheels, ensure precision,

What Is the Difference Between Cutting and Grinding?

Learn the key differences between cutting and grinding in manufacturing. Discover their definitions, applications, best practices, and tool selection tips.

Subscribe

Simply enter your email below and click “Subscribe” to stay connected with everything new and exciting.