-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

How To Select the Right Diamond Wheels for Saw Grinding

What are the critical factors you must evaluate to ensure you choose the correct diamond wheel for your saw sharpening operations?

Selecting the right diamond wheel requires aligning five critical specifications: abrasive type (Resin1 vs. Hybrid2) for material compatibility, bond hardness for the specific grinding contact area (Face vs. Top), grit size for the desired surface finish, wheel geometry (such as 12V9 or 4A2) for machine clearance, and diamond concentration to balance corner retention with heat generation.

Matching Diamond Specifications to TCT Saw Blade Materials

Which diamond wheel specification is best for grinding Tungsten Carbide Tipped (TCT) saw blades safely and effectively?

Resin bond diamond wheels are the primary choice for sharpening TCT saw blades because their self-sharpening capability ensures a cool cutting action, preventing thermal damage to the heat-sensitive carbide tips.

Why Resin Bond is the Standard for Tungsten Carbide Tipped Saws

In the saw filing room, heat is the greatest enemy of tungsten carbide. When you grind a carbide tip, excessive friction generates high temperatures. This heat can cause “cobalt leaching,” where the binder holding the carbide grains together weakens. Consequently, the saw tooth becomes brittle and may chip during the first cut.

Resin bond wheels are the standard solution because they are “friable.” This means the bond holding the diamond grit wears away at a controlled rate. As the diamonds become dull, the bond breaks down to release them, exposing new, sharp diamonds underneath. This continuous self-sharpening action keeps the grinding zone cool.

Conversely, a metal bond wheel holds diamonds too tightly. It does not release dull grit easily. If you use a standard metal bond on a TCT saw, the dull diamonds will rub against the carbide instead of cutting it. This rubbing generates intense heat, leading to thermal cracks in the saw tip.

| Feature | Resin Bond | Metal Bond |

|---|---|---|

| Cutting Action | Free-cutting, cool | Hard, generates heat |

| Wheel Wear | Faster (Self-sharpening) | Very Slow |

| Primary Use | TCT Saw Sharpening | Glass, Ceramics, Concrete |

| Risk to Carbide | Low | High (Thermal Cracking) |

Using Hybrid Bonds for CNC Manufacturing of New Saw Blades

While resin bonds are excellent for service shops regrinding used saws, saw blade manufacturers often face different challenges. When producing thousands of new blades on fully automatic CNC machines (such as Vollmer or Walter grinders), wheel life becomes a critical production cost.

Here, hybrid bonds offer a strategic advantage. A hybrid bond combines the durability of metal sintered bonds with the free-cutting porosity of resin bonds.

In high-volume manufacturing, deep grinding passes are common. A pure resin wheel might wear down too quickly, losing its profile shape before the batch is finished. A hybrid wheel maintains its corner form much longer.

Think of this like choosing a cutting tool insert for a CNC lathe. A resin wheel is like a finishing insert—delicate but leaves a perfect surface. A hybrid wheel is like a roughing insert—tougher, capable of removing more material without failing, yet still capable of a decent finish.

Note: Hybrid bond formulations vary significantly between manufacturers. Always verify the specific dressing requirements with your wheel supplier, as some hybrid bonds require specialized dressing sticks to properly open the face.

Avoiding Steel Body Contact to Prevent Wheel Loading

A critical error in selecting wheels for TCT saws is ignoring the steel saw body. Diamond wheels are designed specifically to cut tungsten carbide. They are not designed to grind the steel plate (the shoulder) behind the tip.

Steel is a ductile, “gummy” material compared to brittle carbide. If your diamond wheel grinds the steel body while sharpening the tip, the soft steel chips will weld onto the surface of the wheel. This phenomenon is called “loading.”

Once a wheel is loaded with steel, the diamond particles are covered. The wheel stops cutting and begins to act like a friction drive. It rubs the carbide, generating extreme heat and potentially burning the saw tip.

To prevent this, you must ensure the diamond layer specifications match the projection of the carbide tip. If the tip is thin, the diamond section must not overlap onto the steel shoulder.

Common Loading Indicators:

- Visual: Dark, metallic smudges appear on the wheel face.

- Audible: The grinding sound changes from a crisp hiss to a low-pitched drone.

- Result: The machine amperage spikes as the spindle fights the increased friction.

Therefore, for operations where touching the steel body is unavoidable (such as relieving the steel back), you should not use a standard diamond wheel. Instead, you must use a wheel specifically designed for “dual materials” or switch to a CBN (Cubic Boron Nitride)3 wheel for the steel portion solely.

Selecting the Correct Bond Hardness for Face, Top, and Side Grinding

The hardness of the bond must be inversely proportional to the contact area of the grind. For large contact areas like the tooth face, a softer bond is required to promote self-sharpening and prevent heat buildup. Conversely, for small contact areas like top bevels, a harder bond is essential to maintain the wheel’s profile and ensure accurate corner retention.

Softer Bonds for Cool Cutting on Wide Face Grinding Areas

The “face” of a Tungsten Carbide Tipped (TCT) saw tooth typically presents the largest surface area to the grinding wheel. When a diamond wheel engages this wide flat surface, the friction is significant.

If you use a hard bond here, the wheel will hold onto the diamond particles too tightly. As the diamonds dull, they cannot break free. Instead of cutting, these dull diamonds rub against the wide carbide face. This generates intense heat, which can damage the carbide binder.

Therefore, you must choose a softer bond for face grinding. A soft bond releases dull diamonds quickly. This constant exposure of fresh, sharp diamonds ensures the cutting action remains “cool” and aggressive.

Think of this like surface grinding4 a large steel plate. If you use a hard wheel on a broad surface area, the wheel glazes over and burns the workpiece because the chips have nowhere to go. You need a softer wheel that breaks down easily to keep the cut open and the coolant reaching the interface.

Key Benefits of Soft Bonds for Face Grinding:

- Reduced Power Consumption: The spindle load remains low because the wheel is cutting, not rubbing.

- Better Surface Quality: Prevents thermal cracking on the face, which is the most critical surface for chip flow.

- Consistent Removal Rates: The wheel does not require frequent dressing to open the face.

Harder Bonds for Profile Retention on Narrow Top Bevels

Top grinding is a completely different operation. The contact area is much smaller, often just a thin line or a small point, especially when grinding Alternate Top Bevel (ATB) or Triple Chip Grind (TCG) geometries.

Because the contact area is small, the unit pressure on the wheel is very high. If you use the same soft bond here that you used for the face, the wheel will wear out prematurely. Specifically, the corners of the diamond wheel will break down.

When the wheel corners round off, you lose the precise geometry of the tooth. A rounded wheel cannot produce a sharp cutting edge on the saw tooth.

For this reason, a harder bond is necessary. A hard bond provides a stiff matrix that holds the diamond particles firmly in place, even under high unit pressure. This ensures the wheel maintains its square edge or specific angle profile throughout the grinding cycle.

Note: Bond hardness scales (often designated by letters like L, N, R) are not standardized globally. A “Hard” bond from one manufacturer might behave like a “Medium” bond from another. It is crucial to test samples when switching suppliers.

Specialized Bonds for Side Grinding to Minimize Deflection

Side grinding (or flank grinding) presents a unique mechanical challenge. The goal is to establish the radial and tangential clearance angles. This determines the saw blade’s kerf width.

The challenge here is “wheel deflection.” Side grinding wheels are often used on the rim of a cup shape (like a 4A2 or 12A2 shape). If the bond is too hard, the wheel will not cut freely. Instead, the resistance causes the wheel or the saw blade body to flex or “deflect” away from the cut.

This deflection results in tapered teeth or uneven kerf widths. The saw blade will then bind in the cut during use.

To solve this, manufacturers use specialized free-cutting bonds that are also structurally rigid. These bonds are designed to be free-cutting under low pressure. They allow the abrasive to cut the carbide without requiring the heavy feed force that causes deflection.

| Grinding Operation | Contact Area | Recommended Bond Hardness | Primary Goal |

|---|---|---|---|

| Face Grinding | Large / Wide | Soft | Prevent heat and glazing (Cool Cutting) |

| Top Grinding | Small / Narrow | Hard | Maintain corner form and profile (Life) |

| Side Grinding | Medium | Medium-Soft (Free Cutting) | Prevent wheel deflection and maintain tolerance |

Determining Grit Size Based on Saw Tooth Finish Requirements

Selection depends strictly on the balance between material removal rates and the required Surface roughness5 (Ra). Use coarse grits (80–120 US Mesh) for aggressive stock removal during repairs, medium grits (180–320 US Mesh) for standard maintenance sharpening, and fine grits (400–600+ US Mesh) for polishing precision blades used on laminates and non-ferrous metals.

Coarse Grits for Retipping and Repairing Broken Teeth

When a saw blade comes into the service shop with broken teeth or requires complete retipping, you face a significant stock removal task. In this scenario, the primary goal is rapid shaping, not surface finish. You need to remove large amounts of tungsten carbide quickly to establish the correct tooth geometry.

For these heavy-duty operations, coarse grit diamond wheels are essential. Typically ranging from 80 to 120 US Mesh (D181 – D126 FEPA), these wheels feature large diamond particles.

These large particles act like the teeth of a roughing end mill in a milling machine. They take deep “bites” out of the carbide material. If you attempt to use a fine grit wheel for this heavy removal, the small space between the diamond particles will clog immediately with carbide dust. This clogging leads to excessive heat generation and wheel glazing. Consequently, using coarse grits prevents thermal damage during the initial roughing phase.

Note: Mesh sizes can vary slightly depending on the abrasive standard used (US Mesh vs. FEPA vs. microns). Always consult your wheel supplier’s conversion chart to ensure you are ordering the correct particle size.

Medium Grits for General Sharpening of Rip and Crosscut Saws

For routine maintenance where the saw blade is simply dull but not damaged, medium grit wheels are the industry standard. This category covers the vast majority of woodcutting applications, including rip saws (cutting with the grain) and crosscut saws (cutting across the grain).

In these applications, you typically remove only 0.05mm to 0.15mm of material. A grit size between 200 and 325 US Mesh (D76 – D46 FEPA) offers the perfect compromise. It removes material fast enough to keep cycle times low but leaves an edge sharp enough for natural timber.

Consider the operation of a standard localized workshop grinder. You need a “universal” wheel that can handle incoming jobs without constant wheel changes. A D54 or D64 (FEPA) grit wheel serves this purpose perfectly. It provides a “commercial edge” that satisfies the cutting requirements of softwoods and hardwoods without the extended cycle time required by finer grits.

Fine Grits for High-Finish Melamine and Aluminum Cutting Saws

When the application shifts to brittle or unforgiving materials, the rules change. Saws designed to cut Melamine, Particle Board, or Aluminum require an exceptionally high edge quality. Even a microscopic imperfection on the saw tooth can cause visible chipping on the top or bottom of a melamine board.

To achieve a “chipless cut,” you must use fine grit wheels, typically 400 to 600 US Mesh (D46 – D20 FEPA). These small diamond particles polish the carbide face. They reduce the surface roughness (Ra) of the tooth, which reduces friction during the cut.

Furthermore, a polished tooth face prevents material adhesion. When cutting aluminum, a rough tooth face encourages the soft metal to “stick” or weld to the carbide. A mirror finish produced by a fine grit wheel allows the aluminum chips to slide off effortlessly, preventing built-up edge (BUE).

| Application | Material Focus | Recommended Grit (US Mesh) | Recommended Grit (FEPA) |

|---|---|---|---|

| Retipping / Roughing | Heavy Carbide Removal | 80 – 120 | D181 – D126 |

| General Woodworking | Rip & Crosscut Saws | 180 – 325 | D91 – D46 |

| Precision Cutting | Melamine, PVC, Aluminum | 400 – 600 | D46 – D25 |

| Ultra-Precision | PCB / Electronics | 800 – 1200 | D15 – D7 |

Preventing Micro-Chipping on the Cutting Edge with Multi-Stage Grinding

A common defect in saw grinding is “micro-chipping.” This occurs when the diamond particles in the wheel are too large relative to the fragile edge of the carbide tip. As a large diamond particle strikes the cutting edge, it can fracture the brittle carbide, leaving a jagged edge invisible to the naked eye.

Under magnification, this edge crumbling resembles the breakout seen when drilling through brittle material without a backing board. When this saw cuts, these micro-fractures propagate, dulling the saw instantly. To prevent this, professional sharpening services often employ a multi-stage grinding process.

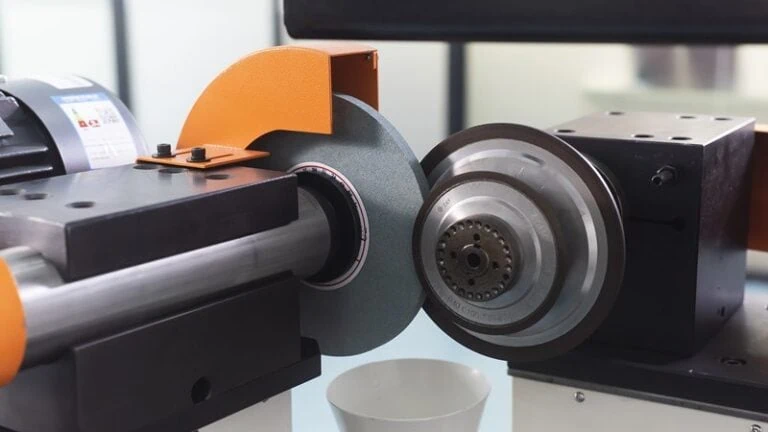

This process involves using a coarse wheel for the rough grinding pass and automatically switching to a fine grit wheel for the final “spark-out” pass. On advanced CNC machines like Vollmer or Walter, this is often achieved using “Dual Grit” or “Sandwich” wheels.

These wheels feature a coarse grit section for the bulk of the grind and a fine grit section on the rim or finishing face. By stepping down the grit size, you remove the deep scratches left by the coarse diamonds. This ensures the final cutting edge radius is less than 5 microns, guaranteeing maximum tool life and cut quality.

Choosing the Right Wheel Shape for Your Saw Grinding Machine

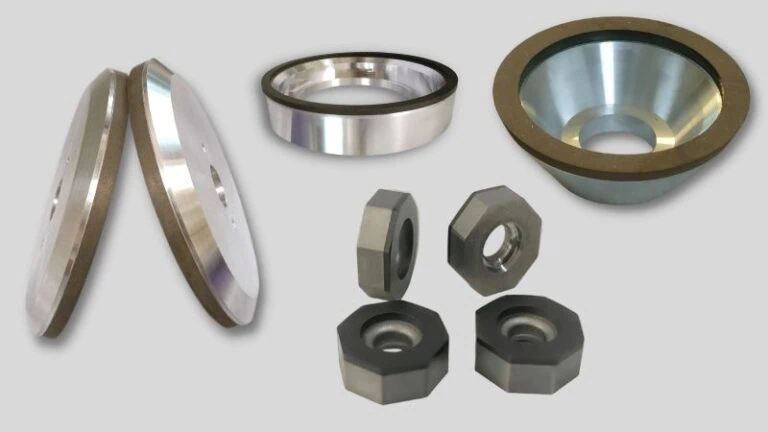

Select the wheel shape based on the specific surface of the saw tooth you intend to grind. Use 12V9 or 11V9 dish wheels for face and top grinding to ensure clearance between teeth, 4A2 or 14F1 saucer wheels for precision side grinding to achieve radial relief, and 1A1 straight wheels for hollow grinding or relieving steel chip limiters.

12V9 and 11V9 Wheels for Standard Face and Top Sharpening

For the majority of circular saw maintenance, you will work on the face (the front) and the top of the carbide tip. The industry standard shapes for these tasks are the 12V9 (Dish)6 and 11V9 (Flaring Cup) wheels.

The 12V9 is particularly critical for face grinding. Its unique dish angle allows the abrasive rim to reach the face of the saw tooth without the wheel hub hitting the next tooth in line.

Consider a milling operation where a large diameter face mill cannot machine a tight internal corner radius without gouging the adjacent wall. Similarly, the 12V9 is angled specifically to fit into the tight “gullet” space between teeth without colliding with the neighboring tip.

The 11V9 flaring cup is often used for top grinding. Its wider rim supports the grinding pressure better on the top bevel. This stability is crucial when grinding steep angles, such as Alternate Top Bevel (ATB) geometries.

- 12V9: Best for Face Grinding due to excellent tooth clearance.

- 11V9: Best for Top Grinding due to structural rigidity.

Note: The angle of the dish (typically 45° or 30°) varies by machine setup. Verify the required “V” angle with your machine manual before purchasing to prevent collision.

4A2 and 14F1 Profiles for Precision Side Grinding

Side grinding, also known as flank grinding, requires a wheel that can grind the narrow sides of the tip without touching the steel saw body. This requires a wheel with a very thin profile.

The 4A2 (Saucer)7 wheel is the standard solution here. It features a thin, abrasive rim that projects outward. This projection allows the wheel to grind the carbide side while maintaining a safe distance from the saw shoulder. If you used a thick wheel here, you would grind away the steel support behind the carbide.

The 14F1 wheel is a more specialized profile, often featuring a radius or a “U” shape. This is frequently used on automatic machines for specific tooth geometries that require a curved side profile or for maintaining a specific radial clearance angle.

| Wheel Shape (FEPA) | Common Name | Primary Application | Key Feature |

|---|---|---|---|

| 12V9 | Dish Wheel | Face Grinding | 45° angle clears adjacent teeth |

| 11V9 | Flaring Cup | Top Grinding | Rigid body for bevel accuracy |

| 4A2 | Saucer Wheel | Side Grinding | Thin rim avoids steel body |

| 14F1 | Profile Wheel | Specialized Side/Face | Custom radius or profile |

| 1A1 | Straight Wheel | Chip Limiters | Flat peripheral grinding |

1A1 Wheels for Hollow Grinding and Chip Limiter Relief

Not all grinding happens on the flat surfaces of the carbide. Some specialized saw blades require “hollow grinding,” where the face of the tooth is concave (scooped out). This sharpness is essential for cutting melamine without chipping.

For this operation, you need a 1A1 (Straight) wheel with a radiused edge. The 1A1 wheel works like a bench grinder wheel, cutting on its outer periphery rather than its face. The curvature of the wheel determines the curvature of the hollow grind on the tooth.

Additionally, many anti-kickback saw blades feature “chip limiters” (a steel hump behind the tooth). As you sharpen the saw, the tooth gets smaller, but the steel limiter does not. Eventually, the limiter becomes higher than the tooth, preventing the saw from cutting. A coarse 1A1 diamond or CBN wheel is used to grind down this steel limiter to restore the correct cutting depth.

Ensuring Hub Compatibility with Vollmer, Walter, and Akemat Machines

Even if you select the perfect diamond shape, it is useless if it does not fit your machine’s spindle. High-precision CNC machines like Vollmer, Walter, and Akemat require extremely tight tolerances on the wheel bore.

The “Bore” (H dimension) must match the machine spindle exactly. A loose fit causes “Run-out8,” where the wheel wobbles. Even a runout of 0.02mm can cause the wheel to hammer the brittle carbide, leading to microscopic fractures.

Furthermore, you must check the Bolt Circle. Many CNC grinders do not rely solely on the center nut; they use a flange with screws for extra rigidity. For example, a Walter Woodtronic machine might require a specific bolt pattern that differs from an Akemat machine.

Always verify these mounting dimensions:

- Bore Diameter (H): (e.g., 20mm, 32mm)

- Bolt Hole Pattern: Number of holes and Pitch Circle Diameter (PCD).

- Hub Thickness: Ensure the wheel hub is not too thick for your spindle nut threads.

Adjusting Diamond Concentration for Tooth Geometry and Feed Rates

How does the amount of diamond in your wheel affect the precision of your saw tooth geometry and the speed of your machine?

Diamond concentration, defined as the weight of diamond per unit volume, directly impacts wheel life and profile retention. High concentrations (C100–C125) are critical for maintaining the sharp corners required for complex Triple Chip Grinds (TCG). Conversely, lower concentrations (C50–C75) are superior for rapid stock removal on large forestry saws because they generate less heat and allow for faster feed rates.

High Concentration for Maintaining Corners on Triple Chip Grind (TCG)

The “Triple Chip Grind” (TCG) is a common tooth geometry for cutting non-ferrous metals and laminates. It relies on precise 45-degree chamfers on the tooth corners. When grinding these chamfers, the corner of the diamond wheel does all the work.

If you use a wheel with low diamond concentration here, the wheel’s corner will wear down quickly. It will turn into a radius (a rounded edge) instead of a sharp corner. Consequently, the saw tooth will not have the correct shape, leading to poor cutting performance.

To prevent this, you need a High Concentration wheel, typically C100 (4.4 carats/cm³) or C125. This means the wheel is densely packed with diamond particles.

Think of this like a high-density milling cutter equipped with a maximum number of inserts. It holds its dimension longer because the workload is distributed among many cutting edges. This density ensures the wheel keeps its square profile, even after grinding thousands of teeth.

Low Concentration for Rapid Stock Removal on Forestry Saws

Forestry and lumber mill saws are different. They are large, rugged, and often hit nails or rocks. When repairing these saws, you often need to grind away a lot of damaged carbide. Precision is secondary to speed and cost.

For these “hogging” operations, a Low Concentration wheel (typically C50 or C75) is the better choice. A lower concentration means there is more space between the diamond particles.

This spacing is vital for “chip clearance.” When you grind deep and fast, you generate a lot of carbide dust. If the diamonds are too close together (High Concentration), that dust gets trapped. The wheel “loads up” and stops cutting.

A low concentration wheel acts like a coarse-pitch saw blade. It has plenty of “gullet” space between the cutting points to carry away the waste material. This allows you to run the machine at higher feed rates without stalling the spindle.

Balancing Concentration with Coolant Flow to Prevent Carbide Burning

There is a direct link between diamond concentration and heat generation. Every diamond particle that touches the carbide creates friction. Therefore, a High Concentration wheel creates more friction and more heat than a Low Concentration wheel.

If you switch to a high concentration wheel to improve wheel life, you must ensure your coolant system can keep up. High concentration wheels act almost like a solid wall; it is harder for the coolant to penetrate the cut zone.

If the coolant cannot reach the contact point, the carbide tip will turn black or crack (heat checking).

Guidelines for Balancing Concentration and Coolant:

| Concentration | Friction Level | Coolant Requirement | Best Application |

|---|---|---|---|

| C50 – C75 | Low | Low (Mist or Light Flood) | Heavy removal, Repair, Roughing |

| C100 | Medium | High (Flood Coolant) | Standard Manufacturing, Top Grinding |

| C125+ | High | Very High (High Pressure) | Profile Grinding, Corner Retention |

Therefore, if your machine has a weak coolant pump or poor nozzle positioning, stick to a lower concentration (C75). It is safer for the saw blade. Only upgrade to C100 or C125 if you have flood coolant directed precisely at the grinding interface.

Conclusion

Selecting the correct diamond wheels for saw grinding is not about finding a “one size fits all” solution. It is about balancing variables. You must balance the need for speed (soft bonds, low concentration) against the need for life (hard bonds, high concentration). You must balance the aggression of coarse grits against the finish requirements of fine grits.

By systematically evaluating your saw materials, grinding machine capabilities, and end-user finish requirements using the guidelines above, you can optimize your grinding operation. The right wheel will not only reduce your consumable costs but also protect the expensive carbide tips you are sharpening, ultimately delivering a better product to your customers.

References

- Resin bond wheels1 – ZYDiamondTools guide to selection and application of Resin Bond Diamond & CBN grinding wheels.

- Hybrid bond wheels2 – Detailed analysis of Hybrid Bond Diamond/CBN wheels and their benefits for CNC grinding.

- CBN (Cubic Boron Nitride)3 – Comprehensive guide from ZYDiamondTools explaining CBN abrasives and their application for ferrous metals.

- Surface grinding4 – Wikipedia article explaining the surface grinding process and mechanics.

- Surface roughness5 – Wikipedia reference for understanding surface roughness parameters and conversions.

- 12V9 (Dish)6 – Product page for 11V9 and 12V9 Hybrid Bond Diamond and CBN Grinding Wheels.

- 4A2 (Saucer)7 – Product specifications for 4A2 Diamond Grinding Wheels used in side grinding.

- Run-out8 – Wikipedia explanation of Run-out tolerance and its impact on rotational parts.