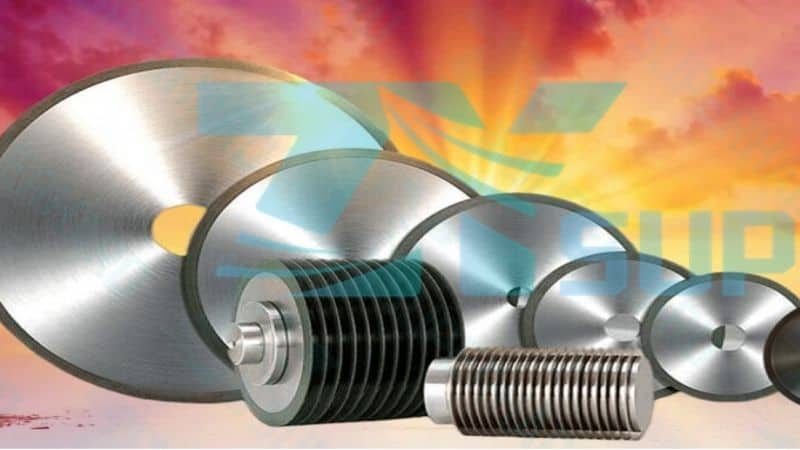

Diamond saw blades have high hardness and high strength. Its manufacturing cost is also very high. The main reason is that the price of diamond blades is high. Secondly, the material requirement of the saw blade base is high. Therefore, its high manufacturing cost leads to the high price of diamond saw blades.

However, because the diamond saw blade has sharp and durable characteristics. And with the diamond saw blade, manufacturing technology is increasingly mature, more and more recognized, and accepted by most consumers. The use of diamond saw blade consumers also more and more. However, many workers of enterprises only know to use diamond saw blades but do not pay attention to the maintenance of diamond saw blades. Some of them even know nothing about the maintenance method of diamond saw blades. Thus, the service life of diamond saw blades is greatly reduced. It can not play with its sharp and durable cost performance.

I will share some maintenance methods for diamond saw blades. I hope you can learn about the maintenance of the saw blade so as to play the maximum performance of the diamond saw blade.

Diamond Saw Blade Maintenance Methods

- Diamond saw blades, such as those not immediately used, should be folded down from the saw table coated with anti-rust oil after flat, or use the inner hole to hang it up. A flat diamond saw blade could not stack other items or footsteps, and to pay attention to moisture and anti-rust corrosion.

- Then the diamond saw blade is no longer sharp, and the cutting surface is rough, must promptly unload it from the saw table and send it to the manufacturers for resharpening. Diamond saw blade is a high-speed cutting tool, and its requirements for dynamic balance are quite high. Please do not give the diamond saw blade to non-professional manufacturers for resharpening. The resharpening can not change the original angle and destroy the dynamic balance.

- The diamond saw blade of the inner diameter correction, positioning hole processing, etc., must be handed over to the original factory side. If processing is bad, it will seriously affect the diamond saw blade life and use effect. And may lead to personal property damage. Reaming, in principle, can not exceed the original hole diameter of 20mm not to affect the balance of stress.