-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

A Comprehensive Guide to Machining Hard Cast Iron with PCBN

How can you successfully and efficiently machine hard cast iron, a notoriously difficult material?

Successfully machining hard cast iron requires a systematic approach that begins with understanding its core challenges—extreme hardness, high abrasiveness, and intense heat generation. Success then depends on selecting the right PCBN tool by balancing grade toughness with hardness, choosing the correct insert type and geometry, applying effective dry machining strategies with optimized parameters, and knowing how to troubleshoot common failures like tool wear, chipping, and poor surface finish.

What Challenges Make PCBN Essential for Machining Hard Cast Iron?

So, what exactly makes hard cast iron a machinist’s nightmare compared to other metals?

Hard cast iron presents three major machining challenges: its extreme hardness and brittleness cause tool chipping and workpiece fracture; its highly abrasive microstructure leads to exceptionally rapid tool wear; and the intense heat generated during cutting creates high thermal stress, which softens and degrades conventional cutting tools.

The Problem of Extreme Hardness and Brittleness

Imagine trying to cut a pane of glass versus a block of wood. The wood is softer and gives way, but the glass is incredibly hard and resists the cut. Hard cast iron is very much like that pane of glass. Materials like chilled cast iron or high-chromium white iron can have a hardness exceeding 60 HRC (Rockwell Hardness1). This extreme hardness means a conventional cutting tool, like one made from tungsten carbide2, struggles to penetrate the surface effectively.

Furthermore, this hardness comes with a significant trade-off: brittleness. When you apply too much force to the glass, it doesn’t bend—it shatters. Similarly, hard cast iron has very low ductility. Under the immense pressure of machining, the material doesn’t form a smooth, continuous chip. Instead, it tends to fracture and break away in small, abrasive segments. This action creates a hammering effect on the tool’s cutting edge.

This combination poses a dual threat:

- For the Tool: The shock and impact from cutting a brittle material can easily cause the tool’s sharp edge to micro-chip or even fracture entirely.

- For the Workpiece: The cutting forces can induce micro-cracks in the component itself, compromising its structural integrity.

A prime example is the machining of large chilled cast iron rolls used in steel rolling mills. The roll’s surface is intentionally hardened to resist wear during its own operation. Attempting to resurface these rolls with standard carbide tools often results in immediate tool failure because the tool simply isn’t hard enough to overcome the workpiece and tough enough to survive the brittle cutting action.

Dealing with High Abrasiveness and Rapid Tool Wear

Now, let’s add another layer of difficulty. The internal structure of hard cast iron is filled with extremely hard particles. During machining, these particles act like microscopic sandpaper, relentlessly grinding against the tool’s cutting edge.

These abrasive elements are typically:

- Iron Carbides (Cementite3): Naturally occurring hard compounds within the iron.

- Chromium Carbides: Found in high-chrome irons, these are even harder and more abrasive than simple iron carbides.

This process is known as abrasive wear, and it’s the primary reason conventional tools fail so quickly. The edge doesn’t necessarily chip or break; it gets worn down and rounded off at an astonishing rate.

The data speaks for itself. In applications involving high-chromium cast iron pumps or mill liners, a standard coated carbide insert might be completely worn out after machining for just one or two minutes. This rapid wear leads to several costly problems in a production environment:

- Constant Tool Changes: This results in significant machine downtime.

- Inconsistent Quality: As the tool wears, the dimensions and surface finish of the part change, leading to scrapped parts.

- Increased Costs: The budget for tooling and the labor cost for frequent changes skyrocket.

Managing High Thermal Stress and Its Impact on Cutting Tools

Finally, cutting any hard material generates an immense amount of friction and, consequently, heat. The energy needed to shear the hard cast iron is converted directly into thermal energy, concentrated in a tiny area where the tool tip meets the workpiece. The problem is that cast iron is a poor conductor of heat. It doesn’t draw the thermal energy away from the cutting zone efficiently.

As a result, the temperature at the tool’s tip can easily exceed 1000°C (1832°F). This intense, localized heat has a devastating effect on most cutting tool materials.

The Impact of High Temperatures

This concentrated heat leads to a critical failure mode known as thermal softening. Even a tool that is very hard at room temperature can lose its hardness when it gets extremely hot. For example, tungsten carbide tools begin to soften significantly above 800°C, making them highly susceptible to wear and deformation when machining hard cast iron. The tool edge essentially becomes too soft to continue cutting the hard material effectively.

Furthermore, if coolant is applied incorrectly, it can cause thermal shock. This happens when the hot cutting edge is rapidly cooled by the fluid, then reheats just as quickly as it re-engages the material. This repeated cycle of expansion and contraction creates microscopic cracks in the tool, leading to sudden and unpredictable catastrophic failure. Therefore, any tool used for this application must possess exceptional “hot hardness”—the ability to retain its strength and sharp edge even when glowing red-hot.

Why PCBN Emerges as the Only Viable Solution

Given these immense difficulties, it becomes clear that conventional tools are simply outmatched. PCBN (Polycrystalline Cubic Boron Nitride) isn’t just another option; its fundamental properties directly counteract the specific problems that make hard cast iron so formidable.

- To Combat Hardness and Brittleness: PCBN is the second hardest material on earth, surpassed only by diamond. It is significantly harder than the iron carbides in the workpiece, allowing it to cut cleanly rather than plow through the material. This reduces cutting forces and minimizes the risk of fracturing the brittle cast iron.

- To Combat Abrasive Wear: Because of its extreme hardness, PCBN is exceptionally resistant to the abrasive wear caused by hard carbide particles. Where a carbide tool wears down in minutes, a PCBN insert can machine for hours, providing the long, predictable tool life necessary for productive manufacturing.

- To Combat High Thermal Stress: This is PCBN’s defining advantage. It possesses incredible “hot hardness” and thermal stability. It maintains its cutting edge at temperatures well above 1000°C, precisely where carbide and ceramic tools fail. Furthermore, it is chemically inert to iron at these temperatures, preventing the diffusion wear that plagues other materials.

In essence, PCBN was engineered to thrive in the exact high-heat, high-abrasion environment that destroys other tools. This makes it the only truly effective and economical choice for the high-performance machining of hard cast iron.

How Do You Select the Right PCBN Insert for the Job?

With so many options available, how do you choose the perfect PCBN insert for your specific task?

To select the right PCBN insert, you must make three critical decisions. First, choose the optimal PCBN grade by balancing the material’s hardness against its toughness to match your operation. Second, decide between a cost-effective tipped insert for general use or a robust solid insert for heavy-duty applications. Finally, specify the correct insert geometry, including edge preparation, shape, and corner radius, to maximize strength and performance.

Choosing the Optimal PCBN Grade for Hardness and Toughness

Think about choosing tires for a vehicle. A hard, slick racing tire is perfect for a smooth track but would fail instantly on a bumpy, gravel road. An off-road tire with deep treads, however, is tough enough for the gravel but would wear out quickly on the racetrack. Selecting a PCBN grade for hard cast iron involves a similar, critical trade-off between hardness (wear resistance) and toughness (impact resistance).

- High CBN Content Grades: These grades are the “racing slicks.” Their high hardness makes them exceptionally resistant to the abrasive wear from high-chrome or chilled irons. They are the best choice for continuous finishing passes on uniform castings, like resurfacing a chilled iron roll, where tool life and surface finish are paramount.

- Low CBN Content Grades: These are the “off-road tires.” Their higher binder content gives them the toughness needed to absorb impacts. They are essential for roughing passes or machining cast iron parts with interruptions, such as a pump housing with bolt holes. Using a brittle, high-CBN grade here would lead to immediate edge fracture.

To simplify this, here is a quick guide for hard cast iron applications:

| PCBN Grade Type | Key Characteristic | Best Hard Cast Iron Application | Analogy |

|---|---|---|---|

| High CBN Content | Maximum Hardness & Wear Resistance | Smooth Finishing Cuts | Racing Tire |

| Low CBN Content | Maximum Toughness & Impact Resistance | Roughing / Interrupted Cuts | Off-Road Tire |

Important Note: Grade designations (such as BN250, KB5630, etc.) vary significantly between manufacturers. Always consult your tooling supplier’s technical data to match their specific grade to your hard cast iron type and machining operation.

Solid vs. Tipped PCBN Inserts: Which One to Use and When

Once you have an idea of the grade, the next choice is the insert’s construction, which directly relates to the demands of the cast iron component.

Tipped PCBN Inserts

This is the workhorse design for most hard cast iron jobs. A small PCBN tip is brazed onto a strong carbide base. This design is cost-effective because the expensive PCBN material is used only at the cutting edge, while the tougher, less expensive carbide provides support.

Use Tipped Inserts for: Finishing and medium-duty roughing on most hard cast iron parts, such as brake drums, pump impellers, and valve seats. They provide an excellent balance of performance and price.

Solid PCBN Inserts

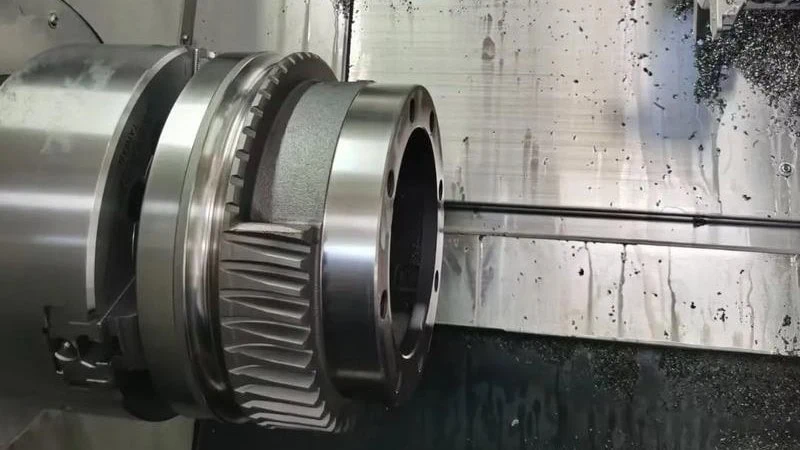

A solid PCBN insert4 is made entirely of the PCBN material, offering unmatched strength and heat dissipation.

Use Solid Inserts for: The most brutal cast iron applications. This includes heavy roughing of large, inconsistent castings like those found in mining or steel production, or taking deep cuts on components with a thick, abrasive outer scale. The robustness of a solid insert is necessary to survive these extreme conditions.

Deciphering Insert Geometry: Edge Preparation, Shapes, and Corner Radii

The final piece of the puzzle is the insert’s geometry. For brittle hard cast iron, a strong geometry is not just a recommendation—it’s a requirement.

The Importance of Edge Preparation

A perfectly sharp edge will fracture instantly on hard cast iron. The edge must be strengthened.

- Chamfer (T-Land): A small, angled flat on the cutting edge. A heavy chamfer is non-negotiable for roughing passes or breaking through the abrasive scale on a raw casting. It provides the blunt force needed to survive the impact.

- Hone (Radius): A slight rounding of the edge. This is suitable for finishing passes on pre-machined surfaces where a good balance of strength and sharpness is needed to achieve a fine surface finish.

Choosing Insert Shapes

For hard cast iron, the rule is simple: use the strongest shape possible for the job.

- Strongest: Round (R) inserts are the first choice for heavy roughing and facing large, uneven castings. Their shape distributes cutting force and heat efficiently, maximizing strength.

- General Purpose: Square (S) and Trigon (T) inserts offer strong corners and are versatile for turning and creating shoulders on components like cast iron rolls.

- Finishing/Profiling: Diamond (C, D, V) shapes are the weakest due to their acute angles. They should only be used for light finishing passes where necessary to machine a specific profile on the cast iron part.

Selecting the Corner Radius

The corner radius of the insert’s tip is a critical factor in managing cutting pressure on hard cast iron.

- Use a Larger Radius (e.g., 1.2 mm or more) for roughing passes. This increases the strength of the corner and allows for higher feed rates without fracturing.

- Use a Smaller Radius (e.g., 0.8 mm or less) for finishing passes. This reduces the tool pressure on the workpiece, which helps prevent vibration (chatter) and achieves a better surface finish.

What Are the Most Effective Machining Strategies?

Once you have the right tool, what’s the best way to actually use it to machine hard cast iron?

The most effective strategies involve three key elements. First, you must begin with the correct starting parameters for speed, feed, and depth of cut to ensure a stable process. Second, you should almost always use dry machining to protect the tool from thermal shock. Finally, you need to adopt specific tactics for challenging conditions like interrupted cuts and rough surface scale to prevent premature tool failure.

Starting Point: Recommended Speeds, Feeds, and Depth of Cut

Machining with PCBN is like driving a high-performance car; you must use the right parameters to maintain control and get the best performance. PCBN performs best at high speeds, which generates heat that helps soften the workpiece material just ahead of the cutting tool, actually making it easier to cut. Using parameters that are too slow can increase cutting forces and lead to chipping.

Below is a table with generally accepted starting points for machining hard cast iron (HRC 55-65).

| Operation | Cutting Speed (Vc) | Feed Rate (fn) | Depth of Cut (ap) |

|---|---|---|---|

| Roughing | 80 – 120 m/min | 0.2 – 0.4 mm/rev | 1.0 – 4.0 mm |

| Finishing | 100 – 180 m/min | 0.05 – 0.2 mm/rev | 0.1 – 0.5 mm |

- Cutting Speed (Vc): This is how fast the workpiece surface moves past the cutting edge. Higher speeds are generally better for finishing.

- Feed Rate (fn): This is how quickly the tool travels along the length of the workpiece. Higher feeds remove material faster but create a rougher finish.

- Depth of Cut (ap): This is how deep the insert cuts into the material on each pass.

Crucial Reminder: The values in this table are conservative starting points only. The ideal parameters for your job will depend on your specific PCBN grade, machine rigidity, workpiece hardness, and setup. Always begin with the recommendations from your tooling supplier and then carefully adjust them to optimize your process.

The Critical Choice: Dry Machining vs. Coolant Application

What about coolant? In most machining operations, coolant is essential. However, for hard cast iron with PCBN, the rules change dramatically.

The overwhelming recommendation is to machine completely dry.

Here’s why: PCBN tools achieve their best performance at the very high temperatures generated during the cut. An insert tip can easily reach a glowing-red 1000°C (1832°F). Spraying conventional coolant onto this super-heated edge causes an immediate and massive temperature drop, creating tiny cracks in the tool—a phenomenon called thermal shock. This is the same reason a hot glass dish will shatter if you pour cold water on it. Thermal shock will lead to unpredictable and catastrophic tool failure.

The Exception: Flood Coolant

The only exception to this rule is if your machine is equipped for high-pressure, high-volume flood coolant. This means the tool and cut are completely submerged in a continuous, powerful flow of fluid. In this scenario, the temperature is kept consistently low from the very start, preventing the thermal shock cycle. However, this is a specialized setup and not common.

For most applications, if you need to clear chips away from the cutting zone, use a directed jet of compressed air. This effectively removes chips without causing any thermal shock to the insert.

Best Practices for Handling Interrupted Cuts and Surface Scale

Interrupted cuts and rough casting surfaces are two of the toughest challenges. They require specific strategies to avoid destroying the PCBN insert.

Strategy for Interrupted Cuts

An interrupted cut5 is any situation where the tool repeatedly enters and exits the material—for example, milling a surface or turning a shaft with a keyway. Each entry is a small impact on the cutting edge.

- Reduce the Feed Rate: The most effective technique is to reduce the feed rate by about 50% just before the tool enters the cut. This creates a “soft entry,” lessening the impact force and protecting the edge from chipping. Many modern CNC controls can program this automatically.

- Use a Tough Insert: As mentioned in the previous section, always use a tougher, low-CBN grade insert with a strong chamfered edge preparation for interrupted cuts.

Strategy for Surface Scale

The “scale” is the hard, abrasive, and uneven outer skin on a casting. It can be significantly harder than the material underneath and often contains sand and other impurities from the casting process.

- Get Under the Skin: The best approach is to set your first depth of cut deep enough to get completely underneath the scale layer. This allows the strongest part of the insert to do the work and avoids having the delicate tool nose dragging through the most abrasive region.

- Use a Dedicated Roughing Insert: For the first pass that removes the scale, use a very strong insert—ideally a round, tough-grade PCBN insert. After this rough pass, you can switch to a finishing insert for the subsequent cuts in the clean material.

- Slow Down for the First Pass: Reduce the cutting speed (Vc) by 20-30% for the initial pass through the scale. This lowers the thermal and mechanical shock of engaging with the rough, unpredictable surface.

How Do You Troubleshoot Common Failures in Hard Cast Iron Machining?

So what do you do when things go wrong and your PCBN tool isn’t performing as expected?

Troubleshooting common failures is a systematic process. The key is to first identify the type of failure—is it predictable wear, sudden breakage, or poor surface quality? Once identified, you can solve predictable flank and crater wear by adjusting speeds and feeds, prevent catastrophic chipping by improving setup rigidity and using tougher inserts, and diagnose a poor surface finish by checking for tool wear and reducing vibration.

Identifying and Solving Premature Flank and Crater Wear

Tool wear is normal, but when it happens too quickly on expensive PCBN inserts6, it costs you time and money. The two most common types of predictable wear are flank and crater wear.

Troubleshooting Flank Wear (Abrasive Wear)

This is the classic failure mode when machining high-chrome white iron. It appears as a uniform, flat wear land on the side of the insert, caused by the relentless grinding of hard chromium carbides.

- Primary Cause: The cutting speed is too high, generating excessive heat that softens the tool and accelerates abrasion.

- Solutions:

- Reduce Cutting Speed (Vc): This is your main tool for controlling flank wear.

- Select a Harder PCBN Grade: If the wear is consistently high in a continuous cut, a high-CBN content grade with superior hardness may be a better choice.

Troubleshooting Crater Wear

Crater wear is a dish-shaped cavity on the top face of the insert. While less common in cast iron than in steel, it can occur at very high speeds.

- Primary Cause: Excessive heat from a combination of high cutting speeds and high feed rates, causing the hot, segmented cast iron chip to erode the tool face.

- Solutions:

- Reduce Cutting Speed and Feed Rate: Lowering these parameters will reduce the temperature and pressure on the tool face.

- Use a Coated PCBN Insert: Some PCBN inserts have coatings that act as a thermal barrier, protecting the tool face.

Preventing Edge Chipping and Catastrophic Fracture

Unlike predictable wear, chipping is a sudden breakage. For a brittle material like hard cast iron, this often points to excessive impact or a lack of strength in the setup.

The table below outlines the most common causes and their solutions when machining hard cast iron.

| Cause of Chipping / Fracture | How to Solve It |

|---|---|

| Lack of Rigidity (Vibration) | Common when machining large, poorly supported castings. Solution: Use the shortest possible tool overhang and ensure the workpiece is clamped securely. |

| Wrong PCBN Grade | The grade is too brittle. Solution: Switch to a tougher, low-CBN content grade, especially for roughing or interrupted cuts on cast iron parts. |

| Incorrect Edge Preparation | The edge is too sharp for the scale or interruptions. Solution: Switch to an insert with a stronger, chamfered edge (T-land). |

| Interrupted Cut Impact | Hitting a lug, hole, or keyway on a cast part too aggressively. Solution: Reduce the feed rate as the tool enters and exits the material. |

| Built-Up Edge (BUE) | Material welding to the tool tip. Solution: Increase the cutting speed. This increases heat, which in the case of cast iron, often helps create a cleaner cut and prevent sticking. |

Diagnosing and Improving Poor Surface Finish

A poor surface finish on your final pass can ruin a cast iron component. If you see grooves or a dull appearance, follow this checklist.

Step 1: Inspect the Tool’s Corner Radius

This is the #1 cause. The small corner radius of the insert is what generates the finished surface, and even slight abrasive wear will degrade the finish.

- Problem: A visible wear land on the corner radius of the insert.

- Solution: Simply rotate the insert to a fresh edge or replace it.

Step 2: Check for Vibration (Chatter)

Vibration creates a distinct, wavy pattern on the surface, a common issue when turning long or thin-walled cast iron parts.

- Problem: The setup lacks rigidity, causing the tool to bounce.

- Solution:

- Try increasing or decreasing the cutting speed by 10%.

- If that doesn’t work, reduce the depth of cut.

- Use an insert with a smaller corner radius to reduce cutting pressure.

Step 3: Evaluate the Feed Rate

If you can see lines on the part that look like the threads on a screw, your feed rate is too high.

- Problem: The tool is moving forward too quickly, leaving behind a visible trail.

- Solution: Reduce the feed rate (fn) for the finishing pass.

Step 4: Look for Chip Dragging

The brittle, segmented chips produced by hard cast iron can be particularly problematic if they are not cleared away.

- Problem: A chip gets caught and dragged between the insert and the newly machined surface, leaving a scratch.

- Solution: Use a powerful jet of compressed air aimed directly at the cutting zone to forcefully blow chips clear.

Conclusion

Machining hard cast iron is undoubtedly a demanding task, but it is far from impossible. Success is not found in a single “magic” insert or secret parameter but in a systematic and knowledgeable approach. By first understanding the fundamental challenges the material presents and recognizing why PCBN is the definitive solution, you can then make intelligent decisions. The process flows logically from selecting the correct PCBN grade and geometry for the specific application to implementing disciplined machining strategies, most notably the preference for dry cutting. Finally, having a clear, problem-solving framework for troubleshooting common failures ensures that you can maintain a stable, efficient, and high-quality production process. With this comprehensive understanding, you can confidently turn one of the most challenging materials into a predictable and profitable component.

If you’re looking for PCBN tools for machining hard cast iron, contact us and let our technical experts help you find the perfect solution for your application!

References

- Rockwell Hardness1 – A Wikipedia article providing a comprehensive overview of the Rockwell hardness test.

- tungsten carbide2 – A ZYDiamondTools article comparing the properties and applications of PCD and Tungsten Carbide tools.

- Cementite3 – A ScienceDirect topic page providing a technical explanation of cementite in metallurgy.

- solid PCBN insert4 – ZYDiamondTools product page for solid CBN inserts used in heavy-duty hard machining applications.

- interrupted cut5 – A ZYDiamondTools guide on how PCBN tools provide solutions for machining with interrupted cuts.

- PCBN inserts6 – ZYDiamondTools product page for CBN/PCBN inserts.