-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

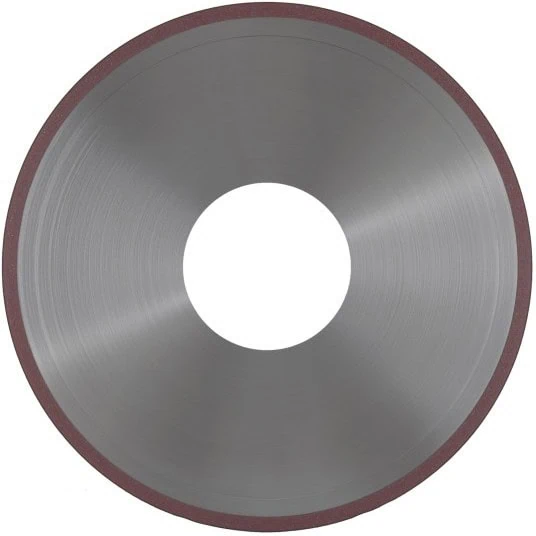

17 Types Of Commonly Used Diamond Cutting Discs, What You Need?

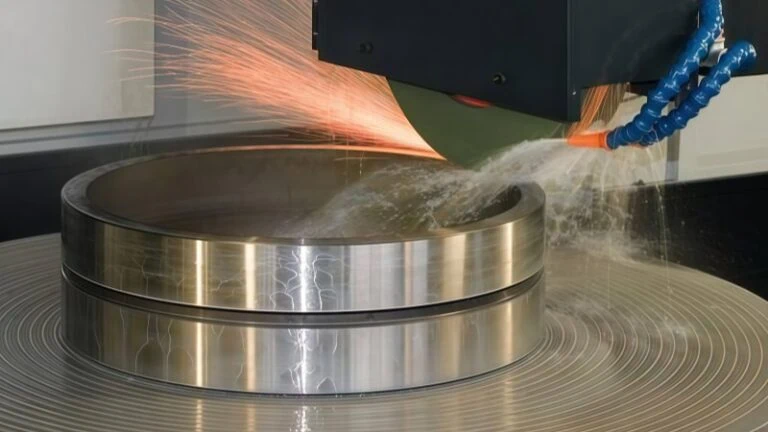

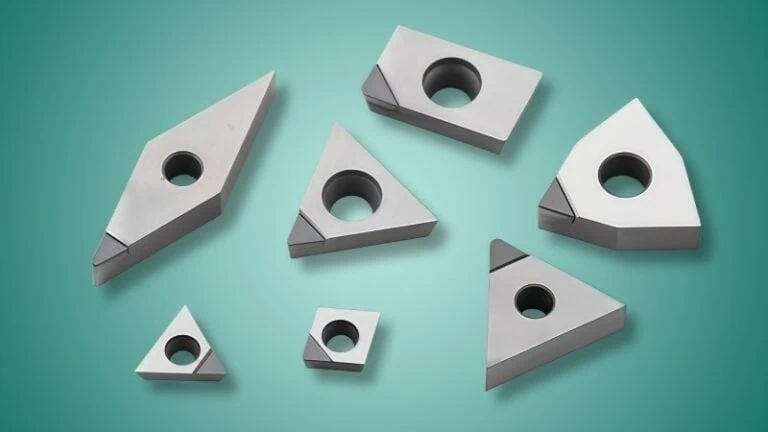

Diamond cutting discs have a wide range of applications in various industrial production. I will introduce you to 17 kinds of commonly used diamond cutting discs. These include metal bond and resin bond cutting discs.

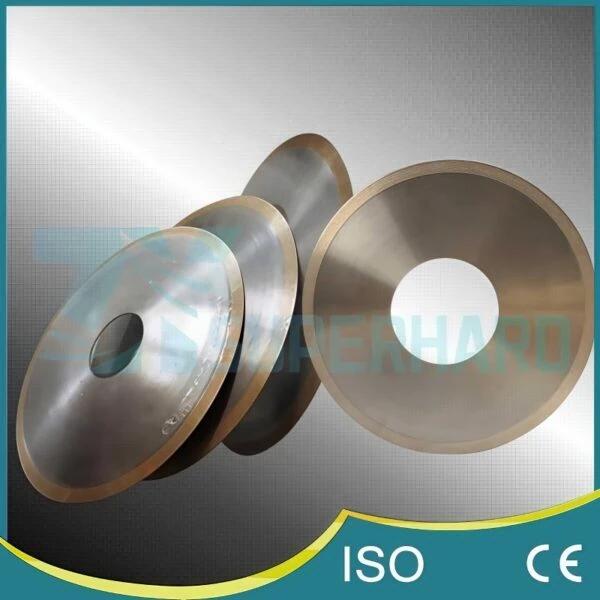

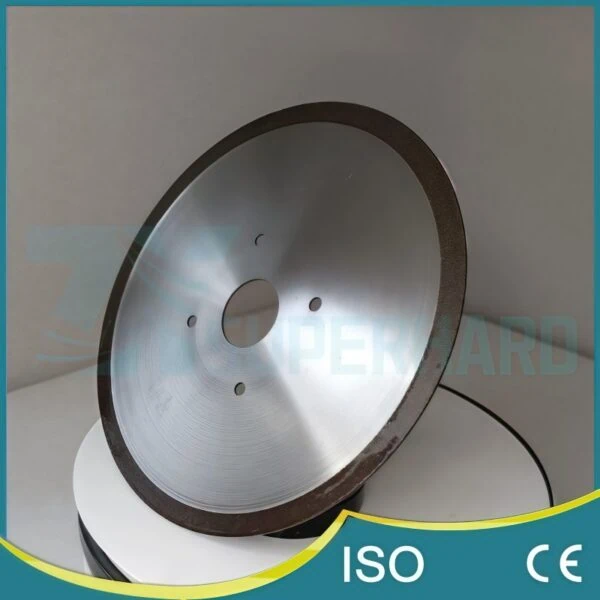

Metal Bond Diamond Cutting Discs Series

The abrasives of metal bond cutting discs have strong holding power, high wear resistance, good edge shape retention, and long service life.

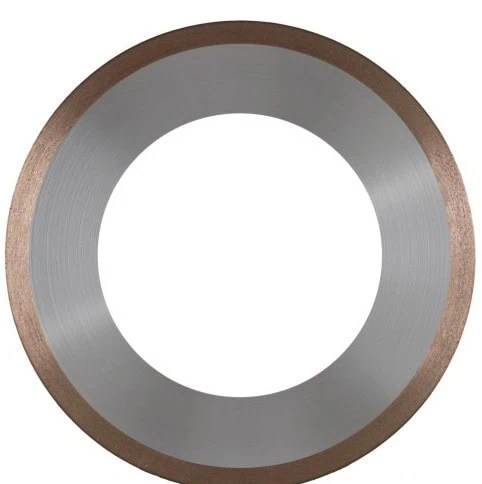

Diamond Cutting Disc For Glass Tube And Quartz Tube

This kind of cutting disc is mainly used for cutting small-diameter, thin-walled glass tubes. It can maintain good durability while keeping good sharpness. According to customer feedback, the service life can basically be maintained for 45-60 days/piece. During use, the shape can be maintained intact, with the advantages of high precision, small slit, and good surface quality processing.

CBN Cutting Disc For Valve Stem

This product is used to cut valve stems in automobile engines. It has the advantages of sharpness, high cutting efficiency, long life, and smooth and neat cutting without burr.

Diamond Cutting Disc For Zirconia Ceramic

This disc can be cut continuously without slipping and dulling during use, and it also overcomes the short life of the resin bond cutting disc. Custom sizes are available!

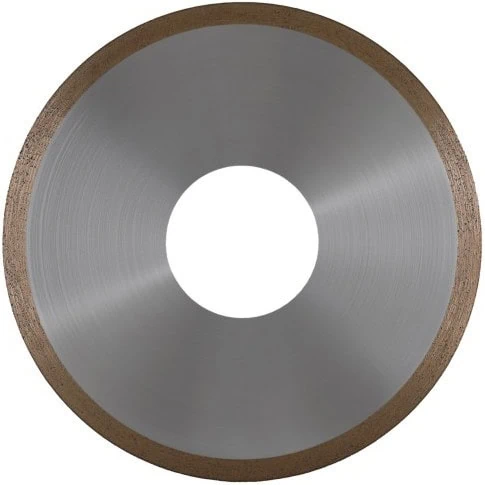

Copper Plated Cutting Disc

The surface of the substrate of this product is copper plated to craft standard, water, and corrosion resistant, and it can be customized for customers with special requirements.

Diamond Cutting Disc For Optical Glass

This disc is mainly used for optical glass opening and processing and can perform high-load depth cutting. It has high sharpness, vertical cutting angle, and long-lasting durability.

Diamond Cutting Disc For Alumina Ceramic

This disc can cut all kinds of alumina ceramics and refractory materials and can be used to process the required ceramic pieces, blocks, rods, plates, grooves, etc., as needed. Sharp cutting, high processing efficiency, good finish, and long life!

Diamond Cutting Disc For Glass

Glass thickness above 15MM is difficult to cut with a glass cutter. This disc is designed for users who only have hand tools and equipment glass cutting tools. Only need a marble machine or angle grinder (a marble machine is better). You will be able to easily cut the 15-30MM thickness of glass, cutting sharp, with no chipped edge.

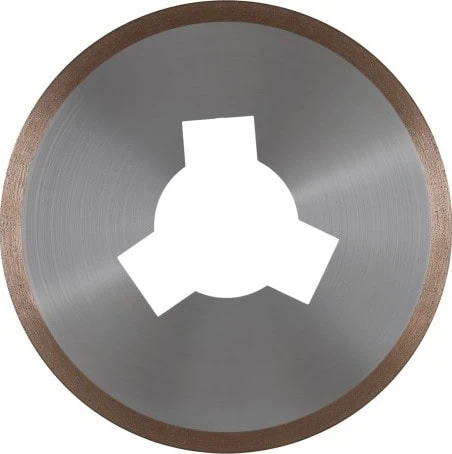

Diamond Cutting Disc For Brake Pad Grooving

The brake pad is a composite material with metal wires inside, which is tough and requires high sharpness of the disc. According to the special requirements of brake pad material, we have developed a product with moderate sharpness, a non-stick blade, and no chipping. It is ideal for cutting and slotting brake pads. Any specifications can be customized!

Diamond Cutting Disc For Superfinishing Oil Stone

Superfinishing oil stones are commonly used as silicon carbide, aluminum oxide, diamond, CBN oil stones according to their abrasives. According to different cutting requirements, we can provide you with the corresponding disc. For a better cutting experience, we plated a layer of diamond on the surface of the disc to prevent stucking. We also polish the cross section to ensure stable straight cutting.

Diamond Cutting Blade For Circuit Board

This disc is mainly used for cutting various composite circuit boards such as copper-based, rubber-based, and plastic-based circuit boards. The cutting process is a sharp, non-sticky knife with high precision and good processing surface quality while having an extremely high service life. Any specifications can be customized!

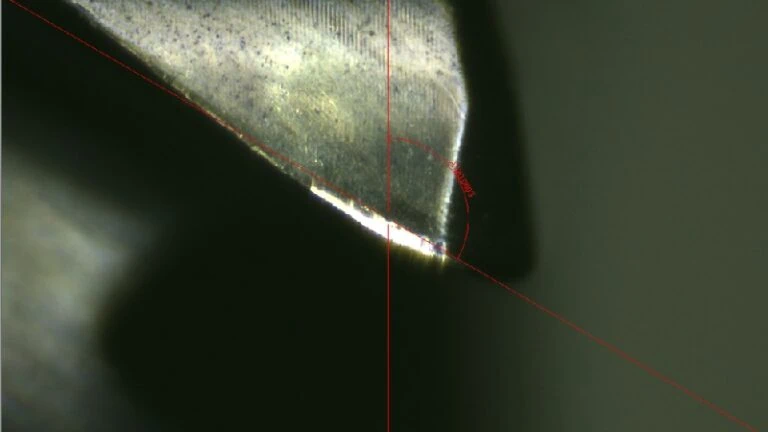

Diamond Cutting Disc For Piezoelectric Crystal

The piezoelectric crystal is a precious material, which needs to be cut vertically, so the sharpness of the disc, the material of the substrate, and the strength of the connection between the blade and the substrate are all relatively high requirements. We adopt new technology and use a high-strength substrate to improve the overall rigidity of the disc, which ensures vertical cutting and thus improves the yield of our customers.

Resin Bond Diamond Cutting Discs Series

The resin bond cutting disc has good self-sharpening, sharp cutting, high efficiency, and easy-to-achieve large depth of cut and large feed. The bond is flexible, which can improve the machining quality and workpiece finish.

Diamond Cutting Disc For Quartz (High Borosilicate Glass Tube) Processing

This disc is specialized for precision cutting of quartz and high borosilicate glass tubes, with good self-sharpening, sharp cutting without chipping, high surface finish, and long service life. Mainly used in high borosilicate glass tubes, quartz tubes, induction lamps, u-tubes, electronic cigarette tubes, chemical laboratory equipment, and other quartz glass-shaped products.

Diamond Cutting Disc For Carbide Processing

This disc is used for processing of carbide(cobalt-tungsten alloy Yg8)type. It can be perfectly used for cutting into bars, blocks, and grooving according to customers’ cutting needs. The cutting edge is sharp, has a long service life, smooth cutting edge, and no chipping. Any specification can be customized.

Diamond Cutting Disc For Quartz Crucible

This disc is mainly for precision cutting or grooving of quartz products, suitable for the following products: quartz glass rods, quartz glass sheets, quartz glass crucibles, furnace core rods, quartz glass boats, quartz crucible, etc. With the features of sharp cutting, smooth section, and long service life!

Diamond Cutting Disc For Optical Glass

This disc is mainly used for optical glass cutting and processing, including camera lens, microscope lens, magnifying lens, telescope lens, glasses lens, and other optical glass. It has high sharpness, a small cutting slit, long life, and high cutting efficiency. It can improve the cutting rate and save the cost for users.

Diamond Cutting Disc For Glass Cup (Tea Strainer) Slotting

This disc is mainly used for slotting the tea strainer of a glass cup. It has a sharp cutting edge, smooth and neat cutting section, no chipping, and no cracks. It can well maintain a stable sharpness and cutting life, which greatly improves productivity and cutting yield for users!

Diamond Cutting Disc For Magnetic Materials

The material is a brittle material; this disc can efficiently and precisely cut NdFeB, silicon steel, amorphous, nanocrystalline, ferrite, magnetic powder core, and other materials. Any specifications can be customized.

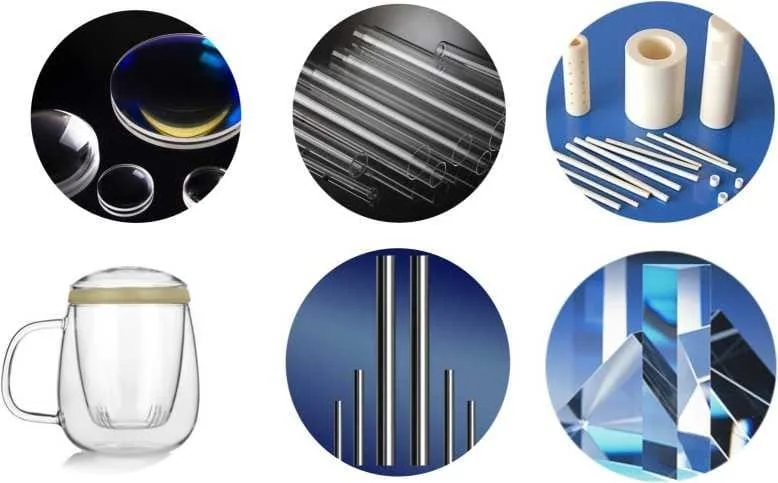

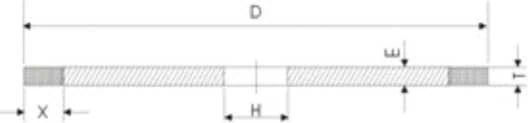

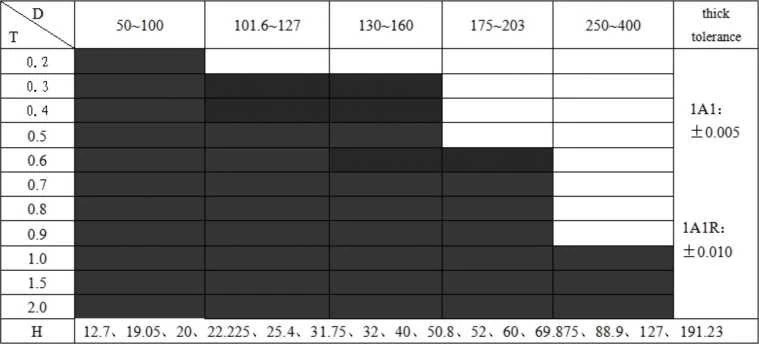

Detailed Summary Of The Processing Range

Glass material: Various glass tube / Glass spout / Tea strainer/ High borosilicate glass (electronic cigarette) / Capillary glass tube / Optical glass / Quartz glass / Crystal glass / Gem / Crystal / Jade

Ceramic material: Alumina / Zirconia / Silicon Carbide / Boron Carbide / Boron Nitride / Black Ceramic / Glass Products

Abrasive material: Refractory / Superfinishing stone

Magnetic material: Ferrite/NdFeB

Alloy material: High-speed steel / Abrasive steel / Alloy steel Brittle metal material: Carbide (YG Series)