-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

What is a Wire Drawing Die and How Does it Actually Work?

Ever wonder how a thick metal rod is transformed into the fine wire used in everything from giant bridges to tiny microchips?

A wire drawing die is a specialized tool that reshapes metal by pulling it through a precisely engineered internal bore. This process works by using plastic deformation to reduce the wire’s diameter and increase its length. The die’s effectiveness depends on its internal geometry, the material it’s made from, and the use of proper lubrication to manage extreme friction and heat.

The Process: How a Wire is Reshaped Inside the Die

So, how exactly does a solid metal rod get squeezed into a thin, uniform wire just by passing through a small, simple-looking tool?

A wire is reshaped inside a die as it is pulled through a series of five precisely engineered internal zones. These zones work in concert to lubricate the wire, gradually compress its diameter, stabilize its new size, and relieve stress. This controlled process, known as plastic deformation, permanently changes the wire’s shape and internal structure.

The Anatomy of a Die: The 5 Critical Zones

To understand how a die works, you must first look inside. It’s not just a simple hole. Instead, the internal profile is a highly engineered channel divided into five distinct zones. Each zone performs a specific task in a seamless sequence, much like an assembly line for reshaping metal.

Imagine forcing a thick rope through a series of ever-tighter funnels to make it thinner; a drawing die works on a similar principle, but with incredible precision and force.

Here is a breakdown of the five zones and their functions:

| Zone Number & Name | Primary Function |

|---|---|

| 1. Entrance Zone | This is the wide, bell-shaped opening. Its smooth, curved surface guides the wire perfectly into the center of the die, preventing it from scratching or scoring on a sharp edge. It also allows lubricant to be carried into the die with the wire. |

| 2. Lubrication Zone | Following the entrance, this zone helps establish a high-pressure film of lubricant around the wire. This ensures that the entire surface of the wire is coated before the intense work of reduction begins, which is critical for the die’s lifespan. |

| 3. Reduction Zone | This is the true workhorse of the die. In this cone-shaped section, the wire’s diameter is actively reduced. The angle of this zone, known as the reduction or approach angle, is a critical design element. The specific angle, often between 6 and 15 degrees, depends heavily on the material being drawn; always confirm the optimal specifications with your die supplier to ensure efficiency and quality. |

| 4. Bearing Zone | Immediately after reduction, the wire passes through this short, straight, cylindrical section. Its purpose is not to reduce the wire further, but to stabilize the new diameter and give the wire its final, uniform size and roundness. It also provides a smooth surface finish. |

| 5. Exit Zone | This final zone provides back-relief. It is angled away from the bearing zone to reduce stress as the newly formed wire exits the die. This prevents the wire from expanding slightly and scratching against the sharp back edge of the bearing zone, which would ruin the surface finish. |

The Role of Lubrication in the Drawing Process

Without proper lubrication, the entire wire drawing process would instantly fail. The friction and heat generated from forcing metal through a die at high speed are immense. Lubrication isn’t just helpful; it’s essential.

So, what critical tasks does the lubricant perform?

- Reduces Friction: First and foremost, lubricant creates a thin, protective barrier between the wire and the die surface. This drastically reduces the pulling force required and, most importantly, prevents the wire from welding to the die under the extreme pressure and heat.

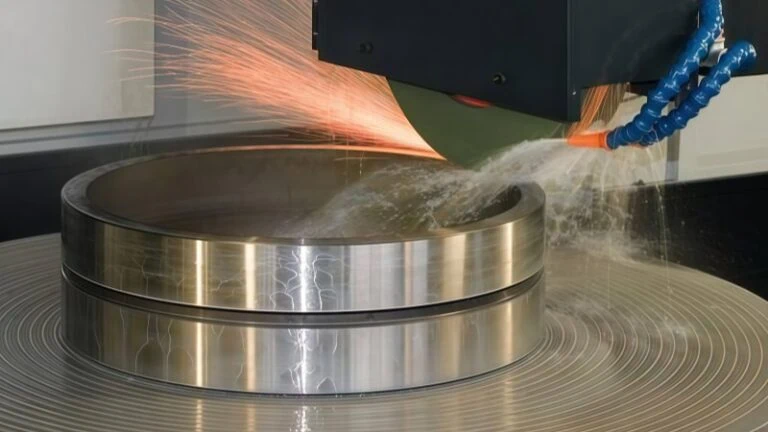

- Acts as a Coolant: The drawing process generates a tremendous amount of heat. Lubricants, especially in “wet drawing” processes where dies are fully submerged, carry this heat away, preventing the wire from losing its temper and the die from failing prematurely.

- Improves Surface Finish: A consistent layer of lubricant ensures a smooth, polished, and defect-free surface on the final wire.

Think about the different methods used in the industry. For thick steel wire, manufacturers often use dry drawing, where the wire rod is pulled through a box of soap-like powder lubricant (e.g., calcium stearate). For very fine copper wire used in electronics, wet drawing is preferred, where multiple dies are submerged in a liquid oil-based lubricant that floods the system.

Understanding the Physics: Deformation and Work Hardening

What is happening to the metal on a microscopic level? The process relies on two fundamental physical principles: plastic deformation and work hardening.

Plastic Deformation

When you bend a paperclip slightly, it springs back to its original shape. This is called elastic deformation. But if you bend it sharply, it stays bent. That permanent change is plastic deformation. Wire drawing forces the metal’s internal crystal structure to rearrange and slide past one another, causing a permanent change in shape. The die applies just enough stress to exceed the metal’s elastic limit and force it into a new, thinner form.

Work Hardening

Have you ever noticed that the more you bend that paperclip, the harder it gets to bend it again? That phenomenon is called work hardening1 (or strain hardening), and it is a direct consequence of plastic deformation.

As the wire is drawn, its internal crystal structure becomes tangled and compressed. This makes the material significantly stronger and increases its tensile strength, but it also makes it less ductile (more brittle).

This is often a desired outcome. For instance, drawing high-carbon steel wire for bridge cables or tire reinforcement relies on work hardening to achieve extreme strength. A common AISI 1080 steel wire can see its tensile strength increase from around 1,200 MPa to over 2,000 MPa through the drawing process.

However, if a wire needs to be made exceptionally thin, it may become too hard and brittle to be drawn further. In these cases, manufacturers must perform an intermediate step called annealing2—heating the wire to relieve the internal stress and soften it—before it can be drawn through smaller dies.

What materials make the best wire drawing dies?

Given the immense forces and friction involved in reshaping solid metal, what materials are actually tough enough to be used for wire drawing dies?

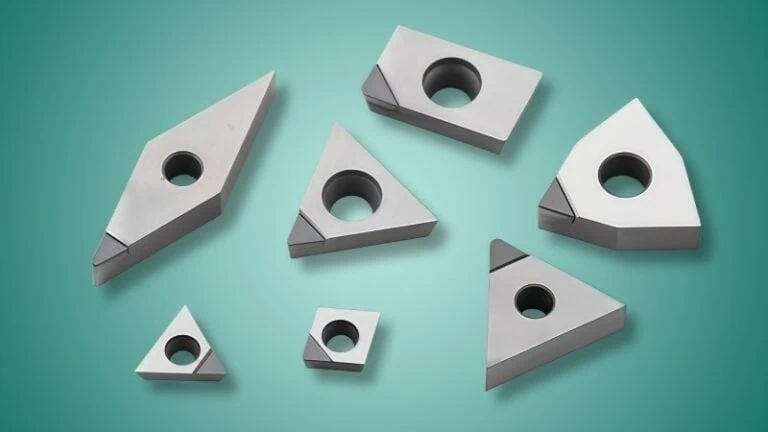

The best materials for wire drawing dies are exceptionally hard substances capable of withstanding extreme wear and pressure. The primary choices are Polycrystalline Diamond (PCD) for high-speed and high-precision applications, Tungsten Carbide for its versatile performance and cost-effectiveness with harder materials, and Natural Diamond for drawing ultra-fine wires where a flawless surface is critical.

The choice of die material is one of the most important decisions in the wire drawing industry. It directly impacts the drawing speed, the quality of the final wire, the lifespan of the tool, and the overall cost of production. While other materials like ceramics exist, the following three represent the core of modern wire manufacturing.

To quickly compare these key materials, consider the following table:

| Feature | Polycrystalline Diamond (PCD) | Tungsten Carbide (TC) | Natural Diamond (ND) |

|---|---|---|---|

| Hardness | Extremely High | Very High | The Highest |

| Wear Resistance | Exceptional | Good to Very Good | Excellent |

| Toughness | Good | Excellent | Low (Brittle) |

| Cost | High | Low to Medium | Very High |

| Primary Use Case | High-speed non-ferrous wire | Ferrous & hard-to-draw wire; large diameter drawing | Ultra-fine wire; superior surface finish needs |

Polycrystalline Diamond (PCD): For Speed and Precision

Polycrystalline Diamond is not a single, naturally occurring crystal. It is a synthetic composite made by fusing thousands of microscopic diamond crystals together with a metal binder under extreme heat and pressure. This process creates a die material that has the hardness of diamond but is much tougher and more resistant to chipping from impact.

Key Advantages of PCD

PCD’s main advantage is its extraordinary wear resistance3. In high-volume operations, this translates directly into longer die life, less downtime for changes, and more consistent wire quality over millions of meters. For example, in high-speed copper drawing applications, a PCD die can have a service life 50 to 200 times longer than a comparable tungsten carbide die. Its high thermal conductivity also efficiently pulls heat away from the wire, preserving its metallurgical properties.

Primary Applications

PCD is the material of choice for drawing most non-ferrous wires where speed and dimensional accuracy are paramount. This includes:

- Copper wire for electrical cables and magnet wire.

- Aluminum wire for power transmission cables.

- Welding wires and various alloy wires.

The performance of a PCD die is influenced by its diamond grain size. A finer grain provides a better surface finish, while a larger grain offers maximum wear resistance. Therefore, it is essential to discuss your specific application needs with your supplier to select the optimal grade.

Tungsten Carbide: The Versatile Workhorse

Tungsten Carbide (TC) is a composite material made of hard tungsten carbide particles held in a softer, tougher metal binder, usually cobalt. By changing the amount of cobalt and the size of the TC particles, manufacturers can create a wide range of grades with different properties.

Key Advantages of TC

The standout feature of tungsten carbide is its excellent combination of hardness and toughness. While not as hard as diamond, it is far less brittle, making it much more resistant to fracture under high impact or when drawing irregularly shaped materials. This toughness, combined with its significantly lower cost, makes it incredibly versatile and economical for a huge range of jobs.

Primary Applications

Tungsten carbide is the go-to material for drawing harder materials, especially ferrous wires that would cause excessive wear on more expensive dies. Common applications include:

- High and low-carbon steel wire for ropes, springs, and tire reinforcement.

- Stainless steel wire for welding rods and medical devices.

- Large-diameter rods and bars (a process called bar drawing).

Just like with PCD, the specific grade of tungsten carbide is crucial. A grade with higher cobalt content will be tougher but less wear-resistant. Consulting your die supplier to match the right TC grade to your material and process is a critical step for success.

Natural Diamond: For Ultra-Fine Wire Applications

Natural Diamond (ND) is the original die material and remains the undisputed champion for a very specific niche: producing ultra-fine wires with a perfect surface finish. An ND die uses a single, high-quality industrial diamond, carefully oriented to leverage the crystal’s hardest plane.

Key Advantages of ND

What makes natural diamond special? It can be polished to a near-perfect mirror finish, which is a level of smoothness that even the finest PCD cannot match. This allows wire to be drawn through it with minimal friction, resulting in a flawless, mirror-like surface on the final product. Its unparalleled hardness also ensures incredible dimensional accuracy.

Primary Applications

The use of natural diamond is reserved for applications where the cost is justified by the extreme demand for quality and micro-dimensions, often for wires smaller than 0.01 mm in diameter. This includes:

- Gold and copper bonding wires for connecting microprocessor chips to their packages.

- Tungsten filaments for lighting and electronic applications.

- Specialized medical wires and surgical suture wires.

However, its single-crystal structure makes it brittle and prone to catastrophic failure if it encounters an impurity in the wire or an unexpected shock. This fragility, combined with its high cost, makes it unsuitable for general-purpose drawing.

Where are the products of wire drawing used?

So after all this complex engineering to create perfectly formed wires, where do they actually end up?

Products made through wire drawing are fundamental to nearly every aspect of modern life. They are used structurally in construction and infrastructure as steel cables and concrete reinforcement, functionally in electronics as copper and aluminum wiring, and universally in countless everyday consumer goods, from paper clips and springs to musical instrument strings.

The applications of drawn wire are so widespread that it’s nearly impossible to go through a day without using or relying on dozens of products that depend on it. From the largest bridges to the smallest microchips, these precisely engineered wires form the backbone of our world. Let’s explore some of the most significant areas.

In Construction and Infrastructure

In the world of construction, wire isn’t just for tying things together; it’s a primary structural component that provides immense strength and resilience. The high tensile strength achieved through work hardening makes steel wire an indispensable material for building the modern world.

Here are just a few critical examples:

- Suspension Bridge Cables: What holds up a massive suspension bridge? Not solid steel bars, but main cables composed of thousands of individual high-tensile steel wires bundled together. Each wire is drawn to an exact specification to ensure it carries its share of the immense load.

- Prestressed Concrete Strand: Look at a modern parking garage or bridge beam. It’s likely reinforced with prestressed concrete (PC) strand, a product made of multiple steel wires twisted together. This strand, often specified to standards like ASTM A416, is tensioned before the concrete sets, actively compressing the concrete and giving it incredible strength to span long distances without cracking.

- Reinforcement Mesh: The concrete slab your house is built on is likely strengthened by a grid of welded steel wire, known as wire mesh. This product, made from cost-effective drawn steel wire, provides tensile strength to the concrete, preventing it from cracking under stress.

- Fencing and Guy Wires: From simple chain-link fences to the guy wires that stabilize utility poles, drawn steel wire provides strength and durability against the elements.

In Electronics and Electrical Wiring

While construction relies on the strength of steel wire, our electronic world runs on the conductivity of copper and aluminum wire. In this field, the precision and smooth surface finish provided by diamond dies are crucial for ensuring efficient electrical flow and reliable performance.

Have you ever wondered what’s inside the power cord for your computer?

- Building and Power Wiring: The wires inside the walls of your home and the massive overhead cables that form the power grid are all made from drawn aluminum or copper. Stranded wire, which consists of many finer wires twisted together, is used where flexibility is needed, while solid-core wire is used for permanent installations.

- Magnet Wire: This is the hidden hero of every electric motor, transformer, and solenoid. Magnet wire is a copper or aluminum wire, drawn to a precise diameter and coated with a very thin layer of enamel insulation. It can then be tightly wound to create the electromagnetic coils that make these devices work.

- Data and Communication Cables: High-speed data transfer through Ethernet, coaxial, and other communication cables is only possible because of the high-quality, fine-gauge copper wires inside. Their consistent diameter and flawless surface, products of precision drawing, are essential for carrying high-frequency signals with minimal distortion.

- Automotive Wiring Harnesses: A modern car contains over a mile of wire, bundled into complex wiring harnesses that function as the vehicle’s central nervous system, controlling everything from the engine to the headlights.

In Everyday Consumer Goods

Beyond the massive scale of infrastructure and the high-tech world of electronics, drawn wire is quietly integrated into hundreds of products we use every single day. Often, we don’t even think of them as “wire.”

Ever stopped to think about how many drawn-wire products you might use before lunchtime?

- Springs and Fasteners: The spring in your retractable pen, the paper clip holding your documents, the staples in your stapler, and the metal frame of your coat hanger are all made from steel wire that was drawn to a specific size and temper.

- Musical Instruments: The beautiful sound from a piano, guitar, or violin comes from strings made of specialized steel, brass, or nylon wire. Each string is drawn to a painstakingly precise diameter to produce the correct musical note.

- Kitchen and Retail: Common items like kitchen whisks, dish racks, the wire basket of a shopping cart, and the shelves in a refrigerator are all constructed from steel wire that has been drawn, cut, bent, and welded.

- Medical Field: The applications in medicine are life-saving. Drawn wire is used to create everything from orthodontic braces and surgical staples to the incredibly fine and flexible guidewires that surgeons use in minimally invasive procedures.

How do you select the right die for a specific job?

With all these different materials and factors, how do you actually choose the perfect wire drawing die for a specific task?

Selecting the right wire drawing die involves a systematic evaluation of three key areas. First, you must match the die material to the wire material being drawn. Second, you need to consider operational factors like drawing speed and the area reduction ratio. Finally, you must weigh the long-term economics of die lifespan and maintenance requirements to find the most cost-effective solution.

Making the right choice is a balancing act between performance, quality, and cost. A die that is perfect for one job could be a costly failure in another. By carefully considering the following points, you can ensure you are using the most efficient and economical tool for your production needs.

Matching Die Material to Wire Material

This is the most fundamental step in the selection process. The interaction between the wire and the die determines the wear rate, surface finish, and overall success of the operation. Using the wrong die material on a wire can lead to rapid failure of the die, breakage of the wire, or a poor-quality final product.

The basic rule is to match the properties of the die to the demands of the wire.

| Die Material | Best For (Wire Type) | Key Reason |

|---|---|---|

| Tungsten Carbide (TC) | Hard, ferrous materials (steel, stainless steel) | Toughness. It can withstand the high stress and abrasive nature of steel. |

| Polycrystalline Diamond (PCD) | Softer, non-ferrous materials (copper, aluminum) | Wear Resistance. It provides extremely long life in high-speed applications. |

| Natural Diamond (ND) | Ultra-fine wires of any material (gold, tungsten) | Hardness & Polish. It creates a perfect surface finish on micro-wires. |

For instance, trying to use an expensive PCD die to draw large-diameter, abrasive steel rod would be a costly mistake; the die would likely fracture due to its lower toughness. Conversely, using a tungsten carbide die for high-speed copper drawing would result in rapid wear and frequent, costly downtime compared to a PCD die.

Factoring in Drawing Speed and Reduction Ratio

Beyond the materials, you must consider the specifics of the drawing process itself. Two of the most important operational parameters are speed and reduction ratio.

Drawing Speed

How fast will the wire be pulled through the die? Modern wire drawing machines can operate at speeds exceeding 2,500 meters per minute.

- High Speed: Generates immense heat. This favors PCD dies, which have excellent thermal conductivity and can dissipate heat quickly, protecting both the die and the wire.

- Low Speed: Generates less heat, making Tungsten Carbide a viable and cost-effective option.

Reduction Ratio

This refers to how much the wire’s cross-sectional area is reduced in a single pass. A typical reduction in area per die is between 15-25% for ferrous wires and 20-45% for non-ferrous wires.

- High Reduction: Puts enormous stress and pressure on the die. This often favors the superior toughness of Tungsten Carbide, which is less likely to fracture under extreme pressure.

- Low Reduction: Puts less stress on the die, allowing for a wider range of die material choices, often guided by speed and desired finish.

The optimal drawing speed and reduction ratios are highly dependent on your specific equipment and material grade. It is always best to consult the operational guidelines from your machine and die suppliers to determine the ideal parameters for your setup.

Key Considerations for Die Lifespan and Maintenance

Is the cheapest die always the most economical choice? Rarely. A smart selection process looks beyond the initial purchase price to the total cost of ownership4, which is heavily influenced by die life and maintenance.

Calculating the True Cost

Imagine you are producing copper wire. A tungsten carbide die might cost significantly less upfront than a PCD die. However, if the TC die must be replaced every day and the PCD die runs for three months straight, the “cheaper” option quickly becomes far more expensive. You must account for:

- The cost of replacement dies over time.

- The cost of production downtime during each die change.

- The potential for scrap wire produced as a die begins to wear out of tolerance.

For high-volume production, a longer-lasting die like PCD almost always provides a lower cost per meter of wire produced, despite its higher initial price.

The Importance of a Maintenance Schedule

Drawing dies are not disposable consumables; they are precision tools that can be maintained to extend their life significantly. A proactive maintenance program is essential for maximizing your investment.

Core Maintenance Practices

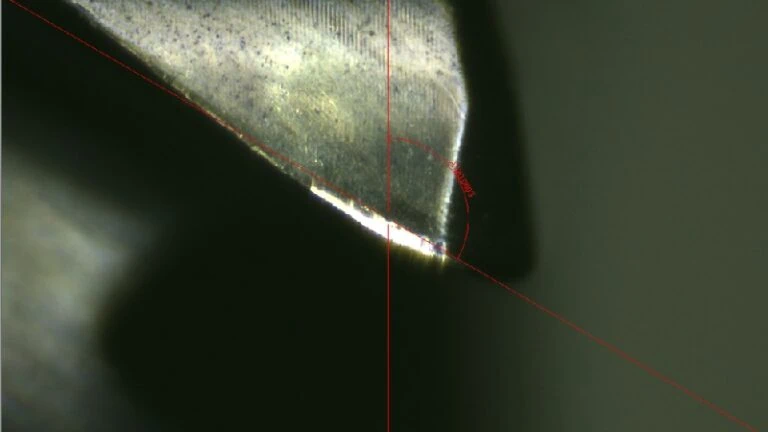

- Regular Inspection: Dies should be inspected frequently with a microscope to look for early signs of wear, such as a visible “wear ring” forming in the reduction zone.

- Thorough Cleaning: After use, dies must be cleaned, typically in an ultrasonic bath, to remove all lubricant residue and microscopic metal particles that could cause defects on the next run.

- Repolishing and Recutting: Once a wear ring appears, the die should be removed from service and sent for re-polishing. A skilled technician can polish away the worn area and resize the die to the next largest standard size. A single die can often be recut and polished multiple times, drastically extending its useful life.

Many die suppliers offer expert recutting services and can provide guidance on the optimal maintenance schedule for your specific application, ensuring you get the absolute maximum value from every die.

Conclusion

From its highly engineered internal profile to the advanced materials used in its construction, the wire drawing die is a remarkable tool that is fundamental to modern manufacturing. Understanding how it works reveals a sophisticated process of controlled deformation, managed by critical factors like lubrication and heat dissipation. The products created through this process are woven into the very fabric of our society, from massive infrastructure projects to the intricate electronics in our pockets. Ultimately, the ability to select the right die by balancing material science, operational demands, and long-term economics is what enables industries to produce the vast quantities of high-quality wire that our world depends on every day.

References

- work hardening1 – Wikipedia’s comprehensive article defining and explaining the phenomenon of work hardening, or strain hardening.

- annealing2 – A Wikipedia article detailing the annealing process in materials science, including its purpose and effects.

- extraordinary wear resistance3 – A ZYDiamondTools guide to the key properties of PCD, including hardness, toughness, and wear resistance.

- total cost of ownership4 – A ZYDiamondTools guide explaining the Total Cost of Ownership (TCO) concept as it applies to superhard tooling.