-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

What is a CBN Grinding Wheel: A Complete Guide

What exactly is a CBN grinding wheel and why is it becoming so popular?

A CBN grinding wheel is a high-performance abrasive tool made with Cubic Boron Nitride, the second-hardest material known. It is used for precision grinding hard, ferrous materials (like steel), offering significant advantages in longevity, cool grinding, and low-maintenance operation over traditional wheels.

What Exactly is a CBN Grinding Wheel?

So, what is a CBN grinding wheel, and what makes it special?

A CBN grinding wheel is a high-performance abrasive tool that uses Cubic Boron Nitride as its cutting material. Cubic Boron Nitride (CBN) is the second-hardest material known, surpassed only by diamond. These wheels are specifically designed for precision grinding very hard, ferrous (iron-based) materials like hardened steels.

What Does CBN Stand For?

“CBN” is the industry abbreviation for Cubic Boron Nitride1.

This is not a brand name; it is the name of the synthetic (man-made) abrasive crystal itself. Scientists created this material to be incredibly hard and thermally stable.

Because of its extreme hardness, CBN is known as a “superabrasive.” The only other material in this category is diamond, which means CBN is not just a “better” version of a normal grinding wheel; it’s in a completely different class of tool.

The Core Construction of a CBN Wheel

A common misconception is that a CBN wheel is a solid block of Cubic Boron Nitride. This is incorrect and would be incredibly expensive.

Instead, a CBN wheel has three main components:

- The Abrasive: These are the tiny, sharp particles of CBN that do the actual cutting.

- The Bond: This is the “glue” or “matrix” that holds the CBN particles in place. The bond anchors the particles, allowing them to cut effectively.

- The Core: This is the solid body of the wheel, usually made of steel or aluminum. The bond and abrasive mixture is applied as a layer to the edge or face of this core.

Think of it like this: the abrasive particles are the “cutting teeth,” the bond is the “jaw” that holds the teeth, and the core is the “body” that gives the tool its shape and stability. The specific type of bond used2 (such as vitrified, resin, or electroplated) is a critical factor in how the wheel performs, which we will cover later.

How CBN Wheels Differ from Traditional Abrasives

The most important difference to understand is how CBN wheels function compared to the “traditional” brown, white, or gray wheels. These common wheels are typically made from Aluminum Oxide or Silicon Carbide.

The key differences are not just in the material, but in the entire grinding philosophy.

- Traditional Wheels are “Friable”: This means their abrasive grains are designed to break down and wear away as they get dull. As they wear, new, sharp grains are exposed. This is why a traditional wheel gets smaller over time and constantly needs to be ‘dressed’ or reshaped.

- CBN Wheels are “Durable”: CBN is not friable. It is so hard and wear-resistant that the abrasive particles do not break down easily. The wheel is designed to hold its shape and profile far longer. It does not wear away rapidly, which is why a CBN wheel rarely needs dressing compared to its traditional counterparts.

Another core difference is heat. Aluminum Oxide is an insulator, meaning it traps heat at the point of contact. This is what causes a steel tool to overheat, turn blue, and lose its hardness (lose its “temper”).

CBN, on the other hand, is an excellent thermal conductor. It pulls heat away from your tool and puts it into the wheel body, where it dissipates. This keeps the cutting edge cool, protecting the tool from heat damage.

Here is a simple breakdown of the main property differences:

| Feature | Traditional Wheels (e.g., Aluminum Oxide) | CBN Wheels (Cubic Boron Nitride) |

|---|---|---|

| Abrasive Material | Aluminum Oxide, Silicon Carbide | Cubic Boron Nitride (a “superabrasive”) |

| Hardness | Hard | Exceptionally hard (second only to diamond) |

| Wear Action | Friable: Grains break down to expose new sharp edges. The wheel changes shape and size quickly. | Durable: Grains are extremely wear-resistant. The wheel holds its profile and shape. |

| Heat Handling | Insulator: Traps heat at the grinding point, which can burn the tool. | Conductor: Pulls heat away from the tool and into the wheel body, preventing overheating. |

Where Are CBN Grinding Wheels Best Used?

Now that you know the benefits, where is the right place to use a CBN wheel?

CBN grinding wheels are best used for grinding very hard, iron-based (ferrous) metals. Their primary application is sharpening tools made from High-Speed Steel (HSS), air-hardening tool steels (like A2 or D2), and other hardened steel alloys. They are the superior choice for these materials but should not be used on carbide.

What Materials Are Suitable for CBN Grinding?

The number one rule is simple: CBN is for hard ferrous materials. “Ferrous” just means the metal contains iron, which includes all types of steel.

CBN is chemically stable when it grinds iron, which is why it works so well. It is specifically designed for materials that are already hardened. Grinding soft, unhardened steel with a CBN wheel is possible, but it’s overkill and a waste of the wheel’s potential.

A good rule of thumb is to use CBN on steels with a hardness of 45 HRC (Rockwell Hardness C)3 or higher. While this is a general guide (and you should always check recommendations for your specific material), it’s the point where traditional wheels start to struggle, and CBN starts to shine.

Good materials for CBN:

- High-Speed Steel (HSS)4:** The most common use.

- Hardened Tool Steels: This includes A2, D2, M2, and other “alphabet steels.”

- Hardened Stainless Steels: Many modern stainless alloys are very hard and tough to grind.

- Superalloys: Iron or cobalt-based alloys (like Inconel) that are notoriously difficult to machine.

- Hardened Cast Iron

Specific Applications: Grinding High-Speed Steel (HSS) and Other Hard Alloys

Let’s look at real-world examples of where CBN is the clear winner.

High-Speed Steel (HSS)

This is the most important application for CBN. HSS is used for lathe tools, drill bits, and end mills precisely because it holds its hardness even when it gets hot (its “red hardness”).

However, when you sharpen HSS on a regular aluminum oxide wheel, you can easily generate too much heat. This creates the dreaded “blue” color, which means you have overheated the edge and ruined its temper, making it soft.

- Workshop Analogy: Using a traditional wheel on HSS is a gamble. You’re trying to sharpen the tool without damaging it. Using a CBN wheel is a guarantee. Because it grinds cool, it cannot overheat the tool.

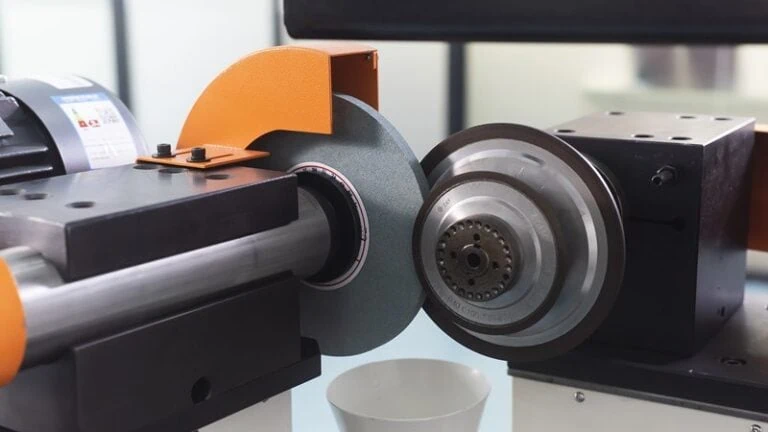

- Popular Case: Woodturning: The woodturning community has almost universally adopted CBN wheels. They sharpen HSS gouges and chisels constantly. A CBN wheel on a bench grinder (often an 8-inch, 180-grit wheel) gives them a perfect, repeatable, and fast-sharpening experience every time, without any fear of ruining their expensive tools.

Other Hard Alloys

This same benefit applies to any high-performance tool steel. If you are a machinist sharpening a custom lathe tool or a woodworker sharpening a high-end D2 steel chisel, CBN protects the investment you’ve made in that tool.

Will CBN Wheels Sharpen Carbide Lathe Tools?

This is a critical point, and the answer is a clear No. You should not use CBN to sharpen carbide.

This is the most common mistake new users make. They think, “Carbide is hard, CBN is hard… so it should work.” But it’s not about hardness; it’s about chemistry.

Tungsten Carbide (what most carbide tools are made of) is not a steel. It’s a “cermet,” a composite of ceramic (tungsten) and metal (cobalt binder). Using CBN on carbide is extremely inefficient. The wheel will “load up” (clog) with carbide dust, stop cutting, and can even be damaged.

This brings us to the most important rule in superabrasive grinding: use the right abrasive for the right material.

- CBN (Cubic Boron Nitride) is for Ferrous Metals (Steel, HSS, Cast Iron).

- Diamond is for Non-Ferrous & Non-Metals (Carbide, Glass, Ceramic).

Diamond, on the other hand, is the correct choice for carbide5. However, you must never use a diamond wheel on steel. Diamond is pure carbon. At the high temperatures of grinding, the carbon in the diamond wheel reacts with the iron in the steel. This chemical reaction (graphitization) causes the diamond abrasive to break down and wear out incredibly fast.

This is the simple takeaway:

| Abrasive | Best For | Worst For (Avoid) |

|---|---|---|

| CBN | Ferrous Metals: All hardened steels, HSS, stainless steel. | Carbide, Aluminum, Glass, Ceramics. |

| Diamond | Carbide (Tungsten), Glass, Ceramics, Stone. | Ferrous Metals: (All steels) – it will be destroyed. |

For a deeper dive into this critical decision, see our detailed guide on choosing between CBN and diamond wheels6.

How Do You Choose the Right CBN Grinding Wheel?

With so many options, how do you pick the right CBN wheel for your specific needs?

To choose the right CBN grinding wheel, you must match three main factors to your job: the wheel’s “bond type” (how the abrasive is held), the “grit size” (its coarseness), and the “physical specs” (like diameter, arbor hole, and profile) to fit your machine.

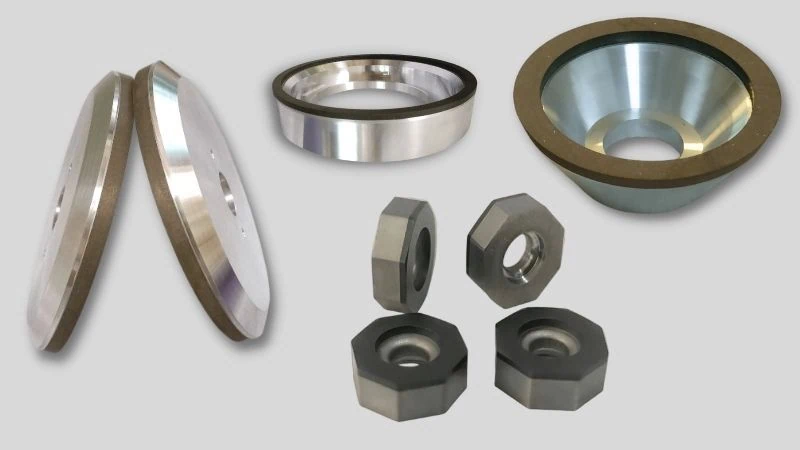

Understanding Different Bond Types (Vitrified, Resin, Metal, Electroplated)

The “bond” is the material that acts like glue, holding the tiny CBN abrasive particles in place. The type of bond completely changes how the wheel performs, how long it lasts, and what it costs.

Think of the bond as the “tool holder” for the abrasive grains. A very rigid, hard bond (like vitrified) is great for precision, while a single, exposed layer (electroplated) is very aggressive.

For most workshop applications, you will most likely use Electroplated wheels7.

Here is a simple breakdown of the common types:

| Bond Type | What It Is | Best For… |

|---|---|---|

| Electroplated | A single, highly concentrated layer of CBN plated onto a steel core. | Bench grinders, sharpening HSS tools, fast material removal. |

| Vitrified | A hard, porous, glass-like (ceramic) bond that holds the CBN. | High-precision CNC grinding, long life, excellent form holding. |

| Resin | CBN particles mixed into a softer, phenolic resin bond. | Tool & cutter grinders, applications needing a fine surface finish. |

| Metal | CBN particles are fused with metal powders to form a very tough bond. | Extreme durability, heavy-duty production, and grinding difficult alloys. |

For sharpening tools on a standard bench grinder, an electroplated wheel is the most common and effective choice. The particles are fully exposed, making them cut very aggressively and coolly.

Selecting the Correct Grit Size for Your Application

This is just like choosing sandpaper. The “grit” number tells you how coarse (aggressive) or fine (for finishing) the wheel is.

- Low Number = Coarse Grit (removes material fast, leaves a rough finish)

- High Number = Fine Grit (removes material slowly, leaves a sharp, polished finish)

Coarse Grits (e.g., 80 – 120)

These wheels are for heavy-duty work. You should choose a coarse grit if your primary goal is:

- Fast Material Removal: This is often called “hogging.”

- Reshaping: When you need to completely change the profile of a tool.

- Fixing Damaged Tools: Grinding out large nicks or chips.

Fine Grits (e.g., 180 – 220+)

These wheels are for the final sharpening and honing of an edge.

- Final Sharpening: Creates a clean, razor-sharp edge.

- Touching Up: A few light passes will restore a slightly dull edge.

- Better Surface Finish: Leaves the tool face smooth and polished.

Common Choice: For many users, especially woodturners sharpening HSS gouges, a 180-grit wheel is seen as the perfect “all-around” choice. It’s fine enough to produce a fantastic cutting edge but still aggressive enough to sharpen a dull tool quickly without needing to switch wheels.

Important Considerations: Wheel Diameter, Profile, and RPM

This final step is about matching the wheel to your grinder for safety and proper function.

Wheel Diameter and Arbor Hole

This is the most basic requirement.

- Diameter: The wheel’s diameter (e.g., 8 inches) must match what your grinder is designed for.

- Arbor Hole: This is the center hole in the wheel. It must match the diameter of your grinder’s shaft (e.g., 5/8″ or 1/2″). A wheel that doesn’t fit the arbor is useless.

Wheel Profile

For bench grinders, you will almost always use a Type 1 wheel. This is a standard flat wheel where the abrasive is on the outer face (the edge). You may also see wheels with abrasive on the side or with a special radius, but these are for more specialized tool-grinding machines.

RPM (Grinder Speed)

This is a critical factor for both safety and performance.

- Safety: Every wheel has a maximum RPM rating printed on it. You must never run a wheel on a grinder that spins faster than this rating.

- Performance: Most bench grinders are either “low speed” (around 1750 RPM) or “high speed” (around 3450 RPM). CBN generally performs exceptionally well at high speeds, as it cuts more efficiently.

However, the “best” speed can depend on the wheel’s bond type and what you are grinding. Always check the manufacturer’s recommendation for the specific wheel you bought. They will list the optimal or required RPM range to ensure both safety and the best grinding results.

Conclusion

Switching to a CBN grinding wheel is a significant upgrade for any workshop that works with hardened steel. While the initial cost is higher, the benefits are clear: a cool-grinding, low-maintenance wheel that lasts for years and won’t damage your tools.

By understanding that CBN is for steel (and diamond is for carbide) and selecting the right grit and bond for your application, you can save time, money, and frustration. The result is a faster, more consistent sharpening process that gives you a better, stronger, and longer-lasting cutting edge every time.

References

- Cubic Boron Nitride1 – Wikipedia article explaining the science and properties of the cubic form of boron nitride.

- The specific type of bond used2 – ZYDiamondTools blog post explaining the different grinding wheel bond types and how to select one.

- 45 HRC (Rockwell Hardness C)3 – Wikipedia article defining the Rockwell scale for measuring material hardness.

- High-Speed Steel (HSS)4 – Wikipedia article detailing the properties and applications of High-Speed Steel.

- correct choice for carbide5 – ZYDiamondTools blog post guiding the selection of diamond wheels specifically for grinding tungsten carbide.

- choosing between CBN and diamond wheels6 – ZYDiamondTools blog post that directly compares CBN and diamond wheels to help users choose the right one.

- Electroplated wheel7 – ZYDiamondTools product page for electroplated bond diamond and CBN wheels.