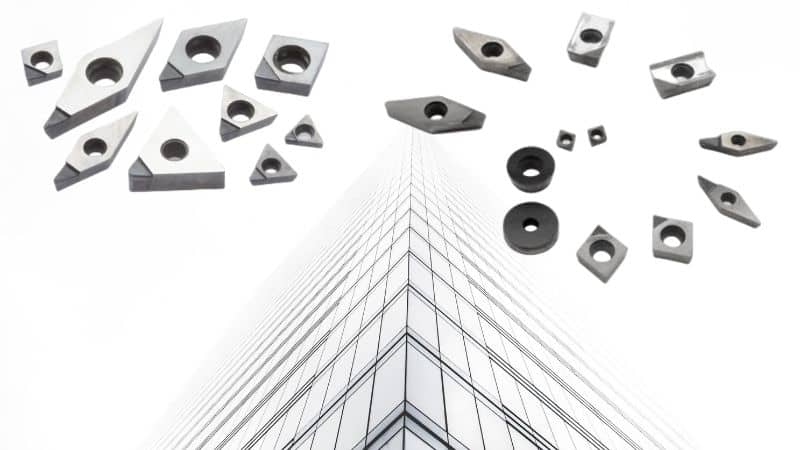

What Are PCD Inserts

The full name of PCD is Polycrystalline Diamond, which is a kind of synthetic diamond. It is a polycrystal produced by mixing the diamond powder with a small amount of metal powder and sintering it at high temperatures (1400℃) and high pressure. It has a hardness of up to 6000 HV.

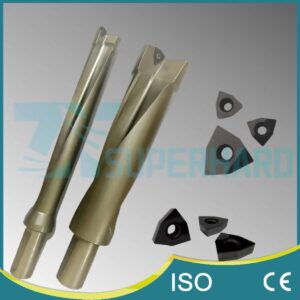

PCD inserts are turning tools made of PCD, supplemented by a binding agent.

What Are PCD Inserts Used For?

PCD has very high abrasion resistance and toughness, which makes it ideal for cutting high-hardness materials. It is capable of cutting materials at a very high speed. This can save time and increase efficiency.

PCD inserts are commonly used for machining non-ferrous materials, of which aluminum is the most popular. However, it is not well suited for processing ferrous metals. Because ferrous metals often contain carbides that can chemically react with the carbide matrix of PCD inserts, resulting in a shortened life of the PCD inserts.

Advantages And Disadvantages Of PCD Inserts

Advantages

- Excellent wear resistance and toughness

- Very high-cutting speed

- Extremely high corrosion resistance

- High polishing precision

- Long service life

Disadvantages

- High price

- A bit brittle

Typical Application Areas For PCD Inserts

3C Industry

A large number of aluminum materials are used in the manufacture of 3C products. PCD inserts perform very well when processing these materials, which require a very high degree of fineness.

Aerospace Industry

With the rapid development of the aerospace industry and the use of composite materials, fibers, etc., PCD inserts have a long service life and ensure consistent dimensions. At the same time, there is no need to change tools frequently, which reduces the labor intensity of workers. Therefore, the application of PCD inserts in this field also shows an upward trend.

Automotive Industry

Aluminum alloy materials are increasingly used in the automotive industry. It plays a significant role in the lightweight and miniaturization of the whole car. Therefore, PCD inserts are also widely used in the automotive industry.

Construction Industry

Due to aluminum’s light weight and corrosion resistance, aluminum and aluminum alloy are widely used in the construction industry, such as aluminum ceiling, aluminum square pass, aluminum veneer, aluminum curtain wall, and so on. Therefore, PCD inserts are also often used.

Conclusion

In conclusion, compared with other turning tools, PCD inserts have undeniable advantages when machining aluminum. If you want to improve efficiency and save costs, you may give it a try.