-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

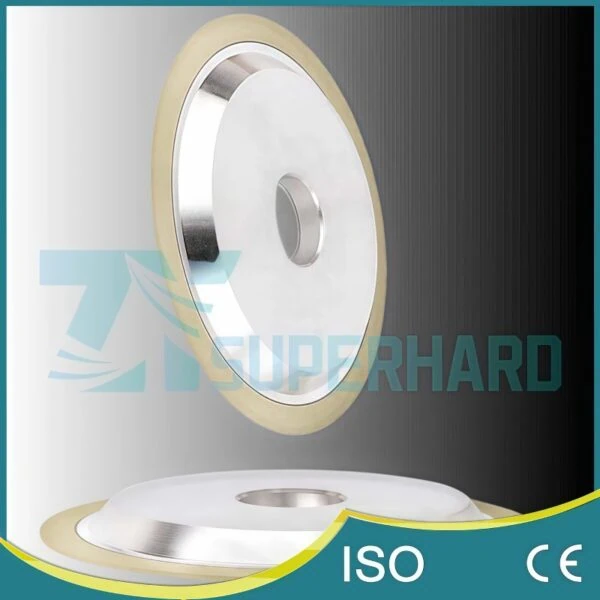

Vitrified Bond Diamond & CBN Grinding Wheels: A Comprehensive Guide to Selection and High-Performance Grinding

When looking to optimize your precision grinding operations, how can you fully understand and best utilize vitrified bond diamond and CBN grinding wheels?

Vitrified bond diamond and CBN grinding wheels represent advanced tooling designed for high-performance grinding of hard and brittle materials. Understanding their unique properties, knowing when to use diamond versus CBN, correctly selecting wheel specifications, and recognizing their operational benefits are key to maximizing precision, efficiency, and cost-effectiveness in demanding industrial applications.

This guide provides comprehensive insights into the vitrified bonding system, helps you choose the right abrasive and wheel parameters for your specific needs, and highlights the tangible performance and economic advantages these wheels can bring to your manufacturing processes.

What Makes Vitrified Bond Superabrasive Wheels Unique and Highly Effective?

So, what exactly sets vitrified bond superabrasive wheels apart and makes them so effective for tough grinding jobs?

Vitrified bond superabrasive wheels are unique because their glass-like ceramic bond securely holds superabrasive grains like diamond or CBN, creating a strong, rigid, and porous structure. This design allows for excellent form holding, efficient material removal, and superior performance in high-precision grinding of very hard materials.

Their effectiveness stems from key properties like high thermal stability for demanding applications, controlled porosity for better cooling and chip clearance, and exceptional wear resistance. These characteristics lead to longer wheel life, improved workpiece quality, and suitability for automated grinding processes where consistency is crucial.

Understanding the Vitrified Bonding System: Key Characteristics and Benefits

The vitrified bonding system is a bit like making high-tech pottery. Imagine mixing super-strong abrasive particles, either diamond or CBN (Cubic Boron Nitride), with special clays and other ceramic materials. This mixture is then pressed into the shape of a grinding wheel and fired at very high temperatures1 in a kiln, often exceeding 1000°C (1832°F). This intense heat melts the ceramic materials, causing them to fuse and form an exceptionally strong, glass-like (vitreous) structure that locks the abrasive grains firmly in place. Think of it as tiny “posts” of super-strong ceramic holding each cutting grain.

This process results in several key characteristics and direct benefits:

- Exceptional Strength and Adhesion: The vitrified bond forms a powerful mechanical and chemical grip on the abrasive grains. Consequently, the grains are less likely to pull out prematurely, ensuring they are used effectively for cutting. This leads to more efficient grinding.

- Inherent Porosity: During firing, the bonding materials create a network of interconnected pores or tiny air pockets throughout the wheel’s structure. This isn’t a flaw; it’s a design feature! We’ll explore why this is so important shortly.

- Chemical Inertness: Once fired, the vitrified bond is very stable and doesn’t easily react with coolants or the materials being ground. This stability contributes to a longer-lasting and predictable grinding performance.

- Dressability: Despite their hardness, vitrified bonds can be effectively “dressed.”2 Dressing is like sharpening a pencil; it removes worn abrasive grains and any embedded material (loading), exposing fresh, sharp cutting edges and restoring the wheel’s desired shape. This ability to be reconditioned is a significant advantage for consistent, long-term use.

Core Properties: Examining Porosity, Rigidity, Thermal Stability, and Wear Resistance

Several core properties make vitrified bond wheels stand out. These properties are engineered into the wheel and are crucial for their high performance.

Controlled Porosity: The Space for Performance

Porosity refers to the tiny, interconnected voids or pores within the grinding wheel’s structure. Why would empty space be a good thing?

- Coolant Delivery: These pores act like channels, allowing grinding fluids (coolants) to reach the cutting zone more effectively. This is vital for cooling the workpiece and the wheel, especially when grinding heat-sensitive materials like aerospace superalloys or some tool steels. Better cooling prevents thermal damage, such as burn marks or micro-cracks, on the workpiece.

- Chip Clearance: As the wheel grinds, tiny chips of material are removed. The pores provide space for these chips to escape, preventing them from clogging the wheel’s surface (a condition known as “loading”). A loaded wheel cuts poorly and generates excessive heat. For instance, when grinding gummy materials like some stainless steels or aluminum (though diamond/CBN are less common for aluminum), adequate chip clearance is paramount.

- Reduced Loading: With efficient chip removal, the abrasive grains remain exposed and ready to cut, maintaining the wheel’s sharpness and cutting efficiency.

The level of porosity can often be tailored during manufacturing. Different grinding applications may benefit from different porosity levels. For example, a higher porosity might be chosen for rapid stock removal where chip volume is high, while a lower porosity might be used for achieving very fine surface finishes. It’s always a good idea to discuss your specific application and material with your supplier, as they can guide you on the optimal porosity range and other wheel specifications.

High Rigidity: Holding the Line for Precision

Rigidity, or stiffness, means the wheel strongly resists bending or changing its shape under grinding forces. Imagine trying to write precisely with a flimsy pen versus a sturdy one; the sturdy one gives you more control.

- Form Holding: Vitrified bonds are very rigid. This allows the wheel to maintain its precise profile or shape for longer periods, even when grinding complex forms or hard materials. This is critical in applications like grinding the intricate flutes of a carbide drill bit or the precise profile of a gear. If the wheel deforms, the workpiece won’t meet the required dimensional accuracy.

- Dimensional Accuracy: Because the wheel holds its shape, it can produce parts with very tight tolerances, meaning the parts are consistently the correct size and shape. This is essential in industries like automotive component manufacturing (e.g., grinding camshaft lobes) or bearing production.

- Reduced Vibration: A rigid wheel is less prone to vibration during grinding, which can lead to a better surface finish on the workpiece and reduced wear on the grinding machine’s spindles.

Excellent Thermal Stability: Standing Up to the Heat

Thermal stability3 is the ability of the vitrified bond to withstand high temperatures without degrading or losing its strength. Grinding, especially at high speeds or with heavy material removal, generates significant heat right where the wheel touches the workpiece.

- High-Temperature Operations: Vitrified bonds don’t soften or break down easily at the temperatures commonly encountered in aggressive grinding operations. This makes them suitable for high-speed grinding and for use with CBN abrasives, which are often used to grind hard steels at high temperatures where their cutting efficiency is optimal.

- Bond Integrity: The bond’s ability to resist thermal shock (rapid changes in temperature) ensures that the abrasive grains remain securely held, even under demanding conditions. For example, in internal grinding of hardened steel bores, where coolant access can be limited, the bond’s thermal stability is crucial.

Superior Wear Resistance: Lasting Longer

Wear resistance in this context refers to how well the vitrified bond itself resists erosion and breakdown during the grinding process.

- Extended Wheel Life: A bond that wears slowly means the wheel lasts longer. The strong ceramic posts holding the abrasive grains are eroded at a controlled rate, ideally matching the wear rate of the abrasive itself. This ensures that new, sharp abrasive edges are exposed just as the old ones become dull, maintaining cutting efficiency over time.

- Consistent Performance: Because the bond wears predictably, the grinding performance remains more consistent throughout the wheel’s usable life. This is particularly important for automated or CNC grinding operations where predictable tool life is essential for production planning. For instance, a factory producing thousands of precision tool steel punches daily relies on the consistent wear of vitrified CBN wheels for unattended operation.

Decisive Advantages: Why Choose Vitrified Bonds Over Resin, Metal, or Electroplated Options?

While resin, metal, and electroplated bonds each have their place, vitrified bonds offer a unique combination of properties that make them the preferred choice for many demanding superabrasive applications. Why might you select a vitrified bond wheel over others?

Consider this comparison:

| Feature | Vitrified Bond | Resin Bond4 | Metal Bond5 | Electroplated Bond |

|---|---|---|---|---|

| Primary Binder | Ceramic (Glass-like) | Phenolic or Polyimide Resins | Metal powders (e.g., Bronze, Steel, Nickel alloys) | Nickel coating |

| Rigidity/Form Holding | Very High | Moderate to Good | Highest | Moderate (depends on core) |

| Porosity Control | Excellent (can be engineered) | Limited | Very Low / None | None (single abrasive layer) |

| Thermal Stability | Excellent | Moderate (can soften at high temps) | Very High | Good (limited by abrasive/core) |

| Dressability | Good (standard methods) | Good | Difficult (requires specialized techniques) | Not Dressable |

| Abrasive Layers | Multiple | Multiple | Multiple | Single Layer |

| Typical Wheel Life | Long to Very Long | Moderate to Long | Very Long | Short to Moderate (depends on application) |

| Impact Resistance | Moderate | Good | Highest | Low to Moderate |

| Common Use Case | High precision, form holding, CNC grinding, hard materials | General purpose, fine finishing, tool sharpening | Extreme wear resistance, cut-off, some profiling | Complex forms, rapid initial stock removal |

Let’s break down some key comparisons:

Vitrified vs. Resin Bonds

Resin bonds are somewhat softer and more elastic than vitrified bonds. This can be an advantage in applications requiring a very fine finish or where there’s a lot of shock or vibration. However, for high-precision tasks:

- Vitrified bonds offer superior rigidity. This means better form holding and dimensional accuracy, critical for CNC operations where the wheel’s shape must be maintained. For example, in producing complex geometries on carbide cutting tools, vitrified diamond wheels outperform resin bonds in maintaining tight tolerances over long production runs.

- Vitrified bonds have higher thermal stability. They can handle higher temperatures without the bond degrading, allowing for more aggressive material removal rates.

- Vitrified bonds allow for engineered porosity. This leads to better coolant delivery and chip clearance, which is often limited in resin bonds.

Vitrified vs. Metal Bonds

Metal bonds are extremely tough and offer the highest level of wear resistance, making them suitable for very demanding applications. However:

- Vitrified bonds are generally more free-cutting due to their porous structure, which can lead to lower grinding forces and less heat generation in certain applications.

- Vitrified bonds are significantly easier to dress and true. Metal bond wheels often require specialized dressing tools and techniques, which can be time-consuming. This ease of dressing for vitrified wheels means less downtime and more consistent performance. For example, re-profiling a metal bond wheel used for grinding deep forms in steel can be a complex operation, whereas a vitrified CBN wheel for a similar, though perhaps less aggressive, task can be dressed more readily on the machine.

Vitrified vs. Electroplated Bonds

Electroplated wheels have a single layer of abrasive particles (diamond or CBN) electrochemically bonded to a metal core, typically with nickel. They offer a very aggressive initial cut and are excellent for grinding complex forms where dressing is not feasible. But:

- Vitrified bonds have multiple layers of abrasive. This means they can be dressed multiple times, exposing fresh abrasive, leading to a much longer overall tool life compared to single-layer electroplated wheels.

- Vitrified bonds offer more consistent performance over their lifespan. As an electroplated wheel wears, its cutting ability diminishes because there are no underlying abrasive layers. A vitrified wheel, when dressed, presents a renewed cutting surface.

- While electroplated wheels are good for intricate profiles initially, maintaining that profile over many parts is a challenge. Vitrified wheels, due to their dressability and rigidity, can maintain profile accuracy for a much larger production volume.

In essence, the unique manufacturing process and resulting properties of vitrified bonds—especially their engineered porosity, high rigidity, thermal stability, and good dressability—make them highly effective for a wide range of precision grinding tasks with superabrasives, striking an excellent balance between aggressive cutting action, precision, and overall tool life.

Diamond or CBN: Which Abrasive is the Right Choice for Your Specific Material and Application?

When it comes to superabrasive grinding wheels, how do you decide whether diamond or CBN is the correct cutting material for your job?

Choosing between diamond and CBN superabrasives6 depends primarily on the material you are grinding. Diamond is generally the best choice for non-ferrous (not iron-based) and non-metallic materials, such as tungsten carbide, ceramics, and glass, due to its extreme hardness.

Conversely, CBN (Cubic Boron Nitride) excels when grinding hard ferrous materials like hardened steels, tool steels, and superalloys. This is because CBN maintains its hardness and chemical stability at high temperatures in the presence of iron, a scenario where diamond would rapidly degrade.

Diamond Vitrified Wheels: When and Why to Use Them

Diamond is famously known as the hardest natural material on Earth. It’s made of carbon atoms locked in a very strong crystal structure. This incredible hardness makes vitrified diamond grinding wheels the top choice for shaping and finishing some of the toughest and most abrasive materials, especially those that are not iron-based. If you’re working with something extremely hard and brittle, diamond is often the answer.

Optimal Materials for Diamond (e.g., Tungsten Carbide, Ceramics, Glass, Composites, PCD/PCBN)

Vitrified diamond wheels are highly effective when grinding:

- Tungsten Carbide7 (and other cemented carbides): This material is incredibly hard and wear-resistant, commonly used for cutting tools, dies, and wear parts. Diamond’s superior hardness allows for efficient material removal and the creation of sharp, precise edges.

- Advanced Ceramics: This group includes materials like alumina (aluminum oxide), zirconia, silicon carbide, and silicon nitride. These are used for their heat resistance, wear resistance, and electrical properties. For example, grinding a zirconia ceramic component for a medical implant requires the precision and cutting power of a diamond wheel.

- Glass (Optical and Technical): From telescope lenses to specialized industrial glass components, diamond wheels can grind and shape glass with high precision.

- Composites: Materials like Carbon Fiber Reinforced Plastics (CFRPs), Glass Fiber Reinforced Plastics (GFRPs), and Ceramic Matrix Composites (CMCs) are known for being tough and abrasive. Diamond effectively cuts through the hard reinforcing fibers and the matrix material.

- PCD (Polycrystalline Diamond) and PCBN (Polycrystalline Cubic Boron Nitride)8: Interestingly, diamond wheels are also used to manufacture and resharpen tools made from other superabrasive materials like PCD and PCBN. This shows just how capable diamond abrasives are.

It’s worth noting that the specific grade and composition of these advanced materials can vary. Therefore, consulting with your grinding wheel supplier can help fine-tune the diamond wheel specification for optimal results on your particular material.

Common Industrial Applications for Vitrified Diamond Wheels

You’ll find vitrified diamond wheels performing critical tasks in many industries:

- Cutting Tool Manufacturing: This is a major application. Diamond wheels are essential for manufacturing and resharpening solid carbide drills, end mills, reamers, and inserts. For instance, creating the complex flute geometry of a carbide end mill requires highly precise vitrified diamond grinding.

- Electronics Industry: Used for slicing and dicing silicon wafers for microchips, grinding ceramic substrates for circuit boards, and shaping ferrite components for electronics.

- Optics and Photonics: Precision grinding of glass lenses, prisms, mirrors, and fiber optic components.

- Aerospace and Automotive: Grinding ceramic wear parts, thermal barrier coatings, and finishing composite components used in aircraft and high-performance vehicles.

- Medical Device Manufacturing: Shaping ceramic and carbide components for surgical tools and implants.

CBN (Cubic Boron Nitride) Vitrified Wheels: When and Why to Use Them

CBN (Cubic Boron Nitride) is a man-made material, second only to diamond in hardness. It was specifically developed to tackle a major challenge: efficiently grinding hard, iron-based (ferrous) materials. While diamond is harder, CBN has a crucial advantage when it comes to grinding steels – it doesn’t easily react chemically with iron, especially at the high temperatures generated during grinding. This thermal and chemical stability makes it the go-to abrasive for these tough metals.

Optimal Materials for CBN (e.g., Hardened Steels, Tool Steels, Superalloys, Cast Iron)

Vitrified CBN wheels are the premier choice for grinding:

- Hardened Steels: This includes steels heat-treated to high hardness levels (typically 50 HRC and above), such as bearing steels (like 52100), die steels (D2, A2), and case-hardened components.

- Tool Steels: High-Speed Steels (HSS like M2, T15), cold work tool steels, and hot work tool steels. These are used to make cutting tools, punches, and dies. For example, sharpening an HSS milling cutter with a vitrified CBN wheel restores its cutting edges efficiently.

- Superalloys: These are high-performance alloys, often nickel-based (e.g., Inconel®, Hastelloy®) or cobalt-based (e.g., Stellite®), many of which are compatible with CBN grinding. They are used in high-temperature environments like jet engines and turbines.

- Cast Iron: Particularly chilled cast iron or hardened grades of cast iron, which can be quite abrasive and hard.

Similar to advanced non-metallic materials, the specific alloy composition and heat treatment of these ferrous metals can influence grinding performance. Discussing your exact workpiece material with your supplier will help ensure you get the most suitable CBN wheel.

Common Industrial Applications for Vitrified CBN Wheels

Vitrified CBN wheels are workhorses in these key sectors:

- Automotive Industry: Precision grinding of critical engine and transmission parts like crankshafts, camshafts, gears, fuel injection nozzles, and valve lifters. For example, grinding the journals of a hardened steel crankshaft to achieve precise diameters and smooth surface finishes is a common CBN application.

- Aerospace Industry: Grinding high-strength, heat-resistant superalloy components for jet engines (e.g., turbine blades, discs, shafts) and landing gear systems.

- Bearing Manufacturing: Grinding the inner and outer races, rollers, and balls for various types of bearings to extremely tight tolerances.

- Tool and Die Making: Manufacturing and resharpening HSS and other steel cutting tools, grinding stamping dies, and forming tools.

- General Precision Engineering: Internal grinding of hardened steel bores, surface grinding of precision machine tool components, and jig grinding operations.

Critical Selection Factor: Understanding Chemical Compatibility with Your Workpiece

The most important reason for choosing between diamond and CBN often comes down to simple chemistry. What happens when these super-hard materials meet your workpiece at high grinding speeds and temperatures?

- Diamond’s Challenge with Iron: Diamond is made of carbon. When diamond grinds ferrous materials (those containing iron, like steel) at high temperatures, a chemical reaction can occur. The carbon in the diamond can react with the iron in the workpiece to form iron carbide. This process, sometimes called “graphitization” or chemical wear, causes the diamond abrasive to break down and wear out very quickly. This makes diamond generally unsuitable for efficiently grinding most steels.

- CBN’s Advantage with Iron: CBN, on the other hand, is made of boron and nitrogen. It is much more chemically stable when grinding iron-based materials at high temperatures. It doesn’t readily react with iron, so it maintains its hardness and sharp cutting edges much longer than diamond would in the same application. This is why CBN was specifically developed—to effectively grind hard ferrous metals.

The Consequences of an Incorrect Choice:

- Using diamond on steel: You’ll likely experience extremely rapid wheel wear, a poor surface finish (possibly with burn marks), and significantly higher costs due to frequent wheel replacement.

- Using CBN on some non-metals: While CBN can grind some non-metallic materials, diamond is usually the more effective and economical choice for materials like tungsten carbide, ceramics, or glass due to its superior hardness.

Therefore, the fundamental rule is quite clear:

- Use Diamond for: Hard non-metallic materials (ceramics, carbides, glass, stone) and non-ferrous metals.

- Use CBN for: Hard ferrous metals (steels, cast irons, and many superalloys).

Understanding this chemical compatibility is the cornerstone of selecting the right superabrasive for your vitrified bond grinding wheel, ensuring efficient, high-quality, and cost-effective grinding operations.

How Can You Confidently Select the Optimal Vitrified Wheel Specifications for Peak Performance?

Once you’ve chosen between diamond or CBN, how do you navigate the many specifications to pick the perfect vitrified grinding wheel for your specific job?

Selecting the optimal vitrified wheel specifications involves understanding key parameters like abrasive grit size, concentration, and bond hardness (grade), which dictate cutting action and finish. You also need to choose the correct wheel shape and dimensions compatible with your grinding machine and the geometry of the part you’re grinding.

Furthermore, success depends on matching these specifications to your operational goals, such as desired material removal rate and surface finish, and implementing the right coolant strategy. Careful consideration of these interconnected factors ensures peak performance and efficiency from your vitrified superabrasive wheel.

Deciphering Key Wheel Parameters: Abrasive Grit Size, Concentration, and Hardness Grade

Understanding the “language” of wheel specifications is the first step to making an informed choice. Three fundamental parameters define the cutting portion of your vitrified superabrasive wheel: grit size, concentration, and hardness grade.

Abrasive Grit Size: The Sharpness of Your Tool

Imagine sandpaper – some types are very rough for removing lots of material quickly, while others are fine for a smooth touch. Abrasive grit size in a grinding wheel works similarly.

- What it is: Grit size refers to the physical size of the individual diamond or CBN abrasive particles. It’s typically indicated by a number (e.g., based on mesh screen sizes like FEPA or ANSI standards). A smaller number (like 80 grit) means larger, coarser particles, while a larger number (like 600 grit) means smaller, finer particles.

- Its effect:

- Coarse Grits (e.g., 60/80 to 120/140): These larger particles take bigger “bites” out of the material. They are excellent for rapid material removal (stock removal) but will leave a rougher surface finish. For instance, when initially shaping a hardened steel component, a D181 (80/100 mesh) vitrified CBN wheel might be used.

- Medium Grits (e.g., 140/170 to 230/270): These offer a balance between decent material removal and a reasonable surface finish. They are often used for general-purpose grinding or as an intermediate step.

- Fine Grits (e.g., 270/325 and finer): Smaller particles take tiny “bites,” resulting in a smoother surface finish but slower material removal. These are used for finishing operations where precision and low surface roughness are critical. A D46 (325/400 mesh) vitrified diamond wheel might be used to achieve a fine finish on a ceramic seal. For ultra-fine finishes, even finer micron-sized grits are available.

- Selection Tip: The choice depends on how much material you need to remove and the final surface quality required. Hard, brittle materials often respond well to finer grits, while some ductile materials may need coarser grits to prevent the wheel from “loading up” with material. Grit size recommendations can vary significantly based on the specific material subtype and desired grinding outcome. Therefore, it’s highly advisable to consult your wheel supplier for detailed guidance tailored to your application.

Abrasive Concentration: How Many Cutters?

Concentration tells you how much superabrasive (diamond or CBN) is packed into the working part of the grinding wheel.

- What it is: It’s the amount of abrasive grains per unit volume of the abrasive layer. It’s often expressed as a number, where 100 concentration represents a standard amount (e.g., 4.4 carats of diamond per cubic centimeter for 100 concentration). Other common concentrations are 50, 75, and 125.

- Its effect:

- Higher Concentration (e.g., C100, C125): More cutting points are actively working. This can lead to faster material removal (up to a point), longer wheel life (as there’s more abrasive to wear), and better form holding (the wheel keeps its shape better). This is often preferred for grinding very hard or brittle materials, or when maintaining an intricate wheel profile is crucial. For example, a vitrified diamond wheel with C100 concentration might be used for grinding precision grooves in tungsten carbide.

- Lower Concentration (e.g., C50, C75): Fewer cutting points are engaged. This can result in a more “free-cutting” action, potentially reducing grinding heat and forces in some applications. It might be chosen for grinding large surface areas or when the cost of the wheel is a significant factor for less demanding jobs.

- Selection Tip: The ideal concentration often depends on the grit size, the material being ground, and the contact area between the wheel and the workpiece. A larger contact area might benefit from a lower concentration to reduce grinding forces. Since the optimal concentration is linked to other wheel parameters and the specifics of your operation, it’s wise to seek expertise from your wheel provider to make the best selection.

Hardness Grade (Bond Hardness): Holding Power of the Bond

This doesn’t refer to the hardness of the diamond or CBN itself (which are already superhard!), but rather to how strongly the vitrified bond material holds onto those abrasive grains.

- What it is: The “grade” indicates the tenacity of the bond posts. It’s typically represented by letters of the alphabet – progressing from soft (e.g., G, H, J) to hard (e.g., R, S, T).

- Its effect (The “Self-Sharpening” Principle):

- Softer Grades: The bond releases dull abrasive grains more easily, exposing fresh, sharp grains underneath. This “self-sharpening” action is good for grinding very hard materials, large surface areas, or when trying to prevent the wheel from loading or glazing (becoming smooth and losing its cut). However, a softer grade wheel will generally wear faster. For instance, a J-grade vitrified CBN wheel might be used for surface grinding a large, hardened tool steel plate to ensure consistent cutting.

- Harder Grades: The bond holds onto the abrasive grains for a longer time. This is beneficial for maintaining precise wheel profiles (good form holding) and can lead to longer wheel life if the abrasive grains don’t dull too quickly. Harder grades are often used for softer materials or when the contact area is small. If the grade is too hard for the application, the dull grains won’t be shed, and the wheel can glaze, losing its cutting ability.

- Selection Tip: The goal is to achieve a balance where the bond wears away just as the abrasive grains become dull. If grinding a very hard material, a softer bond allows for continuous exposure of new sharp points. If grinding a softer material, a harder bond can be used to prolong wheel life. Bond grade selection is a critical balance. The optimal grade can differ significantly even for the same workpiece material if other grinding conditions (like machine stability or speeds) change, so expert advice from your wheel manufacturer is invaluable.

Choosing the Correct Wheel Shape, Dimensions, and Core Material for Your Machine

Once you have an idea of the abrasive specifications, you need to ensure the wheel physically fits your machine and can reach the surface you intend to grind.

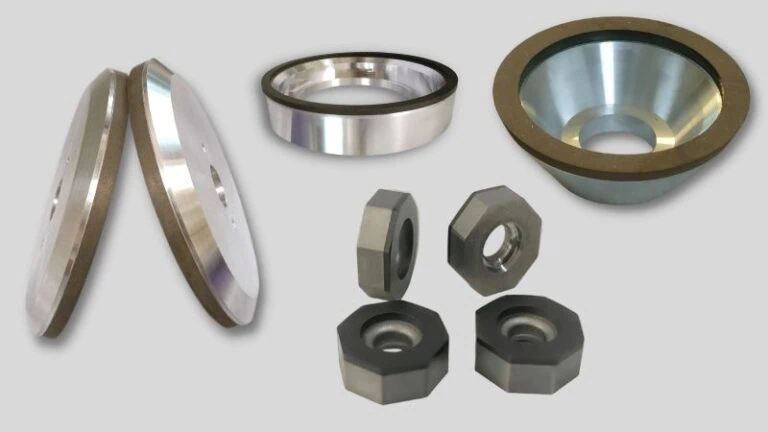

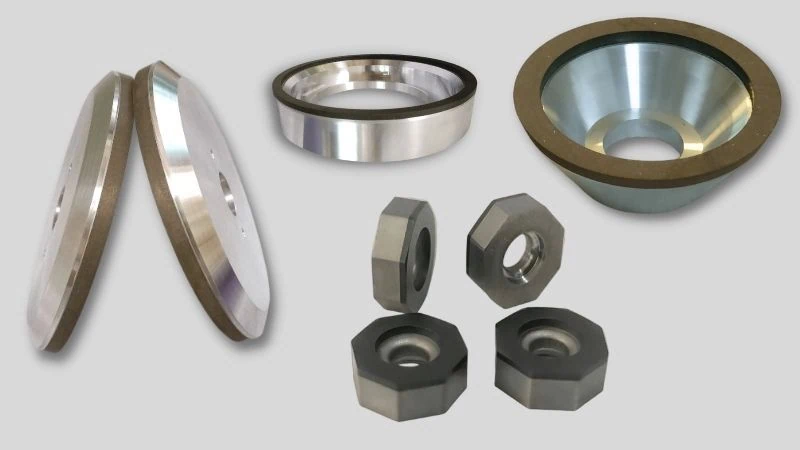

- Wheel Shape: Grinding wheels come in many standard shapes, often designated by types (e.g., ANSI or FEPA standards).

- Common Shapes:

- Type 1 (Straight Wheel): Used for general surface grinding, cylindrical grinding, and tool sharpening.

- Type 6 (Straight Cup Wheel) & Type 11 (Flaring Cup Wheel): Used for surface grinding, tool and cutter grinding, and grinding flat surfaces with the face of the wheel.

- Type 12 (Dish Wheel): Often used for tool and cutter grinding, especially for grinding in slots or creating specific profiles.

- The shape is chosen based on the grinding operation (e.g., surface grinding, internal grinding, tool grinding) and the geometry of the workpiece. For example, grinding the internal bore of a hardened gear would require an internal grinding wheel, often a smaller diameter Type 1 wheel, perhaps mounted on a quill.

- Common Shapes:

- Dimensions: Every wheel has critical dimensions.

- Key Dimensions: These include the outside Diameter (D), wheel Thickness (T or sometimes H for height), and Hole size (H – bore diameter). For shaped wheels, there are additional dimensions like rim width (W), wall thickness (U for cup wheels), depth of recess (E), etc.

- Importance: These must match your grinding machine’s specifications (e.g., maximum allowable wheel diameter, arbor size for the hole, available space within wheel guards). Using an incorrectly sized wheel is dangerous and ineffective. The diameter also influences the surface speed of the wheel at a given RPM. Always meticulously check your grinding machine’s manual for compatible wheel dimensions before ordering any wheel. Safety first!

- Core Material (for some wheels):

- While many smaller vitrified superabrasive wheels are made entirely of the abrasive/bond mixture, larger wheels or those designed for specific performance characteristics may have a distinct core. The vitrified abrasive section forms a rim bonded to this core.

- Common Core Materials: Aluminum alloys, steel, or sometimes advanced composite materials.

- Why different cores?

- Aluminum: Lightweight, good heat dissipation. Often used to reduce the overall weight of larger wheels.

- Steel: Offers maximum rigidity and stability, essential for high-precision applications and large diameter wheels that operate at high speeds, like those used in production crankshaft grinding.

- Composites: Can offer good vibration damping properties and a balance of light weight and rigidity.

- The choice of core material is typically determined by the wheel manufacturer based on the wheel’s size, intended application, and operational speeds.

Matching Wheel Specifications to Your Grinding Operation (e.g., Material Removal Rate, Surface Finish Requirements)

The ultimate goal is to select wheel specifications that achieve your desired operational outcomes efficiently and economically.

- Targeting Material Removal Rate (MRR):

- If your priority is to remove a lot of material quickly (high MRR), you’d generally lean towards:

- Coarser grit sizes

- Higher abrasive concentrations (to provide more cutting points, though there’s an optimal limit)

- Possibly a slightly softer bond grade to ensure continuous exposure of fresh, sharp abrasive.

- For example, in a production scenario for rough grinding cast iron engine blocks before a finishing pass, a vitrified CBN wheel with a coarse grit and robust concentration might be chosen to maximize throughput.

- Keep in mind that aggressive MRR can impact surface finish and may require more machine power.

- If your priority is to remove a lot of material quickly (high MRR), you’d generally lean towards:

- Achieving Specific Surface Finish (Ra, Rz, etc.):

- If a very smooth, high-quality surface finish is paramount, you’ll need:

- Finer grit sizes (this is the most influential factor).

- The concentration and bond grade must also be carefully selected to complement the fine grit and prevent issues like wheel loading or workpiece burn.

- For instance, producing optical components from glass requires an exceptionally fine vitrified diamond wheel (often in the micron or sub-micron grit range) to achieve the necessary low surface roughness (Ra)9. This often involves multiple grinding steps, progressing from coarser to finer grits.

- If a very smooth, high-quality surface finish is paramount, you’ll need:

- Maintaining Form Holding / Profile Accuracy:

- For applications where the wheel must maintain a precise shape or profile (e.g., grinding gear teeth, thread grinding, tool sharpening):

- Finer grit sizes often contribute to better edge stability.

- Higher abrasive concentrations provide more support for the wheel’s profile.

- Harder bond grades resist breakdown, helping to preserve the wheel’s form.

- The inherent rigidity of the vitrified bond itself is a major advantage here.

- For applications where the wheel must maintain a precise shape or profile (e.g., grinding gear teeth, thread grinding, tool sharpening):

- The Balancing Act: Grinding often involves balancing competing objectives. You might want a good surface finish and a reasonable material removal rate. This might lead to a compromise in wheel selection or, more commonly in production, employing a multi-stage process: a “roughing” stage with a wheel optimized for MRR, followed by a “finishing” stage with a wheel optimized for surface quality. The relationship between wheel specifications and grinding results can be intricate. Documenting your grinding parameters, results, and consulting with your grinding wheel supplier or an application engineer is crucial for optimizing your specific process effectively.

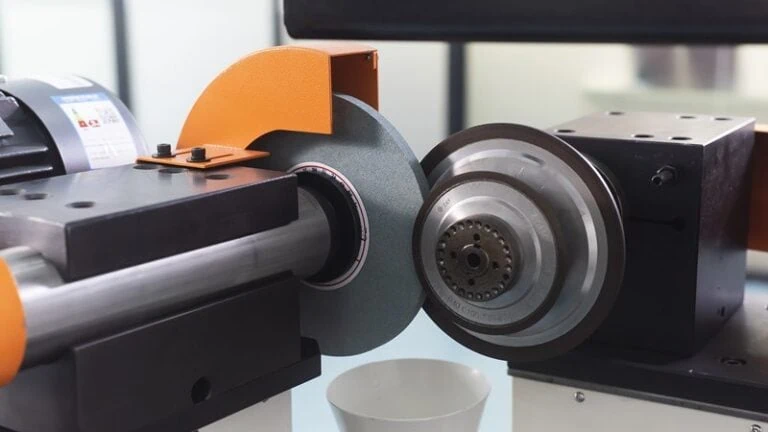

The Importance of Coolant: Selection and Application for Vitrified Wheels

You wouldn’t run a high-performance engine without oil, and similarly, high-performance grinding with vitrified superabrasive wheels almost always relies on the proper use of grinding fluids (coolants).

- Why Coolant is Essential:

- Cooling: Grinding generates intense heat at the point of contact. Coolant dissipates this heat, preventing thermal damage to the workpiece (like burn marks, microstructural changes, or distortion) and protecting the vitrified bond and abrasive from overheating.

- Lubrication: Coolant reduces friction between the abrasive grains and the workpiece. This leads to lower grinding forces, less energy consumption, reduced heat generation, and often a better surface finish.

- Cleaning (Flushing): Coolant effectively washes away the tiny chips of material (swarf) and any dislodged abrasive particles from the grinding zone. This is vital for preventing the porous structure of vitrified wheels from “loading” (clogging), which would drastically reduce cutting efficiency and could scratch the workpiece.

- Types of Coolants Suitable for Vitrified Wheels:

- Soluble Oils (Emulsions): A common choice, forming a milky emulsion when mixed with water. They offer a good balance of cooling and lubricating properties.

- Synthetic Fluids: These are chemical solutions in water and typically provide excellent cooling, good workpiece visibility (as they are often transparent), and help keep the machine clean.

- Semi-Synthetic Fluids: A hybrid, aiming to combine the benefits of soluble oils and synthetics.

- Straight Oils: Not mixed with water, these offer the best lubrication and can produce excellent surface finishes. However, they provide less cooling than water-based fluids and can create mist or smoke, requiring proper ventilation and fire safety measures.

- Effective Coolant Application:

- Simply flooding the area isn’t always enough. The nozzle type, position, angle, and pressure are critical to ensure the coolant effectively penetrates the grinding zone. The goal is to get the fluid directly to the wheel-workpiece interface.

- For vitrified wheels, their porous structure can aid in coolant transport if the application is optimized. Some grinding machines even support “through-the-wheel” coolant delivery for maximum efficiency.

- Filtration is key! Keeping the coolant clean by removing swarf and contaminants is essential for achieving good surface finishes and prolonging both wheel and coolant life.

- Specific Example: When grinding heat-sensitive aerospace alloys with vitrified CBN wheels, a well-maintained synthetic coolant, delivered at adequate pressure through precisely aimed nozzles, helps to control temperature, flush away chips effectively from the wheel’s pores, and achieve the desired precision and surface finish without thermal damage.

The choice of coolant and its application method can have a profound impact on the performance of your vitrified superabrasive grinding wheels. It’s highly recommended to consult with both your coolant supplier and your grinding wheel manufacturer for recommendations best suited to your specific materials, machine, and operational goals.

What Tangible Performance and Economic Benefits Can These Advanced Wheels Bring to Your Operations?

Beyond the technical specifications, what real-world advantages and cost savings can using vitrified bond diamond or CBN grinding wheels truly deliver to a manufacturing operation?

Vitrified bond diamond and CBN grinding wheels offer significant performance benefits, including faster material removal rates which shorten cycle times and boost productivity. They also enable superior surface finish quality and tighter geometric tolerances, leading to higher quality parts and fewer rejects.

Economically, these advanced wheels contribute to lower overall tooling costs through extended wheel lifespan and reduced dressing frequency. Furthermore, their consistent and predictable performance enhances process stability, making them ideal for automated or ‘lights-out’ machining environments, ultimately improving operational efficiency.

Achieving Higher Material Removal Rates and Significantly Reduced Cycle Times

One of the most immediate impacts of switching to vitrified bond superabrasive wheels is the potential to remove material much faster than with conventional abrasive wheels. This translates directly into shorter grinding cycles.

How is this achieved?

- The vitrified bond, as we’ve discussed, securely holds the extremely hard diamond or CBN abrasive particles. This strong bond, combined with the inherent thermal stability of ceramic, allows for more aggressive grinding parameters. You can often increase speeds, feed rates, or the depth of cut without quickly damaging the wheel or the workpiece.

- Diamond and CBN abrasives themselves are far more durable and maintain their cutting sharpness longer than conventional abrasives like aluminum oxide or silicon carbide. They simply cut more efficiently for a longer duration.

The result?

- More Parts Per Hour: Faster grinding means each part takes less time to complete. For example, in a production environment grinding hardened steel gears, a switch to a vitrified CBN wheel could, in some cases, reduce the grinding time per gear by 20-50% or even more compared to older abrasive technologies. If a gear previously took 2 minutes to grind, it might now take only 1 to 1.5 minutes.

- Increased Machine Throughput: When each part is finished faster, the overall output of your grinding machines increases significantly. This means you can produce more with the same equipment.

- Reduced Lead Times: Faster production naturally leads to quicker fulfillment of orders.

Ultimately, higher material removal rates driven by these advanced wheels mean a substantial boost in overall productivity and operational capacity.

Attaining Superior Surface Finish Quality and Tighter Geometric Tolerances

It’s not just about speed; it’s also about the quality of the finished part. Vitrified bond superabrasive wheels are renowned for their ability to produce exceptional surface finishes and hold very tight dimensional and geometric tolerances.

Here’s why:

- Inherent Rigidity: The vitrified bond is very stiff and resistant to deflection. This rigidity means the wheel maintains its precise shape during grinding, and this accuracy is directly transferred to the workpiece.

- Fine Abrasive Capability: Diamond and CBN abrasives are available in very fine grit sizes. When combined with the stable vitrified bond, these fine grits can produce exceptionally smooth, often mirror-like, surfaces with very low surface roughness (Ra) values.

- Consistent Cutting: The controlled wear and self-sharpening nature of well-chosen vitrified superabrasive wheels lead to a more consistent cutting action, minimizing issues like chatter or vibration that can mar surface finish.

The benefits are clear:

- Higher Quality Parts: You can consistently produce components that meet or exceed even the most demanding specifications for surface quality and dimensional accuracy. For instance, manufacturers of precision bearings rely on vitrified CBN wheels to achieve sub-micron tolerances and flawless surface finishes on bearing races, which is critical for their performance and longevity.

- Reduced Scrap and Rework: When parts are ground correctly the first time with high precision, the amount of rejected parts or parts needing costly rework plummets. This saves material, labor, and machine time.

- Enhanced Product Performance: Components with superior surface finishes and tighter tolerances often perform better and last longer. For example, a precisely ground fuel injector nozzle will ensure better fuel atomization and engine efficiency.

Maximizing Wheel Lifespan, Reducing Dressing Frequency, and Lowering Overall Tooling Costs

While vitrified bond superabrasive wheels might have a higher initial purchase price compared to conventional wheels, they often lead to significant long-term cost savings. This is primarily due to their extended lifespan and reduced maintenance needs.

Consider these factors:

- Dramatically Longer Wheel Life: Diamond and CBN are exceptionally wear-resistant. Because the vitrified bond holds these superabrasive particles so effectively, allowing them to do more work before being shed, the wheels last much, much longer. In some applications grinding hardened steels, a vitrified CBN wheel might last 50 to 200 times longer than a conventional aluminum oxide wheel.

- Reduced Dressing Frequency: Dressing is the process of re-sharpening and re-profiling the grinding wheel. Because vitrified superabrasive wheels maintain their sharpness and form for longer, they need to be dressed far less frequently.

- Impact of Less Dressing:

- More Uptime: Every time a wheel is dressed, the machine is not producing parts. Less dressing means more valuable production time.

- Less Abrasive Consumed: Dressing removes a layer of the wheel. Less frequent dressing means less of the valuable superabrasive material is wasted.

- Impact of Less Dressing:

- Lower Overall Tooling Costs: When you factor in the extended life and reduced dressing, the cost per part ground is often significantly lower with vitrified superabrasive wheels. By looking at the total cost of ownership10, rather than just the initial price, the economic advantages of these advanced wheels become very compelling. Imagine a scenario in a tool manufacturing plant: a vitrified diamond wheel for grinding carbide inserts might cost more upfront, but if it grinds 10,000 inserts before needing replacement, while a cheaper conventional wheel grinds only 200, the cost-effectiveness of the diamond wheel becomes apparent.

- Reduced Labor and Inventory: Fewer wheel changes and less dressing also mean reduced labor associated with these tasks and a smaller inventory of replacement wheels to manage.

Enabling Process Stability for Lights-Out Machining and Automation

The consistency and predictability of vitrified bond superabrasive wheels make them ideal partners for modern automated manufacturing environments, including “lights-out” (unattended) operations.

How they contribute to stability:

- Predictable Wear and Long Life: Knowing that a wheel will perform consistently for an extended period allows for reliable production planning and scheduling. You can trust the wheel to maintain its cutting ability and dimensional accuracy over many parts or long cycle times.

- Reduced Operator Intervention: Because these wheels last longer and require less frequent dressing or adjustment, the need for human operators to constantly monitor and intervene is significantly diminished.

- Compatibility with Automated Systems: The predictable nature of these wheels makes them well-suited for integration with automated dressing systems and robotic loading/unloading systems in CNC grinding cells.

The operational advantages include:

- Feasibility of Unattended Machining: This is a huge benefit. Machines can continue producing parts accurately even after workers have gone home, maximizing the utilization of expensive CNC grinding equipment.

- Improved Part-to-Part Consistency: Automation reduces the variability that can sometimes be introduced by different operators or manual adjustments, leading to more uniform product quality.

- Enhanced Overall Equipment Effectiveness (OEE): By minimizing downtime for wheel changes, dressing, and adjustments, vitrified superabrasive wheels help improve the OEE of your grinding machines.

- Streamlined Production Flow: A stable, predictable grinding process contributes to a smoother, more efficient overall production workflow. For example, automotive manufacturers running high-volume production lines for components like transmission shafts depend on the process stability offered by vitrified CBN wheels to maintain output and quality with minimal interruption.

By investing in vitrified bond diamond or CBN grinding wheels, and by carefully selecting the right specifications for your application (as discussed in previous sections), you are not just buying a tool, but unlocking a range of benefits that can enhance productivity, improve quality, reduce costs, and support modern manufacturing strategies.

Conclusion

Selecting the right vitrified bond diamond or CBN grinding wheel is a critical decision that significantly impacts grinding efficiency, workpiece quality, and overall operational costs. By understanding the core principles of the bonding system, the distinct advantages of diamond and CBN abrasives for specific materials, the nuances of key wheel specifications, and the profound performance and economic benefits these advanced wheels offer, you are well-equipped to make informed choices that drive productivity and precision in your operations.

The journey to optimal grinding involves careful consideration of each of these factors. For tailored advice and to ensure you unlock the full potential of these advanced grinding tools for your specific applications, consulting with experienced suppliers and application engineers is always recommended. This collaborative approach will help you navigate the options and implement the best possible grinding solution, ultimately enhancing your manufacturing competitiveness.

Ready to enhance your grinding operations with the ideal solution? Explore our comprehensive range of Vitrified Bond Diamond & CBN Grinding Wheels on our product page. Discover our standard offerings or contact us to discuss fully customizable wheels tailored to your unique specifications and performance goals.

References

- fired at very high temperatures1 – Wikipedia page explaining the process of Sintering.

- “dressed.”2 – ZYDiamondTools blog post: “Master Diamond Wheel Dressing: Your Practical How-To Guide.”

- Thermal stability3 – ScienceDirect topic page discussing thermal stability in the context of materials science.

- Resin Bond4 – ZYDiamondTools blog post: “Resin Bond Diamond & CBN Grinding Wheels: Mastering Selection and Application for Superior Results.”

- Metal Bond5 – ZYDiamondTools blog post: “Metal Bond Diamond & CBN Grinding Wheels: Why They Excel and How to Select the Perfect One for Your Application.”

- Choosing between diamond and CBN superabrasives6 – ZYDiamondTools blog post: “Choosing Between CBN and Diamond Grinding Wheels: Which One Is Right For Your Needs?”

- Tungsten Carbide7 – Britannica article explaining the properties and uses of tungsten carbide.

- PCD (Polycrystalline Diamond) and PCBN (Polycrystalline Cubic Boron Nitride)8 – ZYDiamondTools blog post: “Mastering PCD and PCBN Tool Sharpening: Essential Techniques and Best Practices.”

- surface roughness (Ra)9 – Get It Made UK resource page explaining surface roughness.

- total cost of ownership10 – ZYDiamondTools blog post: “Total Cost Of Ownership (TCO) Explained: A Guide For Superhard Tooling & Abrasives.”