-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

Struggling with Interrupted Cuts? How PCBN Tools Provide the Ultimate Solution

When faced with the extreme forces and temperatures of machining hardened materials with interruptions, how can you achieve both high productivity and reliable tool life?

The definitive solution is a well-planned strategy centered on Polycrystalline Cubic Boron Nitride (PCBN) tooling. By understanding the unique challenges of interrupted cutting, correctly selecting the appropriate PCBN grade, implementing proven best practices, and learning how to troubleshoot common issues, you can transform a difficult, unpredictable operation into a stable, efficient, and highly profitable process.

Why Is PCBN the Superior Choice for Interrupted Cutting?

When you’re facing a tough machining job with constant starts and stops, why do so many experienced machinists turn to Polycrystalline Cubic Boron Nitride (PCBN) tools?

The answer lies in PCBN’s unique combination of exceptional toughness and high thermal stability. Unlike more brittle materials, PCBN can withstand the repeated physical impacts of interrupted cuts without fracturing. Simultaneously, it effectively manages the rapid temperature swings that occur as the cutting edge enters and exits the workpiece, preventing thermal shock and preserving its hardness for a longer, more predictable tool life.

The Unique Challenges of Interrupted Cuts: Impact, Vibration, and Thermal Shock

Interrupted cutting is one of the most demanding machining operations. Imagine trying to cut a metal gear. The cutting tool engages with a gear tooth, then cuts through air, then engages with the next tooth. This cycle happens hundreds or thousands of times per minute, creating three distinct challenges.

- Mechanical Impact: Each time the tool re-engages the workpiece, it experiences a sharp physical shock. This is like a tiny hammer blow to the cutting edge. A material without sufficient strength and toughness will simply chip or break under this repeated stress.

- Vibration: The constant on-and-off cutting action creates high-frequency vibrations, often called chatter. This vibration can destabilize the cutting process, leading to a poor surface finish on the part and causing microscopic cracks to form and grow on the tool’s cutting edge.

- Thermal Shock: The cutting edge becomes extremely hot (often exceeding 1000°C) when it’s cutting metal and then cools rapidly as it passes through open air. This rapid heating and cooling cycle creates immense internal stress in the material. Think of what happens when you pour cold water into a hot glass—it shatters. This is thermal shock1, a primary cause of tool failure in interrupted cutting.

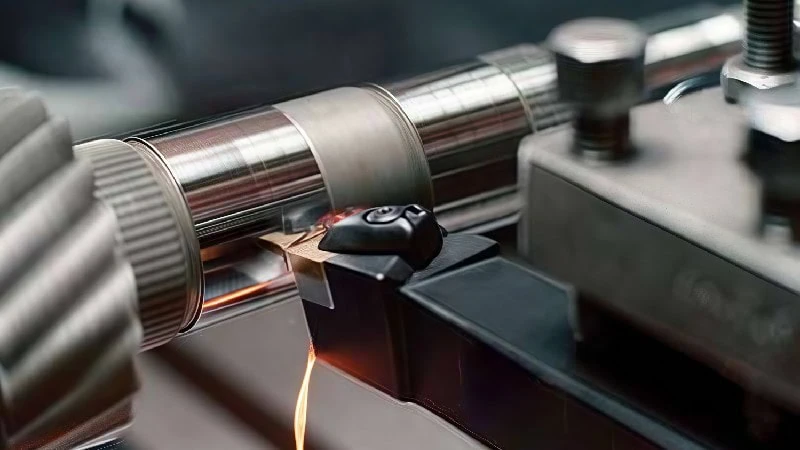

How PCBN Material Properties Overcome These Challenges

PCBN is an engineered composite material, created by sintering cubic boron nitride grains with a ceramic or metallic binder under extreme pressure and temperature. This structure gives it a powerful combination of properties that directly counter the challenges of interrupted cutting.

High Fracture Toughness

Fracture toughness2 is a material’s ability to resist cracking and breaking. Because PCBN is a composite, it has a much higher fracture toughness than monolithic materials like ceramics. This inherent strength allows the cutting edge to absorb the repeated mechanical impacts of interrupted cutting without chipping. It provides a reliable and robust cutting edge where brittle tools would fail.

Excellent Thermal Stability

PCBN maintains its extreme hardness even at very high temperatures. Furthermore, it has high thermal conductivity, which means it can pull heat away from the cutting edge very quickly. This dual capability is crucial for resisting thermal shock. By dissipating heat rapidly, PCBN minimizes the severity of temperature swings, reducing internal stress and preventing the formation of thermal cracks. This allows for higher cutting speeds and more aggressive machining, even in interrupted conditions.

A Head-to-Head Comparison: PCBN vs. Ceramics in Interrupted Applications

While both PCBN and ceramics are used for hard turning3, their performance profiles in interrupted applications are vastly different. Choosing the right one is critical for both productivity and profitability. The wrong choice can lead to scrapped parts and constant, costly tool changes.

Here is a direct comparison to clarify their strengths and weaknesses:

| Feature | PCBN (Polycrystalline Cubic Boron Nitride) | Ceramic Inserts (e.g., Alumina, SiAlON) |

|---|---|---|

| Toughness & Impact Resistance | Excellent. Specifically designed to handle mechanical shock. The primary choice for medium to heavy interruptions. | Low to Medium. Inherently brittle and highly susceptible to chipping or catastrophic failure upon impact. |

| Thermal Shock Resistance | Excellent. High thermal conductivity prevents the formation of cracks from rapid temperature changes. | Poor to Fair. Low thermal conductivity makes it prone to cracking in applications with significant temperature fluctuation. |

| Typical Application | Hard turning of components with keyways, holes, splines, or casting crust. Ideal for interrupted and continuous cutting. | Finishing of hardened steels and cast irons in smooth, continuous cutting operations. |

| Cutting Speed Capability | Very High. Often exceeds 150 m/min, but always consult your tool supplier for specific grade recommendations. | Very High. Can achieve excellent finishes at high speeds, but only in stable, uninterrupted conditions. |

| Cost-Effectiveness | Higher initial tool cost but significantly longer tool life and higher process security in interruptions lead to a lower cost per part. | Lower initial tool cost but can result in a higher cost per part in interrupted cuts due to frequent tool failure and downtime. |

In summary, while a ceramic insert may perform well in a perfectly smooth, continuous finishing pass, it lacks the fundamental toughness required to survive the punishment of an interrupted cut. In real-world tests on machining hardened steel gears (HRC 60) with four interruptions per revolution, properly selected PCBN grades consistently demonstrate a tool life 5 to 10 times longer than advanced ceramic inserts, drastically reducing machine downtime and improving overall process reliability. For any application involving interruptions, PCBN is not just a better choice—it is the correct engineering solution.

How Do You Select the Right PCBN Grade for Your Job?

With so many PCBN grades available, how can you be certain you’re choosing the most effective and cost-efficient one for your specific interrupted cutting job?

Selecting the right PCBN grade requires a systematic approach. You must first evaluate the severity of the interruption, then match the tool’s properties—primarily its CBN content and binder type—to the specific workpiece material and its hardness. This ensures you achieve the optimal balance between wear resistance for longevity and toughness to prevent chipping.

Assessing the Severity of Interruption (Light, Medium, or Heavy)

Not all interruptions are created equal. The first step in choosing the correct PCBN grade4 is to accurately judge the intensity of the interruptions in your process. Think of it like choosing tires for a vehicle; you wouldn’t use racing slicks for an off-road rally.

- Light Interruption: This involves minor breaks in the cut, such as a single keyway or small cross-holes on a shaft. The tool is cutting for most of the revolution. The primary demand on the tool is still wear resistance, with a small need for added toughness.

- Medium Interruption: This level includes more significant breaks in the surface. Good examples are machining splined shafts or parts with multiple, larger gaps. The impacts are more frequent and forceful, demanding a PCBN grade with a balanced profile of both toughness and wear resistance.

- Heavy Interruption: This is the most demanding scenario, involving severe and repeated impacts. Imagine facing the side of a gear, where the tool cuts a tooth, then a large air gap, then the next tooth. Other examples include machining hexagonal stock or roughing castings with significant surface irregularities. In these cases, toughness is the most critical property, as a brittle tool would fail almost immediately.

Matching the PCBN Grade to Workpiece Material and Hardness

Next, you must consider what you are cutting. The workpiece material and its hardness level directly influence how the PCBN tool will wear. This factor must be balanced with the severity of the interruption.

Hardened Steels (45-68 HRC)

These materials generate immense heat and pressure at the cutting edge. The primary challenge here is abrasive wear, where the hard particles in the steel slowly grind away at the tool. For hardened steels with a hardness typically measured between 45-68 HRC, you need a PCBN grade that offers excellent wear resistance to hold its sharp edge.

Cast Irons (Grey, Ductile)

Cast irons are highly abrasive due to the presence of hard iron carbides and potential sand inclusions from the casting process. Therefore, a PCBN grade with high abrasion resistance is essential for achieving a reasonable tool life. For castings with a rough, uneven “skin” or scale, a tougher grade is needed for the initial roughing passes.

Powdered Metals & Sintered Alloys

These materials can have varying densities and may contain hard, abrasive particles. This requires a versatile PCBN grade that balances toughness to resist chipping on inconsistent surfaces with wear resistance to handle the abrasive nature of the material.

Understanding the Role of CBN Content and Binder Type

This is the core of PCBN grade selection. The “grade” is determined by its recipe: how much CBN it contains and what material (the binder) is used to hold the CBN grains together. This recipe dictates the tool’s final balance between toughness and wear resistance.

| PCBN Characteristic | Description | Best Suited For |

|---|---|---|

| High CBN Content (>80%) | Contains a high percentage of CBN grains. This results in extreme hardness and superior wear resistance. | Lightly interrupted cuts on hardened steel and cast iron where surface finish and long tool life are priorities. |

| Low CBN Content (40-70%) | Contains more binder material, which acts as a shock absorber. This significantly increases the tool’s toughness. | Medium to heavy interrupted cuts where resisting impact and chipping is the most important factor. |

| Ceramic Binder | Uses a ceramic material to bond the CBN grains. This provides excellent chemical stability and retains hardness at very high temperatures. | High-speed finishing applications with light or no interruptions. It enhances wear resistance. |

| Metallic Binder (e.g., Co, TiC) | Uses a metal to bond the CBN grains. This creates a much tougher composite material that is better at absorbing impacts. | The go-to choice for heavy interruptions and unstable machining conditions. |

Ultimately, you are making a strategic trade-off. A high-CBN grade with a ceramic binder is incredibly wear-resistant but more brittle. In contrast, a low-CBN grade with a metallic binder sacrifices some wear resistance to gain the critical toughness needed to survive heavy impacts.

Recommended PCBN Grades for Common Interrupted Cutting Scenarios

By combining these three factors—interruption severity, workpiece material, and grade composition—you can confidently select the right tool for the job.

- Scenario: Finishing a hardened steel shaft (62 HRC) with a single, small keyway.

- Interruption: Light.

- Challenge: Primarily abrasive wear with minor impact.

- Recommendation: A high CBN content grade with a ceramic binder. This will provide the best wear resistance for a long tool life and superior surface finish, while having just enough toughness for the light interruption.

- Scenario: Rough turning a cast iron housing with a rough casting skin.

- Interruption: Medium to Heavy (due to the uneven surface).

- Challenge: High abrasion combined with significant impact upon entering the cut.

- Recommendation: A low-to-medium CBN content grade with a tough metallic binder. This provides the shock resistance needed to survive the initial rough passes without fracturing.

- Scenario: Hard turning the face of a large transmission gear (60 HRC).

- Interruption: Heavy.

- Challenge: Extreme, repeated impacts that will shatter a brittle tool.

- Recommendation: A low CBN content grade with a strong metallic binder. This grade is engineered for maximum toughness above all else. Success here also heavily relies on a strong edge preparation, which will be discussed in the next section.

A final reminder: These are strong industry guidelines. However, specific grade designations and their performance nuances can vary between manufacturers. It is always a critical final step to consult your tool supplier’s technical data to find the exact product that matches these characteristics for your unique application.

What Are the Best Practices for Machining with PCBN in Interrupted Cuts?

Now that you’ve selected the perfect PCBN grade, how do you set up your machining process to guarantee success and maximize tool life in a demanding interrupted cut?

Successful machining with PCBN in interrupted cuts hinges on a holistic approach. This involves using conservative cutting parameters to reduce impact force, ensuring maximum machine and tool holder rigidity to absorb vibration, applying coolant judiciously to avoid thermal shock, and selecting a robust tool edge preparation to strengthen the cutting edge against chipping.

Optimizing Cutting Parameters: Speed, Feed, and Depth of Cut

In an interrupted cut, your primary goal is stability, not aggressive metal removal. The cutting parameters you choose are your first line of defense against the destructive forces of impact and vibration. The general rule is to start conservatively and optimize from a safe, stable baseline.

- Cutting Speed (Vc): High speed means high impact velocity. For interrupted cutting, it’s wise to reduce the cutting speed by 20-30% compared to what you would use for a smooth, continuous cut in the same material. This lessens the force of the “hammer blow” each time the tool re-engages the workpiece.

- Feed Rate (fn): The feed rate determines your chip thickness, which directly correlates to the cutting force. A lower feed rate reduces the stress on the cutting edge during impact. Think of it as tapping gently versus swinging with full force. For heavily interrupted cuts, reducing the feed rate is crucial for preventing the edge from fracturing.

- Depth of Cut (ap): While PCBN can handle significant depths of cut, maintaining a consistent and moderate depth is key in interrupted applications. A smaller, more uniform depth of cut leads to more predictable cutting forces, which helps maintain stability and reduces the risk of overload.

Once the process is proven to be stable with these conservative parameters, you can cautiously increase speed and feed to find the optimal balance of productivity and tool life. Always consult your tooling supplier, as their recommended starting parameters are an invaluable and safe starting point.

The Critical Importance of Machine and Tool Holder Rigidity

A high-performance PCBN tool will fail if it’s used in a weak or unstable environment. Rigidity in your setup is not just a recommendation; it is a requirement.

Imagine trying to write with a pen that has a flimsy, flexible tip—you would have no control. The same principle applies here.

Machine Stability

The machine tool itself is the foundation of the entire process. It must be robust and well-maintained. Any play in the spindle bearings, looseness in the turret, or wear in the guideways will be amplified during an interrupted cut, creating excessive vibration and leading to tool failure. A modern, rigid CNC machine is heavily preferred over older or less robust equipment.

Secure Tool Holding

This is arguably the most critical and often overlooked element.

A key engineering principle to remember is that doubling the tool overhang (the distance the tool sticks out from the holder) can increase tool tip deflection by up to eight times.

Therefore, always use the shortest possible tool and holder combination. Secure clamping is also essential. A high-quality hydraulic, shrink-fit, or robust mechanical clamping system provides superior grip and concentricity compared to a standard, worn-out holder. This minimizes runout and ensures the tool enters the cut precisely and consistently, reducing the chance of unpredictable impacts.

Effective Coolant Strategies: When to Use It and When Not To

This topic is critical and often counter-intuitive. With PCBN, the wrong coolant strategy can do more harm than good by creating the very thermal shock you are trying to avoid.

The Case for Machining Dry

For most medium-to-heavy interrupted cuts in hardened steel, the best practice is to run completely dry. PCBN is designed to handle high temperatures, and maintaining a consistently hot cutting zone is far more stable for the tool than subjecting it to a hot-cold-hot-cold cycle. This thermal stability prevents the formation of micro-cracks that lead to tool failure.

When to Use Flood Coolant

If coolant is necessary—for example, to control the thermal expansion of the workpiece or to flush chips away—it must be applied correctly. A weak or intermittent stream of coolant is the worst-case scenario. You must use a high-volume, continuous flood of coolant aimed directly at the cutting edge. The goal is to keep the tool constantly submerged and cool throughout the entire revolution, both in and out of the cut, thus preventing the damaging temperature fluctuations.

Essential Edge Preparations (Hone, Chamfer/K-Land) for Maximum Tool Life

A sharp edge is a weak edge. For interrupted cutting, the geometry of the cutting edge must be strengthened to withstand impact. This is known as edge preparation5. Think of the difference between a delicate razor blade and a robust wood-splitting axe; for interruptions, you need the axe.

The two most common edge preparations are a hone and a chamfer (often called a T-Land or K-Land).

| Edge Preparation | Description | Best For |

|---|---|---|

| Hone | A slight rounding of the cutting edge (e.g., a 0.01-0.02 mm radius). | Light interruptions. It removes any micro-defects from the grinding process and adds strength without significantly increasing cutting forces. |

| T-Land / K-Land | A small, flat surface ground onto the cutting edge at a negative angle (e.g., 20 degrees), which is then honed. | Medium to heavy interruptions. This creates a strong, blunt, and extremely robust platform that can absorb direct impacts without fracturing. |

For any significant interruption, a T-Land is standard practice. The specific angle and width of the T-Land (e.g., 0.1mm x -20°) are critical variables that directly impact performance. These specifications are engineered for different applications, so always refer to your supplier’s recommendations to select an insert with the appropriate edge preparation for your specific level of interruption.

PCBN in Action: Real-World Case Studies

The theory and best practices are clear, but the true test of any tooling strategy is its performance on the shop floor. The following real-world case studies demonstrate how a systematic PCBN approach solves complex interrupted cutting challenges and delivers significant, measurable results.

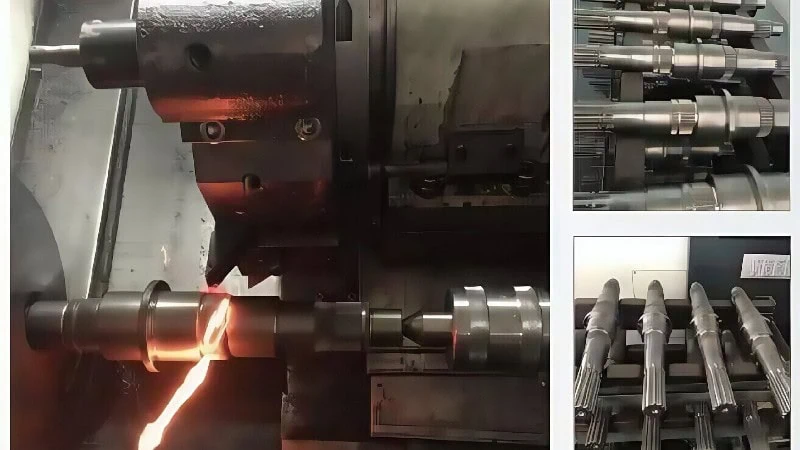

Case Study 1: Hard Turning a Hardened Steel Splined Shaft

This example from the automotive industry demonstrates a dramatic increase in tool life by switching from ceramics to PCBN for a medium-interruption application.

The Challenge

A manufacturer was tasked with finishing the outer diameter of a 4140 alloy steel shaft, hardened to 60 HRC. The shaft featured six splines along its length, creating six interruptions per revolution. Their existing process using a standard ceramic insert was failing, with catastrophic tool failure often occurring after just 10-15 parts. This led to high tooling costs, frequent machine stoppages, and inconsistent part quality.

The Solution

The process was re-evaluated based on best practices for interrupted cutting.

- PCBN Selection: A low-to-medium CBN content grade with a tough metallic binder was chosen. This provided the necessary impact resistance to handle the splines without sacrificing too much of the wear resistance needed for the hardened steel.

- Edge Preparation: The insert was specified with a T-Land edge preparation (0.15mm x -20°) to provide a strong, reinforced cutting edge.

- Cutting Parameters: The machine was run dry to prevent thermal shock. Parameters were set conservatively at first and then optimized.

| Parameter | Value |

|---|---|

| Cutting Speed (Vc) | 120 m/min |

| Feed Rate (fn) | 0.12 mm/rev |

| Depth of Cut (ap) | 0.20 mm |

The Results

The results were immediate and significant.

The ceramic inserts averaged 15 pieces per cutting edge. The new PCBN solution achieved a consistent and predictable tool life of 150 pieces per edge—a 10-fold increase.

This change drastically reduced the cost-per-part and increased machine uptime. Furthermore, the dimensional consistency and surface finish of the shafts improved markedly because the tool did not degrade unpredictably.

Key Takeaway: For medium interruptions on hard materials, matching a tough PCBN grade with a correct edge preparation is the key to transforming an unstable process into a reliable one.

Case Study 2: Machining Interrupted Bores in a Transmission Gear

This case focuses on a heavy interruption scenario where process reliability was the primary goal.

The Challenge

An aerospace supplier needed to finish the internal bore of a high-strength steel transmission gear (62 HRC). The bore was intersected by a lubrication cross-hole, creating a severe interruption during the finishing pass. Their goal was to hold a very tight tolerance (±0.005 mm) and achieve a high-quality surface finish, but the impact from the hole was causing chatter and unpredictable tool chipping.

The Solution

Success required focusing on maximum toughness and system rigidity.

- PCBN Selection: A low CBN content grade (approx. 50% CBN) with a highly ductile metallic binder was selected for maximum impact strength.

- Edge Preparation: A wide T-Land (0.20mm x -25°) was used to create an exceptionally robust cutting edge.

- Process: The operation was performed on a rigid CNC lathe with a high-quality hydraulic chucking system. Critically, the process was run completely dry to create a thermally stable environment.

The Results

The focus on toughness and stability paid off. The previous method could not guarantee even 50 parts without an operator checking for tool failure. The new PCBN process achieved a stable and predictable tool life of over 300 gears per edge. This reliability allowed the manufacturer to run the process with minimal operator supervision, significantly boosting labor productivity and Overall Equipment Effectiveness (OEE).

Key Takeaway: In severe interruptions, prioritizing toughness and system rigidity—including running dry to eliminate thermal shock—is the key to achieving the process stability needed for precision manufacturing.

Case Study 3: Facing a Cast Iron Component with Drilled Holes

This example shows how PCBN can solve the dual challenges of high abrasion and interruption simultaneously.

The Challenge

A foundry was facing a grey cast iron pump housing. The operation involved machining the main flange face flat to create a seal. This face had eight drilled bolt holes, creating multiple interruptions. The highly abrasive nature of the cast iron was rapidly wearing down their tungsten carbide tools, while the interruptions were causing them to chip. Tool life was unacceptably low.

The Solution

This application required a grade that could handle both abrasion and impact.

- PCBN Selection: A high CBN content grade was chosen to provide the superior wear resistance needed to combat the abrasive cast iron. However, it was specified with a binder system known for good toughness to handle the interruptions from the bolt holes.

- Edge Preparation: A simple, light hone was sufficient for this level of interruption, strengthening the edge without creating excessive cutting forces.

The Results

The comparison was stark.

- Carbide Tool Life: 25 pieces per edge before failure from excessive flank wear.

- PCBN Tool Life: Over 400 pieces per edge, with wear progressing in a slow, predictable manner.

The PCBN solution not only lasted 16 times longer but also maintained the required surface flatness across the entire production run.

Key Takeaway: PCBN is not a single material but a versatile family of grades. The right grade can be selected to overcome combined challenges—in this case, extreme abrasion and moderate interruption—that are impossible to solve efficiently with a single-material tool like carbide.

How Can You Troubleshoot Common Problems?

Even with the best planning, what should you do when your interrupted cutting process isn’t working perfectly and you need to solve a problem on the shop floor?

Troubleshooting PCBN in interrupted cuts involves a logical process of elimination. First, diagnose the most common failure mode, such as edge chipping, by examining the tool. Then, systematically review your setup, starting with the PCBN grade and edge preparation, followed by machine rigidity and cutting parameters, to identify and correct the root cause of the instability.

Diagnosing and Preventing Premature Edge Chipping or Breakage

Edge chipping is the most frequent problem in interrupted cutting. The appearance of the worn or broken tool is the best clue to understanding the root cause. Be a detective: examine the tool closely under magnification before making any changes.

| Symptom / Observation | Potential Cause | Corrective Action |

|---|---|---|

| Micro-chipping: Small, inconsistent chips along the length of the cutting edge. | Insufficient Toughness or Vibration. The PCBN grade cannot withstand the repeated small impacts. | 1. Switch to a tougher PCBN grade (lower CBN content, metallic binder). 2. Implement a stronger edge prep (T-Land). 3. Address vibration (see next section). |

| Gross Fracture: A large piece of the tool tip has broken off cleanly. | Excessive Impact Force. The initial impact upon entering the cut is too severe. | 1. Reduce the feed rate and/or cutting speed immediately. 2. Verify the tool is set exactly on the machine’s centerline. 3. Choose a tougher PCBN grade. |

| Thermal Cracks: Cracks forming perpendicular (90°) to the cutting edge. | Thermal Shock. The tool is experiencing rapid heating and cooling cycles. | 1. Turn the coolant completely off and run the application dry. 2. If coolant is required, apply it as a high-volume, continuous flood to prevent any dry periods. |

| Rapid Flank Wear: The edge hasn’t chipped, but it has worn down very quickly, leading to failure. | Insufficient Wear Resistance. The PCBN grade is tough enough but too “soft” for the workpiece material’s abrasiveness. | 1. Switch to a PCBN grade with a higher CBN content. 2. Increase the cutting speed, as this can sometimes reduce abrasive wear on certain materials. |

Strategies for Eliminating Vibration and Chatter

Vibration, or chatter, is a system-wide problem that creates poor surface finishes and leads to micro-chipping. If you hear a high-pitched squeal or see tell-tale wavy patterns on the workpiece, you must address the system’s rigidity.

Follow this checklist, from easiest to most complex fix:

- Reduce Tool Overhang: This is the #1 cause of vibration. Shorten the tool holder or use a shorter boring bar. Remember, doubling the overhang can increase deflection by eight times. A shorter, stouter setup is always better.

- Inspect Tool Clamping: Ensure your tool holder is in good condition and the insert is clamped securely. A high-quality hydraulic, milling, or shrink-fit chuck provides far better rigidity and vibration dampening than a worn, standard collet chuck.

- Modify Cutting Parameters: Sometimes you can “tune” the process out of a resonant frequency that causes chatter. Try increasing or decreasing the cutting speed by 10-15%. A slight change in RPM can often break the harmonic vibration and stabilize the cut.

- Evaluate System Rigidity: If the above steps don’t work, look at the entire machine setup. Is the workpiece held securely? If using a tailstock, is it engaged with adequate pressure? Is the machine itself robust enough for the operation?

Solving Issues with Poor Surface Finish

A poor surface finish is a symptom of another problem, usually vibration or tool wear. If the dimensional accuracy of your parts is good but the finish is not, investigate these common causes.

Issue: Visible chatter marks or a wavy finish

This is a direct result of vibration. The solution is not to change the tool grade, but to address the root cause of the chatter by following the steps outlined in the previous section. A more rigid setup is required.

Issue: A dull, smeared, or torn-looking surface

This indicates the cutting edge is no longer sharp and is pushing or “plowing” through the material instead of shearing it cleanly.

- Cause: The tool has worn out due to excessive abrasion. The PCBN grade you selected lacks the necessary wear resistance for the workpiece material.

- Solution: Switch to a PCBN grade with a higher CBN content or one with a binder that provides better high-temperature hardness. You can also consult your tooling supplier about a different insert geometry with a more positive rake angle, which can sometimes provide a better shearing action.

Issue: Scratches or drag marks in the direction of the cut

This is most often caused by chips not being evacuated from the cutting zone effectively. The chip gets trapped and dragged between the tool and the workpiece.

- Cause: Ineffective chip control or flushing.

- Solution: If running wet, increase coolant pressure and volume to forcefully flush chips away. If running dry, use a directed, high-pressure air blast. You can also experiment with an insert that has a different chipbreaker geometry designed to create smaller, more manageable chips for your specific depth of cut and feed rate.

Conclusion

Mastering interrupted cuts is not about finding a single “magic” tool, but about implementing a complete and logical strategy. PCBN is, without question, the superior cutting tool material for these demanding applications due to its unmatched combination of toughness and thermal stability.

By following the principles outlined here—systematically selecting the correct grade based on the application’s unique demands, adhering to best practices for rigidity and cutting parameters, and using a logical approach to troubleshooting—you can overcome the challenges of impact and vibration. This allows you to transform difficult interrupted cutting operations from a source of frustration and downtime into a predictable, productive, and profitable part of your manufacturing process.

References

- Thermal Shock1 – A ScienceDirect topic page providing a scientific overview of the thermal shock phenomenon in materials.

- Fracture Toughness2 – A Wikipedia article explaining the material property of fracture toughness and its importance in resisting cracks.

- Hard Turning3 – A ZYDiamondTools guide explaining the process of hard turning and comparing it to traditional grinding.

- PCBN Grade4 – A comprehensive ZYDiamondTools article covering the fundamentals of CBN cutting tools, which form the basis of PCBN grades.

- Edge Preparation5 – A ZYDiamondTools article explaining the importance of edge preparation (radiusing/honing) for PCBN inserts.