-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

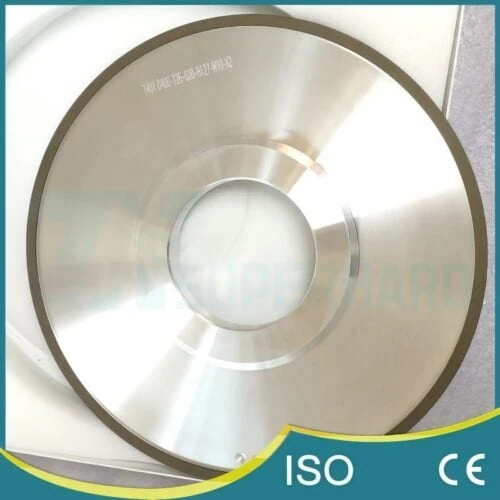

Resin Bond CBN Periphery Grinding Wheels

Resin bond CBN wheels (400 mesh) for precision wet periphery grinding of HSS & hardened steels. Delivers sharp, cool cutting with excellent finish and wear resistance. Ideal for heat-sensitive alloys.

Precision Resin Bond CBN Wheels for Wet Periphery Grinding of HSS & Hardened Steels

Achieve superior surface finishes, maintain tight tolerances, and ensure cool grinding when processing High-Speed Steel (HSS), hardened tool steels, and other challenging ferrous alloys with ZYsuperhard’s Resin Bond CBN Periphery Grinding Wheels. Optimized specifically for wet grinding operations using the wheel’s outer diameter, these wheels combine the exceptional grinding power of Cubic Boron Nitride (CBN) with the benefits of an advanced resin bond matrix, delivering sharp, efficient cutting with minimal thermal impact – ideal for finishing applications requiring high precision and surface integrity.

The Resin Bond CBN Advantage for Hardened Steels & HSS:

This carefully engineered wheel configuration offers distinct benefits for grinding heat-sensitive and hard ferrous materials:

- CBN – The Premier Abrasive for Steel: CBN’s extreme hardness (second only to diamond) ensures efficient grinding of hard materials, while its crucial chemical inertness with iron prevents adhesion (sticky chips) common at high temperatures. This allows effective grinding of all types of HSS (including high-vanadium grades like M2, M35, M42, ASP23, T1), hardened tool steels, die steels, bearing steels, and certain cast irons. CBN also boasts high thermal stability (withstanding 1250-1350°C) and excellent thermal conductivity, contributing significantly to a cooler grinding process.

- Resin Bond – Delivering Cool Cutting & Fine Finishes: Our specialized resin bond system provides a degree of resilience and free-cutting action, which minimizes grinding forces and heat generation. This is vital for preventing thermal damage (like softening, burning, or micro-cracks) to the workpiece surface and preserving the critical hardness of HSS tool edges. Resin bonds are renowned for their ability to produce excellent surface finishes, making them particularly suitable for final grinding passes (as indicated by the standard 400 mesh fine grit offering).

- Optimized for Wet Grinding: Explicitly designed for use with coolants, maximizing the benefits of heat removal, chip flushing, improved surface quality, and extended wheel life associated with wet grinding processes.

Key Features:

- High-Quality CBN Abrasive: Utilizes premium CBN abrasive, typically offered in fine grits like 400 mesh as standard for high-precision finishing operations, ensuring sharp cutting edges. Other grit sizes are available upon request for different stock removal or finish needs.

- Advanced Resin Bond Formulation: Engineered to provide the optimal balance between strong abrasive grain retention (for good wheel life and durability) and controlled bond erosion (for self-sharpening and sustained free-cutting performance).

- Precision Manufactured Wheel Body: Built on a stable, accurately manufactured core (standard Dia 400mm example, with customizable body materials like Aluminum matrix, steel matrix, etc., available) ensuring smooth, balanced operation essential for precision grinding machines.

Core Applications:

Ideal for high-quality precision periphery grinding operations (e.g., OD cylindrical grinding, surface grinding using the wheel periphery) on a variety of demanding materials:

- HSS Cutting Tools: Finish grinding of flutes, relief angles, cutting edges, and profiles on HSS end mills, drills, reamers, taps, hobs, broaches, circular saw blades, and inserts to achieve maximum sharpness and fine finishes.

- Hardened Steel Components: Precision finishing of hardened steel shafts, axles, gears, bearing races, mold components, hydraulic pistons/cylinders, and other machine elements requiring tight dimensional tolerances and smooth functional surfaces.

- Difficult-to-Grind Ferrous & Other Materials: Effectively grinds certain challenging cast irons (e.g., Vanadium-Titanium cast iron, High-Phosphorus cast iron, Chilled cast iron), thermal spray coatings (Nickel-based, Iron-based), and potentially suitable for specific Titanium alloys (like TC4, though CBN’s advantage over specialized carbide/diamond needs case-by-case evaluation).

Customization:

While offering standard configurations (like the Dia 400mm, 400 mesh example), ZYsuperhard provides highly customized Resin Bond CBN wheels. We can tailor Diameter, Thickness, Hole Size, Abrasive Layer Dimensions (W, X), specific CBN Grit Size (coarser or finer), CBN Concentration, and bond hardness/characteristics to perfectly match your specific grinding machine, workpiece material, coolant type, and application requirements (roughing vs finishing).

Choose ZYsuperhard Resin Bond CBN wheels for consistently cool, precise, and efficient finishing of your HSS, hardened steel, and other challenging alloy components. Contact us to discuss your specific wet grinding application needs.