-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

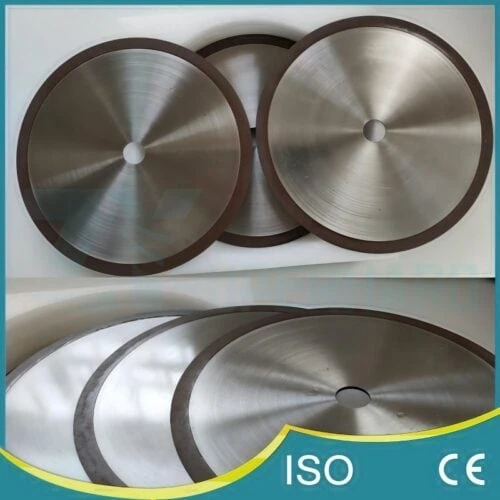

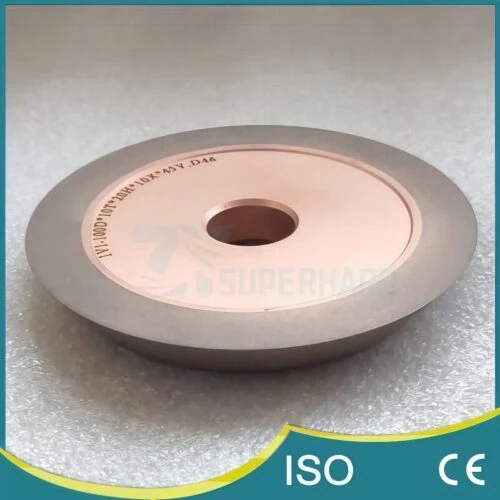

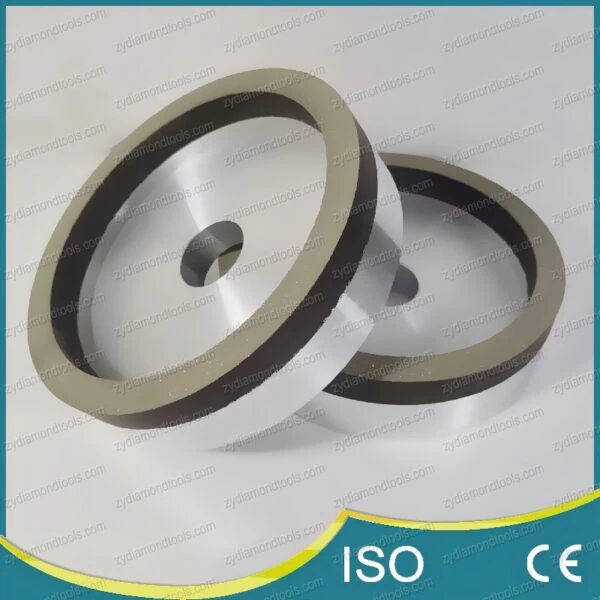

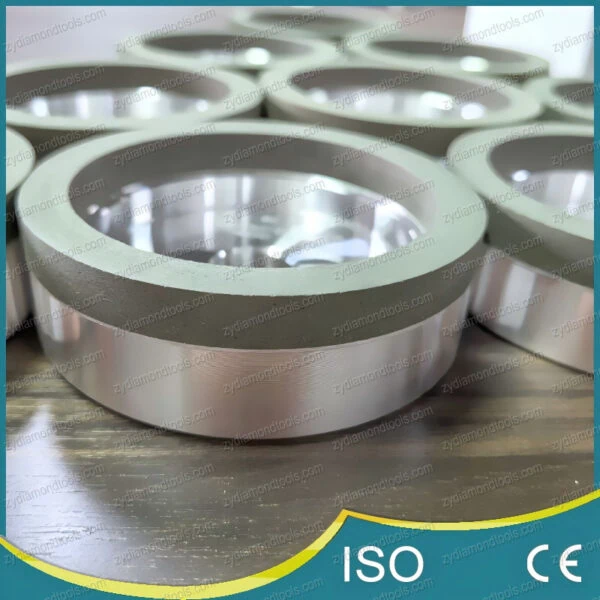

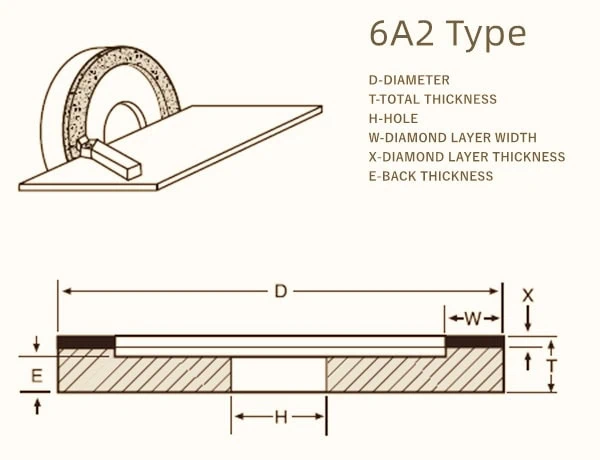

Industrial 6-inch Resin Diamond Cup Wheel | Shape Type 6A2

The definitive choice for high-precision grinding of Tungsten Carbide, Engineering Ceramics, PCD, and PCBN. This 6A2 cup wheel is engineered for high productivity and superior surface finishes, ensuring extended tool life to directly reduce your operational costs.

Key Features & Benefits

- Selected High-Quality Diamond Abrasive: Features carefully selected, high-grade synthetic diamond particles. The sharp, strong, and thermally stable abrasive ensures powerful grinding force and consistent, efficient cutting performance over the life of the wheel.

- Advanced Resin Bond Formula: Utilizes a high-performance resin bond with excellent self-sharpening properties and elasticity. This prevents workpiece burning, absorbs grinding vibrations, and helps achieve a superior surface finish, potentially reducing the need for subsequent polishing steps.

- Professional Dynamic Balancing Control: Each wheel undergoes strict dynamic balancing control before shipment. This ensures stable, low-vibration operation at high speeds, which protects your machine’s spindle and is critical for achieving high-precision machining results.

- Lightweight & High-Strength Body: Designed with a lightweight yet robust body that reduces the load on the machine spindle. This design also aids in rapid heat dissipation, contributing to a more stable and effective grinding process.

Primary Applications

Engineered for a range of high-precision grinding tasks, our wheels provide solutions across multiple industries. Applications are broadly categorized into two main types:

1. Manufacturing & Regrinding of Cutting Tools

This is the primary application, focusing on creating and restoring the sharp, precise geometry of various cutting tools.

- Solid Carbide (Tungsten Carbide) Tooling: Used for manufacturing new tools (end mills, drills, reamers) and regrinding them to extend their service life.

- Superabrasive Tooling (PCD & PCBN): Essential for the precision finishing of Polycrystalline Diamond (PCD) and Polycrystalline Cubic Boron Nitride (PCBN) cutting edges.

- Specialized & Other Tooling: Includes the sharpening of alloy milling cutters and the precision grinding of specialty blades, such as those used for PCB V-cutting.

2. Grinding of High-Wear Industrial Components

Beyond cutting tools, this wheel is ideal for the surface and form grinding of durable components made from hard, brittle materials.

- Ceramic Components: Grinding of high-performance ceramic parts used in aerospace, medical, and semiconductor applications.

- Wear Parts: Finishing of tungsten carbide or cermet components like seals, nozzles, and guides that require high wear resistance.

- Magnetic Materials: Shaping and finishing of hard magnetic components for motors and sensors.

Target Materials

Excels at grinding a wide range of hard and brittle materials, including but not limited to:

- Tungsten Carbide (WC): All grades of cemented carbide.

- Advanced Engineering Ceramics: Such as Alumina (Al₂O₃), Zirconia (ZrO₂), and Silicon Nitride (Si₃N₄).

- PCD (Polycrystalline Diamond) & PCBN (Polycrystalline Cubic Boron Nitride) Composites.

- Magnetic Materials.

- Cermets (Ceramic-Metal Composites).

Custom Solutions

If our standard products do not meet your specific requirements, we can engineer and manufacture a fully customized grinding wheel solution. We will tailor the grit size, bond hardness, concentration, and dimensions to perfectly match your machine, material, and performance goals. Contact us to discuss your custom specifications.

Guidelines for Use and Maintenance

I. Daily Operation Standards

- Installation & Balancing

- Before mounting, inspect the wheel for integrity. Ensure it matches the spindle to prevent run-out. Perform dynamic balancing if necessary (imbalance amount ≤5g·cm).

- Secure with a specialized flange, ensuring clamping force is uniform to prevent vibration and localized wear.

- Grinding Parameter Control

- Rotational speed must not exceed the wheel’s maximum rated linear speed (typically ≤35m/s for resin bond wheels).

- Use a moderate feed rate to avoid excessive cutting force, which can lead to wheel chipping or excessive wear.

- Prioritize water-based coolants (e.g., emulsion) for temperature reduction to prevent high temperatures from causing resin bond failure.

II. Periodic Maintenance Measures

- Dressing & Cleaning

- Every 8-10 hours, dress the wheel surface with a diamond dressing pen or roller to restore sharpness (recommended dressing feed: 0.01-0.02mm).

- After dressing, clear metal chips from the wheel’s pores to prevent clogging (use compressed air or a specialized cleaning agent).

- A White Aluminum Oxide (WA) oil stone can be used to dress resin diamond wheels, but note: the stone’s hardness must be lower than the wheel’s abrasive; apply light pressure and slow speed during dressing to avoid damaging the resin bond layer.

- Lubrication & Inspection

- Add lubricating grease to the main spindle bearings every 3 months.

- Check the wheel’s thickness for wear; it must be replaced when the remaining thickness is less than 1/3 of the initial value.

III. Storage & Environmental Requirements

- Store in a dry environment (humidity <60%) to prevent the resin bond from absorbing moisture and deforming.

- If unused for a long period, it is recommended to apply anti-rust oil to the wheel’s end face to prevent oxidation.

IV. Common Issue Resolution

- Wheel Glazing (Dullness): Immediately dress the wheel and check if the coolant flow is sufficient.

- Abnormal Vibration: Re-perform dynamic balancing or check the spindle bearing clearance (standard value: 0.01-0.03mm).

Following these methods can extend the grinding wheel’s lifespan by 30%-50% while ensuring processing accuracy and safety.