1.It is used for periphery grinding of HSS.

2.Detailed HSS material as follows,

-Tungsten high speed steel 1.3355

-Powdered high speed steel ASP23

-Molybdenum/cobalt high speed steel M42

-Molybdenum/cobalt high speed steel M35

-Molybdenum high speed steel M2

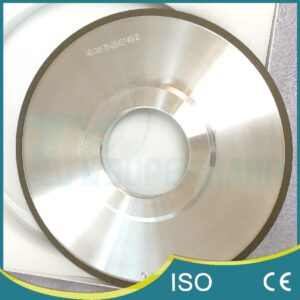

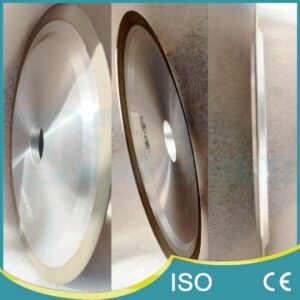

3.Characteristics of CBN grinding wheel

The hardness of CBN is higher than that of ordinary abrasives. High hardness means stronger and sharper cutting ability; CBN is more difficult to wear than standard abrasives; CBN can maintain the shape of abrasive particles. The high compressive strength of CBN means that it can keep the particles intact and not easily broken when used in harsh conditions. CBN has good thermal conductivity and can achieve cold cutting during grinding.

-High hardness, high toughness. Cubic boron nitride (CBN) is the human synthesis of hardness second only to diamond super hard material is much higher than ordinary corundum and silicon carbide abrasive, so it has a better cutting ability, sharper.

– Cubic boron nitride with good thermal stability can withstand the high temperature of 1250-1350 degrees Celsius; When grinding and cutting iron materials, there will be no sticky chip phenomenon. CBN wheels are ideal for grinding hardened steel, high vanadium, high-speed steel (HSS), high-speed aluminum steel, and other metal materials more sensitive to ground temperature.

– Strong chemical inertness doesn’t readily happen a chemical reaction with iron group elements, so it is very suitable for grinding materials with high temperature, high hardness, and low heat conductivity

– Good thermal conductivity CBN thermal conductivity can reach tens of times to one hundred times of corundum grinding wheel, so it can quickly export grinding heat, reduce the thermal deformation of the workpiece. Therefore, it is very suitable for grinding materials with low thermal conductivity, such as various spraying (welding) materials: nickel base, iron base, etc.; Cast iron materials: vanadium-titanium cast iron, high phosphorus cast iron, cold cast iron, etc. Titanium alloy class: such as TC4, etc.