-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

Looking to Perfect Carbide Roller Notching? Why PCD Tools/Inserts Are Your Best Bet and How to Choose Wisely

If you’re aiming to master the art of notching hard carbide rollers, what makes Polycrystalline Diamond (PCD) tools the leading choice, and how can you ensure you select and use them effectively for optimal results?

PCD tools/inserts are the best bet for perfecting carbide roller notching due to their unparalleled material properties which deliver superior performance, precision, and long-term cost-effectiveness. Choosing wisely involves understanding these inherent material advantages, correctly defining the tool specifications to match your specific application needs, and adhering to optimal operating guidelines to fully maximize their potential and achieve consistent, high-quality outcomes.

What Makes PCD the Superior Material for Notching Extremely Hard Carbide Rollers?

When you need to cut precise grooves, or notches, into incredibly hard materials like carbide rollers, what makes Polycrystalline Diamond (PCD) tools the top choice for this demanding job?

PCD tools are superior for notching hard carbide rollers primarily due to their exceptional hardness, leading to outstanding wear resistance. This advantage, in turn, translates into significantly longer tool life, reduced machine downtime, the ability to maintain tight tolerances for precise notches with excellent surface finish, and ultimately, greater overall cost-effectiveness in many demanding applications despite a higher initial tool investment.

Extreme Hardness and Wear Resistance: The PCD Advantage

Imagine you’re trying to scratch a very hard stone. You wouldn’t use a piece of chalk, would you? You’d need something even harder or just as hard that won’t crumble. Carbide rollers, often made from tungsten carbide, are like that super hard stone. To cut or “notch” them effectively, you need a cutting tool material that is up to the challenge. This is where Polycrystalline Diamond (PCD) steps in.

Understanding PCD’s Strength

PCD is a man-made material, created by fusing tiny diamond particles together at high pressure and high temperature. This process gives PCD incredible hardness, very close to that of a natural diamond, which is one of the hardest substances known. Consequently, PCD exhibits exceptional wear resistance1. This means it can withstand a great deal of rubbing and grinding (abrasion) without quickly wearing down, especially when machining tough materials like hardened steels or, in this case, carbide.

When a PCD notching insert meets a carbide roller, its superior hardness allows it to penetrate and cut the carbide material efficiently. Because it resists wear so well, the PCD cutting edge stays sharp and effective for a much longer period compared to other cutting tool materials, such as conventional cemented carbide tools2, when used on such abrasive workpieces. It’s important to remember that different grades of PCD are available, offering varying degrees of hardness and toughness, so consulting with your tool supplier can help match the best PCD grade to your specific type of carbide roller and notching application.

Achieving Longer Tool Life and Reduced Machine Downtime

One of the most significant practical benefits of PCD’s wear resistance is a dramatically extended tool life. Think about it: if your notching tool stays sharp longer, you don’t have to stop the machine as often to change worn-out inserts.

The Ripple Effect of Extended Tool Performance

This extended life of PCD notching tools has a powerful ripple effect:

- Reduced Machine Downtime: Every time a machine is stopped for a tool change, it’s not producing parts. With PCD inserts lasting significantly longer—sometimes 10 to 50 times longer than carbide tools in highly abrasive applications depending on conditions and materials—the machine keeps running and producing for extended periods. This drastically cuts down on non-productive downtime.

- Increased Productivity: More uptime directly means more carbide rollers can be notched in the same amount of time. This boost in output is crucial in production environments.

- Lower Tool Consumption: While one PCD insert might cost more initially, if it replaces many conventional inserts, the overall number of tools purchased and managed decreases.

- Consistent Production Flow: Fewer interruptions for tool changes lead to a smoother, more predictable manufacturing process. For instance, a facility notching hundreds of carbide rollers for rolling mills could see a substantial reduction in hourly or daily tool changes, leading to more consistent output and easier production scheduling.

While specific tool life can vary based on the exact PCD grade, the carbide roller’s composition, the notching parameters, and machine conditions, the general trend is a substantial improvement. Always refer to supplier recommendations for expected performance in your particular setup.

Ensuring Precision Notches and Excellent Surface Finish

When you’re making notches in carbide rollers, the accuracy of those notches—their depth, width, and shape—is often critical. Similarly, the smoothness of the cut surface, known as surface finish, can be very important for the roller’s final performance.

PCD tools excel in these areas for several key reasons:

- Maintained Cutting Edge Integrity: Because PCD resists wear so well, the cutting edge of the notching tool or insert retains its original geometry (shape and sharpness) for much longer. A tool that doesn’t wear quickly will continue to cut the same shape accurately, part after part. This is vital for achieving tight tolerances.

- Reduced Built-Up Edge (BUE): Some materials, when being cut, tend to stick to the tool’s cutting edge, forming what’s called a built-up edge. This BUE can degrade the surface finish and alter cutting accuracy. PCD’s low friction characteristics and chemical inertness with many non-ferrous materials (including the binders in some carbides) reduce the tendency for BUE formation, promoting cleaner cuts.

- Thermal Stability: While PCD tools must be used with appropriate cooling when machining materials that generate significant heat, certain PCD grades offer good thermal stability. This helps maintain the tool’s integrity and cutting performance even as temperatures rise at the cutting zone, contributing to consistent dimensional accuracy.

Consider a scenario in a rolling mill where carbide rollers with precisely machined rib or pass notches are used to produce rebar. If the notches wear or are inconsistently sized, the rebar produced will also be out of specification, leading to waste. PCD inserts help maintain that critical notch profile, ensuring the final product meets quality standards with a smooth finish that can reduce friction in the roller’s end-use application.

Overall Cost-Effectiveness for Demanding Applications

It’s true that PCD notching tools and inserts often have a higher upfront purchase price compared to tools made from other materials like tungsten carbide or ceramics. This can sometimes make businesses hesitate. However, looking only at the initial price doesn’t tell the whole story. To understand the true value, we need to consider the total cost of operation3.

Beyondnın Initial Price Tag: Calculating True Value

The overall cost-effectiveness of PCD tools in notching carbide rollers comes from several factors that often outweigh the higher initial investment, especially in medium to high-volume production or when machining particularly difficult grades of carbide:

- Lower Tool Cost Per Part: Even if a single PCD insert costs more, if it machines, for example, 20 times more carbide rollers than a conventional insert, the actual tool cost attributed to each notched roller becomes significantly lower.

- Savings from Reduced Downtime: As discussed, less frequent tool changes mean less machine downtime. Machine time is valuable, and reducing downtime translates directly into cost savings and increased production capacity.

- Reduced Labor Costs for Tool Changes: Fewer tool changes also mean less operator time spent on setting up and replacing tools.

- Improved Part Quality and Reduced Scrap: The precision and superior surface finish achieved with PCD can lead to fewer rejected rollers that don’t meet quality standards. This reduction in scrap material and rework saves money.

For example, a company machining grooves in tungsten carbide seal rings might find that while a PCD insert is three times the price of a carbide insert, it lasts thirty times as long and produces parts with a consistently better finish, thereby eliminating a secondary polishing step. In such a case, the adoption of PCD results in substantial net savings. It’s this calculation of total benefits versus total costs that reveals PCD’s strong economic advantage in demanding applications like notching carbide rollers.

How Do You Define the Correct Specifications for Your PCD Notching Inserts?

So, you understand that Polycrystalline Diamond (PCD) is an excellent material for making tools to notch tough carbide rollers. But how do you actually choose or define the exact PCD notching insert that will work best for your specific task?

Defining the correct specifications for your PCD notching inserts involves carefully matching the PCD grade to your carbide roller material, meticulously detailing key geometrical features like the notch profile and cutting edges, accurately selecting insert dimensions and their required tolerances, and deciding whether a standard or a custom-designed insert is the most suitable solution for your application. Close consultation with your PCD tool supplier is vital throughout this process.

Matching PCD Grade to Your Specific Carbide Roller Material

Not all PCD is the same, just like not all carbide rollers are identical. PCD “grades” differ mainly in the size of the diamond particles used to make them and sometimes the type of binder material. Choosing the right grade is like picking the right kind of tire for a car – you need one that matches the road conditions and how you want the car to perform.

Understanding PCD Grades and Their Impact

The size of the diamond grains in PCD affects its properties:

- Finer Grain PCD (e.g., sub-micron to ~5µm diamond grains): These grades typically offer the best edge quality and wear resistance when a very smooth surface finish is required on the carbide roller. They are often preferred for finishing operations or when machining less abrasive carbide grades that still demand high precision.

- Medium Grain PCD (e.g., ~10µm to 25µm diamond grains): This is often a good all-around choice, balancing wear resistance with toughness. It’s suitable for many general-purpose notching applications on various carbide roller

materials. - Coarser Grain PCD (e.g., >25µm diamond grains): These grades are generally tougher and more resistant to chipping. They might be chosen for applications with interrupted cuts, heavier notching operations (roughing), or when machining carbide rollers that are particularly abrasive or contain harder inclusions.

The type of carbide roller you are notching also plays a big role. Carbide rollers can vary in their composition, such as the percentage of cobalt binder and the grain size of the tungsten carbide. A more abrasive carbide might require a PCD grade with higher wear resistance, while a tougher carbide might need a tougher PCD grade.

Here’s a very general guide (always confirm with your supplier):

| PCD Grain Size Category | Typical Diamond Size | Key Characteristics | Common Use Case for Carbide Notching |

|---|---|---|---|

| Fine | < 5µm | Best surface finish, good wear resistance | Finishing, high precision notches |

| Medium | 5µm – 25µm | Good balance of wear resistance & toughness | General purpose notching |

| Coarse | > 25µm | Highest toughness, good for interruptions | Roughing, very abrasive carbide grades |

Crucially, the ideal PCD grade can vary significantly. It’s always best to discuss your specific carbide roller material (if known, provide its grade or composition) and the desired outcome (e.g., surface finish, tool life) with your PCD tool supplier. They have the expertise to recommend the most suitable grade from their offerings.

Key Geometrical Features: Notch Profile, Cutting Edges, and Clearances

The “geometry” of the PCD notching insert refers to its shape, especially the part that does the cutting. Getting this right is essential for creating the correct notch accurately and efficiently. Think of it like a key needing the right shape to fit a lock.

Defining the Shape that Cuts

Important geometrical features include:

- Notch Profile: This is the exact shape of the groove you want to create in the carbide roller (e.g., V-shape, U-shape, rectangular, or a more complex custom profile like those used for specific rebar patterns). The tip of the PCD insert must be precisely shaped to form this profile. You’ll often need to provide a drawing or detailed specifications of the desired notch.

- Cutting Edges:

- Edge Preparation: PCD cutting edges can be very sharp, but for machining hard materials like carbide, they are often given a slight “hone” (rounding) or a “chamfer” (a small flat angle) to make them stronger and prevent chipping. The type of edge preparation influences both tool life and the finish on the roller.

- Number of Usable Edges: Some insert designs might offer multiple cutting edges if the geometry allows, which can provide better value.

- Clearance Angles (Relief Angles): These are angles ground behind the cutting edge. They prevent the non-cutting part of the insert from rubbing against the freshly cut surface of the carbide roller. Proper clearance reduces friction, heat, and tool wear, and is crucial for achieving a good surface finish. Too little clearance causes rubbing; too much can weaken the cutting edge.

- Rake Angle: This is the angle of the cutting face relative to the workpiece. For machining very hard materials like carbide with PCD, rake angles are often neutral or slightly negative to provide maximum strength to the cutting edge.

The exact geometry, especially for complex notch profiles or specific edge preparations, is highly specialized. Detailed technical drawings and close collaboration with your tool supplier are essential to ensure the PCD insert geometry perfectly matches your notching requirements. Small variations in angles or profiles can significantly impact performance and the quality of the notched carbide roller.

Selecting Appropriate Insert Dimensions and Tolerances for Your Rollers

Once you know the PCD grade and the cutting geometry, you need to specify the physical size of the PCD notching insert and how precise those dimensions need to be (“tolerances”).

Getting the Size and Precision Right

- Overall Insert Dimensions: This includes the length, width, and thickness of the PCD insert itself, or the diameter and length if it’s a cylindrical shank tool. These dimensions must be compatible with the tool holder or clamping mechanism in your notching machine. For instance, if the PCD insert is brazed onto a carbide shank, the shank dimensions are also critical.

- Cutting Feature Dimensions: These are the specific measurements of the part of the insert that forms the notch – for example, the exact width of a rectangular notching tip, the radius of a U-notch, or the depth of the cutting feature. These directly determine the dimensions of the notch on the carbide roller.

- Tolerances: A tolerance specifies how much a dimension can vary from its stated value (e.g., ±0.01mm). Tighter tolerances mean the insert will be made more precisely, which is often necessary for high-precision notching. However, extremely tight tolerances can increase the cost of the PCD insert. You need to define tolerances that are strict enough to meet your quality requirements for the notched roller but not unnecessarily tight.

For example, if a carbide roller requires a V-notch with an included angle of 60 degrees and a depth of 3mm, the PCD insert must be manufactured to produce this angle and depth within acceptable limits (tolerances). Always provide your tool supplier with detailed drawings or specifications of the carbide roller and the desired notch, including all critical dimensions and required tolerances. They can then ensure the PCD insert is manufactured to meet these needs.

Standard vs. Custom PCD Insert Designs: When to Opt for Tailored Solutions

Finally, you’ll need to consider whether a “standard” off-the-shelf PCD notching insert will work, or if you need a “custom” designed solution.

Making the Choice: Off-the-Shelf or Made-to-Order?

- Standard PCD Inserts:

- What they are: These are inserts with common shapes, sizes, and PCD grades that manufacturers might keep in stock or produce regularly. They are often designed for more general-purpose notching applications.

- When to use them: If your required notch profile is simple and common (e.g., a basic V-groove or straight slot), and a standard size fits your machine and application, a standard insert might be a quicker and more economical option.

- Potential limitations: May not offer the optimal geometry or PCD grade for highly specialized carbide roller notching tasks. Availability of very specific standard notching inserts for carbide can be limited.

- Custom PCD Inserts:

- What they are: These inserts are designed and manufactured specifically for your unique application. This means the PCD grade, all geometrical features (like intricate notch profiles), dimensions, and tolerances are tailored to your exact requirements.

- When to use them:

- When you have a complex or proprietary notch profile.

- If you need very specific dimensions or extremely tight tolerances.

- When you want to optimize the insert design (PCD grade, geometry) for a particular grade of carbide roller to maximize tool life or performance.

- If standard options simply don’t meet your needs.

- Considerations: Custom inserts4 typically have longer lead times and may have a higher initial cost per piece due to the design and manufacturing effort. However, for critical or high-volume applications, the improved performance and tool life of a custom solution can often justify the investment.

The decision between standard and custom often comes down to the complexity of your notching task, the volume of rollers to be processed, and your performance goals. Discussing your application in detail with your PCD tool supplier is the best way to determine if a standard insert is adequate or if a custom-designed PCD notching insert will provide better value and results for your carbide rollers. They can help you weigh the trade-offs.

What Are the Key Operating Guidelines for Optimal Performance of PCD Notching Tools on Carbide?

You’ve selected your specialized PCD notching tool; now, how do you actually use it on carbide rollers to get the best performance and longest life?

Achieving optimal performance from PCD notching tools on carbide rollers hinges on applying recommended cutting parameters, utilizing effective coolant and lubrication strategies, diligently monitoring tool wear patterns for timely replacements, and adhering to best practices for tool holder selection, machine setup rigidity, and routine maintenance. Following these guidelines, in close consultation with your tool supplier, is key to success.

Recommended Cutting Parameters (Speed, Feed, Depth of Cut) for PCD on Carbide

Think of cutting parameters as the recipe for how your PCD tool will interact with the carbide roller. The main ingredients are cutting speed, feed rate, and depth of cut. Getting this recipe right is crucial for good results. Using the wrong settings can lead to poor tool life, bad surface finish, or even damage to your expensive PCD tool or the carbide roller.

Understanding Each Parameter’s Role

- Cutting Speed (Vc): This is how fast the surface of the carbide roller passes by the PCD cutting edge, usually measured in meters per minute (m/min) or surface feet per minute (SFM)5.

- For PCD notching tungsten carbide, cutting speeds can vary widely, for example, from around 30 m/min to over 100 m/min (approximately 100-330 SFM). However, this is a very general range.

- Too slow: Can sometimes lead to chipping of the PCD edge because the tool is “pushing” more than cutting.

- Too fast: Can generate excessive heat, potentially damaging the PCD (especially if cooling is inadequate) or accelerating abrasive wear.

- Feed Rate (f): This is how quickly the PCD tool advances into or along the carbide roller per revolution or per tooth, usually measured in millimeters per revolution (mm/rev) or inches per revolution (IPR).

- A higher feed rate generally means faster material removal but can increase cutting forces and potentially lead to a rougher surface finish or edge chipping if too aggressive.

- A lower feed rate typically improves surface finish but slows down the operation.

- Depth of Cut (ap): This is how much material the PCD insert removes in one pass, or the depth of the notch if cut in a single pass.

- For notching, this might be the full depth of the desired groove. However, for very deep or wide notches, it might be better to use multiple shallower passes, especially with PCD, which is hard but can be brittle.

- Attempting too deep a cut can put excessive stress on the PCD insert, leading to premature failure.

Important Note on Parameters: The ideal cutting speed, feed rate, and depth of cut are highly dependent on the specific PCD grade, the exact composition and hardness of your carbide roller, the geometry of the PCD notching insert, the rigidity of your machine and setup, and the coolant application. Always start with the cutting parameter recommendations provided by your PCD tool supplier. These are your best initial guidelines. Then, you may need to carefully adjust these parameters based on the actual results (tool wear, surface finish, cycle time) to optimize the process for your specific application.

Effective Coolant and Lubrication Strategies for Heat Management and Swarf Removal

When PCD tools cut hard materials like carbide rollers, a lot of heat can be generated at the cutting zone. Also, small chips of carbide material (called swarf) are produced. Managing this heat and removing the swarf effectively is vital for protecting the PCD tool and achieving a good quality notch.

Why Cooling and Lubrication Matter

- Heat Management: PCD can lose its hardness and wear out very quickly if it gets too hot (generally, diamond starts to degrade significantly above 700°C or about 1300°F). Proper cooling helps keep the PCD insert’s temperature within safe limits.

- Swarf Removal: If swarf isn’t cleared away, it can get trapped between the tool and the workpiece, causing scratches on the surface finish or even recutting of chips, which can damage the PCD edge.

- Lubrication: While PCD has low friction, a lubricant can further reduce friction, which in turn reduces heat generation and cutting forces, potentially improving tool life and surface finish.

Common Strategies

- Flood Coolant: This is the most common method for PCD machining of carbide. A generous flow of liquid coolant (often a water-based emulsion or synthetic fluid) is directed at the cutting zone.

- Ensure good flow rate and pressure: The coolant stream must reach the actual point of cutting. Use nozzles positioned correctly.

- Maintain coolant quality: Keep the coolant clean and at the correct concentration as recommended by the coolant supplier.

- Minimum Quantity Lubrication (MQL): In some specific, lighter PCD applications, MQL (a fine mist of oil in air) might be considered. However, for heavy notching on hard carbide, flood coolant is generally more reliable for heat removal.

- Dry Machining: This is generally not recommended for PCD notching of carbide rollers due to the high heat generated and the abrasive nature of carbide dust.

The choice of coolant type and its application method can impact tool life and performance. Consult both your PCD tool supplier and your coolant supplier for recommendations suitable for your specific PCD grade and carbide roller material.

Monitoring Tool Wear Patterns and Implementing Timely Insert Replacements

Even though PCD tools last a long time, they don’t last forever. As the PCD notching insert cuts the carbide roller, it will gradually wear down. It’s important to watch for signs of wear and replace the insert before it wears too much or fails completely. Letting a tool get too worn can damage the carbide roller, the tool holder, or even the machine.

Recognizing Wear and Knowing When to Act

- Common PCD Wear Patterns:

- Flank Wear6: This is a gradual abrasive wearing away of the material on the side (flank) of the cutting edge. It looks like a shiny flat area. This is the most common and predictable type of wear.

- Chipping: Small pieces of the PCD cutting edge break off. This can be caused by an unstable setup, interrupted cuts, or using the wrong cutting parameters.

- Crater Wear: A dishing or crater forming on the top face of the tool (less common with PCD unless there are chemical interactions, which are not typical with carbide).

- How to Monitor Wear:

- Visual Inspection: Regularly look at the PCD cutting edge, often with a microscope or a strong magnifying glass.

- Surface Finish Changes: If the surface finish of the notched carbide roller starts to get rougher or shows drag marks, it’s a sign the tool is wearing.

- Dimensional Changes: If the notches are no longer meeting the required size tolerances, the tool is likely worn.

- Increased Cutting Forces or Power Consumption: Modern machines can often monitor how much power the spindle is using. A sudden increase can indicate a dull or failing tool.

- Sound Changes: Experienced machinists can often hear when a tool is starting to dull or chip.

- When to Replace the Insert:

- Most tool suppliers will provide guidelines for maximum allowable wear (e.g., a maximum flank wear land width, like VB = 0.2mm or 0.3mm).

- Replace the insert when it reaches this wear limit, or if you see significant chipping, or if the part quality is no longer acceptable.

- It’s better to replace a tool a bit early based on predictable wear than to wait for it to break, which can cause more significant problems.

Keeping records of tool life and wear patterns can help you optimize when to change tools for consistent production.

Best Practices for Tool Holder Selection, Setup Rigidity, and Maintenance

The best PCD notching insert in the world won’t perform well if it’s not held securely in a stable machine. The entire system – from the machine spindle to the tool holder to how the carbide roller is clamped – needs to be rigid and well-maintained.

Ensuring a Solid Foundation for Cutting

- Tool Holder Selection:

- The tool holder (or the machine’s collet/clamping system for shank tools) must grip the PCD insert or its shank very securely. Any movement or vibration will dramatically reduce tool life and hurt surface finish.

- Use high-quality, precision-balanced tool holders, especially if operating at higher cutting speeds.

- Ensure the pocket or seat for the insert is clean and undamaged.

- Setup Rigidity:

- Machine Tool Condition: The machine itself should be in good condition, with minimal play or vibration in the spindle bearings and machine slides.

- Workpiece Clamping: The carbide roller must be clamped very securely to prevent it from moving or vibrating during the notching operation.

- Tool Overhang: Keep the distance the PCD tool sticks out from the holder (the overhang) as short as possible. A longer tool overhang acts like a lever and can increase vibration.

- Maintenance:

- Regular Checks: Periodically inspect tool holders for wear or damage. Ensure clamping mechanisms are functioning correctly.

- Cleanliness: Keep the machine, tool holders, and the cutting area clean. Swarf buildup can interfere with proper tool seating and coolant flow.

- Careful Handling of PCD Tools: PCD is hard but also somewhat brittle. Avoid dropping PCD inserts or banging them against hard surfaces, as this can easily chip the delicate cutting edges. Store them properly when not in use.

Think of this like building a tower: if the foundation is shaky, the whole tower will be unstable. A rigid, well-maintained setup is the foundation for successful PCD notching on carbide rollers.

Conclusion

Perfecting the notching of carbide rollers is a challenging yet achievable task with the right approach. Polycrystalline Diamond (PCD) tools and inserts undeniably stand out as the superior choice due to their exceptional material properties that lead to longer life, higher precision, and better overall economy.

Successfully leveraging PCD technology involves a three-pronged strategy:

- Understanding Why PCD Excels: Recognizing the inherent advantages of PCD’s hardness, wear resistance, and its impact on precision and cost-effectiveness is the first step.

- Defining the Right Tool: Carefully selecting the appropriate PCD grade, meticulously defining the insert’s geometry and dimensions, and deciding between standard or custom designs are crucial for matching the tool to the specific demands of your carbide roller application.

- Optimizing Operation: Implementing correct cutting parameters, ensuring effective cooling and lubrication, diligently monitoring tool wear, and maintaining a rigid, stable machining environment are all key to unlocking the full potential of your PCD notching tools.

By focusing on these areas and working closely with experienced PCD tool suppliers, you can significantly enhance your carbide roller notching operations, achieving superior quality, improved productivity, and a stronger bottom line.

References

- exceptional wear resistance1 – ZYDiamondTools blog post explaining key properties of PCD including wear resistance.

- conventional cemented carbide tools2 – ZYDiamondTools blog post comparing PCD and Carbide cutting tools.

- total cost of operation3 – ZYDiamondTools blog post explaining the Total Cost of Ownership (TCO) for superhard tooling.

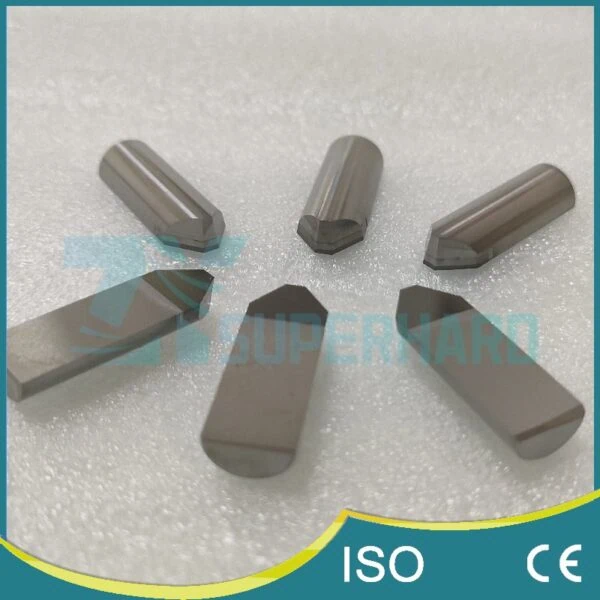

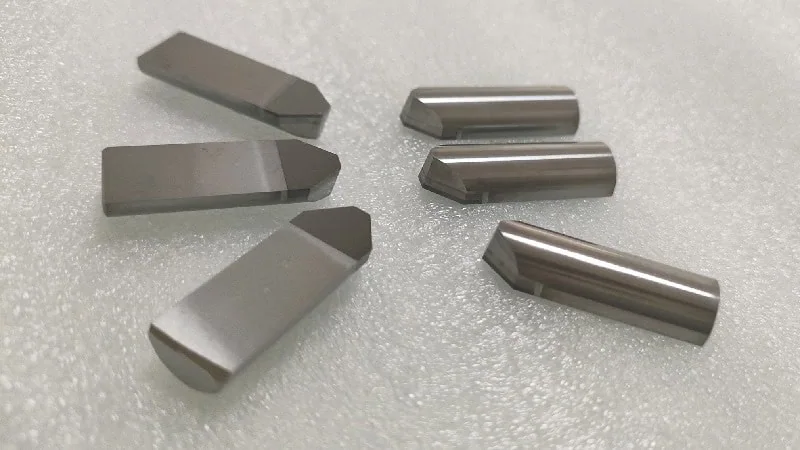

- Custom inserts4 – ZYDiamondTools product page for custom PCD notching tools for tungsten carbide roll machining.

- surface feet per minute (SFM)5 – Wikipedia page explaining the concept and calculation of Surface Feet per Minute (SFM) in machining.

- Flank Wear6 – ScienceDirect topic page providing an overview and details on flank wear in cutting tools.