Product Categories

Didn’t find what you were looking for? Don’t worry, just send us a message, and our professional sales team will contact you within 24 hours! We can customize according to your needs!

PCD Grooving Insert 8040 Series

Description

Achieve high precision and efficiency in full-radius grooving and profiling operations on non-ferrous metals and abrasive composites with these high-performance PCD indexable inserts. Part of the 8040 size series, they feature a precise 8.0mm cutting width and a true R=4.0mm full radius cutting edge, ideal for creating perfect semi-circular groove profiles or complex contours where accuracy and surface finish are paramount. Leverage the exceptional properties of Polycrystalline Diamond to effectively machine challenging materials at high speeds.

The PCD Advantage for Full Radius Machining

When machining non-ferrous materials (especially high-silicon aluminum) and abrasive composites (like CFRP/GFRP), traditional carbide inserts often suffer from rapid abrasive wear, built-up edge (BUE), or limitations in cutting speed. These PCD inserts overcome these challenges:

- Exceptional Wear Resistance: PCD is significantly harder than carbide, offering outstanding resistance to abrasive wear, leading to much longer tool life, fewer tool changes, and consistent profile accuracy over long production runs.

- High Cutting Speeds: The thermal stability and hardness of PCD allow for significantly higher cutting speeds (Vc) compared to carbide, drastically reducing cycle times.

- Superior Surface Finish: The ability to maintain a sharp, durable edge results in excellent surface finishes on aluminum, copper, composites, and other non-ferrous materials, often minimizing secondary finishing needs.

- Reduced Built-Up Edge: PCD’s lower friction coefficient compared to carbide helps prevent material adhesion (BUE), particularly problematic when machining aluminum alloys.

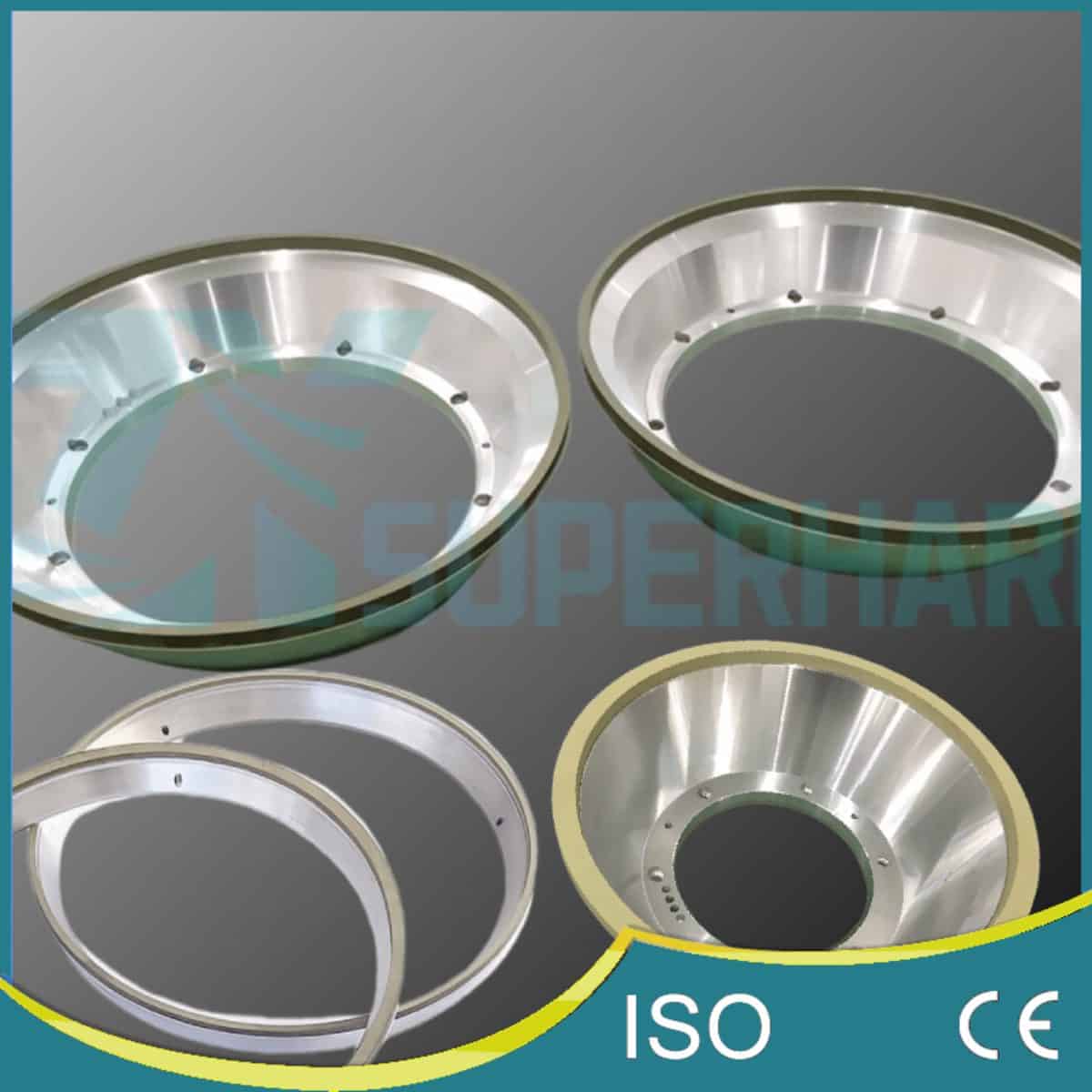

Features of These PCD Full Radius Inserts

- Precise Full Radius Geometry: Feature an R=4.0mm full-radius cutting edge ground to tight tolerances on an 8.0mm width, ensuring accurate semi-circular groove generation or precise profile machining.

- Robust Construction: A high-quality PCD cutting edge is securely brazed onto a tough carbide substrate, providing the optimal balance of extreme hardness and wear resistance at the edge with robust support from the base.

- Application-Specific Rake Face Options:

- Flat Top: Provides a smooth cutting action, often preferred for finishing passes or in materials where chip control is less critical.

- With Chip Breaker: Features specifically engineered geometry on the rake face to aid in controlling and breaking chips, beneficial in deeper grooves or materials prone to long, continuous chips.

- Compatibility: Designed with interface geometry suitable for use in tool holders intended for GIDA 80-40 style full radius inserts.

Applications & Material Suitability

These PCD full radius inserts excel in:

- Full Radius Grooving: Creating precise, smooth R=4.0mm round-bottom grooves.

- Profiling & Contouring: Generating external or internal profiles with a defined 4.0mm radius on suitable materials.

- Specific Radius Turning: Applications where a large radius edge is needed for turning operations.

Suitable Workpiece Materials:

- Aluminum Alloys: Including low-silicon, high-silicon alloys, cast and wrought aluminum.

- Copper Alloys: Copper, Brass, Bronze.

- Composites: Carbon Fiber Reinforced Polymers (CFRP), Glass Fiber Reinforced Polymers (GFRP).

- Graphite: For electrode manufacturing or other graphite components.

- Plastics: Especially reinforced or abrasive plastics.

- (Not suitable for ferrous materials like steel or cast iron)

Cutting Parameter Guidance

Optimal results require appropriate parameter selection:

- Cutting Speed (Vc): PCD allows for very high speeds on target materials (often 500-3000 m/min or higher, depending on specific material and conditions).

- Feed Rate (f): Balance feed for desired surface finish and chip load. Refer to specific PCD grade recommendations.

- Depth of Cut per Pass (ap): The recommended maximum depth per pass (ap max) for this insert is 4.0mm. The typical maximum grooving depth (CDX) achievable with compatible holders for this system is 25.0mm (holder dependent).

Important Note: Optimal cutting parameters are highly dependent on the specific PCD grade, workpiece material details, machine rigidity, coolant application (often crucial), and the required outcome. Start with recommended values and optimize carefully. Please consult our technical team for guidance.

Tool Holder Compatibility

Always use these inserts with high-quality, rigid tool holders designed for the corresponding insert size and style (compatible with GIDA 80-40 full radius type) to ensure secure clamping, accurate positioning, and optimal performance. Verify holder compatibility, especially regarding full radius clearance.

Customization & Ordering

Select the optimal configuration for your task – these inserts are readily available with either a Flat Top or an integrated Chip Breaker rake face. We also excel at providing tailored solutions. Take advantage of customization options including different PCD grades, edge preparations, and other modifications to perfectly match your machining needs. Our technical experts are available to help you determine the best fit. Contact us to explore possibilities and discuss your application.

Didn’t find what you were looking for? Don’t worry, just send us a message, and our professional sales team will contact you within 24 hours! We can customize according to your needs!

You may be interested in...