-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

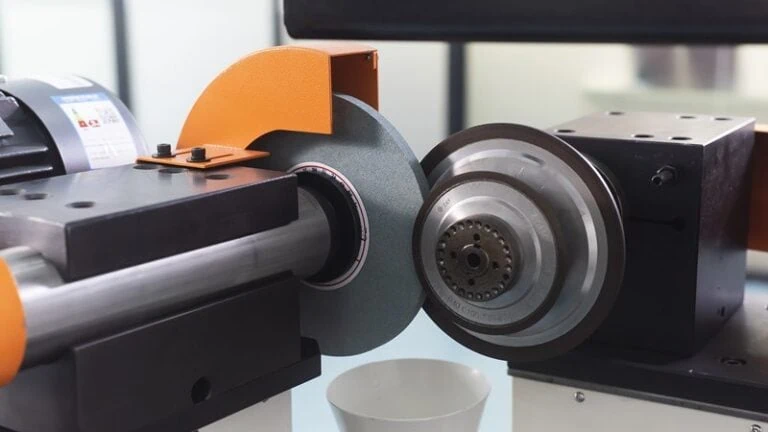

How Do You Select the Right Diamond Grinding Wheel for Your Specific Process?

How do you ensure you are choosing the absolute best diamond grinding wheel configuration for your manufacturing needs?

Selecting the right diamond grinding wheel1 requires a systematic analysis of the workpiece material’s hardness and ductility, which dictates the abrasive type. This is followed by choosing the appropriate bond system (resin, metal, vitrified, or plated) to balance cutting speed with wheel life, determining the optimal grit size for surface finish requirements, and adjusting the diamond concentration based on the available coolant system and contact area constraints.

Analyzing Your Workpiece Material Properties

The physical properties of your workpiece are the starting point for all abrasive decisions.

The hardness and ductility of your workpiece represent the most critical factors in selecting a grinding wheel. Hard, brittle materials like tungsten carbide2 require diamond abrasives to fracture and remove material efficiently without generating excessive heat. Conversely, the material’s tendency to produce long, stringy chips determines the necessary spacing between abrasive grains to prevent the wheel from clogging during the process.

Impact of Hardness and Brittleness on Abrasive Choice

The first step in your selection process is understanding exactly how hard and brittle your material is. In the grinding industry, diamond is the hardest known abrasive. Therefore, it is the standard choice for materials that are extremely hard but also brittle, such as tungsten carbide, ceramics, and glass.

However, you must distinguish between hardness and toughness. Hardness refers to how well a material resists being scratched or penetrated. Brittleness refers to how easily it breaks or shatters when stressed. For example, a ceramic insert is very hard but will shatter if dropped. When you grind these materials, the diamond grains must penetrate the surface to create small chips.

If you use the wrong abrasive on a hard material, the wheel will glaze over. This means the abrasive grains dull and rub against the part instead of cutting it. This generates friction and heat, which can crack expensive workpieces.

Material Compatibility Guide:

| Material Type | Characteristics | Recommended Action |

|---|---|---|

| Tungsten Carbide | High Hardness, Low Ductility | Primary use for Diamond Wheels. Requires sharp cutting action. |

| Technical Ceramics | Extreme Hardness, High Brittleness | Requires diamond with strictly controlled friability (ability to self-sharpen). |

| Ferrous Metals (Steel) | High Toughness, Chemical Reactivity | Avoid Diamond. Carbon in diamond reacts with iron at high heat. Use CBN instead. |

Think of this interaction like a milling operation. When milling cast iron (brittle), the material breaks into small powder-like chips. This is similar to how diamond grinds carbide. If you tried to use that same cutter geometry on soft aluminum, it would not work because the material behaves differently. Similarly, the specific grade of your workpiece dictates how the diamond grain interacts with the surface.

Addressing Material Loading and Clogging Risks

After assessing hardness, you must analyze the “gumminess” or ductility of the material. This factor determines the risk of loading. Loading happens when the material being ground becomes soft due to heat and sticks to the surface of the grinding wheel.

When a wheel loads, the chips fill the empty spaces (pores) between the diamond grains. Once these spaces are full, the diamond can no longer cut. It simply rubs against the part. This is a common issue when grinding materials that are not purely hard, such as:

- Carbide with high Cobalt content (The cobalt binder is soft and sticky).

- Cermets (Ceramic-metal composites).

- Specific sprayed coatings.

If your process involves these materials, you cannot simply choose a standard dense wheel. You must anticipate the volume of chips that will be produced.

Signs You Are Facing a High-Loading Application:

- Chip Formation: The material produces long, stringy chips rather than dust.

- Smearing: You see material smeared across the face of the wheel after a pass.

- Power Spikes: The machine spindle load increases rapidly because the wheel is clogged.

To visualize this, consider drilling a deep hole. If the flutes of the drill bit get packed with chips, the drill can no longer cut and will eventually overheat or break. In grinding, the “flutes” are the microscopic spaces between diamond particles. If your material analysis predicts high loading, you know you will need a wheel specification designed with more open space (porosity) to allow those chips to escape.

Choosing the Correct Bond Type for Your Application

The bond system is the chassis of the grinding wheel, determining how it behaves under stress.

The bond type3 acts as the binder that holds the diamond abrasive grains in place, determining the wheel’s rigidity, wear rate, and ability to release dull particles. Selecting the right bond ensures the wheel retains its structural integrity for precision work while eroding at a controlled rate to expose sharp new diamonds, preventing the tool from glazing or losing its profile.

Resin Bond for Free Cutting and Fine Finishes

Resin bond wheels4 are the most widely used options in the diamond grinding industry. Manufacturers create these by mixing diamond abrasive with phenolic resin5 and fillers, then curing them under heat and pressure.

The primary advantage of a resin bond is its self-sharpening capability. As you grind, the resin wears away at a consistent rate. This erosion releases dull diamond grains and exposes fresh, sharp edges. Consequently, resin bonds offer a “free cutting” action, which means they remove material quickly without generating excessive heat.

Consider a surface grinding operation. If you need a smooth finish on a carbide insert, a resin bond is forgiving. It has a slight amount of elasticity. This elasticity acts like a shock absorber, reducing chatter marks on the workpiece.

Key Characteristics:

- Fast Material Removal: Excellent for stock removal on hard materials.

- Cool Grinding: The bond breaks down before heat builds up significantly.

- Versatility: Suitable for both wet and dry grinding (though wet is preferred).

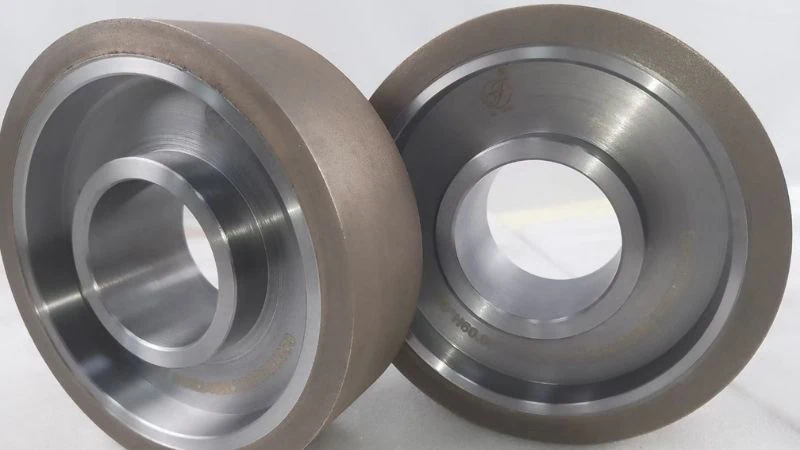

Metal Bond for Durability in Heavy Grinding

In contrast to resin, metal bond wheels use sintered6 bronze, copper, or steel alloys to hold the diamond. This creates the strongest possible retention of the abrasive grain.

You should choose a metal bond when wheel life and form holding are your top priorities. Because the metal matrix is so hard, it does not wear away easily. This makes it ideal for grinding highly abrasive materials like glass, ceramics, and ferrites that would quickly destroy a resin wheel.

Think of a metal bond wheel like a rigid turning tool holder. It does not flex. This rigidity allows the wheel to hold a sharp corner or a specific radius for a very long time. However, this durability comes with a trade-off. Metal bonds grind slower and require more spindle power. They also generate significant heat, meaning you must use coolant.

Comparison of Resin vs. Metal Bond:

| Feature | Resin Bond | Metal Bond |

|---|---|---|

| Wear Rate | High (Self-sharpening) | Low (Long Life) |

| Cutting Action | Free, Aggressive | Slower, requires pressure |

| Profile Retention | Low to Medium | Excellent |

| Dressing | Easy to dress | Difficult (often requires EDM) |

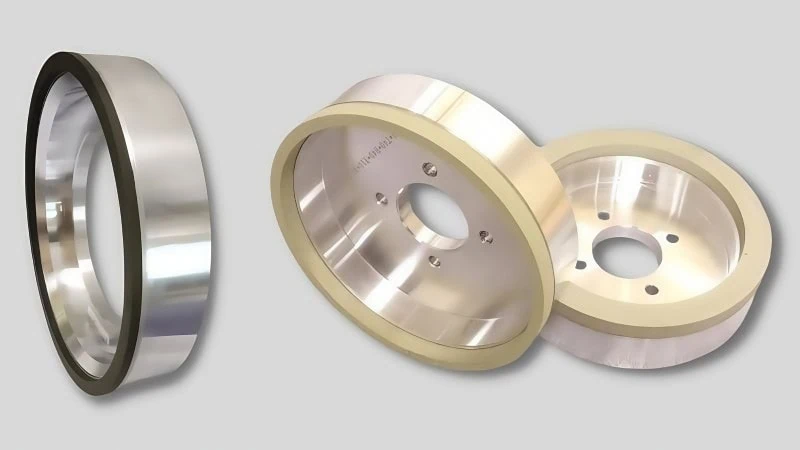

Vitrified Bond for High Precision Automated Processes

Vitrified bonds are composed of ceramic materials or glass. They are melted to fuse with the diamond grain, creating a porous, rigid structure.

This bond type is the premium choice for high-volume, automated precision grinding, such as camshaft grinding or manufacturing PCD (Polycrystalline Diamond) tools7. The magic of the vitrified bond lies in its porosity.

Imagine a sponge structure made of glass. The “holes” in the sponge allow coolant to flow directly to the contact zone and provide space for large chips to escape. This natural porosity prevents the wheel from loading, even during deep cuts.

Furthermore, vitrified wheels are rigid like metal bonds but brittle like glass. This brittleness is actually a benefit. It allows the wheel to be “trued” and “dressed” very precisely directly on the CNC machine using a rotary dresser. You can automate the dressing cycle to maintain perfect roundness without removing the wheel from the machine, significantly reducing downtime.

Electroplated Bond for Complex Profiles and Aggressive Removal

Electroplated (or plated) wheels are fundamentally different from the previous three types. Instead of mixing diamond throughout a binder, a single layer of diamond is chemically bonded to the surface of a steel hub using nickel plating.

Since there is only one layer of abrasive, the diamond particles protrude significantly from the bond. This high “grain exposure” makes electroplated wheels incredibly aggressive. They remove material faster than any other bond type relative to their size.

You would select this bond for complex form grinding. Because the manufacturer machines the steel core to the exact shape you need, the diamond layer follows that contour perfectly. There is no need for you to profile the wheel.

Critical Limitations:

- Finite Life: Once the single layer of diamond wears out, the wheel is useless and must be recoated.

- No Dressing: You cannot dress an electroplated wheel. If you try to true it with a dressing stick, you will simply strip off the diamond layer.

Industry Reminder: Plating thickness and diamond exposure percentages can vary by plating shop. Always confirm the coating tolerance with your vendor, especially for high-precision profile work.

Determining Grit Size and Concentration Levels

Balancing the abrasive size and density is key to optimizing cycle times and costs.

Grit size dictates the trade-off between material removal rates and surface finish quality, where coarser grains cut faster but leave rougher surfaces. Concentration defines the volume of diamond within the bond; higher concentrations improve wheel life and shape retention for precision profiles, while lower concentrations prevent heat buildup in large surface area applications.

Balancing Stock Removal Rate with Surface Finish Requirements

The “grit” refers to the physical size of the diamond particles held in the wheel. In the abrasive industry, this is measured by mesh size. A lower number (e.g., 60 grit) indicates a large, coarse particle. A higher number (e.g., 400 grit) indicates a fine, dust-like particle.

Your selection process must always start with the required surface finish (Ra)8. If the engineering print demands a mirror finish, you cannot use a coarse wheel, regardless of how fast you want to work. However, using a wheel that is too fine for a roughing operation is a common mistake. Fine grits have small spaces between particles. These spaces fill up with chips quickly, leading to burns and slow cycle times.

Think of grit selection like choosing the feed rate on a CNC lathe. A high feed rate (coarse grit) removes metal fast but leaves visible scallop marks. A low feed rate (fine grit) leaves a smooth surface but takes much longer to complete the pass.

Standard Grit Applications and Expected Finishes:

| Grit Size (Mesh) | Classification | Typical Application | Approx. Surface Finish (Ra µin) |

|---|---|---|---|

| 46 – 60 | Roughing | Aggressive stock removal; rapid sizing. | > 32 |

| 80 – 120 | Medium | General purpose; sharpening drills/mills. | 16 – 32 |

| 180 – 220 | Fine | Finishing passes; tight tolerance work. | 8 – 16 |

| 320 – 600 | Super Fine | Polishing; high-precision cutting tools. | < 8 |

Note: Surface finish results depend heavily on machine rigidity and coolant quality. Always conduct a test cut to verify the Ra value matches your specific setup capabilities.

For multi-stage processes, the most efficient strategy is often using two wheels. You use a coarse wheel (e.g., 100 grit) to remove 90% of the stock. Then, you switch to a fine wheel (e.g., 320 grit) for the final spark-out pass. This maximizes both speed and quality.

Selecting Concentration for Tool Life versus Cost Efficiency

Concentration is perhaps the most misunderstood variable in wheel selection. It represents the amount of diamond carat weight per cubic centimeter of bond material.

- Concentration 100: This is the industry standard reference point, containing 4.4 carats/cm³.

- Concentration 75: Contains roughly 3.3 carats/cm³.

- Concentration 50: Contains roughly 2.2 carats/cm³.

Many operators assume that “more diamond is always better.” This is incorrect. While a higher concentration increases the wheel’s life, it also increases the grinding pressure. If there are too many diamond particles, they cannot penetrate the workpiece deeply. They rub instead of cut.

You should select High Concentration (100, 125, or 150) when holding a complex form is critical. For example, when grinding a thread or a small corner radius on a carbide insert, the wheel must not wear down quickly. If it wears, the profile of your tool changes, and the part is scrapped. The dense diamond packing reinforces the wheel’s edge.

Conversely, you should select Low Concentration (50 or 75) for large contact areas. Imagine face grinding a large carbide plate with a 10-inch wheel. If you use a high concentration, thousands of diamond points contact the part simultaneously. This generates immense friction and heat. A lower concentration reduces the number of cutting points. This lowers the grinding force and allows the wheel to cut freely without burning the part.

Concentration Selection Guide:

| Contact Area Size | Recommended Concentration | Reason for Selection |

|---|---|---|

| Small / Narrow | High (100 – 150) | Ensures the wheel edge does not break down; maintains profile accuracy. |

| Medium / Standard | Medium (75 – 100) | Provides a balanced compromise between cut rate and wheel life. |

| Large / Wide | Low (50 – 75) | Reduces grinding pressure; allows better coolant penetration. |

The Critical Role of Coolant in Wheel Selection

Coolant is not just an accessory; it is a component of the cutting tool system that defines your parameter limits.

Coolant availability is the decisive factor in selecting the bond hardness and core material of your grinding wheel. Wet grinding allows for the use of harder, more durable bonds because the fluid manages thermal build-up, whereas dry grinding demands softer, free-cutting bonds and thermally conductive cores to prevent the wheel from overheating and damaging the workpiece.

Requirements for Wet Grinding Processes

When your machine utilizes a flood coolant system, your options for wheel selection expand significantly. The coolant serves three distinct functions: it reduces friction (lubrication), it carries away heat (cooling), and it washes away chips (evacuation).

Because the fluid actively removes heat, you do not need to rely solely on the wheel’s self-sharpening action to prevent burning. Consequently, you can select a harder bond system. A harder bond holds the diamond grains longer. This increases the total lifespan of the wheel and improves its ability to hold a sharp corner.

Consider a deep-feed surface grinding operation. Without coolant, the immense friction would instantly burn the part. With coolant, you can use a durable metal bond or a hard resin bond to remove material aggressively. The fluid acts like the oil in a car engine, preventing the moving parts from seizing due to heat.

Coolant Type Impact on Wheel Performance:

| Coolant Type | Primary Function | Impact on Wheel Selection |

|---|---|---|

| Straight Oil | High Lubricity | Best for Carbide. Reduces friction, allowing for harder, longer-lasting resin bonds. |

| Water-Soluble (Synthetic) | High Cooling | Best for Ceramics/Glass. rapid heat removal prevents thermal shock cracks. |

| Emulsions | Balanced | General purpose. Requires careful concentration monitoring to prevent bacterial growth. |

Note: The effectiveness of any wet grinding process depends on proper nozzle aim. Even the best wheel will burn if the coolant stream does not hit the exact point where the wheel touches the part.

Furthermore, wet grinding allows for higher diamond concentrations. The fluid helps flush out the swarf (chips) that would otherwise clog a dense wheel. This means you can run faster feed rates without the risk of “loading” the wheel face.

Considerations for Dry Grinding Applications

Dry grinding presents a hostile environment for diamond abrasives. Without fluid to dissipate energy, all the heat generated by the cut must be absorbed by either the workpiece or the wheel itself.

Therefore, when selecting a wheel for dry operations—such as manual tool sharpening—you must prioritize cool cutting over wheel life. You cannot use a hard bond. If you do, the friction will raise the temperature above the resin’s limit. Standard phenolic resins can degrade at temperatures as low as 400°F (200°C). Once the bond overheats, it chars and loses its grip on the diamond.

To combat this, you must specify a wheel with high porosity and a softer bond. This allows the dull diamonds to break away quickly. This rapid breakdown ensures that only sharp, cool-cutting diamonds are in contact with the material.

Essential Adjustments for Dry Wheel Specifications:

- Softer Bond: Choose a “soft” or “very soft” grade resin to encourage self-sharpening.

- Lower Concentration: Stick to concentration 75 or lower. Fewer diamonds mean less friction.

- Thermally Conductive Core: Avoid standard plastic or steel hubs. Select an Aluminum or Bakelite composite core. These materials act as a heat sink, pulling thermal energy away from the grinding zone.

- Coarser Grit: Avoid very fine grits (like 400 or 600). They create too much friction for dry running.

Think of dry grinding like a “pecking cycle” in deep hole drilling. You must constantly clear the chips and heat to prevent failure. A dry grinding wheel must “clear itself” (self-sharpen) constantly to stay cool.

Practical Selection Scenarios based on Process Goals

Different applications demand specific wheel “recipes” to succeed.

For carbide tool sharpening, a hybrid or resin bond with medium concentration is optimal for maintaining edge geometry without overheating. When grinding ceramics or glass, a metal bond with fine grit ensures durability against abrasive wear, while composite machining typically requires electroplated wheels to prevent delamination through aggressive, cool-cutting action.

Best Configurations for Carbide Tool Sharpening

Sharpening tungsten carbide cutting tools, such as end mills and drills, is the most common application for diamond wheels. The primary goal here is to restore a razor-sharp cutting edge without altering the tool’s geometry or causing thermal cracks.

For CNC tool grinding operations (like those on Anca or Walter machines), the industry trend has shifted toward Hybrid Bonds. A hybrid bond combines the free-cutting nature of resin with the shape retention of metal. This allows you to grind flutes in a single pass (creep feed) without the wheel losing its shape.

If you are performing Fluting9 operations on solid carbide:

- Bond: Hybrid or Polyimide Resin.

- Grit: 180 to 220 mesh (Standard).

- Concentration: High (100 or 125). You need the density to hold the corner radius.

However, for Gashing (grinding the center of the drill point), the contact area is very small. Here, a standard resin bond works best because it provides a softer cut. Using a wheel that is too hard on the gash will cause center cracking.

Recommended Specs for Carbide Tools:

| Operation | Wheel Shape | Rec. Grit | Concentration | Bond System |

|---|---|---|---|---|

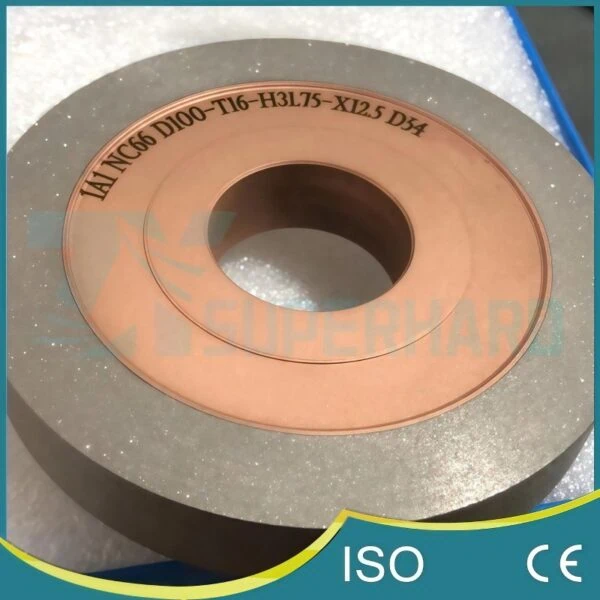

| Fluting | 1A1 / 1V1 | 150 – 220 | 100 – 125 | Hybrid / Polyimide |

| Gashing | 1V1 / 12V9 | 220 – 320 | 75 – 100 | Standard Resin |

| OD Relief | 11V9 | 320 – 400 | 75 | Resin |

Note: Hybrid bond formulations are proprietary to each manufacturer. Always confirm the specific dressability of a hybrid wheel with your supplier, as some require special sticking stones.

Optimal Choices for Ceramic and Glass Grinding

Grinding technical ceramics (like Alumina or Zirconia) and optical glass presents a different challenge: Brittleness. Unlike metal, these materials do not produce chips; they fracture. The risk here is not just burning, but “chipping” the edges of the workpiece.

For these abrasive materials, Metal Bond wheels are generally the superior choice. Ceramics are highly abrasive and will wear down a resin wheel too quickly, causing you to lose size control constantly. A sintered bronze-alloy bond holds the diamond firmly, allowing it to withstand the high abrasion of the ceramic dust.

Imagine using a High-Speed Steel (HSS) cutter on hardened tool steel. It would dull instantly. You need a Carbide end mill to handle that hardness. Similarly, a resin bond is too weak for aggressive ceramic grinding; you need the durability of a metal bond.

However, metal bonds cut slowly. If your process requires a high-quality surface finish (low Ra) on glass, you may need a two-step process:

- Roughing: Metal Bond, 100 Grit. Removes material without losing wheel size.

- Finishing: Resin Bond, 400 Grit. Polishes the surface to remove micro-cracks.

Critical Parameter: For glass and ceramic applications, checking the run-out10 (concentricity) of the wheel is vital. Since the material is brittle, any vibration from an unbalanced wheel will cause immediate edge chipping.

Recommendations for Composite Material Machining

Machining composites, such as Carbon Fiber Reinforced Polymer (CFRP) or fiberglass, is unique because these materials are non-homogeneous. You are cutting both tough fibers and a soft matrix resin simultaneously.

The biggest issue with composites is delamination, where the layers of the material separate due to cutting pressure. To prevent this, you need a wheel that cuts with virtually zero pressure.

Electroplated (Plated) Bonds are the industry standard here. Because the diamonds are highly exposed (sticking out of the plating), they act like micro-saw teeth. This aggressive structure slices through fibers cleanly rather than pushing them.

Furthermore, composites have very low thermal conductivity. They cannot absorb heat. A dense resin or metal wheel would generate friction, melting the composite’s matrix and clogging the wheel instantly. The open structure of a plated wheel allows for maximum air flow and debris evacuation.

Selection Strategy for Composites:

- Wheel Type: Electroplated (Nickel Bond).

- Grit: Coarse (40 – 60 grit). Coarser grits help “shred” the fibers effectively.

- Geometry: Often used on Routers or Burrs rather than traditional grinding wheels.

Remember: Electroplated wheels cannot be dressed. Once the cut quality drops or you see delamination occurring, the tool has reached the end of its life and must be replaced or stripped and replated.

Common Signs of Improper Wheel Selection

Your machine behavior and part quality are the best indicators of whether your wheel choice was correct.

Improper wheel selection primarily manifests through physical damage to the workpiece or abnormal behavior of the grinding wheel itself. Key indicators include thermal damage (burn marks) on the part caused by excessive friction, rapid loss of wheel diameter indicating a bond that is too soft, or a glazed, shiny wheel surface that increases spindle load because the bond is too hard.

Identifying Burn Marks and Thermal Damage

The most dangerous sign of a wrong selection is heat. When a diamond wheel cuts correctly, most of the heat should leave with the sparks and chips. However, if the wheel is not cutting efficiently, that heat goes into your workpiece.

Visual discoloration is the first warning. You might see a straw-colored, blue, or black tint on the surface of the ground part. This is commonly called “grinding burn.” It means the local temperature exceeded the material’s temper limit.

However, heat damage is not always visible to the naked eye. In tungsten carbide, excessive heat can cause cobalt leaching. This happens when the binder (cobalt) melts slightly and moves away from the surface. This leaves a brittle, “spongy” layer that will fail prematurely when the tool is used.

Analyzing Thermal Symptoms:

| Visual Symptom | Likely Cause (Wheel Selection) | The Physics Behind It |

|---|---|---|

| Blue/Black Surface | Bond is too hard / Grit is too fine | The wheel is rubbing instead of cutting. Dull diamonds are trapped in the bond. |

| Micro-Cracks (Checking) | Concentration is too high | Too many diamonds are contacting the part, creating excessive drag and friction. |

| White Spots (on Steel) | Wrong abrasive type | Using Diamond on steel causes chemical reaction (carbon diffusion). |

Think of this like a dull drill bit dwelling in a hole. Instead of cutting chips, it generates friction, squealing noise, and smoke. If your wheel acts like this, you must switch to a softer bond or a more open structure to allow for cooler cutting.

Diagnosing Rapid Wheel Wear and Glazing Issues

Sometimes the workpiece looks fine, but the wheel itself fails. You must monitor the condition of the wheel face to judge if your selection was correct. There are two opposite extremes: Rapid Wear and Glazing.

1. Rapid Wheel Wear

If you find yourself constantly adjusting the machine offsets because the part is coming out oversized, your wheel is wearing down too fast. This indicates the bond is too soft for the material. The bond is releasing the diamonds before they have done their work. This is similar to running a soft aluminum-cutting insert on hardened steel—the edge breaks down immediately.

- Result: High tool costs and poor geometric accuracy.

- Correction: Switch to a harder bond or a higher diamond concentration to improve durability.

2. Glazing

Glazing is the opposite problem. The wheel face looks smooth, shiny, and feels slick to the touch. This happens when the bond is too hard. It holds onto the diamonds even after they have become dull and rounded.

- Result: The wheel stops cutting. You will hear a high-pitched squealing noise. Furthermore, you will see the spindle load meter (%) on your CNC machine climb steadily higher with every pass.

- Correction: You need a softer bond that will erode (break down) easier to expose new, sharp diamonds. Or, you have to dress11 (stick) the wheel every 5 parts to keep it cutting.

Conclusion

Selecting the ideal diamond grinding wheel is not a guessing game; it is a calculated decision based on the specific variables of your production environment. By carefully analyzing your workpiece material, matching the bond type to your precision requirements, and balancing grit and concentration against your coolant capabilities, you can dramatically increase both throughput and part quality.

Every process is unique, and sometimes off-the-shelf solutions do not provide the competitive edge you need. If you are struggling with shortened wheel life, surface finish issues, or inconsistent results, it may be time to re-evaluate your specifications. Contact us today to discuss your specific grinding challenges, and let our technical team help you select the perfect wheel for your application.

References

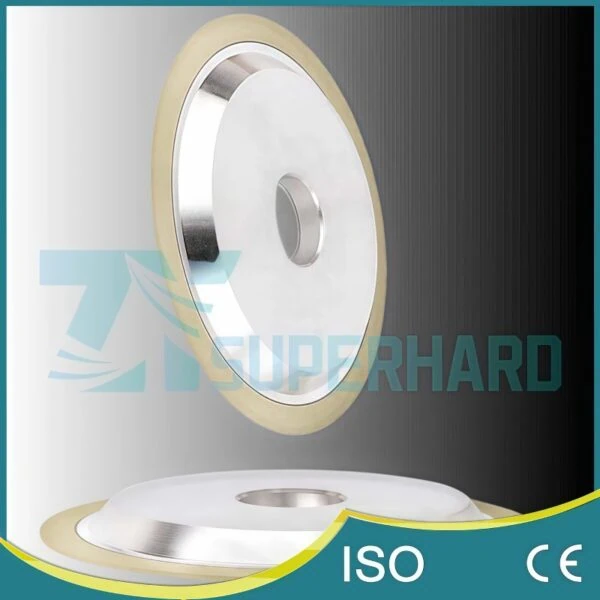

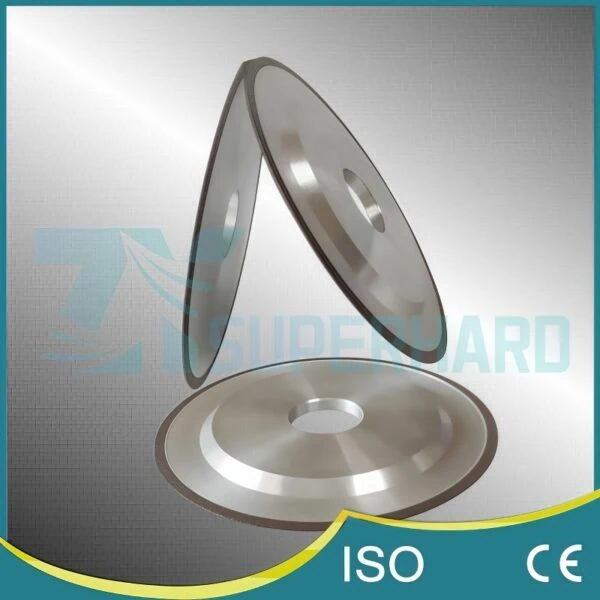

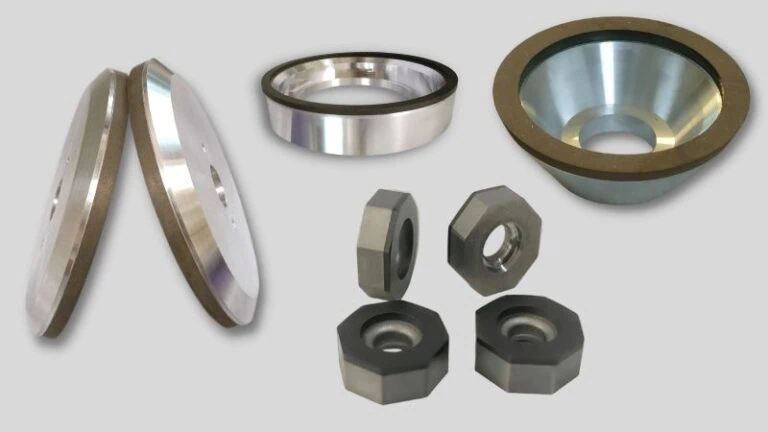

- Diamond Grinding Wheel1 – ZYDiamondTools product category displaying various types of diamond wheels.

- Tungsten Carbide2 – Wikipedia page defining the chemical and physical properties of tungsten carbide.

- bond type3 – ZYDiamondTools comprehensive guide on the technical differences between resin, metal, vitrified, and electroplated bond systems.

- Resin Bond Wheels4 – ZYDiamondTools product category page for resin bond diamond and CBN wheels.

- Phenolic Resin5 – Wikipedia article explaining the properties and uses of phenolic resins.

- Sintering6 – Wikipedia overview of the sintering process used in metal bond wheel manufacturing.

- PCD (Polycrystalline Diamond) Tools7 – ZYDiamondTools comprehensive guide on PCD tool technology and applications.

- Surface Finish (Ra)8 – Wikipedia article explaining surface roughness parameters in machining.

- Fluting9 – ZYDiamondTools product page for the 1V1 fluting and gashing wheel designed for carbide tools.

- Run-out10 – GD&T Basics definition and explanation of runout tolerances in rotating parts.

- Dress11 – ZYDiamondTools practical guide on how to properly dress diamond wheels.