-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

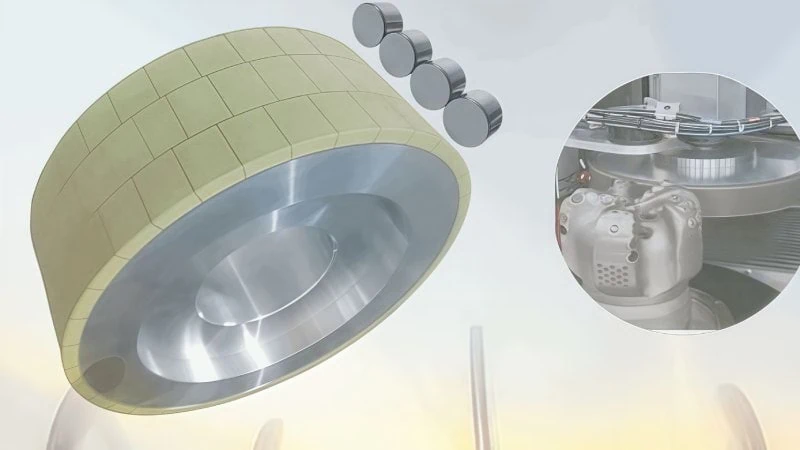

Diamond Cylindrical Grinding Wheels: Selection Case Studies & Operation Guide

How can you master the use of diamond cylindrical grinding wheels, from understanding the right application to executing a flawless operational process?

Mastering these advanced tools involves a systematic, three-part approach. First, you must identify the correct applications where diamond wheels are non-negotiable, specifically for grinding hard and brittle materials to high levels of precision. Second, you must select the right wheel specifications by referencing proven, case-based examples for your specific job, whether it’s aggressive roughing or delicate finishing. Finally, you must optimize the entire grinding process through meticulous setup, correct running parameters, and disciplined wheel maintenance to unlock peak performance and quality.

When Should You Use a Diamond Wheel for Cylindrical Grinding?

So, when is it the right call to choose a diamond wheel over a conventional one for your cylindrical grinding job?

You should use a diamond cylindrical grinding wheel when working with extremely hard or brittle materials like tungsten carbide, ceramics, or hard coatings. It’s also the essential choice when you must achieve very tight dimensional tolerances (often below ±0.002mm) and a superior surface finish. Furthermore, if maximizing grinding speed and minimizing production downtime are your main goals, the long life of a diamond wheel makes it the most cost-effective option.

For Grinding Hard & Brittle Cylindrical Workpieces (Carbide, Ceramics, Coated Shafts)

First and foremost, the choice of a grinding wheel depends entirely on the material of your workpiece. Using the wrong tool for the job leads to poor results and can even damage your parts.

Imagine trying to cut a hardened steel rod with a simple file; the file’s teeth would just wear down without making much of a mark. This is exactly what happens when you try to grind ultra-hard materials with conventional abrasive wheels, such as those made from aluminum oxide or silicon carbide.

Diamond, on the other hand, is the hardest material known. Consequently, it can cut through these tough materials cleanly and efficiently.

Materials That Demand a Diamond Wheel

- Tungsten Carbide: This material is extremely hard and wear-resistant, commonly used for manufacturing items like industrial rollers, cutting tools, and wear-resistant pins. A conventional wheel will struggle to remove material, generating excessive heat that can cause thermal stress and micro-cracks in the carbide. A diamond wheel cuts it with ease.

- Technical Ceramics: Materials like alumina, zirconia, and silicon nitride are incredibly hard but also very brittle. Pushing too hard with a dulling, conventional wheel can cause them to chip or shatter. Because a diamond wheel stays sharp, it grinds with less pressure, making it the only safe and effective choice for finishing ceramic shafts, plungers, and seal rings.

- Hard Coatings: Cylindrical parts are often coated with materials like HVOF (High-Velocity Oxygen Fuel) thermal sprays to improve their surface properties. These coatings are exceptionally abrasive. A diamond wheel1 is necessary to grind these coated surfaces to their final, precise diameter without damaging the coating itself.

Achieving Tight Dimensional Tolerances (<0.002mm) on Rollers and Pins

Is holding a very precise diameter across hundreds of parts a critical requirement for your job? If the answer is yes, then a diamond wheel is not just an option—it’s a necessity.

The key reason for this is wear resistance.

Conventional abrasive wheels wear down relatively quickly during use. Think about what this means for a cylindrical grinding operation. As the wheel grinds, its own diameter shrinks. A shrinking wheel will produce a part with a slightly different diameter than the one before it.

For example, in our experience with high-volume production, an operator might need to constantly adjust the machine to compensate for wheel wear when using a conventional abrasive. A part ground at 8:00 AM might be perfectly in spec, but without adjustment, a part ground at 11:00 AM could be out of tolerance simply because the wheel has worn down.

A diamond wheel, due to its incredible hardness, wears down at a dramatically slower rate. This provides outstanding dimensional stability, meaning it holds its size and shape for a very long time. This stability is what allows you to:

- Maintain tight tolerances (like ±0.002mm) over an entire production run of hundreds or even thousands of parts.

- Ensure consistent part-to-part quality, as the 1st part and the 500th part are ground with a wheel that is virtually the same size.

- Reduce the need for operator intervention and measurement, which boosts productivity.

When Grinding Speed and Wheel Life Are Your Top Priorities

While speed and longevity are always beneficial, in cylindrical grinding, they directly translate into overcoming two of the process’s biggest challenges: maintaining thermal stability on the workpiece and ensuring process consistency across high-volume production runs.

Faster Cycle Times Without Sacrificing Quality

Cylindrical grinding is often used for manufacturing thousands of identical parts, like automotive shafts or hydraulic pistons. In these scenarios, every second of cycle time counts. A diamond wheel’s ability to cut hard materials efficiently allows for higher workpiece rotational speeds and faster traverse rates.

However, the real advantage is not just raw speed, but the ability to grind quickly without generating excessive heat.

- Preventing Thermal Expansion: When grinding a long, thin shaft, heat from an inefficient wheel can cause the part to expand. This makes it impossible to hold a tight diameter tolerance, as the part will shrink and become undersized after it cools. A diamond wheel’s clean, cool cutting action minimizes this thermal expansion, allowing for faster grinding while still holding the final dimension.

- Avoiding Grinding Burn: Pushing a conventional wheel too hard can “burn” the surface of a steel part, creating a brittle metallurgical layer that can lead to premature failure. This is a critical defect for functional components like shafts and rollers. A diamond wheel’s sharpness allows it to remove material without the friction and heat that cause grinding burn, ensuring the surface integrity of the part is maintained even at higher speeds.

Uninterrupted Production and Process Stability

The exceptional lifespan of a diamond wheel is more than just a cost-saving—it is a cornerstone of stable, predictable manufacturing, which is vital for cylindrical parts.

Consider an automated production cell grinding bearing races 24/7. A conventional wheel might require changing and re-dressing every few hours, forcing the entire production line to stop. Each time the process stops, it must be re-qualified. A long-life diamond wheel can run for an entire shift, or even multiple days, without intervention.

This long life directly leads to:

- Massive Reduction in Downtime: Less time is spent changing, mounting, balancing, and dressing wheels.

- Superior Process Consistency: A wheel that barely wears ensures that the 10th part and the 10,000th part are ground under nearly identical conditions. This is the key to holding tight tolerances across an entire production batch without constant operator adjustments.

When you translate these cylindrical grinding-specific advantages into production metrics, the difference becomes clear:

| Metric | Conventional Wheel | Diamond Wheel | Advantage |

|---|---|---|---|

| Wheel Life | 8 – 16 hours | 800 – 1,200 hours | ~100x Longer Life |

| Cycle Time per Part | 90 seconds | 60 seconds | 33% Faster |

| Downtime for Changes | High (Frequent) | Very Low (Infrequent) | Increased Uptime |

Therefore, if your priority is running a high-volume, stable, and efficient cylindrical grinding operation, the superior life and safe speed of a diamond wheel are not just a benefit; they are a strategic necessity.

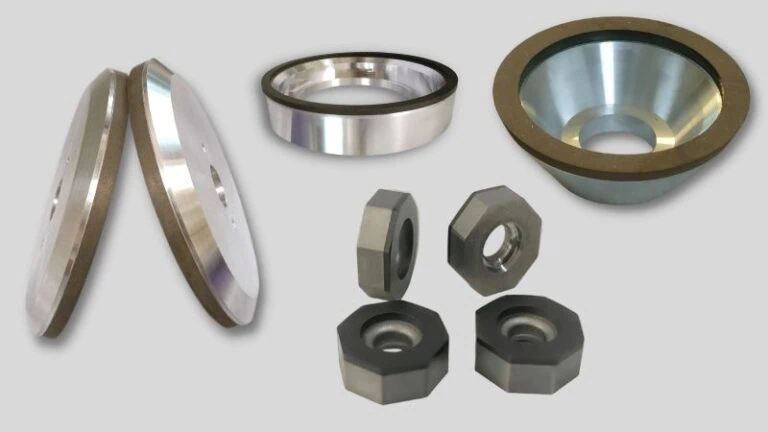

Recommended Wheel Specs for Common Cylindrical Grinding Jobs

Now that you know when to use a diamond wheel, how do you select the right specifications for your particular cylindrical grinding task?

The ideal wheel specification depends entirely on your goal. For aggressive material removal on tough parts like carbide rollers, a metal bond with coarse grit is best. Conversely, for achieving a mirror finish on brittle ceramics, a softer resin bond with very fine grit is necessary. Specialized applications like grinding thermal coatings also require a unique setup, typically a resin bond with a medium-fine grit. These recommendations provide a proven starting point for common industry applications.

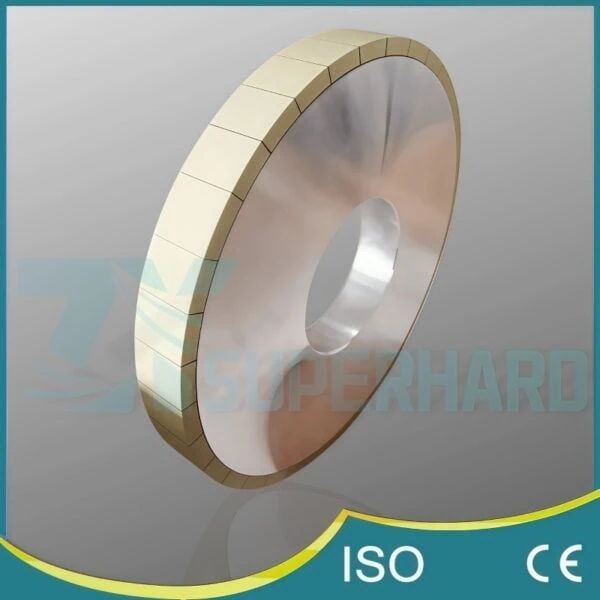

Case 1: Rough Grinding of Tungsten Carbide Rollers

The primary goal here is to remove a large amount of material as quickly as possible. The final surface finish is not the main concern; speed and efficiency are the top priorities.

The main challenge is the extreme hardness of tungsten carbide, which demands a wheel that can withstand high grinding forces without wearing out or losing its shape.

Our Recommendation:

| Specification | Recommended Value |

|---|---|

| Bond Type | Metal |

| Grit Size | Coarse (e.g., 100/120 Mesh) |

| Concentration | High (C100 or C125) |

Why This Specification Works

- Why a Metal Bond? Think of the metal bond2 as the strongest possible grip holding the diamond particles. During aggressive rough grinding, the forces trying to rip the diamond from the wheel are immense. A metal bond provides the best possible retention, leading to a very long wheel life and excellent form holding. This ensures your roller stays perfectly cylindrical from one end to the other.

- Why a Coarse Grit? This is similar to using a roughing end mill in a milling machine. The large diamond particles and the wide spacing between them create plenty of room for material chips to escape. This prevents the wheel from “loading” (clogging up) and allows for much deeper cuts and a higher material removal rate (MRR).

- Why a High Concentration? A higher concentration (more carats of diamond per unit volume) puts more cutting points in contact with the workpiece at all times. For roughing, this translates directly into faster, more aggressive grinding.

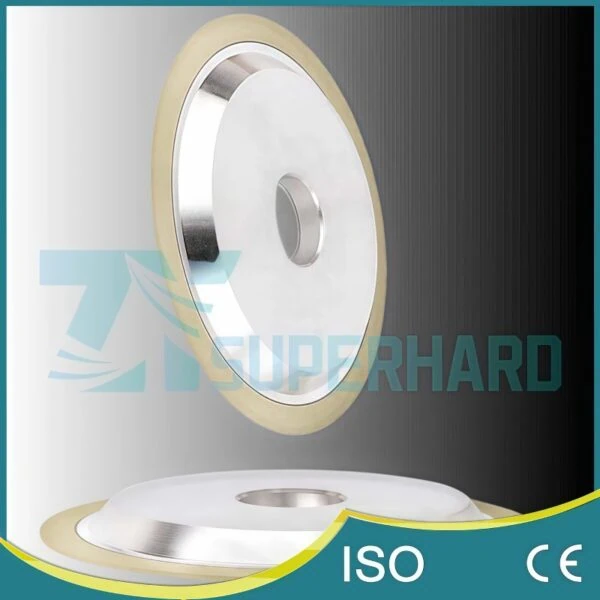

Case 2: Precision Finishing of Ceramic Plungers

Here, the objective is the complete opposite of roughing. The goal is to achieve an extremely smooth, mirror-like surface finish (a very low Ra value3) on a material that is very hard but also brittle. Material removal is minimal.

Our Recommendation:

| Specification | Recommended Value |

|---|---|

| Bond Type | Resin |

| Grit Size | Very Fine (e.g., 400/500 Mesh or finer) |

| Concentration | Medium (C75) |

Why This Specification Works

- Why a Resin Bond? A resin bond4 is “softer” and more friable than a metal bond. This means it allows the diamond particles to micro-fracture and pull out in a controlled way, constantly exposing new, sharp cutting edges. This self-sharpening action results in lower grinding forces and less heat, which is absolutely critical to prevent causing micro-cracks or chipping the brittle ceramic part.

- Why a Very Fine Grit? The principle is just like sanding a piece of wood. You start with coarse paper and finish with very fine paper to get a smooth surface. The tiny diamond particles in a 400/500 mesh wheel create exceptionally small scratches, which collectively produce a reflective, mirror-like finish.

- Why a Medium Concentration? For finishing, an extremely high concentration can sometimes be too aggressive. A slightly lower concentration, like C75, can allow for better coolant delivery to the cutting zone and a gentler polishing action. However, this is one parameter where you should always consult your supplier, as their specific bond formulation may work best with a different concentration.

Case 3: Grinding HVOF Thermal Spray Coatings on Shafts

Grinding thermal coatings is a unique challenge. The coating is very hard and abrasive, but generating too much heat during grinding can damage the bond between the coating and the base metal of the shaft, causing it to fail.

Our Recommendation:

| Specification | Recommended Value |

|---|---|

| Bond Type | Resin |

| Grit Size | Medium-Fine (e.g., 230/270 Mesh) |

| Concentration | High (C100) |

Why This Specification Works

- Why a Resin Bond? The top priority is a cool grinding action. The self-sharpening nature of a resin bond is perfect for this. It prevents the wheel from becoming dull and “plowing” through the material, which is what generates immense heat. This protects the integrity of the coating.

- Why a Medium-Fine Grit? This choice is a balance. The grit needs to be coarse enough to effectively remove the tough coating material without excessive pressure, but fine enough to produce the required surface finish, which is often in the range of 0.2-0.4 Ra (μm).

General Purpose: A Versatile Starting Point for Carbide Parts

What if your shop doesn’t focus on just one thing? Many businesses need a reliable, all-around wheel for grinding various tungsten carbide parts, from shafts and pins to small tooling. This specification is the industry workhorse—a safe and effective starting point.

Our Recommendation:

| Specification | Recommended Value |

|---|---|

| Bond Type | Resin |

| Grit Size | Medium (e.g., 170/200 Mesh) |

| Concentration | High (C100) |

A Critical Note: Think of these recommendations as a highly reliable starting point, not an absolute rule. The ideal specification can be fine-tuned based on your specific grinding machine’s rigidity, the horsepower of the spindle, the coolant you use, and the exact grade of material you are grinding. Always collaborate with your grinding wheel supplier to find the perfect match for your unique application.

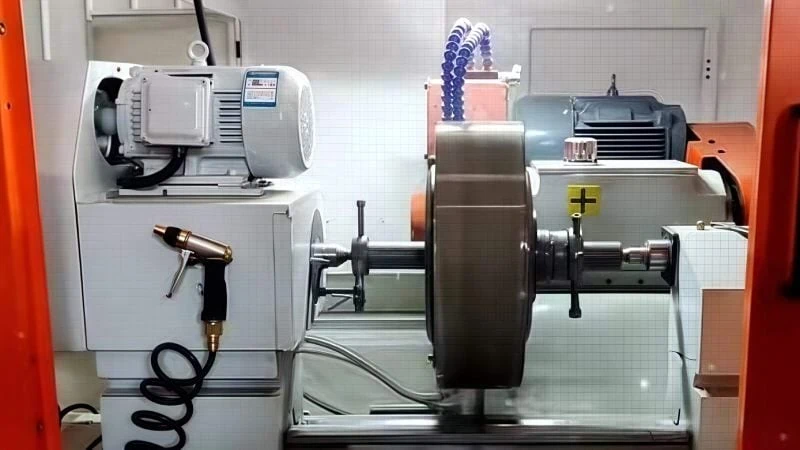

How to Optimize Your Cylindrical Grinding Process?

Once you have the perfect wheel, how do you ensure you get the best possible performance from it?

To optimize your process, you must focus on three key areas. First, ensure the wheel is perfectly mounted and balanced to eliminate vibration. Second, set the correct surface speeds and infeed rates to match the wheel and material. Finally, perform regular truing and dressing to maintain the wheel’s geometric accuracy and cutting sharpness. Mastering these three steps is the key to achieving precision and maximizing wheel life.

Proper Wheel Mounting and Balancing for Vibration-Free Grinding

Before you ever start grinding a part, the success of your operation is determined by the setup. In precision cylindrical grinding, vibration is the number one enemy of quality. An improperly mounted or unbalanced wheel will introduce vibration that directly results in out-of-round parts and poor surface finishes.

Think of it like trying to machine a part in a lathe with an unbalanced chuck. The resulting vibration would make it impossible to achieve a smooth, accurate cut. The same exact principle applies here.

Key Steps for a Perfect Setup

- Inspect and Clean: Before mounting, always inspect the wheel for any cracks or damage. Then, ensure the machine’s mounting flanges and the wheel’s bore are perfectly clean. A single tiny chip or piece of dirt trapped between these surfaces will cause the wheel to wobble, creating runout and vibration.

- Mount Correctly: Use the correct blotters (the paper-like washers) and tighten the flange screws in a star pattern, just like you would tighten the lug nuts on a car wheel. This ensures even pressure and prevents stress on the wheel.

- Balance the Wheel: This is the most critical step. Even a perfectly made wheel has tiny variations in density. Balancing the wheel assembly on a dynamic balancing machine corrects these minor imbalances. For the tight tolerances required in cylindrical grinding, this step is not optional; it is a fundamental requirement for achieving precision.

Setting Surface Speeds and Infeed Rates for Cylindrical Operations

Once the wheel is perfectly set up, the next step is to program the correct running parameters. These settings control how the wheel interacts with the workpiece and are critical for achieving both quality and efficiency. Running the wheel too fast can generate excessive heat and burn the part, while running too slow is unproductive.

Understanding the Key Parameters

- Wheel Surface Speed: This is the most important parameter. It’s not the machine’s RPM, but rather the speed at which the abrasive particles on the wheel’s outer edge are moving. Most resin and vitrified bond diamond wheels perform best within a specific range.

> As a starting point, many applications run between 4,000 and 6,500 SFPM (Surface Feet per Minute), which is about 20 to 33 meters per second. However, this range can vary significantly based on the wheel’s bond type and the material being ground. Always consult your wheel supplier’s technical data sheet for the recommended surface speed for your specific wheel. - Workpiece Speed: The rotational speed of the cylindrical part you are grinding also plays a key role. A faster workpiece speed generally leads to a better surface finish but may increase wheel wear.

- Infeed Rates: This is how fast the wheel is fed into the workpiece. For plunge grinding (feeding straight into the diameter), a slower infeed is used for finishing. For traverse grinding (moving across the length of the part), the traverse speed and depth of cut must be carefully controlled to avoid chatter5 and maintain a straight, cylindrical form.

Truing and Dressing to Maintain a True Cylindrical Wheel Face

A diamond wheel does not last forever without maintenance. Over time, its cutting surface needs to be reconditioned. This is a two-part process called truing and dressing, and it is essential for maintaining consistent, high-quality production.

Many people use the terms interchangeably, but they are two distinct and equally important processes.

Truing – Restoring the Geometry

- What it is: Truing is the process of making the grinding wheel perfectly round and ensuring its cutting face is perfectly straight and parallel to the axis of the workpiece. It restores the wheel’s geometry.

- Why it matters: After many hours of use, a wheel may develop slight high or low spots. Truing removes these imperfections. A trued wheel is the only way to produce a truly round and straight cylindrical part. It’s like re-surfacing the cutting tool itself to make it geometrically perfect again.

Dressing – Restoring the Sharpness

- What it is: Dressing is the process of sharpening the wheel face. It involves removing a tiny amount of the bond material to expose new, sharp diamond particles and clearing away any metal chips that may have become embedded in the wheel (a condition known as “loading”).

- Why it matters: The best analogy is sharpening a knife. A trued wheel may be perfectly round, but if its diamond particles are dull or are clogged with material, it will not cut effectively. It will rub and generate heat instead of shearing material. Dressing6 restores the wheel’s free-cutting ability.

A Professional Tip: The correct procedure and tools for truing and dressing depend heavily on the wheel’s bond type. For example, a metal bond wheel requires a more aggressive dressing process than a softer resin bond wheel. Following the specific maintenance procedures recommended by your wheel manufacturer is the best way to maximize both performance and wheel life.

Conclusion

Achieving exceptional results with diamond cylindrical grinding wheels is not a matter of chance, but a result of a methodical process. By first understanding when these wheels are necessary, then using practical case studies to select the correct specifications, and finally applying disciplined operational procedures, you can transform your grinding operations. This guide provides the framework for that success, empowering you to produce higher quality parts, more efficiently, and with greater consistency.

References

- diamond wheel1 – The main product page for Diamond Cylindrical Grinding Wheels on ZYDiamondTools.

- metal bond2 – A detailed guide on ZYDiamondTools explaining the properties and selection criteria for metal bond grinding wheels.

- Ra value3 – A Wikipedia article that explains the concept of surface roughness, including parameters like Ra.

- resin bond4 – A comprehensive guide on ZYDiamondTools about the selection and application of resin bond grinding wheels.

- chatter5 – A Wikipedia page explaining the phenomenon of machining vibrations, commonly known as tool chatter.

- Dressing6 – A practical how-to guide on ZYDiamondTools that details the process and best practices for dressing diamond wheels.