-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

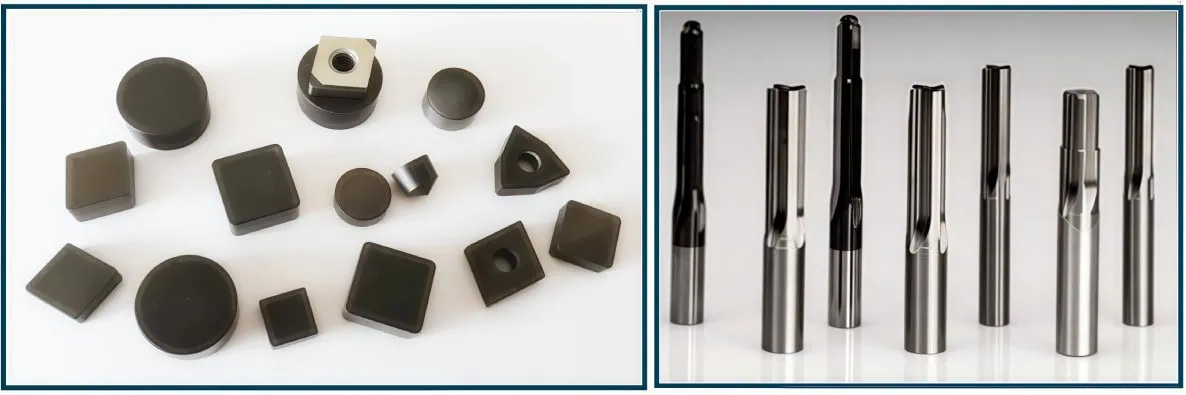

CBN vs. Carbide Tools: Which is the Right Choice for Your Machining Needs?

When it comes to choosing a cutting tool for a critical job, how do you decide between the high-performance specialist, CBN, and the trusted industry workhorse, carbide?

The optimal choice depends entirely on the specific application, material, and production goals. Cubic Boron Nitride (CBN) is the superior, high-performance tool for machining hardened ferrous metals (typically above 45 HRC) at high speeds, where its exceptional hardness and thermal stability result in longer tool life, faster cycle times, and excellent surface finishes.

In contrast, Carbide is the versatile, cost-effective standard for a much broader range of materials, including softer steels, stainless steels, and non-ferrous metals like aluminum and titanium. It is the go-to choice for general-purpose machining and situations where a low initial tool cost is a primary consideration. The decision ultimately requires a careful analysis of the trade-off between a higher upfront investment for CBN and its potential to deliver a lower total cost-per-part.

When Should You Use CBN Tools Over Carbide?

So, when does it make sense to reach for a specialized CBN tool instead of a trusted, all-purpose carbide one?

The decision hinges on two key factors: the hardness of the material you are cutting and your production goals. Choose Cubic Boron Nitride (CBN) tools when machining very hard ferrous metals (above 45 HRC) where high speed, exceptional tool life, and superior surface finish are critical. For softer materials, non-ferrous metals, or when initial cost is the primary concern, carbide remains the more versatile and economical choice.

Let’s explore the specific scenarios where CBN is not just an alternative, but the superior solution.

Ideal Materials for CBN: High-Hardness Ferrous Metals

Think of tool selection like choosing the right tires for a vehicle. You wouldn’t use standard highway tires for a race on a frozen lake; you’d need specialized studded tires. Similarly, CBN tools are the specialized solution for tackling the most challenging materials in machining.

Their primary strength lies in cutting ferrous metals—materials that are based on iron. More specifically, they are designed for materials that have been hardened through heat treatment. The typical threshold where CBN becomes highly effective is for materials harder than 45 HRC (Rockwell Hardness C scale).

Common materials where CBN tools are the go-to choice include:

- Hardened Steels: Tool steels like D2 and M2, bearing steels, and case-hardened components with a surface hardness often ranging from 58 to 65 HRC.

- Cast Irons: Particularly grey cast iron and high-chromium cast iron, which are very abrasive. For instance, in manufacturing automotive brake discs, CBN is essential for achieving the required finish at high production speeds.

- Sintered Metals: Powdered metals that have been fused into a solid, hard mass, such as those used in gears and other complex parts.

- Superalloys: Nickel-based and cobalt-based alloys (like Inconel) that are known for their extreme toughness and heat resistance.

It is important to remember that while a general guideline is HRC 45, the optimal hardness range can vary based on the specific grade of CBN and the tool manufacturer. Consequently, it’s always a best practice to consult your tool supplier’s specifications to match the right tool to your exact material.

Applications Where CBN Excels: Hard Turning and Finishing

Using the right tool for the right job is paramount. You wouldn’t use a sledgehammer to hang a small picture frame. In the same way, CBN tools are not typically used for heavy roughing (removing large amounts of material quickly). Instead, they excel in precision applications.

Hard Turning: The Grinding Replacement

The most significant application for CBN is hard turning1. This is the process of machining a workpiece on a lathe after it has been hardened.

Traditionally, if a hardened part needed final shaping, it had to be moved to a separate grinding machine. This was a slow, multi-step process. Hard turning with CBN tools changes the game entirely. It allows a manufacturer to perform the final, high-precision machining on the same lathe used for other operations.

For example, a manufacturer of hardened transmission shafts (62 HRC) can use CBN inserts to achieve the final diameter and a mirror-like finish in a single pass. This can eliminate the grinding step, which in turn reduces total cycle time, frees up floor space, and lowers capital investment by not needing a separate grinding machine.

Finishing and Semi-Finishing

Beyond hard turning, CBN is the champion of finishing and semi-finishing passes on hard materials. This means taking off the last fraction of a millimeter of material to get the exact final dimensions and a very smooth surface. Because of CBN’s ability to maintain a sharp cutting edge under pressure and heat, it produces a surface finish so fine that it can often be measured in fractions of a micrometer, again, often eliminating the need for polishing or grinding.

Key Performance Advantages of CBN: Speed, Lifespan, and Surface Finish

When used in its ideal application—machining hard ferrous metals—the performance benefits of CBN over carbide are not just slight improvements; they are transformative. These advantages directly translate into higher productivity and better part quality.

Let’s look at a direct comparison for a typical hard turning operation on hardened steel (approx. 60 HRC).

| Performance Metric | CBN Tool (on Hardened Steel) | Carbide Tool (on Hardened Steel) |

|---|---|---|

| Typical Cutting Speed | Exceptionally high, often 120-200 m/min (400-650 SFM). | Very low, typically 40-60 m/min (130-200 SFM). |

| Tool Lifespan | Extremely long; can machine hundreds or thousands of parts before needing replacement. | Very short; experiences rapid wear and may fail after just a few parts. |

| Achievable Surface Finish | Excellent, often creating a mirror-like finish (< 0.4 µm Ra). | Fair to poor (> 1.6 µm Ra); almost always requires a secondary finishing process. |

What does this data mean in a real-world production environment?

- Higher Speed: You can produce parts significantly faster, directly boosting your output and lowering the machining time per part.

- Longer Lifespan: Your machines run for longer without stopping for tool changes. This drastically reduces costly downtime and labor for tool setup.

- Superior Finish: You can often produce a finished part straight off the machine, eliminating secondary operations and simplifying your entire production workflow.

When Are Carbide Tools the Better Option?

Given the impressive capabilities of CBN, when is it actually smarter to stick with the classic, reliable carbide tool?

Carbide tools are the superior choice for a vast range of applications involving softer steels, non-ferrous metals, and general-purpose machining. Their versatility, combined with a significantly lower initial cost, makes them the most practical and cost-effective option for the majority of everyday machining tasks, especially for roughing, interrupted cuts, and jobs where extreme hardness is not a factor.

While CBN is the specialist, carbide is the indispensable workhorse of the machine shop. Let’s look at the specific situations where carbide not only works, but excels.

Versatile Applications of Carbide: Broader Material Compatibility

If a CBN tool is like a specialized surgical scalpel, a carbide tool is the Swiss Army Knife of the machining world. Its incredible versatility comes from its ability to effectively cut a much wider array of materials, making it the default choice for job shops and manufacturing environments that handle diverse projects.

Carbide tools, especially when enhanced with modern coatings, are highly effective on:

- Steels and Stainless Steels: They handle everything from low-carbon steels to tough stainless steel alloys with ease.

- Cast Irons: For standard, non-hardened cast irons, carbide provides excellent performance without the high cost of CBN.

- Non-Ferrous Metals: This is a key area where carbide dominates. It is the ideal choice for materials like aluminum, brass, copper, and titanium. CBN, due to its chemical composition, is generally not suitable for these materials.

- Plastics and Composites: Specialized grades of carbide are also designed to machine abrasive plastics and composite materials like carbon fiber reinforced polymer (CFRP).

For instance, a machine shop producing custom parts for the aerospace industry might machine an aluminum housing in the morning and a titanium bracket in the afternoon. Using a carbide tooling system allows them to switch between these vastly different materials efficiently, often just by changing the specific grade or coating of the carbide insert.

Cost-Effectiveness of Carbide: Initial Investment Considerations

Sometimes, the best tool for the job is the one that makes the most financial sense. The most immediate and compelling reason to choose carbide is its low initial cost.

Key Takeaway: A single carbide insert can be many times cheaper than a comparable CBN insert.

This cost difference is critical in several scenarios:

- Small-Batch Production: For one-off jobs or small production runs, the high cost of CBN tooling can be impossible to justify. Carbide provides a profitable path to completion.

- Prototyping and Testing: When developing a new part, there’s a lot of trial and error. Using less expensive carbide tools minimizes the financial risk during this experimental phase.

- General Inventory: For shops that need to stock a wide variety of tool shapes and sizes, a carbide-based inventory is far more affordable than a CBN-based one.

Situations Favoring Carbide: General Machining and Lower Hardness Materials

Carbide tools are engineered for toughness, which makes them the champion for general-purpose machining and on materials that don’t require the extreme hardness of CBN.

Machining Softer Materials

As a rule of thumb, for any ferrous material with a hardness below 45 HRC, carbide is not only sufficient but often preferable. On these softer materials, a carbide tool can achieve excellent cutting speeds and a good surface finish without the need for a premium-priced tool.

Roughing Operations

Roughing is the process of removing a large volume of material as quickly as possible. This involves deep cuts and high feed rates. The inherent toughness of a carbide substrate allows it to withstand the immense forces of heavy roughing without chipping or fracturing, making it the standard for this application.

Interrupted Cuts

An interrupted cut occurs when the tool repeatedly enters and exits the material during a single pass. A perfect example is facing a part with holes or slots in it. Each time the tool hits the leading edge of the material, it experiences a small impact. A brittle tool might chip under these conditions. The toughness of carbide, however, allows it to absorb these repeated impacts, ensuring a reliable and secure process.

Core Performance Differences: Hardness, Heat, and Speed

To understand why these tools are chosen for different tasks, we need to look at the core scientific properties that define their performance.

The primary differences stem from three fundamental material properties: hardness, thermal stability (or “hot hardness”), and chemical inertness. Cubic Boron Nitride (CBN) is vastly harder and can withstand extreme heat far better than carbide. This allows CBN to maintain a sharp cutting edge when machining hardened ferrous metals at very high speeds, something carbide simply cannot do.

In essence, these scientific advantages are why CBN enables faster cycle times, longer tool life, and superior finishes in demanding applications. While carbide’s toughness gives it an edge in different scenarios, CBN’s unique physical properties make it the undisputed performance leader for high-speed, high-precision work on hard materials.

Let’s break down the science behind why these tools behave so differently under pressure.

Hardness Comparison: The Decisive Factor for High-Hardness Materials

The most basic rule of cutting is that the tool must be significantly harder than the material it’s cutting. Think of it this way: you can’t scratch a diamond with a piece of chalk. The difference in hardness is just too great. The same principle applies in machining.

While both materials are very hard, they exist in different leagues. We can measure this using the Knoop hardness scale2, which is designed for very hard materials.

| Material | Approximate Knoop Hardness (kg/mm²) | Analogy |

|---|---|---|

| CBN | ~4500 | Diamond-like Hardness |

| Tungsten Carbide | ~1800 – 2200 | Extremely Hard |

| Hardened Steel (60 HRC) | ~800 | Very Hard Workpiece |

As you can see, while carbide is more than twice as hard as hardened steel, CBN is more than twice as hard as carbide. This massive gap in hardness is the primary reason why CBN can effectively slice through materials that cause carbide tools to wear down rapidly. This isn’t just a small advantage; it’s a fundamental performance difference that opens up new machining possibilities.

Thermal Stability and Tool Life: Performance Under High Temperatures

What happens when you add intense heat to the equation? The friction from cutting metal generates incredible temperatures at the tool’s tip, often exceeding 1000°C (1832°F). A tool’s ability to remain hard at these temperatures—a property called hot hardness or thermal stability—is crucial for its survival.

This is where CBN truly distinguishes itself.

- Carbide begins to lose its hardness and wear quickly as temperatures rise above 800°C (1470°F). The heat softens the material, causing the sharp edge to deform and fail.

- CBN, on the other hand, maintains its extreme hardness at temperatures up to 1200°C (2190°F) and beyond. It’s built for heat.

Furthermore, CBN has superior thermal conductivity, meaning it efficiently pulls heat away from the cutting edge and transfers it into the chips. This keeps the tool itself cooler and more stable.

There’s one more piece to this puzzle: chemical stability. At high temperatures, the carbon in a carbide tool can chemically react with the iron in steel, causing a type of wear called diffusion wear where the tool material literally dissolves into the workpiece. Because CBN is made of boron and nitrogen, it is chemically inert to iron. It doesn’t react, which prevents this type of wear and is a key reason for its exceptionally long life when cutting steels.

Cutting Speed Capabilities: Impact on Machining Efficiency

So, what’s the practical result of superior hardness and heat resistance? Speed. 💨

Because CBN can withstand the physics of cutting hard materials at extreme temperatures, it can be run dramatically faster than carbide. Think of it like a car engine. A standard engine (carbide) might redline at 6,000 RPM. A Formula 1 engine (CBN) is built with materials that allow it to scream at 15,000 RPM. Trying to run the standard engine at that speed would lead to catastrophic failure.

This capability has a direct and massive impact on machining efficiency. A key metric in manufacturing is the Metal Removal Rate (MRR)3, which measures how quickly you can cut material. Since cutting speed is a primary component of MRR, doubling the speed can effectively cut the cycle time for an operation in half.

For example, a factory producing 100,000 hardened steel gears per year. By switching from carbide to CBN, they might reduce the cycle time for the finishing operation from 60 seconds to 25 seconds. This 35-second saving per part adds up to nearly 972 hours of saved machine time over the year, effectively adding another machine to their production line for free. This makes the abstract concept of “efficiency” very concrete.

How Does Cost Factor into the Decision Between CBN and Carbide?

Ultimately, how does the price tag influence the choice between these two tools?

The financial decision between CBN and carbide boils down to a classic trade-off between upfront investment and long-term operating costs. Carbide has a significantly lower initial purchase price, making it the default for budget-conscious or low-volume jobs. However, for the right high-volume application, CBN’s higher initial cost is frequently offset by its immense productivity gains, leading to a dramatically lower total cost-per-part.

In short, the smarter financial choice isn’t about the price of the tool itself, but about the total cost to produce a single component. Analyzing this “cost-per-part” reveals that investing in a more expensive CBN tool can be one of the most profitable decisions a machine shop can make when conditions are right.

Let’s dive into the numbers to see how this works in practice.

Initial Tooling Costs: Understanding the Price Disparity

There’s no way around it: CBN tools are significantly more expensive than carbide tools. This isn’t just a small markup; it’s a substantial difference that you will see immediately on any price quote. A single CBN cutting insert4 can cost anywhere from 5 to 20 times more than a comparable carbide insert.

Why the big difference? It comes down to the manufacturing process.

- Tungsten Carbide is made by sintering (fusing with heat and pressure) tungsten carbide powder with a binder like cobalt. This is a mature and highly efficient process.

- Cubic Boron Nitride is a synthetic material created under extreme pressures and temperatures, similar to the process for making synthetic diamonds. This complex, energy-intensive synthesis makes the raw material far more valuable.

Think of it like choosing a home heating system. A standard furnace (carbide) has a low upfront cost. A high-efficiency geothermal system (CBN) costs much more to install, but you’re paying for advanced technology that promises significant savings on your energy bills for years to come. It is important to note that this price ratio can fluctuate significantly based on the manufacturer, the specific grade of the tool, and any advanced coatings, so it is crucial to get current quotes from your suppliers.

Long-Term Cost Savings with CBN: Productivity and Tool Life Benefits

So, if CBN is so expensive, how can it possibly save you money? The savings don’t come from the tool’s purchase price; they come from its performance on the shop floor. The initial investment in CBN pays you back in two major ways.

- Massive Productivity Gains: As we saw earlier, CBN can cut hard materials at much higher speeds. This directly reduces the machine time needed for each part. In manufacturing, machine time has a direct cost associated with it (labor, electricity, overhead). The less time a part spends on the machine, the less it costs to produce.

- Drastically Reduced Downtime: CBN’s exceptional tool life means you change tools far less often. Every tool change is a period of non-productive downtime. Reducing tool changes means the machine spends more time doing what it’s supposed to do: making parts and generating revenue. This also reduces labor costs associated with stopping production to swap out a worn insert.

In high-volume manufacturing, machine uptime is the most valuable asset. A tool that keeps the spindle turning is a tool that saves money.

Overall Cost-Effectiveness: Analyzing the Total Machining Expenditure

To see the true financial picture, you must look beyond the tool’s price and calculate the total cost-per-part5. This is the ultimate metric for determining which tool is more economical for a specific job.

Let’s look at a simplified, yet realistic, case study.

Scenario: A shop needs to perform a finishing operation on 10,000 hardened steel bearing races.

Machine Hour Rate (including labor & overhead): $75/hour

| Cost Metric | Carbide Tool | CBN Tool | Analysis |

|---|---|---|---|

| Tool Cost per Insert | $20 | $150 | The CBN tool is 7.5 times more expensive upfront. |

| Parts Machined per Edge | 50 parts | 1,000 parts | The CBN tool lasts 20 times longer. |

| Tool Cost per Part | $0.40 ($20 / 50) | $0.15 ($150 / 1000) | Winner: CBN. The longer life makes CBN’s tooling cost per part much lower. |

| Cycle Time per Part | 90 seconds (1.5 min) | 30 seconds (0.5 min) | The CBN tool is 3 times faster, a massive productivity gain. |

| Machine Time Cost per Part | $1.88 ($75/hr ÷ 40 parts/hr) | $0.63 ($75/hr ÷ 120 parts/hr) | Winner: CBN. The speed advantage drastically cuts the cost of machine time. |

| TOTAL COST PER PART | $2.28 | $0.78 | OVERALL WINNER: CBN |

In this high-volume scenario, despite the high sticker price, the CBN tool saves $1.50 on every single part produced. Over the course of the 10,000-part run, that translates to a total saving of $15,000.

This analysis makes the conclusion clear: choosing the right tool is not about buying the cheapest option on the shelf. It’s about a careful calculation of how that tool’s performance will impact your total operational costs. For the right job, an expensive tool is the cheapest one you can buy.

Conclusion

In the debate of CBN vs. Carbide, there is no single winner for every situation. The best choice is always the one that fits the unique demands of your job.

- Carbide remains the undisputed king of versatility and low-cost entry. It is the reliable, go-to workhorse for a vast majority of machining tasks involving softer steels, non-ferrous metals, and general roughing.

- CBN is the high-performance specialist. Its value is unlocked in high-volume production on hardened ferrous materials where its superior speed, lifespan, and finishing capabilities can dramatically lower the total cost-per-part, turning a high initial investment into significant long-term profit.

By understanding the distinct strengths of each material and analyzing the specific requirements of your application—from material hardness to production volume—you can confidently select the right tool that will deliver not just a quality part, but also the greatest possible efficiency and profitability for your operation.

References

- hard turning1 – A ZYDiamondTools blog post providing a detailed explanation of the hard turning process.

- Knoop hardness scale2 – Wikipedia article explaining the Knoop hardness test for measuring the hardness of brittle materials.

- Metal Removal Rate (MRR)3 – Wikipedia article defining the Material Removal Rate and its importance in manufacturing.

- CBN cutting insert4 – A ZYDiamondTools product page for CBN/PCBN inserts used in hard material machining.

- total cost-per-part5 – A ZYDiamondTools guide explaining Total Cost of Ownership, the principle behind calculating cost-per-part.