-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

What is Diamond Coating Technology and How Do You Choose the Right Partner for Your Application?

What do you truly need to understand before leveraging advanced diamond coating technology for your critical components?

Diamond coating is a process that applies a micro-thin layer of diamond or diamond-like material onto a component’s surface to dramatically improve its hardness, wear resistance, and other properties. Successfully implementing this technology requires understanding the core coating processes (CVD and PVD) and material types (Pure Diamond, DLC, Composite) to select the right fit for your industry. Choosing the best partner is a strategic decision based on their technical expertise, industry-specific experience, quality certifications, and a transparent consultation-to-quotation process.

How Does the Coating Process Actually Work?

So, how is it possible to apply an ultra-thin, incredibly hard layer of diamond onto a completely different material, like a metal tool or a medical implant?

Essentially, diamond coating technology builds a new surface on an object, atom by atom, inside a specialized vacuum chamber. The two primary methods to achieve this are Chemical Vapor Deposition (CVD)1, which uses a chemical reaction from a gas to “grow” a diamond film, and Physical Vapor Deposition (PVD)2, which physically transfers carbon atoms from a solid source onto the object’s surface.

The Science of Chemical Vapor Deposition (CVD)

Think of Chemical Vapor Deposition (CVD) as a highly advanced construction process happening at a microscopic scale. Instead of bricks and mortar, it uses gas molecules and energy to meticulously build a true, crystalline diamond layer directly onto a component’s surface.

The Process: From Gas to Diamond Film

The entire process happens within a sealed vacuum chamber to ensure absolute purity.

- Preparation: First, the component to be coated (called the substrate) is thoroughly cleaned and placed inside the chamber.

- Gas Introduction: Next, a precise mixture of gases is introduced. This typically includes a carbon-source gas, like methane (CH₄), and hydrogen (H₂).

- Activation: The chamber is then heated to extreme temperatures, often exceeding 800°C (1472°F). This intense energy breaks the gas molecules apart, releasing individual carbon atoms.

- Deposition: Finally, these free carbon atoms settle onto the surface of the warmer substrate. Under these specific conditions, they bond with each other in the exact same rigid lattice structure as a natural diamond, forming a uniform, pure, and incredibly hard film.

Because the process uses a gas that fills the entire chamber, CVD is exceptional at coating complex shapes, reaching into small crevices and internal surfaces with remarkable consistency.

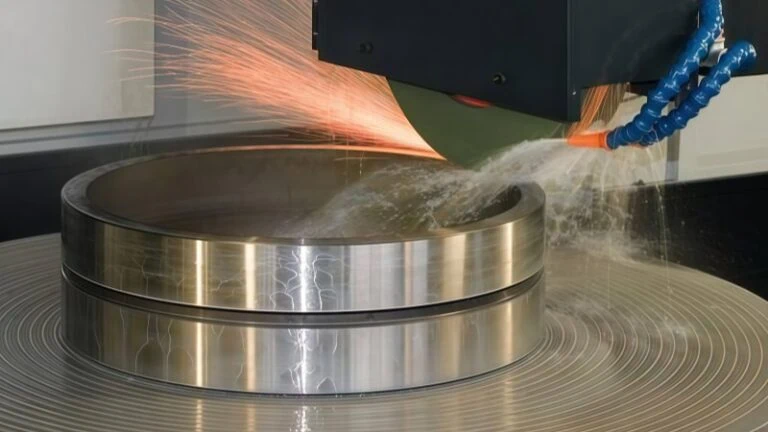

Industry Case Study: CVD for Cutting Tools

In the machining of abrasive materials like carbon fiber reinforced polymers (CFRP) for the aerospace industry, standard carbide tools wear out rapidly. By applying a CVD diamond coating3, a tool’s lifespan can be extended dramatically. For instance, an uncoated carbide drill might fail after drilling 100 holes, whereas a CVD diamond-coated version can often drill over 2,000 holes before needing replacement. This represents a 20x increase in tool life, significantly reducing downtime and manufacturing costs.

Understanding Physical Vapor Deposition (PVD)

In contrast to CVD’s “growing” method, Physical Vapor Deposition (PVD) is more like a microscopic, high-energy spray-painting process. It takes a solid material, turns it into a vapor, and then physically deposits it onto the substrate. While many PVD processes exist, those used for hard coatings often create Diamond-Like Carbon (DLC), not pure crystalline diamond. DLC is extremely hard and slick but has a less organized, amorphous atomic structure compared to true diamond.

The Line-of-Sight Method

The PVD process for DLC coatings typically follows these steps:

- Source Material: A solid block of high-purity graphite (a form of carbon) is placed inside the vacuum chamber.

- Vaporization: A powerful energy source, such as an electric arc or a stream of ions (sputtering), is directed at the graphite. This energy is intense enough to chip off and vaporize carbon atoms, creating a plasma cloud.

- Deposition: An electrical voltage is used to guide these carbon ions, accelerating them toward the component to be coated. They impact the surface with high energy and bond to it, forming a dense and very hard DLC film.

A key characteristic of PVD is that it is a line-of-sight process. Like a spray can, it can only coat the surfaces it can directly “see.” This makes it excellent for external surfaces but less effective for highly complex geometries with hidden areas. A major advantage, however, is that PVD can be performed at much lower temperatures (often below 200°C or 392°F), making it safe for heat-sensitive materials like certain steels or plastics.

Key Differences Between CVD and PVD

Choosing between these processes depends entirely on the application’s requirements, such as the material of the component, its shape, and the desired surface properties. The best approach often involves discussing your specific needs with a coating specialist, as they can recommend the optimal process and parameters.

Here is a clear breakdown of the fundamental differences:

| Feature | Chemical Vapor Deposition (CVD) | Physical Vapor Deposition (PVD) |

|---|---|---|

| Starting Material | Gas (e.g., Methane) | Solid (e.g., Graphite) |

| Process Nature | Chemical reaction grows a film | Physical process transfers material |

| Process Temperature | Very High (typically >700°C) | Relatively Low (typically <450°C) |

| Coating Coverage | Highly uniform, excellent for complex 3D shapes | Line-of-sight, best for external surfaces |

| Typical Coating | Pure Polycrystalline Diamond | Diamond-Like Carbon (DLC) |

| Key Advantage | Extreme hardness, chemical purity | Low-temperature application, high slickness |

What Are the Main Types of Diamond Coatings Available?

When engineers and designers refer to “diamond coatings,” are they all discussing the exact same material?

Not at all. The term “diamond coating” broadly covers three distinct categories, each with unique properties and applications. The main types are Pure Diamond Coatings, which are structurally identical to natural diamond for ultimate hardness; Diamond-Like Carbon (DLC) Coatings, which offer a powerful combination of hardness and extreme slickness; and Composite Diamond Coatings, which embed diamond particles into a metal matrix for exceptional wear resistance.

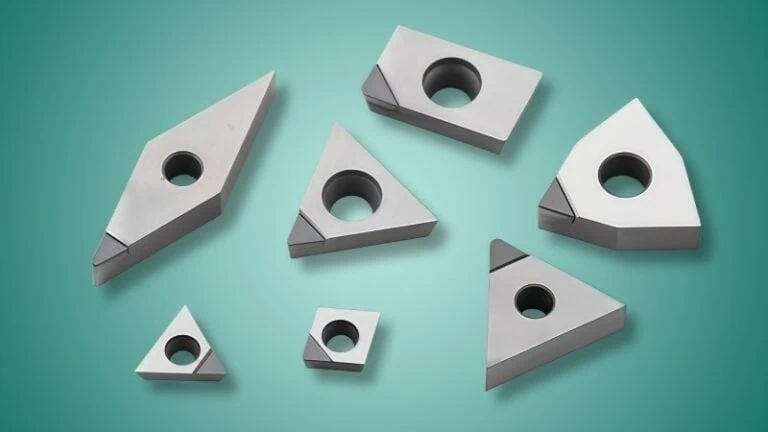

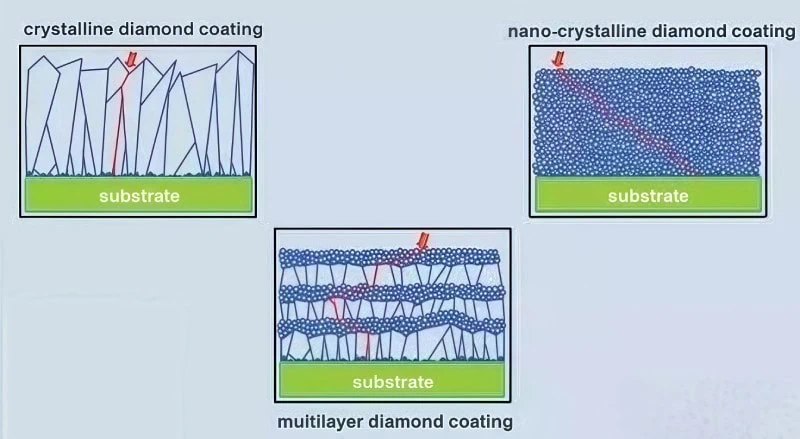

Pure Diamond Coatings (Polycrystalline and Nanocrystalline)

Pure diamond coatings are the real deal—they are made of carbon atoms bonded in the sp³ configuration, the very same structure that gives natural diamond its legendary hardness. This makes them the top choice for applications facing extreme abrasive wear. These coatings are typically applied using Chemical Vapor Deposition (CVD).

Polycrystalline Diamond (PCD)

Imagine building a wall with large, strong, interlocking stones. That’s the structure of a Polycrystalline Diamond (PCD) coating. It consists of many small diamond crystals, or “grains,” that are tightly bonded together.

This structure provides phenomenal hardness, often in the range of 50-100 GPa, making it substantially harder than traditional materials like tungsten carbide. However, the exact hardness and performance characteristics can depend on the crystal size and process used, so it’s always wise to consult your coating provider for their specific material data sheets.

- Key Characteristic: Ultimate hardness and abrasive wear resistance.

- Common Use: Machining highly abrasive non-ferrous materials. For example, PCD-coated end mills are essential in the automotive industry for shaping aluminum engine blocks and piston heads, where they vastly outlast conventional tools.

Nanocrystalline Diamond (NCD)

Now, imagine building that same wall with incredibly fine, smooth sand grains packed together perfectly. This is Nanocrystalline Diamond (NCD), also known as “ultrananocrystalline.” The diamond crystals are exceptionally small (less than 100 nanometers).

This tiny grain structure results in a surface that is not only extremely hard but also incredibly smooth. This smoothness significantly reduces the coefficient of friction, preventing materials from sticking to the surface.

- Key Characteristic: A unique combination of high hardness and an ultra-smooth, low-friction surface.

- Common Use: Applications requiring both wear resistance and a non-stick, smooth finish. In the manufacturing of medical devices, NCD is used to coat precision molds for plastics and silicone, ensuring flawless part release and extending the mold’s lifespan.

Diamond-Like Carbon (DLC) Coatings

It’s important to understand that Diamond-Like Carbon (DLC) is not pure diamond. Instead, it is a remarkable hybrid material containing a mixture of diamond-style (sp³) bonds and graphite-style (sp²) bonds. This blend gives DLC a unique and highly desirable set of properties.

The sp³ bonds provide high hardness, while the sp² bonds contribute to a very low-friction, graphite-like slickness. The result is a tough, wear-resistant film that is one of the slickest surfaces known.

Industry Application: DLC in High-Performance Engines

In the world of competitive motorsports, from Formula 1 to NASCAR, every ounce of power matters. Engine components like valve lifters, wrist pins, and piston rings are coated with DLC. This drastically reduces friction between moving parts. The lower friction translates directly into:

- Reduced Parasitic Energy Loss: More of the engine’s power reaches the wheels.

- Lower Operating Temperatures: Less friction means less heat, improving component life.

- Enhanced Durability: The hard surface protects against wear in high-RPM, high-load conditions.

DLC coatings can achieve a coefficient of friction as low as 0.05 against steel in dry conditions. This value is exceptionally low, but remember that the final performance depends heavily on the specific DLC variant and the operating environment. Always verify performance data with your supplier.

Composite Diamond Coatings

Composite diamond coatings operate on a completely different principle. Rather than a pure film, this coating consists of millions of tiny diamond particles embedded within a metal binder, typically electroless nickel. This is analogous to an aggregate concrete floor, where hard stones (the diamond) are locked in place by a cement matrix (the nickel).

The coating is applied through a plating process where the diamond particles are suspended in a nickel plating bath and are co-deposited onto the part’s surface. The primary benefit here is not just hardness but a tough, durable surface with outstanding wear resistance.

- Key Characteristic: A tough, wear-resistant surface where hardness is provided by embedded diamond particles.

- Common Use: Protecting large components in harsh, erosive environments. For example, in the oil and gas industry, large ball valves and gates that control the flow of crude oil are often coated with a nickel-diamond composite. The oil contains abrasive sand and corrosive elements. The nickel matrix provides excellent corrosion protection, while the diamond particles resist the constant erosive wear from the sand, extending the valve’s life from months to years.

Which Industries Benefit Most from Diamond Coatings?

So where does this advanced technology actually make a tangible, real-world difference?

Diamond coatings provide critical performance enhancements across several key sectors where extreme durability is essential. The most significant benefits are seen in manufacturing and machining with cutting tools, aerospace and automotive for durable components, medical technology for biocompatible implants and surgical instruments, and advanced electronics for thermal management.

Enhancing Cutting Tools and Molds

This is perhaps the most widespread and impactful application of diamond coatings. In manufacturing, time is money, and tool failure means costly downtime. Diamond coatings directly combat this by enabling tools to cut faster, last longer, and handle materials that were previously very difficult to machine.

- The Challenge: Machining highly abrasive materials like graphite (used for making molds), carbon fiber composites (used in aerospace), and high-silicon aluminum (used in engine blocks) destroys standard cutting tools with astonishing speed. The abrasive particles act like sandpaper, wearing down the cutting edge almost instantly.

- The Diamond Solution: Applying a thin film of pure CVD diamond creates a surface with unmatched hardness. This allows the tool to slice through abrasive materials with minimal wear. For example, a standard uncoated carbide end mill might last for only a few minutes when machining graphite, while a CVD diamond-coated equivalent can often run for hours. Performance gains of 20 to 50 times the tool life are common, though this can vary significantly based on the material and machining parameters. It is always best to consult your coating partner for performance estimates in your specific application.

- For Molds: In plastic injection molding, especially with abrasive glass-filled polymers, a Diamond-Like Carbon (DLC) coating on the mold cavity provides a hard, slick surface. This resists the abrasive wear from the plastic flow and makes it easier for the finished part to be ejected, improving cycle times and part quality.

Improving Durability in Aerospace and Automotive

In industries where reliability can be a matter of life and death, or where efficiency is paramount, diamond coatings provide a crucial layer of protection and performance.

Aerospace Reliability

The aerospace industry demands components that can withstand extreme conditions without failing. DLC coatings are frequently applied to critical components to reduce friction and prevent wear.

Application Example: Aircraft Landing Gear

The hydraulic actuators and pivot pins in an aircraft’s landing gear are subjected to immense stress and must operate flawlessly in harsh environments. A DLC coating on these components creates a hard, self-lubricating surface that resists wear and corrosion from hydraulic fluids and runway debris. This extends the service life of the components and increases the time between mandatory, expensive overhauls, directly enhancing the aircraft’s safety and operational readiness.

Automotive Efficiency

Whether in a high-performance racing engine or a modern passenger car, reducing internal friction is key to unlocking power and improving fuel economy.

- The Challenge: Inside an engine, parts like piston pins, valve lifters, and cams are in constant sliding contact under high pressure, leading to energy loss through friction and eventual wear.

- The Diamond Solution: Applying an ultra-slick DLC coating to these components creates a near-frictionless interface. This has a direct, measurable impact:

- Less Wasted Energy: Reduced friction means more of the fuel’s energy is converted into power.

- Increased Durability: The hard coating protects the underlying metal from wear, leading to a longer and more reliable engine life.

- Lower Emissions: A more efficient engine burns fuel more completely, contributing to reduced emissions.

Advancing Medical Implants and Devices

In the medical field, a material must not only be strong but also completely safe for the human body (biocompatible4). Diamond coatings, particularly DLC and Nanocrystalline Diamond, excel in this area, opening the door for longer-lasting implants and better surgical tools.

- The Challenge with Implants: When artificial joints like hips or knees move, tiny particles can wear off the implant surfaces. The body’s immune system can react to this wear debris, leading to inflammation and, over time, a loosening of the implant, which may require a difficult revision surgery.

- The Diamond Solution: Applying a biocompatible DLC coating to the articulating (moving) surfaces of an implant creates an exceptionally hard and smooth surface that is highly resistant to wear. This dramatically reduces the amount of wear debris generated, with the goal of creating a more durable, longer-lasting joint for the patient.

For surgical instruments like scalpels and bone saws, an NCD coating provides a cutting edge that is significantly sharper and more durable than steel alone. This allows surgeons to make cleaner, more precise incisions, which can lead to faster patient recovery.

Applications in Electronics and Optics

Diamond’s benefits extend beyond its mechanical properties. Its unique thermal and optical properties are critical for next-generation electronics and advanced sensor systems.

Thermal Management in Electronics

Did you know that diamond is the most thermally conductive material on Earth? It conducts heat more than five times better than copper.

- The Challenge: Modern electronic components, like CPUs and the power amplifiers in 5G cellular towers, are becoming smaller and more powerful. This means they generate a tremendous amount of heat in a very small area. If this heat isn’t removed efficiently, the component will overheat and fail.

- The Diamond Solution: A thin plate of high-purity CVD diamond is used as a “heat spreader.” It is placed in direct contact with the electronic chip. The diamond rapidly pulls heat away from the chip and spreads it out over a larger area where it can be removed by a traditional heat sink. This superior thermal management allows for the design of more powerful, compact, and reliable electronic systems.

Protecting Sensitive Optics

For optical systems that operate outside of the visible light spectrum, a protective window needs to be both durable and transparent to specific wavelengths of light, such as infrared (IR).

A DLC coating applied to a germanium or silicon lens creates a highly durable, scratch-resistant outer surface that can withstand harsh environmental conditions (like sand, dust, and rain) while remaining perfectly transparent to IR light. This is essential for thermal cameras, military targeting systems, and environmental monitoring sensors, ensuring a clear view while protecting the expensive optics underneath.

How Do I Choose the Right Diamond Coating Supplier?

With so many technical details to consider, how can you confidently select the best coating partner for your specific project?

Choosing the right supplier involves looking beyond just the price tag. The best partners demonstrate strong technical expertise and R&D capabilities to tailor a solution, have proven industry-specific experience with relevant case studies, maintain rigorous quality control and certifications, and follow a clear, collaborative process from the initial consultation to a detailed quotation.

Evaluating Technical Expertise and R&D Capabilities

Not all coating providers are created equal. A basic shop may be able to apply a standard coating, but a true technology partner has the deep scientific knowledge to solve your specific problem. For a critical application, you need a specialist.

So, how can you gauge their expertise? Look for these signs:

- They Ask Smart Questions: A premier supplier will want to know more than just the dimensions of your part. They will ask about the operating environment, the types of stress it will face (abrasion, impact, chemical), the base material, and the specific failure mode you are trying to prevent.

- They Have Engineers on Staff: The ability to speak directly with a materials scientist or an application engineer is a clear indicator of technical depth. These are the people who can truly understand your challenge and recommend or even develop the optimal coating.

- They Can Customize: Does the supplier offer a fixed menu of coatings, or can they modify a process? A partner with strong Research and Development (R&D) capabilities can fine-tune a coating’s properties—like its thickness, hardness, or surface texture—to perfectly match your application’s demands.

Assessing Industry-Specific Experience and Case Studies

A coating that performs flawlessly on a cutting tool may be completely unsuitable for a medical implant. A supplier with experience in your specific industry already understands the unique challenges, standards, and common points of failure you face.

Before committing, you should always ask for proof of their experience.

What to Ask a Potential Supplier:

“Can you show us examples of components similar to ours that you have successfully coated for other clients in the [your industry] sector?”

“Do you have any case studies or performance data demonstrating how your coating solved a problem like ours (e.g., extending life, reducing friction)?”

A confident and experienced partner will be able to provide clear examples. For instance, if you are in the aerospace industry, they should be able to discuss their work on flight-critical components. If you are in the medical field, they should be able to speak to biocompatibility and sterilization processes. This demonstrated experience is one of the most valuable assets a supplier can bring to the table.

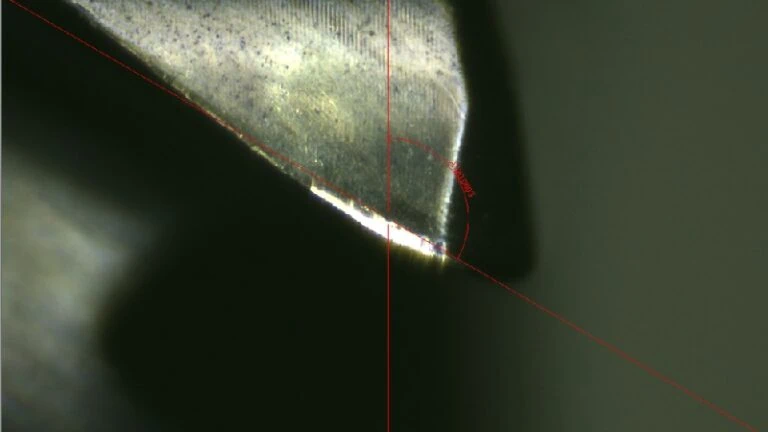

Understanding Their Quality Control and Certification

A perfect test sample is meaningless if the supplier cannot consistently reproduce that quality across thousands of parts in a full production run. This is where rigorous quality control and formal certifications become non-negotiable.

Here’s what to look for to ensure you receive reliable and repeatable results:

- Key Certifications: At a minimum, a professional coating facility should be ISO 90015 certified, which is the global standard for a quality management system.

- For aerospace applications, look for AS9100 certification.

- For medical devices, ISO 13485 is the critical standard.

- Routine Quality Checks: Ask about their standard quality assurance procedures. Professional suppliers will perform routine checks on production batches, including:

- Adhesion Testing: Scratch tests to ensure the coating is firmly bonded to the substrate.

- Thickness Verification: Using techniques like X-ray fluorescence (XRF) to confirm the coating meets the specified thickness.

- Hardness and Surface Analysis: Measuring key properties to ensure they meet your requirements.

- Traceability: In critical applications, the ability to trace a specific part back to its coating batch and the associated quality data is essential. This provides accountability and is a hallmark of a mature quality system.

The Process: From Consultation to Quoting (RFQ)

Finally, the way a supplier engages with you from the very first contact tells you a lot about how they will operate as a partner. A professional process should be clear, collaborative, and consultative.

The Initial Consultation

A good supplier won’t just give you a price list. They will start with a conversation to understand your project. This initial consultation is their opportunity to prove their expertise and your opportunity to see if they are a good fit.

Feasibility and Sample Testing

Are you working on a new or challenging application? A reputable partner may suggest a feasibility study or a pilot run. They might offer to coat a few of your parts at a low cost for you to test in your real-world environment. This “try before you buy” approach shows confidence in their technology and helps de-risk the decision for you.

The Detailed Quotation

A professional Request for Quotation (RFQ) response is much more than just a number. It should be a clear, comprehensive document that outlines:

- The exact coating being proposed and why it was chosen.

- The planned coating thickness.

- Any necessary surface preparation steps.

- The estimated lead time for production.

- A clear breakdown of the costs.

This level of detail ensures there are no surprises and sets the foundation for a successful, long-term partnership.

Key Factors That Determine the Final Cost

After understanding the technology and choosing a partner, it’s important to know what drives the price of a diamond coating service. The final cost is not a single flat rate but is determined by several interconnected variables.

The final cost of diamond coating is determined by three primary factors: the material and complexity of the part itself (substrate and geometry), the specific type and thickness of the coating required, and the total quantity of parts being coated in an order (production volume and batch size).

Impact of Substrate Material and Geometry

Before any coating even begins, the part you provide is a primary driver of the cost. This is because different parts require different levels of preparation and handling.

The Material of Your Part (Substrate)

Not all materials are equally easy to coat. Some require special pre-treatment steps to ensure the diamond film will adhere properly. For example, certain types of steel or aluminum alloys might need an intermediate “binder layer” to be applied before the final diamond coating. These extra steps in the process add time and material, which in turn adds to the cost.

The Shape of Your Part (Geometry)

The size and complexity of your part significantly influence the cost.

- Size and Surface Area: Larger parts simply take up more valuable space inside the coating chamber. Since a provider can only fit a finite number of parts into each coating run, larger parts mean fewer units per batch, which increases the cost allocated to each individual part.

- Complexity: A simple, solid cylinder is easy to handle and fixture. A complex part with deep holes, internal channels, or intricate features requires much more labor-intensive masking (to protect areas that shouldn’t be coated) and specialized racking to hold it in the chamber. This additional handling directly increases the cost.

Required Coating Thickness and Properties

The specific “recipe” you choose for your coating has a direct and significant impact on the final price.

- Coating Type: As we’ve discussed, there are different families of coatings. A highly specialized, pure CVD diamond film requires a longer, more energy-intensive process than a standard DLC coating. As a result, you can expect a pure diamond coating to be more expensive than a DLC or composite diamond coating.

- Coating Thickness: This is one of the most straightforward cost factors. The coating process takes time. A thicker coating requires the parts to spend more time in the deposition chamber. Because running these advanced machines is costly, time is literally money. A 10-micron (μm) thick coating will take significantly longer—and therefore cost more—than a 2-micron thick coating of the same type.

Production Volume and Batch Size

This factor comes down to a simple principle: economies of scale.

The Fixed Setup Cost

Every single coating run has fixed costs associated with it, regardless of the number of parts inside. This includes:

- The labor to clean and prepare the chamber.

- The cost of creating custom fixtures to hold your specific parts.

- The energy and process gases used to create the vacuum and run the recipe.

How Quantity Affects Price Per Part

Because of these fixed setup costs, the number of parts you order has a huge impact on the price you pay for each one.

- Prototypes and Small Batches: If you only need to coat 10 parts, that entire setup cost is divided among just those 10 items. This makes the cost per part relatively high.

- Large Production Runs: If you coat 1,000 parts, a large part of the setup cost is now spread across a much larger number of items, drastically reducing the cost per part.

For this reason, you will always get a more favorable price per piece when ordering in larger production volumes compared to a small prototype or sample run.

Conclusion

Ultimately, diamond coating technology is a powerful engineering tool that can provide a decisive competitive advantage when applied correctly. It transforms the surface of a component, unlocking levels of performance and durability that are otherwise unattainable. However, the technology itself is only half of the equation. The success of your project hinges on a partnership with a supplier who possesses the right blend of technical expertise, industry experience, and a commitment to quality. By thoroughly evaluating potential partners and understanding the factors that drive cost, you can confidently invest in a solution that delivers maximum value and return for your specific application.

References

- Chemical Vapor Deposition (CVD)1 – A Wikipedia article providing a comprehensive overview of the Chemical Vapor Deposition process, its variants, and applications.

- Physical Vapor Deposition (PVD)2 – A Wikipedia article detailing the various methods and uses of Physical Vapor Deposition in science and industry.

- CVD diamond coating3 – A ZYDiamondTools article comparing PCD and CVD diamond tools, providing context for CVD’s application in cutting.

- biocompatible4 – An encyclopedic explanation from Wikipedia on the concept of biocompatibility and its importance in medical applications.

- ISO 90015 – The official page for the ISO 9001 family of quality management standards from the International Organization for Standardization.