-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

What Is a PCD Fly Cutter and How Can It Transform Your Machining Projects?

- Knowledge, PCD & CBN Tools Knowledge

- -2025-03-14

- - byKevin Ray

Post Categories

Product Categories

About Company

Contact Us

Table of Contents

Have you ever wondered what a PCD fly cutter is and how it could change the way you handle machining projects?

A PCD fly cutter is a cutting tool with diamond-tipped inserts that delivers unmatched precision, durability, and speed for machining tasks, especially when working with materials like aluminum. Its diamond tips, made from Polycrystalline Diamond (PCD), stay sharp far longer than traditional steel or carbide tools, making it ideal for creating smooth, mirror-like finishes with minimal effort. This tool is a game-changer for industries like aerospace and automotive, where precision and efficiency are critical, as it reduces downtime, cuts costs, and improves overall project quality. By using a PCD fly cutter, you can achieve professional-grade results faster and more efficiently than with standard tools.

Why Choose a PCD Fly Cutter for Your Machining Needs?

A PCD fly cutter is a top choice because it offers amazing durability, precision, and speed for cutting materials like aluminum. PCD stands for Polycrystalline Diamond, which means it has diamond tips that stay sharp much longer than regular tools made of steel or carbide. This tool is great for getting smooth, shiny finishes on your workpieces with less effort. Plus, it saves you time and money by not needing to be replaced often. For anyone machining parts in industries like aerospace or automotive, a PCD fly cutter boosts efficiency and cuts costs while delivering high-quality results. It’s designed to work fast and handle big jobs, making it a smart investment for your workshop.

Benefits of Using a PCD Fly Cutter

Using a PCD fly cutter comes with some big advantages. Here’s why it’s worth choosing:

- Super Strong: The diamond tips are the hardest material out there, so the tool lasts a long time. Unlike steel tools that wear out fast, this one keeps cutting without needing constant swaps.

- Super Precise: It makes surfaces so smooth they look like mirrors. This is key for parts in planes or cars where every detail matters.

- Super Fast: It can spin quicker than other cutters, so you finish jobs faster. For soft metals like aluminum, it cuts like butter without overheating.

- Works on Many Materials: It’s best for aluminum, but it also handles plastics and composites well. This makes it handy for all kinds of projects.

- Saves Money: Yes, it costs more at first, but it lasts longer and speeds up work. Over time, you spend less on tools and get more done.

Here’s a quick table to sum it up:

| Benefit | What It Means | Why It Helps You |

|---|---|---|

| Durability | Diamond tips stay sharp forever | Fewer tool changes, less downtime |

| Precision | Makes super smooth finishes | Perfect for high-quality parts |

| Speed | Cuts fast without slowing down | Finish jobs quicker |

| Versatility | Works on aluminum, plastics, and more | One tool for many tasks |

| Cost Efficiency | Lasts long and speeds up work | Saves money in the long run |

Think of it like a race car: it’s built tough, moves fast, and gets you to the finish line with a perfect score!

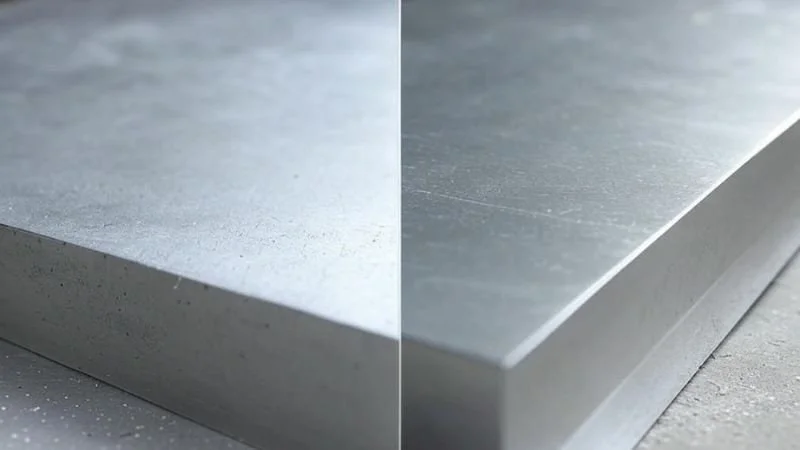

Improving Surface Finish with a PCD Fly Cutter

Want a surface so smooth you can see your reflection? A PCD fly cutter makes it happen. Here’s how it improves your work:

- One Swipe, Done: It cuts so clean that one pass is enough. Unlike other tools that leave rough edges, this one polishes as it goes.

- No Shaking: Its solid design stops wobbling. Less shaking means fewer marks or bumps on your surface.

- Perfect Shape: The diamond tip is shaped just right to slice material smoothly. It’s like using a sharp knife instead of a dull one—less effort, better results.

- Stays Cool: It doesn’t need much coolant because it handles heat well. This keeps your workpiece from warping and makes the tool last longer.

- Even Finish: For big parts like engine blocks, it keeps the surface smooth all over. No patchy spots, just a consistent shine.

Imagine machining an aluminum plate for a car engine. With a PCD fly cutter, you’d get a flawless finish in one go, no extra sanding needed. In real shops, pros use these for cylinder heads because they save time and deliver parts that look and work great.

Here’s a simple breakdown:

| Feature | How It Works | Result |

|---|---|---|

| Single-Pass | Cuts and polishes in one move | Smooth finish, less work |

| No Vibration | Steady tool, no shaking | No surface flaws |

| Cutting Shape | Diamond tip cuts cleanly | Polished look every time |

| Heat Control | Stays cool without much coolant | Longer tool life, perfect parts |

| Big Area Consistency | Same cut quality everywhere | Uniform finish on large pieces |

So, if you’re aiming for top-notch surfaces without the hassle, a PCD fly cutter is your go-to tool!

How to Use a PCD Fly Cutter Effectively?

Have you ever wondered how to make your PCD fly cutter work its best?

To use a PCD fly cutter effectively, you need a proper setup and the right speeds and feeds. First, mount the tool securely on your machine’s spindle and keep the cutting depth shallow, around 0.005 to 0.010 inches. Then, choose speeds and feeds based on your material—for aluminum, try 10,000 to 15,000 RPM and 50 to 100 inches per minute. This ensures smooth cuts and keeps the tool in top shape. With the right approach, this tool can give you amazing results every time.

Best Practices for Setting Up a PCD Fly Cutter

Setting up a PCD fly cutter correctly is super important for great cuts. So, how do you do it? Let’s break it down into simple steps that anyone can follow.

- Mount It Tight: Attach the fly cutter to your machine’s spindle and make sure it doesn’t wiggle. A loose tool can mess up your work, kind of like a wobbly bike wheel.

- Check the Insert: Look at the PCD tip closely. Is it chipped or worn out? If yes, replace it because a bad insert won’t cut well and might even snap.

- Keep Cuts Shallow: Set the depth to 0.005 to 0.010 inches per pass. Going too deep is like overloading a small engine—it strains the tool and makes noisy vibrations.

- Balance It Out: If your cutter has more than one insert, ensure they weigh the same. An unbalanced tool shakes, leaving ugly marks on your material.

- Add Coolant Wisely: For aluminum, use a light mist of coolant. Too much creates a mess, and too little heats up the tool—like finding the perfect water level for a plant.

Think of this setup like adjusting a seesaw. Everything needs to be even and steady for it to work smoothly. In real machine shops, pros often use a dial indicator—a tool like a tiny ruler—to double-check alignment. This trick, from years of experience, prevents mistakes and saves time.

Here’s a handy table to keep you on track:

| Step | Why It Matters | Quick Tip |

|---|---|---|

| Secure Mounting | Stops wobbling | Tighten bolts well |

| Inspect Insert | Prevents bad cuts | Swap out damaged tips |

| Shallow Depth | Avoids tool stress | Start at 0.005 inches |

| Balance Tool | Reduces shaking | Match insert weights |

| Proper Coolant | Keeps things cool | Use a light mist |

Follow these steps, and your PCD fly cutter will be ready to shine.

Recommended Speeds and Feeds for a PCD Fly Cutter

Now, let’s talk about speeds and feeds—how fast your tool spins and moves. Picking the right ones is key. Why? Because they decide if your cuts are smooth or rough.

- Spindle Speed (RPM): This is how fast the tool turns. For aluminum, go with 10,000 to 15,000 RPM. The diamond tip loves high speeds—it cuts clean without sticking.

- Feed Rate: This is how fast the tool moves over the material. For aluminum, aim for 50 to 100 inches per minute. Too slow rubs the tool; too fast can break it.

- Depth of Cut: Stick to 0.005 to 0.010 inches. PCD fly cutters are great for finishing, not heavy digging, like using a paintbrush instead of a shovel.

Why these settings? Diamond tips are tough and stay sharp even at high speeds, unlike steel tools that wear out fast. For example, machining an aluminum car part might use 12,000 RPM and 75 inches per minute. This combo can leave a shiny, smooth finish in one go—pretty impressive, right?

Check out this table for common materials:

| Material | Spindle Speed (RPM) | Feed Rate (IPM) | Depth of Cut (inches) |

|---|---|---|---|

| Aluminum | 10,000 – 15,000 | 50 – 100 | 0.005 – 0.010 |

| Plastics | 8,000 – 12,000 | 40 – 80 | 0.003 – 0.008 |

| Composites | 9,000 – 13,000 | 45 – 90 | 0.004 – 0.009 |

These are starting points. Your machine or job might need small tweaks. Listen to the tool—if it squeaks or the surface looks bad, adjust a little. With the right speeds and feeds, your PCD fly cutter will cut smoothly and last longer.

Where to Buy a PCD Fly Cutter?

You can purchase a PCD fly cutter from top manufacturers like ZYsuperhard or trusted tool suppliers such as Carbide Tooling and CNC Warehouse. For high-quality options, ZYsuperhard, a leading Chinese manufacturer, offers durable and precise PCD fly cutters—visit their site at zydiamondtools.com. Other reliable brands include Amana Tool and Big Fly Cutter, available through specialized retailers. These sources ensure you get a tool that fits your needs, especially if you require customization for specific sizes or features.

Top Brands for PCD Fly Cutters

When you need a PCD fly cutter, some brands are better than others because of their quality and reputation. So, which ones should you trust? Here’s a detailed look at the top brands you can rely on for your machining work.

- ZYsuperhard: This company is a leader in PCD tools. Their fly cutters are precise, long-lasting, and perfect for industries like aerospace or automotive. Plus, they offer custom designs if you need something unique. Check their options at zydiamondtools.com.

- Amana Tool: Famous for woodworking tools, they also make PCD fly cutters for CNC machines. These tools are strong and leave a smooth finish on your work.

- Big Fly Cutter: This brand focuses on large fly cutters, including PCD ones for heavy-duty tasks. Their tools are tough and built for big projects.

- Carbide Tooling: They sell affordable PCD fly cutters that still perform well. This is a great choice if you’re watching your budget.

- Performance CBN: Known for high-speed tools, they also offer PCD fly cutters. These are ideal if you need to cut fast and efficiently.

Why pick these brands? They’ve proven themselves over years of use. For instance, ZYsuperhard has more than 10 years of experience making tools trusted worldwide. Their fly cutters are built to high standards, so you get great results every time.

Here’s a simple table to compare them:

| Brand | What They’re Best At | Why Pick Them? |

|---|---|---|

| ZYsuperhard | Precision and custom tools | High quality, used globally |

| Amana Tool | Woodworking and CNC | Strong, smooth cuts |

| Big Fly Cutter | Large, heavy-duty cutters | Great for big jobs |

| Carbide Tooling | Affordable tools | Good quality for less money |

| Performance CBN | Fast machining | Built for speed |

So, how do you choose? If you need exact cuts, ZYsuperhard is your best bet. But if you’re working on something huge, like a car part, Big Fly Cutter might be better. It all depends on what you’re making!

Choosing the Right PCD Fly Cutter for Your Machine

Picking the right PCD fly cutter isn’t just about grabbing one off the shelf. It’s about finding a tool that works with your machine and project. Think of it like picking the right wrench for a bolt—one size doesn’t fit every job. Here’s how to make the best choice, step by step.

- Match Your Machine: First, check your machine’s spindle size and type. Most fly cutters fit standard spindles, but some need adapters. Always double-check the specs to avoid problems.

- Pick the Right Size: Fly cutters come in sizes like 1.5 inches or 4 inches. Smaller ones are good for tiny, detailed work, while bigger ones cut larger areas faster. What size is your project?

- Count the Inserts: Some fly cutters have one insert, others have more. More inserts can speed up your work, but they cost extra. Decide if speed or cost matters more to you.

- Know Your Material: PCD fly cutters are awesome for cutting aluminum, plastics, or composites. If you’re cutting steel, though, you might need a different tool. What are you working with?

- Customize if Needed: For special jobs, like cutting at a unique angle, get a custom tool. ZYsuperhard, for example, makes custom PCD fly cutters—explore their options at zydiamondtools.com.

Let’s say you’re making a big aluminum airplane wing. A 4-inch fly cutter with multiple inserts would save time. But for a small plastic piece, a 1.5-inch cutter with one insert might be enough. It’s all about matching the tool to the task.

Here’s a quick guide in a table:

| What to Check | How to Decide | Example |

|---|---|---|

| Machine Fit | Spindle size and type | Needs a standard or special fit |

| Size | Workpiece size | 1.5” for small, 4” for big |

| Inserts | Number of cutting edges | One for cheap, more for fast |

| Material | What you’re cutting | Aluminum or plastics |

| Customization | Unique needs | Special size or angle |

Need a tool for something tricky like roll machining? Check out ZYsuperhard’s PCD CVD Notching Tools. They’re perfect for precise cuts in tough materials. By thinking about these steps, you’ll find a fly cutter that makes your work easier and better!

Conclusion

A PCD fly cutter is a powerful tool that can elevate your machining projects by offering durability, precision, and efficiency. From understanding its benefits to setting it up correctly and choosing the right brand, this guide has covered the essential steps to help you get the most out of your PCD fly cutter. Whether you’re working on aluminum parts for aerospace or automotive industries, this tool can save you time and money while delivering professional-grade results. By following the best practices outlined here, you’ll be well-equipped to achieve smooth, flawless finishes with ease. Remember, the right tool makes all the difference—choose wisely and watch your machining projects transform!

Related Posts

What Is a PCD Fly Cutter and How Can It Transform Your Machining Projects?

Learn how a PCD fly cutter can enhance your machining projects with durability and precision. Get setup tips, best practices,

What is the Full Form of PCD Tools and Why Are They Important?

Learn about PCD tools: their full form, key features, and why they’re essential in aerospace, automotive, and woodworking. See how

PCD End Mills for Aluminum Machining: A Comprehensive Guide

For shops dealing with aluminum, PCD end mills mean less hassle and more output. They’re not cheap, but the payoff

PCD Tools: The Ultimate Guide to Polycrystalline Diamond Cutting Tools

Polycrystalline Diamond (PCD) tools set the standard for advanced machining with unmatched hardness and wear resistance. Offering 2-3 times the

Subscribe

Simply enter your email below and click “Subscribe” to stay connected with everything new and exciting.