-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

What Is the Difference Between PCD and CBN Cutting Tools?

Ever wondered about the real differences between those advanced cutting tools, PCD and CBN?

Polycrystalline Diamond (PCD) and Cubic Boron Nitride (CBN) are superhard cutting tool materials offering significant advantages over traditional carbide, but they differ critically in their applications and properties. PCD excels with non-ferrous metals and non-metals due to its extreme hardness, while CBN thrives on hard ferrous materials thanks to its superior thermal and chemical stability.

What Materials Can Each Tool Cut Effectively?

So, what’s the main difference when it comes to the materials PCD and CBN tools can handle?

The fundamental difference lies in their target materials: Polycrystalline Diamond (PCD) excels with non-ferrous metals (like aluminum, copper) and non-metallic materials (like composites, plastics), while Cubic Boron Nitride (CBN) is specifically designed for effectively machining hard ferrous materials, including hardened steels and cast irons.

Understanding which tool works best for which material is crucial for efficient machining. Let’s explore the specialties of each.

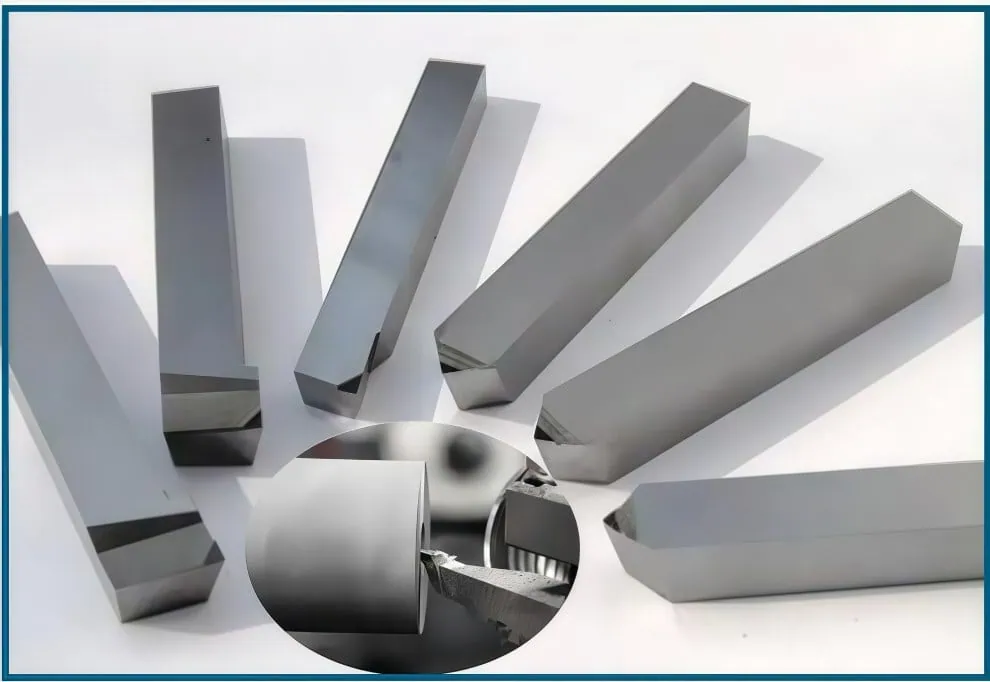

PCD: The Non-Ferrous & Non-Metallic Specialist

Think of PCD as a cutting tool specifically designed for materials that don’t contain iron, or for materials that are very abrasive. Because it’s made from diamond particles sintered together, it’s extremely hard and resistant to wear. Consequently, PCD cutting tools1 perform exceptionally well when machining:

- Non-Ferrous Metals:

- Aluminum and its alloys (especially high-silicon aluminum, which is very abrasive)

- Copper and brass

- Magnesium alloys

- Precious metals like gold and silver

- Tungsten carbide (in its ‘green’ or pre-sintered state)

- Non-Metallic Materials:

- Composites (like Carbon Fiber Reinforced Polymer – CFRP, and Glass Fiber Reinforced Polymer – GFRP)

- Plastics and rubber

- Graphite

- Ceramics (in their ‘green’ or unfired state)

- Wood and wood composites

For instance, in the automotive industry, PCD tools are frequently used for high-speed machining of aluminum engine blocks or cylinder heads, providing long tool life and excellent surface finishes. Similarly, aerospace manufacturers rely on PCD for trimming and drilling abrasive composite components like aircraft fuselage sections. Essentially, if the material is non-ferrous or abrasive, PCD is often the top choice.

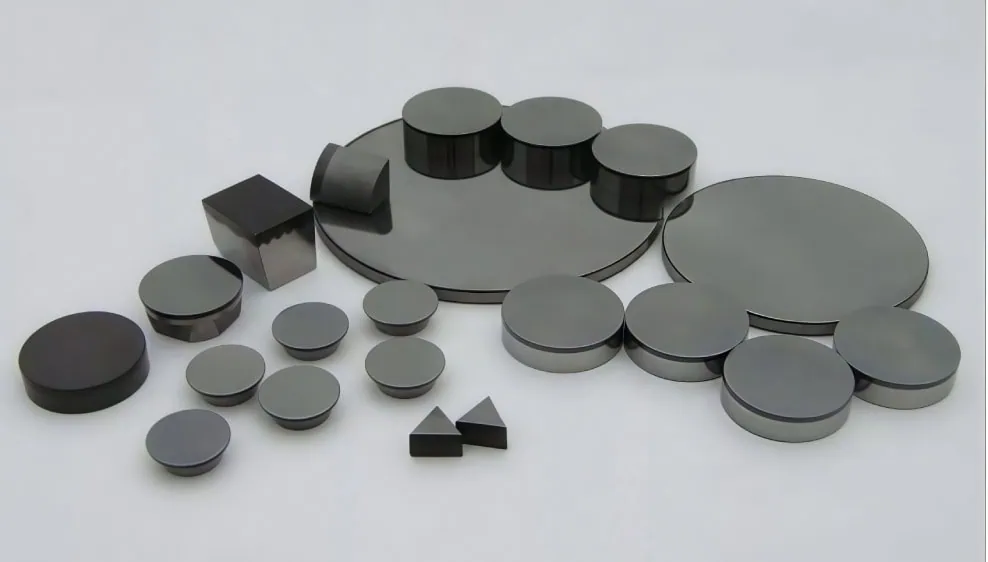

CBN: The Ferrous & Hardened Material Expert

On the other hand, Cubic Boron Nitride (CBN)2 is the go-to material when you need to cut hard materials that do contain iron. It’s the second hardest material known, after diamond, but its key advantage is its ability to withstand high temperatures and remain chemically stable when cutting iron-based metals. Therefore, CBN is the preferred choice for:

- Hardened Ferrous Materials:

- Hardened Steels (typically those above 45 HRC, though the exact range can depend on the specific CBN grade and application – it’s always wise to consult supplier recommendations for optimal hardness ranges)

- Tool Steels

- Bearing Steels

- Cast Irons:

- Grey Cast Iron

- Chilled Cast Iron

- Ductile Iron (requires specific CBN grades for optimal performance)

- Other Difficult-to-Machine Ferrous Materials:

- Powdered Metals (Sintered Irons)

- Certain Superalloys (specifically iron-based or nickel-based ones where PCD isn’t suitable)

A common application for CBN is in the finishing of hardened steel gears or shafts after heat treatment. Machining these hard components requires a tool that can maintain its cutting edge under high heat and pressure, which is exactly where CBN shines. Likewise, high-speed milling of cast iron brake discs often utilizes CBN inserts for maximum productivity and tool life.

Why PCD Struggles with Steel and Iron

You might wonder, if PCD is harder than CBN, why can’t it cut everything? The reason lies in chemistry, specifically how carbon (the main component of diamond) reacts with iron at high temperatures.

When machining steel or cast iron, the cutting process generates significant heat. At temperatures typically above 700°C (about 1300°F), the carbon atoms in the PCD tool begin to react chemically with the iron atoms in the workpiece. Think of it like a chemical attraction – the iron essentially pulls the carbon out of the diamond structure. This reaction forms iron carbide (cementite) and causes the diamond tool edge to break down rapidly, leading to very short tool life.

This chemical reaction is the primary reason PCD is generally unsuitable for machining ferrous materials. CBN, however, is made from boron and nitrogen. These elements do not have the same chemical affinity for iron at high temperatures. Consequently, CBN remains stable and maintains its hardness when cutting hot steel or iron, making it the ideal choice for those challenging applications.

How Do Their Key Physical Properties Compare?

Beyond what they cut, how do PCD and CBN actually differ in their core physical characteristics?

Key physical differences lie in hardness, thermal stability, and chemical reactivity. Polycrystalline Diamond (PCD) is the hardest material but reacts chemically with iron at high temperatures. Conversely, Cubic Boron Nitride (CBN) is slightly less hard but boasts superior thermal and chemical stability, especially when machining ferrous metals.

These fundamental properties are the reasons why each material excels in different areas. Let’s break down these key characteristics.

Hardness: Which Material Ranks Higher?

Hardness is a measure of a material’s resistance to scratching or indentation, and it’s crucial for resisting abrasive wear during cutting. When it comes to sheer hardness:

- PCD (Polycrystalline Diamond): Reigns supreme. It is the hardest known cutting tool material available. Think of diamond’s legendary hardness – PCD harnesses that. Its hardness typically falls in the range of 7000-10000 on the Knoop hardness scale (HK), although specific values can vary.

- CBN (Cubic Boron Nitride): Extremely hard, second only to diamond. It generally measures around 4500-5000 HK.

- For comparison: Conventional Tungsten Carbide tools usually fall between 1800-2400 HK.

This exceptional hardness is why both PCD and CBN offer significantly better wear resistance than carbide when used in their appropriate applications. However, remember that PCD holds the title for the absolute hardest. Specific hardness values can vary slightly depending on the grade, binder material, and manufacturer, so consulting supplier data sheets for precise figures is always recommended.

Thermal Stability: Performance at High Temperatures

Machining generates intense heat at the cutting edge. A tool material’s ability to maintain its hardness and structural integrity at high temperatures (its thermal stability) is vital, especially during high-speed cutting or when machining difficult materials.

- CBN: Exhibits excellent thermal stability. It can withstand cutting temperatures up to 1000°C (1832°F) or even higher for certain grades, without significant loss of hardness or chemical breakdown. This allows it to effectively cut hardened steels and superalloys, which generate considerable heat. Think of it like comparing a material that stays strong near a flame (CBN) versus one that starts to degrade or react (PCD with iron).

- PCD: While diamond itself has very high thermal conductivity (it dissipates heat well), its stability in the presence of ferrous materials is limited by temperature. As mentioned previously, the chemical reaction with iron becomes problematic above roughly 700°C (1300°F). In non-ferrous applications where this reaction isn’t a concern, PCD performs well thermally, but CBN holds the advantage when extreme heat is generated during ferrous metal cutting. The exact temperature limits can depend on the specific grade and application conditions; always check manufacturer specifications.

CBN’s superior performance at high temperatures makes it uniquely suited for the demanding conditions of hard machining.

Chemical Stability: Reactivity Differences

Chemical stability refers to how readily a tool material reacts with the workpiece material it’s cutting, especially under heat and pressure. This is a critical differentiator between PCD and CBN.

- CBN: Is chemically inert (doesn’t react easily) with iron and other components found in ferrous alloys, even at high temperatures. This lack of reactivity prevents the chemical wear that plagues PCD in similar situations.

- PCD: Composed primarily of carbon, it has a high chemical affinity for iron. As explained before, this leads to a diffusion reaction at elevated temperatures, causing rapid tool degradation when machining steels or cast irons. However, PCD is very stable when cutting non-ferrous materials like aluminum or composites, where this specific reaction doesn’t occur.

This difference in chemical stability fundamentally dictates the primary application areas: CBN for ferrous metals, PCD for non-ferrous and non-metallic materials.

Toughness and Handling Considerations

While extremely hard, both PCD and CBN are generally less tough than traditional tungsten carbide3 materials. Toughness relates to a material’s ability to resist chipping, cracking, or fracturing under impact or stress. Think of it like comparing glass (brittle but hard) to metal (tougher but softer).

- PCD & CBN: Are inherently more brittle (less tough) than carbide. This means they are more susceptible to chipping or fracture if subjected to heavy impacts, vibrations, or interrupted cuts (where the tool repeatedly enters and exits the workpiece).

- CBN Grade Variation: The toughness of CBN can vary significantly depending on its specific grade – factors like CBN grain size and the type/amount of binder material (often ceramic) play a large role. Some grades are engineered for higher toughness to handle light interruptions.

- Handling: Due to their relative brittleness, both PCD and CBN tools require careful handling to avoid accidental dropping or edge damage.

This lower toughness compared to carbide means that successful application often requires stable machining conditions: rigid machine tools, secure workpiece clamping, and minimizing vibration. While they offer incredible wear resistance, understanding their toughness limitations is key to preventing premature tool failure.

What Performance Differences Should You Expect in Practice?

Knowing their properties, how do PCD and CBN actually perform differently when put to work?

In practice, both PCD and CBN offer significant performance advantages over traditional tools in their respective applications, primarily through drastically increased tool life, the ability to achieve excellent surface finishes, and enabling much higher cutting speeds, leading to greater productivity.

These performance gains are the practical results of their unique physical properties. Let’s look at what this means for tool life, surface quality, and machining speed.

Comparing Tool Life Potential

One of the most significant practical differences you’ll notice is tool life. When used correctly on the materials they are designed for, both PCD and CBN can last dramatically longer than conventional carbide tools.

- PCD Tool Life: In non-ferrous and abrasive materials, PCD’s extreme hardness leads to exceptional wear resistance. It’s not uncommon for PCD tools to last 10 to 50 times longer, sometimes even more, than carbide tools in the same application. For example, when machining high-silicon aluminum alloys (which are very abrasive), a PCD insert might machine thousands of parts, while a carbide insert might only manage a few hundred before needing replacement.

- CBN Tool Life: Similarly, when machining hardened ferrous materials or cast irons, CBN’s combination of hardness and thermal/chemical stability results in substantially longer life compared to carbide or ceramic tools. Depending on the specific material hardness and cutting conditions, CBN tools can often achieve 5 to 25 times the lifespan of carbide inserts.

This vastly increased tool life directly translates to significant benefits: less machine downtime for tool changes, more consistent part quality over long runs, and reduced overall tooling costs per part, despite the higher initial tool price. However, it’s crucial to remember that these tool life multiples are highly dependent on the specific application, including the exact workpiece material, cutting parameters, machine condition, and coolant usage. Real-world results can vary.

Achievable Surface Finish Quality

Both PCD and CBN are capable of producing outstanding surface finishes on the workpiece, often exceeding what’s possible with traditional tooling.

- Sharp, Durable Edges: Their high hardness allows PCD and CBN tools to maintain a very sharp cutting edge for much longer periods compared to softer materials like carbide. A consistently sharp edge shears material cleanly, reducing built-up edge (BUE) and resulting in a smoother surface.

- High Speed Capability: The ability to run at higher cutting speeds (discussed next) can also contribute to improved surface finishes in many materials.

In practice, using PCD for finishing aluminum or CBN for finishing hardened steel can often produce mirror-like surfaces. This high-quality finish might even eliminate the need for subsequent operations like grinding or polishing in some applications, saving time and manufacturing steps. For instance, achieving a low Ra (surface roughness average) value required for sealing surfaces or high-precision bearing fits is often readily accomplished using CBN or PCD tools.

Optimal Cutting Speed Ranges

A major driver of productivity in machining is cutting speed – how fast the tool moves relative to the workpiece surface (often measured in Surface Feet per Minute (SFM) or meters per minute (m/min)). Both PCD and CBN enable significantly higher cutting speeds than carbide in their preferred materials.

- PCD Cutting Speeds: Especially when machining aluminum alloys, PCD allows for very high cutting speeds. Ranges can typically be from 600 to 3000 m/min (approx. 2000 to 10000 SFM). This enables extremely fast material removal rates.

- CBN Cutting Speeds: For hardened steels (above 45 HRC), CBN typically runs effectively between 100 to 300 m/min (approx. 300 to 1000 SFM). When machining cast irons, speeds can often be even higher, sometimes reaching 300 to 1000 m/min (approx. 1000 to 3300 SFM) or more, depending on the type of cast iron and CBN grade.

These higher speeds directly reduce machining cycle times, allowing more parts to be produced in the same amount of time. Crucially, these speed ranges are general guidelines. The optimal cutting speed for any specific job depends heavily on the exact workpiece material and its hardness, the machine’s rigidity and power, the depth of cut, feed rate, tool geometry, and coolant application. Always start with the tool manufacturer’s recommendations and adjust based on actual performance and conditions. Using these tools at appropriate high speeds leverages their thermal stability (especially CBN) and wear resistance, maximizing productivity gains.

What Are the Core Advantages and Disadvantages of Each?

Okay, summing it all up, what are the main plus points and downsides of using PCD and CBN tools?

The primary advantages of both PCD and CBN include exceptional wear resistance leading to long tool life, high-speed capability, and excellent surface finishes in their respective materials. However, their main limitations are higher initial cost compared to carbide and increased brittleness, requiring careful handling and stable machining conditions. Additionally, their application ranges are highly specific.

Weighing these pros and cons is essential when deciding if these advanced materials are the right choice for your machining tasks. Let’s look closer at the strengths and weaknesses.

Key Strengths of PCD Tooling

When applied to the right materials (non-ferrous metals and non-metallics), PCD offers compelling benefits:

- Exceptional Hardness and Wear Resistance: Its status as the hardest cutting tool material translates directly into superior resistance against abrasive wear, especially with materials like high-silicon aluminum or composites.

- Extremely Long Tool Life: Significantly reduces the frequency of tool changes, leading to more uptime and consistent production runs.

- Superior Surface Finish: Capable of producing very smooth, high-quality finishes on materials like aluminum, brass, and plastics.

- High Thermal Conductivity: Efficiently draws heat away from the cutting zone, which is beneficial when machining non-ferrous metals at high speeds.

- Very High Cutting Speed Capability: Enables dramatic increases in machining speed, particularly in aluminum, boosting productivity significantly.

Key Strengths of CBN Tooling

For tackling hard ferrous materials, CBN brings its own set of powerful advantages:

- Excellent Hardness and Wear Resistance: While second to PCD, its hardness is still exceptional and highly effective against hardened steels and cast irons.

- Outstanding Thermal Stability: Retains its hardness and cutting ability even at the very high temperatures generated during hard machining or high-speed cast iron milling.

- Superior Chemical Stability: Its inertness towards iron prevents the chemical wear that limits PCD, making it ideal for steel and iron.

- Long Tool Life in Hard Materials: Provides extended performance when turning or milling hardened components, reducing tooling costs per part.

- High Cutting Speed Capability: Allows for significantly faster machining of cast irons and hardened steels compared to traditional methods.

- Potential Grinding Replacement: In some precision hard finishing applications, CBN machining can achieve tolerances and finishes that may eliminate the need for slower, more costly grinding operations4.

Important Limitations and Drawbacks

Despite their strengths, both PCD and CBN come with limitations that must be considered:

Common Challenges for Both PCD & CBN

- Higher Initial Cost: These are premium cutting tool materials, and their purchase price is considerably higher than equivalent carbide tools. The exact cost can vary widely based on tool size, complexity, grade, and manufacturer.

- Increased Brittleness: Compared to tungsten carbide, both PCD and CBN are more brittle and less tough, making them more prone to chipping or fracturing, especially under impact or vibration.

- Need for Stable Machining Conditions: To prevent tool failure due to brittleness, they generally require rigid machine tools, secure workpiece clamping, and smooth, stable cutting operations. Interrupted cuts can be particularly challenging.

- Requires Careful Handling: Due to brittleness, these tools must be handled more carefully than carbide tools to avoid accidental damage to the cutting edges.

Specific Application Limitations

- PCD’s Inability to Cut Ferrous Metals: The chemical reaction with iron at high temperatures makes PCD unsuitable for machining steels and cast irons effectively.

- CBN’s Suitability: While excellent for hard ferrous materials, CBN is generally not the most effective or economical choice for softer steels, non-ferrous metals, or non-metallic materials where PCD or even carbide might perform better. Choosing the correct CBN grade (related to grain size and binder content) for the specific ferrous material and operation (e.g., continuous vs. interrupted cut) is also critical for success.

How Do PCD and CBN Compare Financially?

We know they perform well, but how do PCD and CBN stack up when it comes to the price tag?

Financially, both PCD and CBN tools have a significantly higher initial purchase price compared to traditional carbide tools. However, their true value often lies in long-term cost-effectiveness, achieved through dramatically longer tool life and increased productivity, which can lead to a lower overall cost per machined part in suitable high-volume or demanding applications.

Looking beyond the initial sticker price is essential to understand the true economic impact of using these advanced cutting materials.

Understanding the Initial Cost Difference

There’s no way around it: PCD and CBN tools cost more upfront than their tungsten carbide counterparts. You can generally expect to pay several times the price for a PCD or CBN insert or tool compared to a similar carbide one.

- Why the Higher Price? This difference stems from more complex and energy-intensive manufacturing processes involving extremely high pressures and temperatures, as well as the cost of the specialized raw materials (synthetic diamond or cubic boron nitride powders and specific binders).

- PCD vs. CBN Cost: Often, PCD tools tend to be the most expensive, followed by CBN, and then carbide, although this isn’t a strict rule.

- Significant Variation: It’s crucial to understand that the actual cost difference can vary dramatically. Factors like the type of tool (insert, end mill, reamer), its size and complexity, the specific grade of PCD or CBN material, any special coatings, and the manufacturer all heavily influence the final price. Therefore, always obtain specific quotes for your particular needs rather than relying on general multipliers.

Think of it like investing in specialized, high-performance equipment – the initial outlay is greater, but it’s designed for demanding tasks where standard equipment falls short.

Evaluating Long-Term Cost-Effectiveness

While the initial purchase price is higher, the financial justification for using PCD and CBN comes from evaluating the total cost per machined part over the long run. When used in appropriate applications, these tools can significantly lower overall production costs through several key factors:

- Drastically Longer Tool Life: As discussed earlier, PCD and CBN tools can last many times longer than carbide. This means you buy fewer tools over the course of a production run.

- Reduced Machine Downtime: Fewer tool changes are needed. Every time a machine stops for a tool change, it’s not making parts. Reducing this downtime directly increases productive machine hours.

- Increased Productivity: The ability to run at much higher cutting speeds shortens the time it takes to machine each part (cycle time), allowing more parts to be produced in the same timeframe.

- Consistent Quality & Fewer Rejects: Longer tool life means more consistent cutting performance, leading to better dimensional accuracy and surface finish consistency, potentially reducing scrap or rework costs.

- Potential Operation Elimination: In some cases (like hard turning with CBN), the high-quality finish achieved can eliminate the need for separate finishing operations like grinding, saving substantial time and cost.

Imagine calculating your cost per part. While the ‘Tool Cost’ component might be higher with PCD/CBN, the ‘Number of Parts per Tool Edge’ increases dramatically. Simultaneously, the ‘Machine Time Cost per Part’ decreases due to faster cycle times and less downtime. This concept is often analyzed through metrics like Total Cost of Ownership5. For high-volume production or challenging materials where these benefits are fully realized, the overall cost per part often becomes significantly lower compared to using less expensive but shorter-lived carbide tools.

This cost-effectiveness is most apparent in:

- High-volume manufacturing: (e.g., automotive components) where reducing cycle times and tool changes across thousands or millions of parts yields massive savings.

- Difficult-to-machine materials: Where carbide tool life is extremely short, the extended life of PCD/CBN provides a clear economic advantage despite the initial price.

Conversely, for very short runs or one-off parts in easily machinable materials, the higher initial cost of PCD/CBN might be harder to justify economically unless technically required for the material or finish.

How Do You Choose the Right Tool for Your Job?

With all this information, how do you actually decide whether to use PCD, CBN, or stick with carbide for a specific task?

Choosing the right tool involves matching the tool material to your specific workpiece material (PCD for non-ferrous/non-metals, CBN for hard ferrous), considering the machining operation type (e.g., finishing vs. roughing, continuous vs. interrupted cuts), and evaluating if the performance gains and long-term cost savings justify upgrading from standard carbide tools.

Making the right choice requires considering these factors systematically to ensure both technical success and economic sense.

Quick Guide: Matching Tool to Workpiece Material

The absolute first step is always matching the cutting tool material to the workpiece material. This is non-negotiable due to the fundamental properties we’ve discussed:

- Is your workpiece material Non-Ferrous (like Aluminum, Copper, Brass, Magnesium) OR Non-Metallic (like Composites, Plastics, Graphite, Ceramics)?

- If YES, PCD is likely your best choice for high performance and wear resistance.

- Is your workpiece material a Ferrous Metal (Steel or Cast Iron) AND is it Hard (generally above approx. 45-50 HRC for steel)?

- If YES, CBN is specifically designed for this and will likely offer the best performance and tool life.

- Is your workpiece material a softer Steel (below approx. 45 HRC), Stainless Steel, Titanium, or another standard material not listed above?

- If YES, traditional Carbide tooling is often the most suitable and cost-effective option. PCD cannot be used effectively on steels, and CBN may not offer significant advantages over carbide on softer materials to justify its cost.

Getting this initial material match correct prevents fundamental issues like the chemical reaction between PCD and steel, or trying to use CBN on materials where it offers no benefit.

Considering Your Machining Operation Type

Once you’ve matched the tool material potential, consider the specifics of the machining operation:

- Roughing vs. Finishing: Both PCD and CBN truly excel in finishing and semi-finishing operations where maintaining a sharp edge for precision and surface quality is paramount. While tougher grades of CBN exist that can handle some light roughing in hard materials, heavy roughing operations (large depths of cut, high material removal rates) often favor the superior toughness of specialized carbide grades.

- Continuous vs. Interrupted Cuts: Remember that PCD and CBN are generally more brittle than carbide. Continuous cuts (like turning a smooth, uninterrupted diameter) are ideal. Interrupted cuts (like milling across slots, holes, or keyways) introduce impacts that can chip brittle tool edges. While specific ‘tougher’ CBN grades are available designed for interrupted cutting in ferrous materials, heavy interruptions might still necessitate carbide, or require careful application (reduced parameters, stable setup) if using CBN/PCD.

- Tolerance and Surface Finish Needs: If your application demands extremely tight dimensional tolerances or exceptionally fine surface finishes (low Ra values), particularly on hard materials where grinding might be the alternative, the ability of PCD and CBN to hold a precise, sharp edge makes them highly attractive options.

When Upgrading from Carbide Makes Sense

Carbide tools are versatile and cost-effective for many applications. So, when should you seriously consider the higher investment in PCD or CBN? The upgrade typically makes sense when:

- Carbide Tool Life is Unacceptably Short: If you are machining a material perfectly suited for PCD (e.g., high-silicon aluminum) or CBN (e.g., hardened tool steel > 50 HRC) and your carbide tools are wearing out extremely quickly, upgrading is often essential for efficient production. Note that hardness thresholds like HRC are general guidelines; always consult material and tooling suppliers for specific recommendations.

- Productivity Needs Demand Higher Speeds: If your production goals require faster cycle times and your workpiece material allows for the significantly higher cutting speeds achievable with PCD or CBN, the upgrade can unlock substantial throughput gains.

- Required Quality Cannot Be Met with Carbide: If you struggle to achieve the necessary surface finish or dimensional tolerances with carbide tools, potentially leading to scrap, rework, or the need for secondary grinding/polishing operations, PCD/CBN might provide the needed quality directly from the machining process.

- Long-Term Cost Savings Are Evident: When a cost-per-part analysis (considering tool cost, tool life, cycle time, and downtime) shows that the higher initial price of PCD/CBN is offset by savings in other areas, particularly in high-volume or continuous production scenarios.

Conversely, if your current carbide tooling provides adequate tool life, meets all quality requirements, and machining time is not a major bottleneck for your specific job, sticking with carbide is often the most practical and economical approach.

Conclusion

Choosing between PCD, CBN, and traditional carbide cutting tools ultimately comes down to understanding the specific demands of your application. The fundamental difference lies in the workpiece material: PCD is the champion for non-ferrous metals and abrasive non-metals, while CBN excels in machining hard ferrous materials like hardened steel and cast iron.

By considering the key physical properties (hardness, thermal/chemical stability, toughness), expected performance differences (tool life, surface finish, speed), advantages, limitations, and the financial implications (initial cost vs. long-term value), you can make an informed decision. Selecting the right tool material isn’t just about technical feasibility; it’s about optimizing productivity, ensuring quality, and achieving the best possible cost-effectiveness for your specific machining operations. Leveraging the unique strengths of PCD and CBN where appropriate can unlock significant improvements in manufacturing efficiency.

References

- PCD cutting tools1 – Learn All About Polycrystalline Diamond cutting tools from ZYDiamondTools.

- Cubic Boron Nitride (CBN)2 – ZYDiamondTools’ comprehensive guide to CBN cutting tools, covering properties, advantages, applications, types, comparisons, usage, and selection.

- less tough than traditional tungsten carbide3 – ZYDiamondTools blog post comparing the differences between PCD and Carbide tools, including toughness.

- grinding operations4 – Encyclopedia Britannica article describing grinding machines and the grinding process in manufacturing.

- Total Cost of Ownership5 – ZYDiamondTools guide explaining the TCO concept and application for superhard tooling & abrasives.