-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

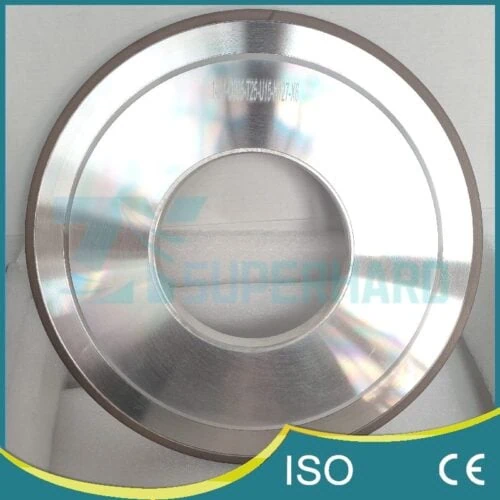

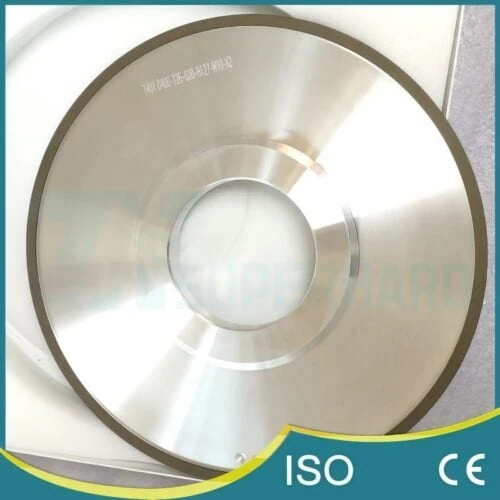

Vitrified Bond Diamond Periphery Grinding Wheels

Precision vitrified diamond wheels for edging carbide, ceramic, PCD & CBN inserts. Optimized for wet grinding on Agathon/Waida machines. Ensure high efficiency, superior edge quality & long life. Custom.

Precision Vitrified Diamond Wheels for Edging Superhard Material Inserts

Achieve superior cutting edge quality, tight dimensional tolerances, and high production efficiency on your indexable inserts with ZYsuperhard’s Vitrified Bond Diamond Periphery Grinding Wheels. Expertly engineered for the demanding process of precision peripheral grinding (edging) of inserts made from ultra-hard materials like Hard Alloy (Tungsten Carbide), Technical Ceramics, Polycrystalline Diamond (PCD), and Polycrystalline Cubic Boron Nitride (PCBN), these wheels deliver exceptional, consistent performance on specialized insert grinding machines such as AGATHON, WAIDA, WENDT, and EWAG.

The Vitrified Bond Diamond Advantage for Insert Edging:

Our advanced vitrified (ceramic) bond system, paired with high-quality diamond abrasive, is specifically optimized for the unique requirements of peripheral insert grinding:

- Maximum Precision & Rigidity: The inherently stiff vitrified bond structure minimizes wheel deflection during grinding, enabling the creation of precise edge geometries (clearance angles, lands), sharp corners, and adherence to micron-level dimensional tolerances with outstanding repeatability.

- Excellent Form Holding & Edge Quality: Vitrified bonds maintain their profile integrity exceptionally well, which is crucial for generating consistent edge preparations and superior cutting edge quality (minimal chipping, excellent sharpness) across large batches of inserts.

- Cool & Clean Grinding Action (Wet Grinding Optimized): Specifically designed for wet grinding, the engineered porosity of the vitrified bond allows efficient coolant penetration and swarf removal directly at the point of contact. This ensures cool cutting action, preventing thermal damage to sensitive insert materials (especially PCD/CBN and ceramics), avoids wheel loading, and contributes to a better surface finish.

- Efficient Diamond Performance & Long Life: The strong ceramic bond securely holds the premium diamond abrasive particles, allowing for efficient material removal on extremely hard insert substrates while balancing wheel wear to provide long, predictable wheel life between dressing cycles.

Key Features:

- Optimized Wheel Shapes: Available in standard, high-performance insert grinding shapes such as 11A2B, 12A2T, 6A2M, 6A2T (and potentially others) designed for optimal access and grinding performance on various insert geometries.

- Premium Diamond Abrasive: Utilizes high-quality diamond selected in fine grit sizes (e.g., standard offerings D46, D64, with other grits customizable) suited for achieving the precision and surface finish required for high-performance cutting edges.

- Proven Machine Compatibility: Engineered and balanced for stable, high-performance operation on industry-leading peripheral insert grinding machines including models from AGATHON, WAIDA, WENDT, EWAG, TDG-MT, and similar platforms.

Core Application:

The primary and specialized application is the high-precision peripheral grinding (edging) of indexable cutting tool inserts made from:

- Hard Alloy (Tungsten Carbide): Finishing clearance angles, lands, and radii on carbide milling, turning, and drilling inserts.

- Technical Ceramics: Precision edging of ceramic inserts (e.g., Alumina, Silicon Nitride based) used for high-speed or specialized cutting applications.

- Polycrystalline Diamond (PCD): Finish grinding the periphery of PCD inserts used for non-ferrous and composite machining.

- Polycrystalline Cubic Boron Nitride (PCBN): Precision edging of PCBN inserts used for hard turning and milling ferrous materials. (Objective: Achieving precise angles, edge sharpness, low surface roughness, and tight dimensional tolerances on the insert periphery.)

Customization:

Beyond standard catalog offerings, ZYsuperhard provides fully customized vitrified diamond wheels tailored to your specific insert grinding machine, insert material, geometry, stock removal needs, and desired edge quality/finish requirements. We can customize dimensions, grit size, diamond concentration, and bond characteristics.

How to dress periphery grinding wheels

In the process of tool grinding, the grinding wheel’s working surface will be blocked by grinding debris. If we continue to operate it because the abrasive exposed cutting edge part is smaller, the cutting ability is reduced, the grinding pressure is increased, and the vibration of the machine tool will be increased, the grinding wheel produces a whistling sound for affecting the processing quality, then need to dress.

- By dressing, the grinding wheel can be kept in a good processing state to ensure processing efficiency and quality. The more smooth the grinding wheel dressing, the smaller the roughness of the machined surface.

- Peripheral grinding machine generally has its own dressing system, including a cleaning wheel and dressing wheel.

- Usually peripheral grinding wheel is trimmed by green silicon carbide or white corundum grindstone.

- Commonly used grain size F80-F500 according to the grinding wheel grain size and fracture requirements;

- Hardness generally selected soft or medium-soft level (J-K)

FAQ and analysis

A. Fast consumption of grinding wheel:

- Grinding wheel threshing too fast

- Low abrasive strength

B. Workpiece burn:

- The grinding wheel is not sharp enough

- Whether the appropriate parameter Settings

- The device is abnormal

C. The workpiece surface roughness is poor:

- Whether the grinding wheel size selection is appropriate

- Whether the processing parameters are reasonable

- Coolant

D. Abnormal machining accuracy:

- Breaking edge

- Parallel flatness

- Size

Choose ZYsuperhard Vitrified Diamond Wheels for consistent edge quality, superior precision, and efficient production when grinding your valuable superhard material inserts. Contact us to discuss your specific insert edging application and requirements.