-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

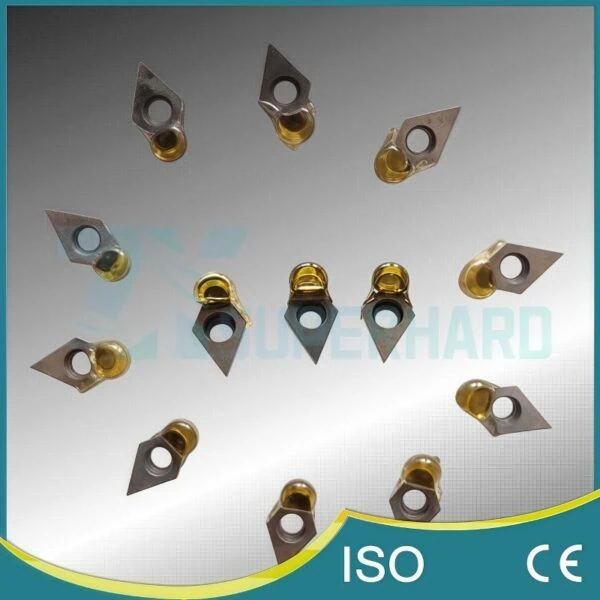

Custom Single Crystal (SCD/MCD) Diamond Inserts

Ultra-precision Single Crystal Diamond (SCD/MCD) inserts for mirror finishes on aluminum, copper, & plastics. Achieve ultimate sharpness and accuracy with custom-ground geometries per your drawing.

Single Crystal Diamond (SCD/MCD) Inserts for Ultra-Precision Machining

Achieve the ultimate in surface finish and dimensional accuracy with custom-manufactured Single Crystal Diamond (SCD/MCD) Inserts. Representing the pinnacle of cutting edge technology, these inserts are the premier choice for applications demanding mirror-like surfaces (Ra < 0.01 μm) and sub-micron tolerances, particularly when machining non-ferrous metals and polymers.

The Pinnacle of Cutting Edge Technology: Single Crystal Diamond

Single Crystal Diamond, also known as Monocrystalline Diamond, is a synthetically grown, flawless diamond structure offering unique machining properties:

- Atomically Sharp Cutting Edge: Can be ground to an exceptionally sharp, defect-free cutting edge (potentially nanometer-scale radius), enabling material shearing with minimal force and deformation.

- Unsurpassed Surface Finish: Capable of producing mirror-like surface finishes (Ra < 0.01 μm) directly from the machining process on compatible materials, often eliminating the need for polishing or lapping operations.

- Ultimate Hardness & Wear Resistance: Provides exceptional abrasion resistance when machining suitable materials, leading to long tool life under appropriate conditions.

- Material Compatibility: Excels when machining most non-ferrous metals (including aluminum & alloys, copper & alloys, oxygen-free copper, gold, silver, brass, bronze), polymers (like Acrylic/PMMA, Polycarbonate), and certain soft composite materials. (Note: SCD is generally unsuitable for machining ferrous metals due to high chemical affinity, or very hard ceramics due to its relative brittleness).

- Important Considerations: While extremely hard, SCD is more brittle than PCD or cemented carbide. Successful application requires high-precision, dynamically stable machine tools, minimal vibration, and carefully controlled cutting parameters.

Customized Insert Geometry to Your Exact Needs

We specialize in manufacturing SCD inserts with meticulously controlled geometries tailored to your specific application and tool holder design. Based on your detailed drawings, we can produce inserts featuring:

- Micro-Precision Dimensions & Tolerances: We possess the capability to achieve exceptional accuracy on critical geometric features. For example, we can manufacture inserts with specific dimensions like width (e.g., 3.92 ± 0.2 mm), cutting edge arc radius (e.g., R 2.2 ± 0.05 mm), center height (e.g., 3.34 ± 0.02 mm), and body thickness (e.g., 2.38 mm), demonstrating our micro-machining precision (Note: these values are illustrative examples of achievable precision based on specific designs, not standard specifications).

- Complex Cutting Edge Profiles: Including highly specific rake angles, clearance angles, facet designs, and edge radii necessary for optimal performance in turning, milling, boring, fly-cutting, grooving, or scribing operations.

- Controlled Crystallographic Orientation: We can orient the diamond crystal structure relative to the cutting edge to maximize wear resistance and edge integrity for specific cutting directions and applications.

Primary Application Areas for SCD Inserts

SCD inserts unlock superior results in industries and processes where ultimate precision and surface quality are non-negotiable:

- Optical Industry: Machining molds and inserts for plastic lenses, light guides, Fresnel lenses, reflectors; direct machining of certain optical crystals or polymers.

- Ultra-Precision Molds & Dies: Creating mirror-finish cavity surfaces for injection molding of high-clarity plastics or forming of reflective components.

- 3C Electronics Manufacturing: Achieving high-gloss, “diamond-cut” aesthetic finishes on metal (e.g., aluminum, magnesium alloys) or plastic casings and components for smartphones, laptops, and consumer electronics.

- Acrylic / Polymer Processing: Generating optically clear, smooth surfaces on PMMA and other plastics for displays, light panels, decorative items, and medical applications.

- Medical Device Industry: Precision machining of non-ferrous metal or polymer components requiring high accuracy, excellent finish, and potentially biocompatibility.

- Jewelry & Watchmaking: Producing high-luster, flawless finishes on precious metals (gold, silver, platinum).

Collaborative Development & Manufacturing

- Your Input is Key: To create the perfect SCD insert, we require your detailed drawings, application specifications (material to be cut, machining operation, desired surface finish Ra / tolerance), and ideally, your intended processing parameters.

- Our Expertise: Our team utilizes this information to craft custom SCD inserts demonstrating excellent quality and precision, precisely tailored to meet your actual processing requirements and machining allowances. These inserts are designed for integration into your specific tool holders or cutting tool bodies (e.g., turning tools, milling cutters, boring bars).

Contact our ultra-precision machining specialists today to discuss your requirements and discover the possibilities with custom Single Crystal Diamond inserts.