-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

PCD Engraving Tools for Tungsten Carbide Roll Rings

Engrave intricate details on hard Tungsten Carbide rolls with our durable PCD tools. Feature thickened tips & vacuum welding for exceptional life and consistent precision. Custom specs available.

Precision PCD Engraving Tools for Tungsten Carbide Roll Rings

Master the challenge of engraving intricate details onto ultra-hard Tungsten Carbide (TC) roll rings with ZYsuperhard’s specialized PCD Engraving Tools. Unlike conventional carbide engraving tools which wear out extremely rapidly when machining highly abrasive Tungsten Carbide, our expertly designed PCD tools deliver the exceptional durability, accuracy, and reliable performance required for creating precise lettering, logos, intricate patterns, and functional textures on TC rolls used in demanding industrial applications.

Engineered for Extreme Durability and Precision Engraving:

- Premium Thickened PCD Tips: We utilize superior raw materials, including options like custom Element Six thickened diamond tips, selected specifically for maximum toughness and wear resistance to withstand the intense conditions of engraving Tungsten Carbide. This ensures significantly extended tool life, even when machining deep or complex high-resolution patterns.

- Advanced Vacuum Welding Technology: The PCD tips are securely and robustly joined to the tool body using a state-of-the-art vacuum welding process. This high-integrity bond enhances overall tool strength, prevents premature tip failure or chipping, and ensures consistent, reliable performance under significant engraving loads.

- Ultra-Fine Grinding for Accuracy: Employing high-precision grinding equipment and processes, each tool is meticulously ground. This critical step ensures consistent dimensional accuracy, precise tip geometry (angles, radius/flat width), and superior cutting edge quality. The result is sharp, clean engraving lines, enhanced tool longevity, and excellent controllability during the CNC machining process.

- Strict Quality Control: Every ZYsuperhard engraving tool undergoes rigorous quality inspection throughout each production stage and prior to shipment, guaranteeing you receive a dependable tool that meets the most exacting standards for performance and precision.

Core Applications on Tungsten Carbide Rolls:

These PCD tools are specifically optimized for high-resolution engraving tasks performed via CNC machining on hard Tungsten Carbide roll rings, including:

- Lettering and Numbering: Creating clear, crisp, and durable identification marks, serial numbers, or branding directly onto the roll surface.

- Intricate Pattern & Texture Engraving: Producing complex decorative patterns, functional textures (e.g., for material grip or specific forming properties), or detailed graphical elements.

- Logo Engraving: Accurately reproducing company logos or other symbols with high fidelity.

- Fine Line Work & Detailing: Achieving sharp, precisely defined lines essential for detailed artwork or technical markings.

Performance & Advantages Summary:

- Exceptional Tool Life: Dramatically outperforms carbide tools when engraving TC materials.

- High Precision & Consistency: Maintains accurate profile and depth, ensuring repeatable results.

- Superior Engraved Finish: Produces clean, sharp, well-defined details without burrs.

- Reliable & Stable Machining: Reduces the risk of tool breakage and ensures a secure, predictable engraving process.

Specifications & Customization:

We offer standard specifications (such as the examples 10*50*0.6*70°, 8*50*0.5*70°, 6*50*0.4*70°) and specialize in custom-made PCD engraving tools. Based on your specific engraving pattern details, required depth, roll material characteristics, and CNC machine capabilities, we can tailor the crucial tip geometry (angle, tip radius/flat width, thickness), shank dimensions, and select the optimal PCD grade to create the perfect solution for your task. We pride ourselves on providing complete specification options and ensuring faster delivery times from our factory source.

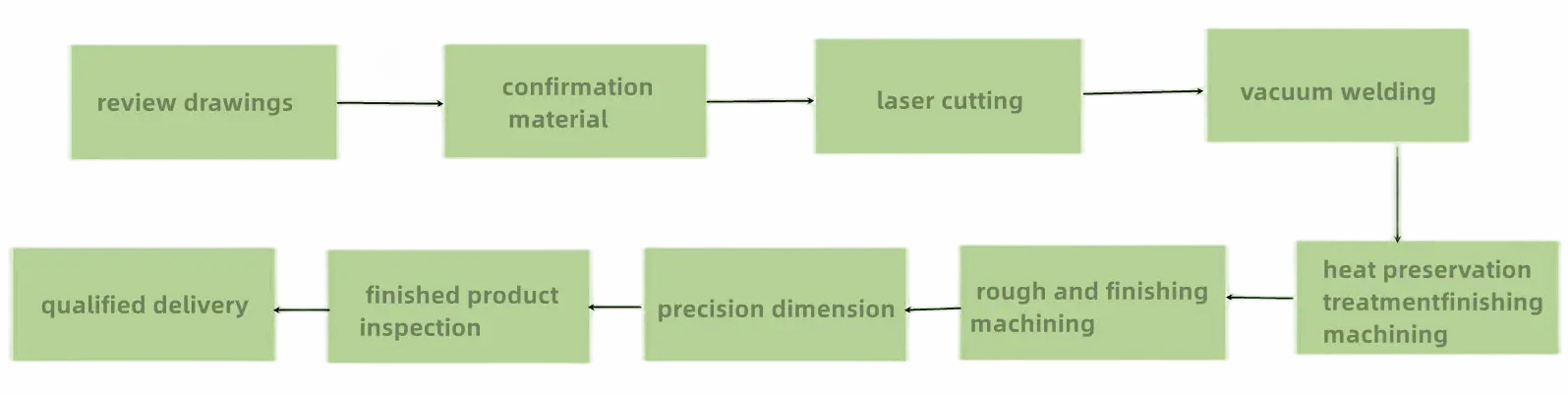

Processing Flow:

Processing Effect:

Factory Display:

Contact ZYsuperhard today to discuss your challenging Tungsten Carbide roll engraving applications and let our experts design the ideal high-performance PCD engraving tool tailored precisely to your needs.