-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

PCD Drilling Tools for Aluminum, Composites & Non-Ferrous Metals

Achieve unparalleled tool life and perfect hole quality. Our PCD drills are engineered for high-speed drilling in aluminum, composites, and more. Drastically increase productivity and lower your cost-per-hole.

Revolutionize Your Drilling Operations with Ultimate Performance and Longevity

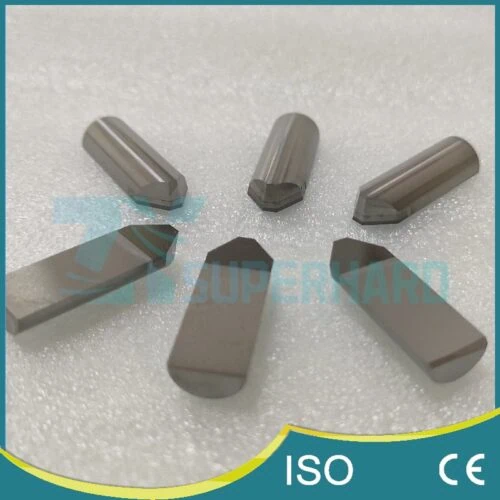

Welcome to our premier line of PCD (Polycrystalline Diamond) drills—the ultimate solution for achieving the highest efficiency and precision in modern hole-making. By brazing industrial-grade diamond tips onto a solid drill body, PCD drills offer a quantum leap in lifespan, speed, and hole quality compared to traditional carbide drills.

Why Choose Our PCD Drills?

- 1. Extreme Durability & Tool Life

Our PCD drills last 50 to 250 times longer than conventional coated drills. This means fewer tool changes, less machine downtime, more consistent production, and significantly reduced overall tooling costs. - 2. Unmatched Drilling Speed

The superior properties of PCD allow for extremely high rotational speeds and feed rates. You can complete more drilling cycles in less time, maximizing your throughput and easily handling high-volume production demands. - 3. Superior Hole Quality

PCD drills produce an excellent hole wall finish and significantly reduce exit burrs. When drilling composites like carbon fiber (CFRP), they minimize delamination and fiber pull-out, ensuring every hole is clean and damage-free. - 4. Consistent, High-Precision Performance

Due to the exceptionally low wear rate of PCD, the drill’s diameter and geometry remain stable even after thousands of holes. This ensures outstanding hole-to-hole consistency and maintains strict dimensional tolerances throughout the entire production run. - 5. Ultimate Cost-Per-Hole Effectiveness

While the initial investment for a PCD drill is higher, its incredible lifespan and efficiency drive your “cost-per-hole” to an absolute minimum. It is the smartest long-term investment for any operation focused on efficiency and cost control.

Primary Applications

Our PCD drills are engineered for the precision drilling of the following demanding materials:

- Non-Ferrous Metals: Aerospace Aluminum, Aluminum Alloys, Copper, Brass, Magnesium Alloys, etc.

- Composites: Precision drilling of Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP), especially for stacked material drilling in the aerospace industry.

- Wood Products: High-abrasion materials like High-Density/Medium-Density Fiberboard (HDF/MDF) and Particle Board.

- Other Materials: Green Ceramics, High-Silicon Aluminum, Engineering Plastics, etc.

Product Specifications

We offer a wide range of standard PCD drill specifications and provide expert customization services to meet your unique requirements.

Standard Specification Examples:

| Model | Drill Diameter D (mm) | Flute Length H (mm) | Overall Length L (mm) |

|---|---|---|---|

| PCD-DR-0200 | 2.0 | 29 | 55 |

| PCD-DR-0400 | 4.0 | 54 | 83 |

| PCD-DR-0600 | 6.0 | 70 | 102 |

| PCD-DR-0800 | 8.0 | 81 | 114 |

| PCD-DR-1200 | 12.0 | 111 | 149 |

⭐ Expert Customization Service ⭐

Our key strength is custom, made-to-order solutions. Whether you need special step drills, countersinks, or specific diameters, lengths, point angles, or coatings, we can manufacture the perfect drill to match your application precisely.

Our Commitment to Quality

All our PCD drills are manufactured using premium-grade PCD blanks from world-leading suppliers and crafted with state-of-the-art precision grinding equipment. Every drill undergoes rigorous quality control inspections to guarantee superior performance and reliability. Choose us for a trusted partner capable of solving your most difficult drilling challenges.