-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

PCBN Mechanically-clamped Turning Tool For Brake Disc

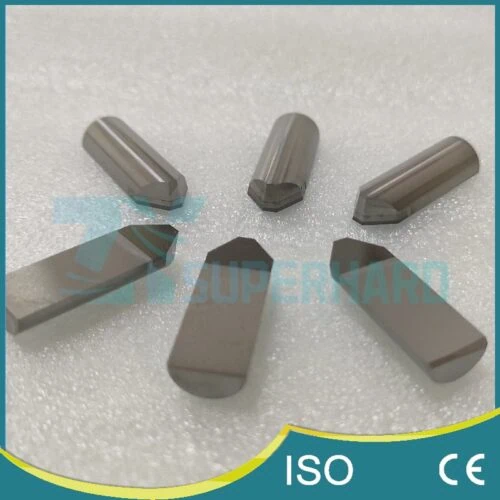

High-performance PCBN turning tools for brake disc machining (cast iron). Mechanically-clamped design with wear-resistant, edge-prepped blades ensures long life, stability, and cost-effective roughing/finishing.

PCBN Mechanically-Clamped Turning Tools for Brake Disc Machining

Elevate the efficiency, quality, and cost-effectiveness of your brake disc manufacturing with these robust PCBN Mechanically-Clamped Turning Tools. Engineered specifically to overcome the challenges inherent in machining abrasive cast iron brake discs, this tooling system combines the extreme hardness of Polycrystalline Cubic Boron Nitride (PCBN) with a rigid, user-friendly design, delivering exceptional performance in both roughing and finishing operations.

The PCBN Advantage in Turning Cast Iron Brake Discs

Brake discs demand tooling capable of handling high wear and generating fine finishes. PCBN is the material of choice for this demanding application:

- Exceptional Hot Hardness & Wear Resistance: PCBN retains its cutting edge integrity even at the high temperatures generated during high-speed cast iron turning, drastically outperforming traditional carbide inserts in terms of tool life and material removal rates.

- Chemical Inertness: PCBN exhibits excellent chemical stability when machining ferrous materials like cast iron, preventing diffusion wear and built-up edge, which helps maintain consistent surface finish and dimensional accuracy.

- Superior Surface Quality Capability: Allows for fine finishing passes that achieve the stringent surface roughness (Ra) and flatness tolerances required for optimal brake performance and noise reduction.

Engineered for Performance, Durability, and Economy

This tooling solution is designed for maximum value and reliability in production environments:

- Cost-Effective Mechanically-Clamped System: This design utilizes replaceable PCBN inserts (blades) secured in a durable tool holder. When an edge wears out, only the insert needs to be indexed or replaced, not the entire tool. This significantly reduces tooling costs, lowers inventory requirements, and allows for quick tool changes directly on the machine.

- High-Rigidity Tool Holder (Tool Bar): Precision machined from high-quality tool steel and subjected to vacuum heat treatment, the tool holder boasts exceptional hardness and rigidity. This provides unwavering support for the PCBN insert, minimizing vibration and ensuring dimensional accuracy and surface quality even under heavy cutting loads.

- Advanced PCBN Insert Technology: We utilize high-grade, highly wear-resistant PCBN composite materials for the inserts. State-of-the-art grinding technology guarantees high dimensional accuracy and consistency from insert to insert.

- Optimized Edge Preparation for Cast Iron: Crucially, for maximizing performance on abrasive brake disc materials, the PCBN cutting edges undergo a specialized chamfering and passivation treatment (edge preparation). This precisely controlled edge geometry significantly enhances the toughness of the cutting edge, prevents micro-chipping, dramatically extends usable tool life, and contributes to achieving superior surface finishes.

Key Benefits for Brake Disc Production Lines

- Increased Productivity: Achieve higher cutting speeds and benefit from significantly longer periods between tool changes, boosting machine uptime and throughput.

- Improved Cost-Efficiency: Realize lower overall tooling cost per brake disc due to the vastly extended life of the specially prepared PCBN inserts and the reusability of the tool holders.

- Consistent High Quality: Reliably meet demanding specifications for dimensional accuracy, flatness, and surface roughness on finished brake discs.

- Versatile Application: Effectively handles both rough machining operations (removing casting skin and bulk material) and precision finishing passes.

Primary Application: Automotive Brake Disc Turning

These tools are specifically developed and optimized for the complete turning process of automotive brake discs, from roughing to finishing stages.

Configuration Options

While tool holder styles often align with machine turret interfaces, key options typically revolve around the PCBN insert itself:

- PCBN Grade Selection: Different PCBN grades are available, optimized for various types of cast iron (e.g., grey cast iron, ductile iron) or specific cutting conditions (continuous vs. interrupted cuts).

- Insert Geometry: Standard ISO insert shapes and sizes are common, but custom geometries may be possible.

- Edge Preparation: Variations in the chamfer size/angle or hone radius can be specified depending on the balance required between edge strength and sharpness.

Contact our technical specialists to identify the optimal PCBN grade, insert geometry, and tool holder combination for your specific brake disc material and machining setup.