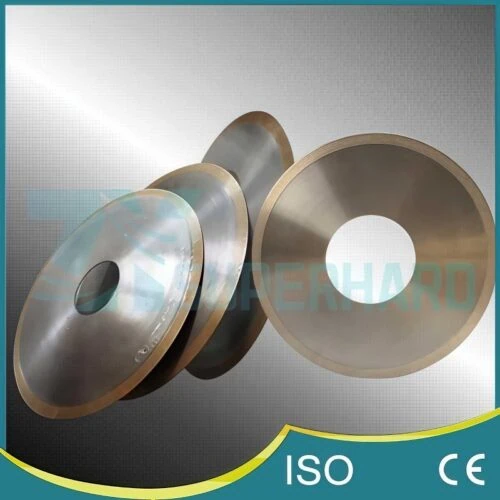

Bronze Sintered Metal Bond Grinding Wheels (Diamond or CBN)

Achieve exceptional longevity and consistent performance when grinding hard and brittle materials with these robust Bronze Sintered Metal Bond Grinding Wheels from ZYsuperhard. Available with either high-performance Diamond or Cubic Boron Nitride (CBN) abrasives, these wheels provide durable, tailored solutions capable of tackling a wide range of demanding grinding applications across numerous industries.

The Advantage of Sintered Bronze Metal Bond

Manufactured through a specialized high-temperature sintering process, the bronze-based metal bond matrix forms the backbone of these wheels, delivering critical characteristics for heavy-duty grinding:

- Superior Wear Resistance & Durability: Compared to resin or vitrified bonds, metal bonds offer outstanding resistance to wear, erosion, and breakdown. This translates directly to significantly longer wheel life, especially beneficial when grinding highly abrasive materials or under high material removal rate conditions.

- Strong Abrasive Holding Force: The rigid metal matrix provides extremely strong mechanical retention for the embedded diamond or CBN grit, preventing premature abrasive pull-out and ensuring sustained, effective cutting action throughout the wheel’s extended lifespan.

- Excellent Form Holding & Profile Stability: Metal bond wheels resist deformation and wear exceptionally well, maintaining their geometric profile integrity for longer periods. This is crucial for precision form grinding and maintaining part accuracy over time.

Abrasive Selection for Target Materials

ZYsuperhard offers these wheels with the optimal superabrasive for your specific material:

- Option 1: Diamond Abrasive Wheels

- Best For: Non-ferrous and Non-metallic Hard Materials.

- Typical Applications: Effectively grinding cemented carbide (tungsten carbide) for tool manufacturing or sharpening, technical ceramics, optical glass, quartz, ferrite, semiconductor materials, natural stone, graphite, composites, and other hard, brittle materials where diamond’s hardness provides superior cutting efficiency. Also used for electrolytic grinding of carbide.

- Option 2: CBN (Cubic Boron Nitride) Abrasive Wheels

- Best For: Hardened Ferrous Metals (Steels & Cast Irons).

- Typical Applications: Efficiently grinding hardened tool steels, die steels, high-speed steels (HSS), bearing steels (typically > HRC 50), stainless steels, cast irons (grey, chilled), and some superalloys.

- Key CBN Benefit: Unlike diamond which reacts chemically with iron at high temperatures, CBN maintains its chemical stability when grinding ferrous materials, preventing excessive wheel wear and ensuring efficient, cool grinding performance.

Fully Customizable Specifications

We provide these high-performance bronze sintered wheels manufactured precisely to your grinding operation’s requirements:

- Abrasive Type: Choice of Diamond or CBN.

- Grit Size: Fully customizable across a wide spectrum, from coarse grits (e.g., 40#, 60# for roughing/high removal) to very fine grits (for finishing), tailored to your specific material and surface finish requirements. Please specify the grit size needed.

- Abrasive Concentration: Adjusted based on application demands (e.g., higher concentration for faster removal, lower for finer finish).

- Wheel Shape & Dimensions: Manufactured according to your drawings or standard specifications. This includes Diameter (D), Thickness (T), Hole Size (H), and a vast array of standard and custom profiles (e.g., Type 1A1 straight wheels, cup shapes like 6A2, dish shapes, custom forms) suitable for surface grinding, cylindrical (OD/ID) grinding, tool and cutter grinding, profile grinding, etc.

Key Performance Summary

- Extreme Durability & Longevity: Maximizes wheel life, reducing tooling costs and changeover frequency.

- Efficient Grinding Action: Optimized abrasive selection (Diamond or CBN) ensures effective material removal on specific hard materials.

- High Material Removal Potential: Capable of aggressive stock removal, especially with appropriate coarse grit selection.

- Reliable & Consistent Performance: Strong bond and grit retention lead to predictable grinding results.

Contact our grinding application experts today. Provide your material details, grinding operation parameters, and required wheel specifications (or drawings) to receive a detailed recommendation for the optimal bronze sintered Diamond or CBN grinding wheel solution.