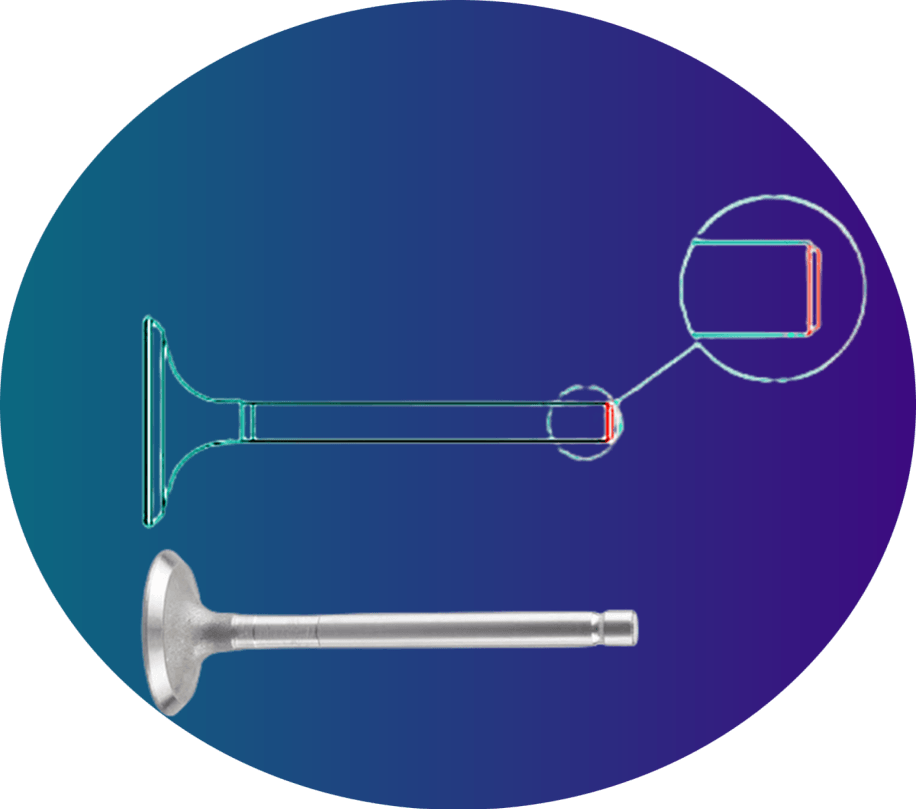

Ultra-Durable Metal Bond CBN Blades for High-Volume Engine Valve Cutting

Maximize productivity and significantly reduce tooling costs in your engine valve manufacturing process with ZYsuperhard’s specialized Metal Bond CBN Cutting Blades. Engineered specifically for the high-volume, precision cut-to-length operations on hardened steel engine valve stems, these blades deliver exceptional durability, consistent cutting accuracy, and a remarkably long service life, making them the premier choice for demanding automotive production lines and engine manufacturing facilities.

Why Metal Bond CBN Excels for Cutting Hardened Steel Engine Valves:

- CBN – The Superior Abrasive for Hardened Steel: Cubic Boron Nitride (CBN) possesses the optimal combination of high hardness and crucial thermal/chemical stability needed to efficiently and cleanly cut the hardened steels (martensitic, austenitic, specialty alloys) typically used for engine valves. It maintains cutting edge integrity even under the high temperatures generated during demanding cutting processes.

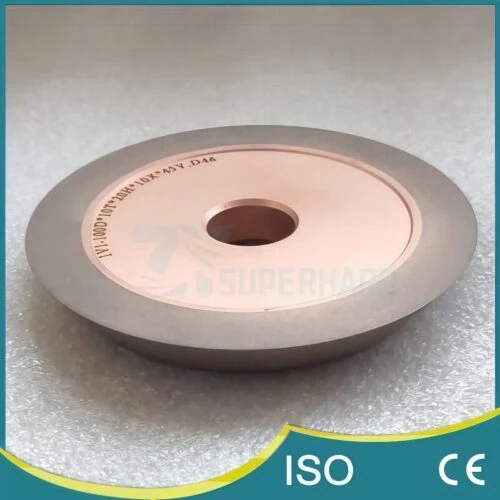

- Extreme Durability Metal Bond: Our robust metal bond system is formulated for maximum wear resistance and securely anchors the premium CBN abrasive particles. This ensures exceptional blade longevity, resisting the abrasive wear from hardened valve steels and maintaining performance stability throughout extended production runs.

- Precision Cutting Edge for Quality Cuts: The synergy between the CBN abrasive and the rigid metal bond allows for a durable yet precise cutting edge. This is critical for achieving clean cuts with minimal burrs, accurate length control (perpendicularity and tolerance), often reducing or eliminating the need for secondary deburring or finishing operations on the valve stem end.

- Optimized for Production Efficiency: Designed for high stability and reliability on automated or semi-automated cutting machines commonly found in high-volume valve manufacturing, contributing to smooth operations and minimal interruptions. (Note: Wet cutting with appropriate coolant is generally recommended for optimal performance and blade life).

Key Features:

- High-Quality CBN Abrasive: Utilizes premium CBN abrasive grades specifically selected for optimal performance and life when cutting hardened valve steels.

- Robust Metal Bond Formulation: Engineered for extreme wear resistance, superior abrasive retention, and consistent cutting performance in high-volume scenarios.

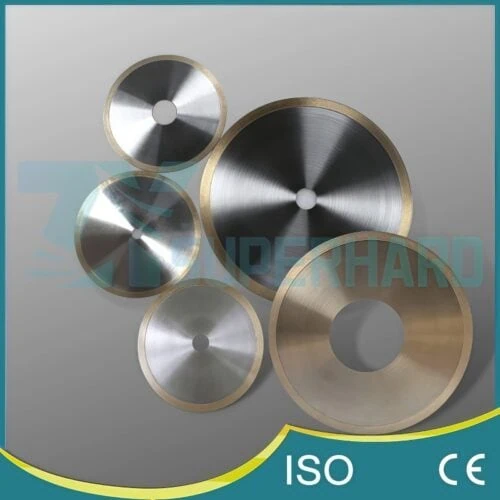

- Precision Manufacturing: Blades are manufactured to tight tolerances for flatness, runout, and balance, essential for high-speed, high-accuracy cutting operations.

- Customizable Specifications: Fully tailored to your exact operational requirements.

Core Application: Engine Valve Cut-to-Length in Manufacturing:

The primary and specialized application for these blades is the precision cutting of hardened steel engine valve stems to their final required length during the valve manufacturing process. They are designed to integrate seamlessly into automated production lines, delivering consistent cut quality and unparalleled tool life day after day.

Exceptional Service Life – Up to 300,000 Cuts:

Through meticulous material selection, optimized bond technology, and precision manufacturing, each ZYsuperhard Metal Bond CBN cutting blade is engineered for extraordinary endurance. Under stable and optimized production conditions (including proper machine setup, coolant application, and material consistency), these blades are capable of achieving approximately 300,000 cuts or potentially more before requiring replacement. This dramatically reduces costly machine downtime for blade changes and significantly lowers the overall tooling cost per valve produced.

Customization:

We provide fully customized Metal Bond CBN cutting blades based on your specific needs. Please provide details such as:

- Required Dimensions: Outer Diameter (e.g., 250mm), Blade Thickness (e.g., 1.5mm), Hole Size / Bore Configuration (e.g., 90mm), including any specific keyways or mounting features.

- Engine Valve Material: Specific grade(s) of hardened steel being cut.

- Machine & Cutting Parameters: Details of the cutting machine, spindle speed, feed rate, coolant type and application method.

- We accept manufacturing based on customer drawings and detailed specifications.

Choose ZYsuperhard Metal Bond CBN blades for unmatched durability, unwavering precision, and significant cost-efficiency in your critical engine valve cutting operations. Contact us to discuss how our cutting solutions can optimize your automotive production process.