-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

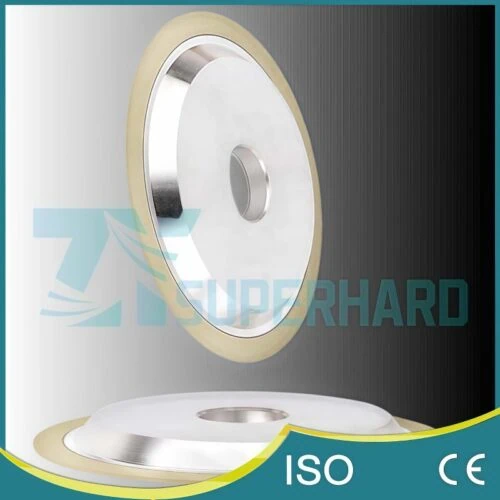

Electroplated diamond grinding wheel

High-efficiency diamond wheels optimized for forming and grinding tungsten carbide tools. Experience sharp, fast cutting with excellent profile retention. Durable, custom solutions provided.

Precision Electroplated Diamond Wheels for Forming & Grinding Hard Materials

Unlock high-efficiency grinding and precise profile generation on Tungsten Carbide tools and other hard materials with ZYsuperhard’s Electroplated Diamond Grinding Wheels. Engineered for applications where intricate shapes, sharp cutting action, and excellent form holding are paramount, these wheels offer aggressive material removal and are particularly well-suited for tool manufacturing, mold making, and specialized profile grinding tasks.

The Electroplated Bond Advantage:

Our advanced electroplating process securely bonds a single, dense layer of high-quality diamond abrasive onto a precision-machined wheel core (typically steel). This unique single-layer structure delivers distinct benefits:

- Maximum Diamond Exposure & Aggressive Cutting: Results in an exceptionally free-cutting grinding action with high material removal rates due to the highly exposed diamond particles. Ideal for efficient shaping and stock removal.

- Excellent Initial Form Holding: The abrasive layer precisely replicates the contour of the pre-shaped core. This ensures outstanding initial profile accuracy and fidelity, which is critical when grinding forming tools, intricate profiles, or features requiring sharp corners and defined edges.

- Cost-Effective Complex Profiles: Electroplating allows for the creation of highly complex custom wheel profiles relatively easily and cost-effectively compared to other bond systems that might require complex molding or CNC dressing processes for similar shapes.

- Sharp & Cool Cutting: The exposed diamond particles provide continuous sharp cutting edges, minimizing grinding forces and heat generation, which is beneficial for processing hard and brittle materials like Tungsten Carbide and ceramics.

Key Features:

- High-Quality Diamond Selection: Utilizes carefully selected and graded diamond material optimized for cutting performance and durability within the single abrasive layer when working on specific hard materials.

- Precision Plating & Core: Employs advanced electroplating techniques for uniform diamond distribution and strong particle adhesion, bonded to dimensionally accurate and stable steel cores (or other materials as required) for smooth, precise operation.

- Wide Grit Range: Available in various grit sizes, from coarse (e.g., 60#) for rapid forming and stock removal to finer (e.g., 800#) for achieving better surface finishes, catering to diverse operational needs.

Core Applications:

While versatile, these wheels are primarily designed for the challenging tasks involving Tungsten Carbide tools and other hard materials:

- Tool Manufacturing & Regrinding: Creating or sharpening complex geometries on carbide cutting tool inserts (like chipbreakers or special edge forms), solid carbide end mills/drills (fluting, gashing), forming special profile cutters, and other tool-making operations requiring precise profile generation.

- Mold & Die Components: Grinding intricate details, profiles, forms, or cavities in components made from Tungsten Carbide or hardened tool steels where diamond provides superior performance.

- Hard Material Forming: Profile grinding technical ceramics, glass, quartz, or other hard, brittle materials where maintaining a precise shape is crucial during the grinding process.

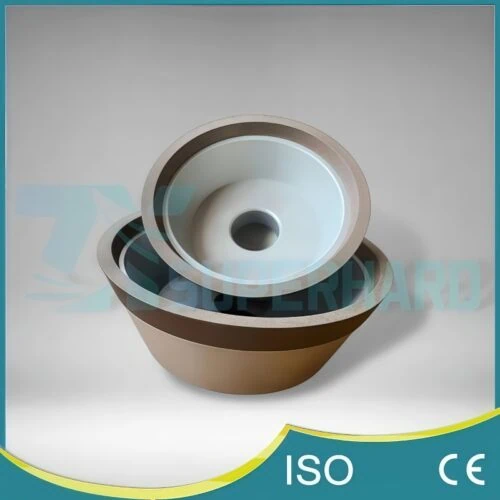

Specifications & Customization:

Standard specifications often include common diameters (e.g., D 100mm – 200mm), thicknesses (e.g., T 10mm), bore sizes (e.g., H 20/32mm), and abrasive layer widths (e.g., X 10mm). However, the true strength lies in customization. ZYsuperhard can manufacture electroplated diamond wheels to virtually any profile or dimension required, based on your detailed drawings or specific application needs, delivering a tailored solution for your unique forming and grinding challenges.

Important Considerations: As a single-layer abrasive system, electroplated wheels offer exceptional initial profile accuracy and cutting performance but have a finite lifespan determined by the wear of this single diamond layer. They are generally not dressable and are replaced once the abrasive layer is consumed.

Choose ZYsuperhard Electroplated Diamond Wheels when you need aggressive cutting, precise complex profiles, and cost-effective custom shapes for grinding Tungsten Carbide tools and other difficult-to-machine hard materials. Contact us to discuss your specific forming or grinding application.