-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

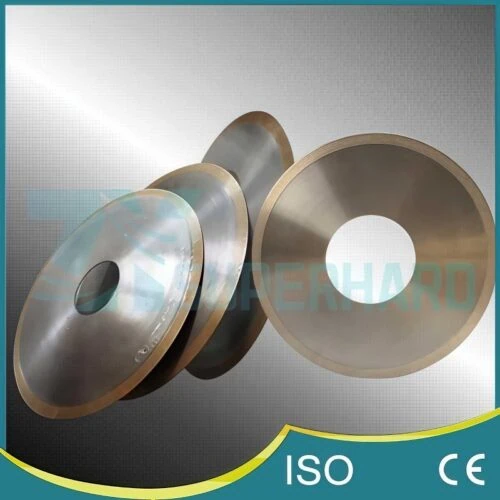

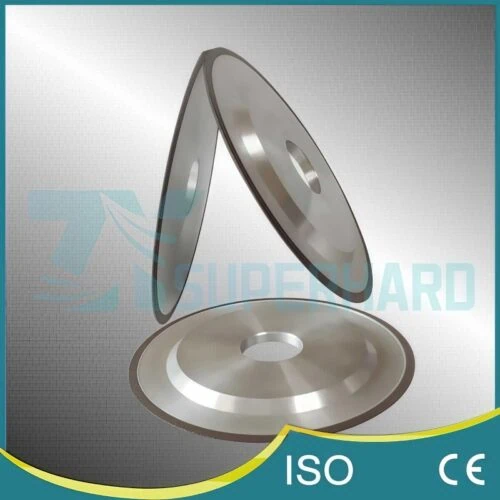

Diamond Cutting Disc For Optical Glass

Cut optical glass with high precision using diamond discs. Available in metal/resin bonds offering sharpness, ultra-thin kerfs, and durability comparable to imports. Custom sizes/grits available.

Diamond Cutting Discs for Precision Optical Glass Processing

Achieve superior precision, minimal waste, and exceptional edge quality when cutting valuable optical glass components with these specialized Diamond Cutting Discs. Engineered specifically for the demanding requirements of the optics industry – processing materials for camera lenses, microscopes, telescopes, eyewear, and more – they provide clean, efficient cutting performance. Choose between advanced metal bond and versatile resin bond systems to perfectly match your application needs.

Mastering the Challenges of Cutting Optical Glass

Optical glass presents unique cutting challenges due to its brittle nature, stringent surface finish requirements, and high material value. Our diamond discs are meticulously designed to address these issues:

- Minimize Chipping & Cracking: Employing high-quality, precisely graded diamond particles ensures sharp, efficient cutting action that significantly reduces mechanical stress and thermal damage, preserving the integrity of the delicate glass material.

- Ensure High Precision & Minimal Waste: These discs create exceptionally narrow, precise cuts (kerfs or “slits”), minimizing valuable material loss and enabling the accurate dimensioning essential for optical components.

Choosing Your Bond: Metal vs. Resin for Optimal Results

The choice of bond system is critical for optimizing performance based on your specific optical glass type, cutting parameters, and desired finish quality:

- Metal Bond Discs: Engineered for maximum durability and wear resistance, delivering the longest possible operational life. Metal bonds allow for the construction of ultra-thin discs (down to 0.3mm thickness), ideal for minimizing kerf loss. They typically utilize diamond grit sizes ranging from 60 to 600, making them well-suited for general-purpose high-efficiency cutting and processing harder types of optical glass.

- Resin Bond Discs: Offer a softer, more free-cutting action, which often results in superior surface finishes and minimized edge chipping, particularly beneficial for more sensitive or brittle glass materials. Resin bonds can incorporate a much wider range of finer diamond grits (from 80 up to 2000), enabling the achievement of demanding, near-polish-ready surfaces directly from the cutting step. Their typical thickness starts from 0.5mm.

Key Performance Advantages

Optimized specifically for optical glass, these diamond discs consistently deliver the performance needed for high-quality results:

- High Sharpness: Enables fast, efficient cutting operations while requiring lower processing forces, minimizing mechanical stress on delicate glass materials.

- Minimal Kerf Width: Achieves ultra-thin, precise cuts (“slits”), maximizing the yield from valuable optical glass blanks and enabling the production of intricate components.

- Extended Durability: Offers substantial operational life within the selected bond system category (metal or resin), contributing to cost-effective production cycles and reduced tooling costs.

- Excellent Edge Quality: Produces clean, smooth cut surfaces with minimal chipping or subsurface damage, meeting the stringent quality control standards demanded by the optical industry.

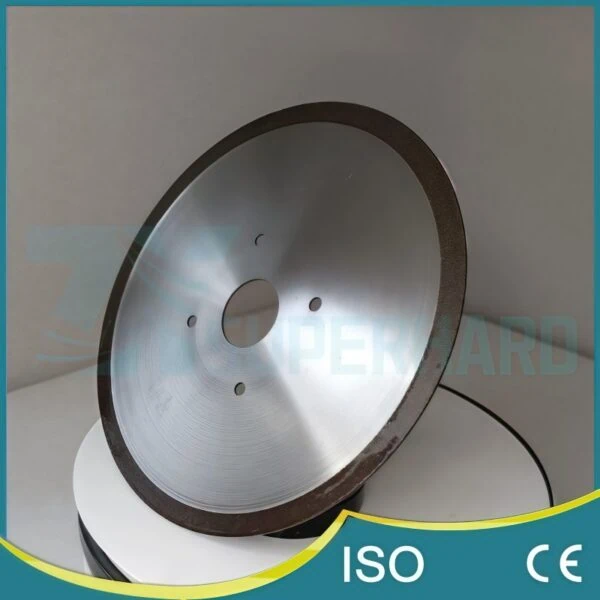

Comprehensive Specifications and Customization

We provide discs manufactured to your exact requirements:

- Standard Parameter Ranges:

- Diameter (D): 60mm – 400mm (Both Bond Types)

- Bore/Hole (H): 12.7mm – 127mm (Both Bond Types)

- Thickness (T): Metal Bond: 0.3mm – 3.0mm; Resin Bond: 0.5mm – 2.0mm

- Grit Size (#): Metal Bond: 60 – 600; Resin Bond: 80 – 2000

- Full Customization: Beyond these extensive standard ranges, we specialize in full customization. This includes non-standard dimensions (D, T, H), specific diamond grit sizes or concentrations within the available ranges, variations in bond formulation for unique materials, and specific geometric features.

Consult with our optical cutting application specialists to identify or design the ideal diamond disc specification to optimize your process and results.