-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

DFT DFS PCD Drill For Wind Turbine Blade Of Wind-powered Electricity Generation

Custom DFT/DFS PCD drill inserts for precision drilling of GFRP wind turbine blade roots. Indexable PCD (e.g., DFT05T308) ensures extreme abrasion resistance & long life. High efficiency for wind power.

High-Performance Indexable PCD Drill System (DFT/DFS Series) for Wind Turbine Blade Root Drilling

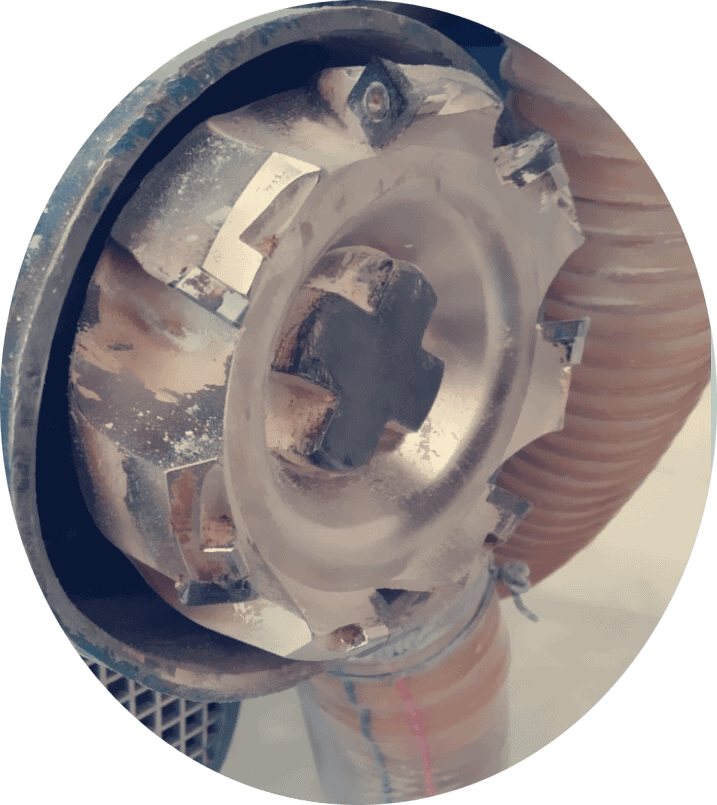

Maximize drilling efficiency and ensure exceptional hole quality in demanding Glass Fiber Reinforced Polymer (GFRP) composites with ZYsuperhard’s specialized Indexable PCD Drilling System (DFT/DFS Series). Manufacturing wind turbine blades requires drilling numerous high-precision bolt holes in the highly abrasive GFRP root section. This task rapidly wears conventional carbide drills, but our system, combining robust indexable drill bodies with long-lasting PCD inserts (DFT type), is engineered as the premium solution for the Wind Power industry, delivering extended tool life, superior hole integrity, and high productivity.

Why PCD Inserts Excel in GFRP Blade Root Drilling:

- Extreme Abrasion Resistance: Polycrystalline Diamond (PCD) offers unparalleled hardness to withstand the intense abrasive wear from GFRP’s glass fibers, resulting in insert life potentially dozens or hundreds of times longer than carbide, drastically reducing tool changes and cost per hole.

- Clean Cutting for Composite Integrity: Sharp, precision-ground PCD edges cleanly shear the resin and fibers, minimizing delamination, fiber pull-out, and heat damage, ensuring high-quality holes meeting strict structural integrity requirements.

- Consistent Performance: The exceptional durability ensures stable cutting and dimensional accuracy over extended use, vital for the many critical holes in blade roots.

Key Features of the ZY Indexable Drilling System (DFT/DFS Series):

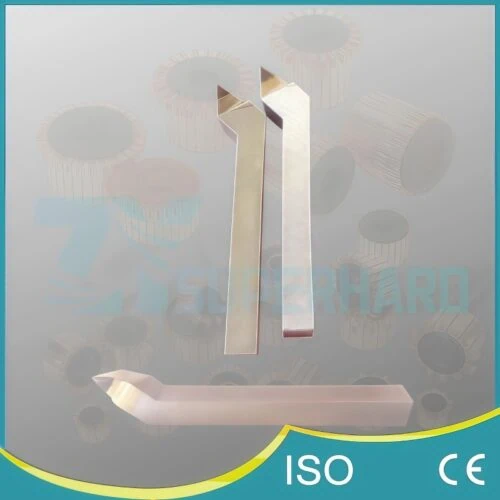

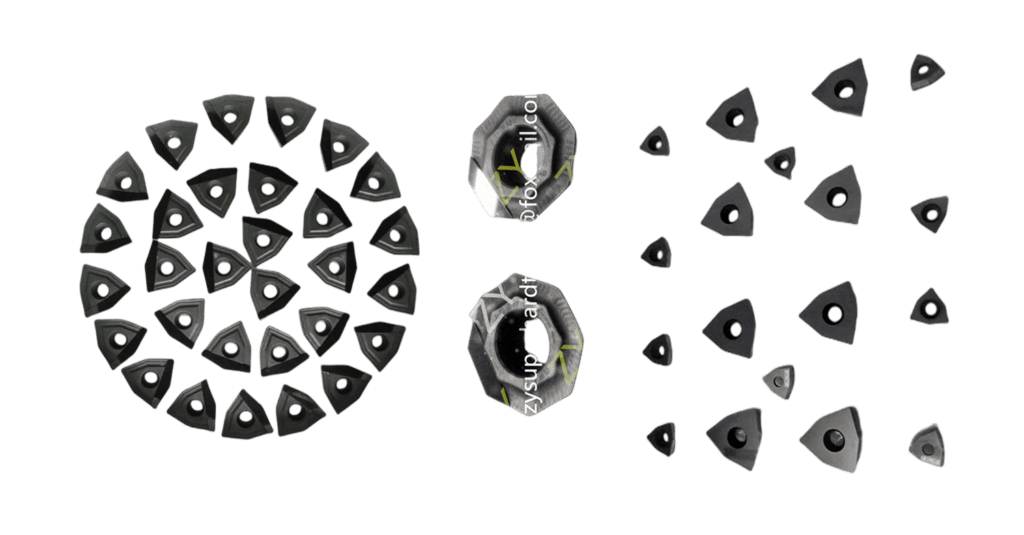

- Durable PCD Inserts (DFT Type): This system utilizes robust, indexable inserts featuring high-quality PCD cutting edges brazed onto a carbide substrate. The specific geometry (shown below), designated within our DFT series for this application, provides a strong and reliable cutting edge configuration proven effective for drilling abrasive GFRP. Premium PCD grades ensure consistent performance and excellent wear resistance.

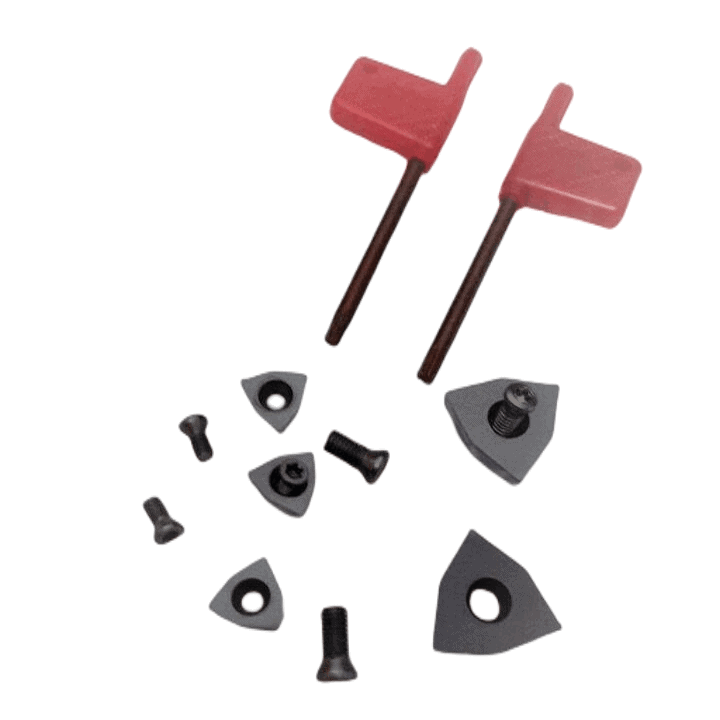

- Indexable Insert Design: Allows for fast and straightforward replacement of worn cutting edges using compatible industry-standard indexable drill bodies (often compatible with holders designed for WCMT or similar ISO standard inserts). This reduces the need to replace entire drill bodies, saving costs and inventory.

- Precision Engineered Drill Bodies/Holders: The system includes high-rigidity tool holders (e.g., Dia 38mm and Dia 70mm standard offerings) designed for stability and accuracy. Key holder features often include:

- Internal Coolant Channels: Delivering coolant directly through the tool body to the cutting edge.

- Nickel-Plated Surface: Provides enhanced durability and corrosion resistance.

- Manufactured to tight tolerances (e.g., ±0.2mm on holder diameter).

- Secure Insert Mounting: Employs high-quality specialized screws for reliable and precise insert seating.

Core Application: Wind Turbine Blade Root Drilling:

Specifically optimized for drilling high-precision bolt holes (axial and radial) in the thick, abrasive GFRP composite roots of wind turbine blades. This system ensures:

- High-Quality Holes meeting strict tolerances (diameter, cylindricity, location) and free from defects.

- Maximum Drilling Efficiency combining long life and optimized parameters.

- Process Reliability essential for large component manufacturing. (Process reliability allows for potentially processing numerous blade holes per insert edge under optimized conditions).

Available System Components & Customization:

- Drill Holders: Standard diameters like 38mm and 70mm readily available, other sizes or configurations can be customized based on drawings.

- PCD Inserts (DFT Series): We offer standard models of our DFT inserts suitable for this system, corresponding to common application sizes. These sizes often align with standard ISO size classes (e.g., corresponding to WCMT06T3 and WCMT0905 size classes).

- DFS Geometries & Full Customization: DFS insert, along with other non-standard configurations or specific customer requirements, are readily available as custom-manufactured solutions. Provide drawings or detailed specs for tailored tools.

- Accessories: High-quality screws and screwdrivers, specifically matched to our inserts and holders, are available.

- Our experienced engineering team assists with standard selections or fully custom designs.

Related Wind Blade Processing Solutions:

ZYsuperhard also offers tooling for other blade processing steps, including PCD Face Milling Inserts (e.g., SEHT/SPMT types), Diamond Coated tools, and Electroplated Diamond Saw Blades. Please inquire or visit relevant product pages for details.

Choose ZYsuperhard’s Indexable PCD Drilling System (DFT/DFS Series) for unparalleled tool life, exceptional hole quality, and optimized productivity in your critical wind turbine blade root drilling operations. Contact us to discuss your specific GFRP drilling application.