-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

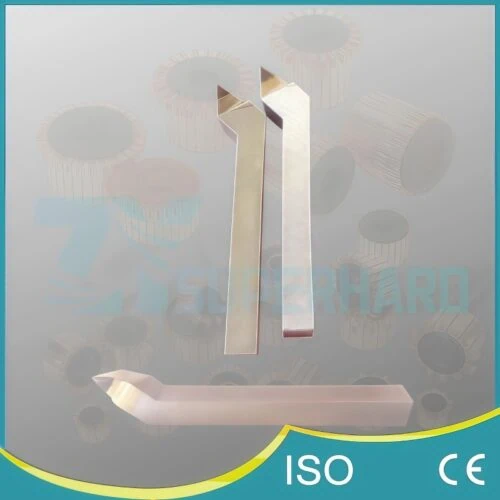

CNC PCD Tools MGMN MRMN Grooving Inserts

High-performance PCD inserts (MGMN/MRMN) for external grooving and parting. Excel on non-ferrous metals and composites at high speeds (to 3000m/min), offering precision and durability. Widths 1.5-4mm.

PCD Grooving & Parting Inserts (MGMN / MRMN Type)

Achieve exceptional efficiency and precision in external grooving and parting operations with these specialized Polycrystalline Diamond (PCD) indexable inserts from ZYsuperhard. Designed to conform to industry-standard MGMN and MRMN geometries, these high-performance inserts deliver extended tool life, superior surface quality, and enable significantly higher cutting speeds when machining a wide range of non-ferrous metals and non-metallic materials.

The PCD Advantage in Grooving and Parting

Utilizing PCD cutting edges for grooving and parting applications on compatible materials offers distinct benefits over traditional carbide or HSS tooling:

- Superior Wear Resistance: PCD’s extreme hardness leads to dramatically longer tool life, especially crucial in abrasive materials like high-silicon aluminum alloys or composites. This reduces the frequency of insert changes and lowers overall tooling costs.

- Low Friction & Anti-Adhesion: The inherent properties of PCD prevent material build-up (adhesion) on the cutting edge, ensuring cleaner cuts, better surface finish within the groove, and more consistent performance throughout the insert’s life.

- High-Speed Machining Capability: PCD allows for significantly higher surface speeds (Vc potentially reaching 1000-3000 m/min depending on the material, see parameter table below), maximizing machine throughput and productivity.

Features of ZYsuperhard’s MGMN/MRMN PCD Inserts

These inserts combine industry-standard designs with high-performance materials:

- Standardized Geometry: Manufactured according to MGMN (neutral cut) and MRMN (potentially right-hand specific) series specifications, ensuring compatibility with a wide range of standard external grooving and parting tool holders available on the market.

- Robust Construction: Feature a precisely ground PCD cutting edge securely brazed or sintered onto a rigid carbide substrate. This composite structure provides the exceptional wear resistance of diamond coupled with the necessary toughness and support from the carbide base.

- Precision Ground Edge: The cutting edges are ground to tight tolerances (indicated by ‘G’ for ground periphery and ‘M’ for tolerance class in the standard designation) to ensure accurate groove widths, clean parting, and precise form generation (including corner radii).

- Number of Cutting Edges: Besides the standard single-ended (1-edge) design, we also offer the double-ended (2-edge) configuration, providing 2 usable cutting edges per insert for enhanced economy.

- Available Configurations: Offered in common industry sizes, specified by width and corner radius (for MGMN):

- Series Designation: MGMN (often with R suffix indicating corner radius), MRMN

- Standard Widths (‘x’00 designation): 1.5mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm

- Common Corner Radii for Grooving (for MGMN, e.g., coded as R04 for 0.4mm): R0.2mm, R0.4mm, R0.8mm (Note: Radius affects groove profile and edge strength; other radii may be available upon request)

Application Focus & Material Suitability

These inserts are primarily designed for use in appropriate external tool holders mounted on CNC lathes or turning centers for operations such as:

- External Grooving: Creating precise circumferential grooves of various widths and depths.

- Parting-Off: Efficiently cutting off finished components from bar stock.

- Suitable Materials:

- Aluminum Alloys (Low and High Silicon)

- Copper, Bronze, Brass, Lead Alloys, Zinc Alloys

- Composite Plastics

- Graphite, Carbon Materials, Rubber

Recommended Cutting Parameters

The following table provides general starting recommendations. Optimal parameters depend heavily on specific material composition, machine rigidity, setup, coolant application, and required surface finish.

| Material | Cutting Speed (Vc m/min) | Feed (f mm/rev) | Example Width of Cut (mm) |

|---|---|---|---|

| Aluminium Alloys Si<5% | 500-3000 | 0.02-0.12 | 1.5 |

| Aluminium Alloys Si<12% | 400-1500 | 0.02-0.10 | 1.5 |

| Copper, Bronze, Lead Alloys | 200-1000 | 0.02-0.12 | 1.5 |

| Brass, Magnesium, Zinc Alloys | 200-2000 | 0.02-0.12 | 1.5 |

| Composite Plastics | 1000-2000 | 0.02-0.12 | 1.5 |

| Graphite, Carbon, Rubber | 100-500 | 0.02-0.12 | 1.5 |

Tool Holder Compatibility and Customization

- Tool Holder Requirement: Always use these inserts with high-quality tool holders specifically designed for MGMN/MRMN insert types to ensure proper clamping, support, and cutting performance.

- Customization Potential: While adhering to standard geometries, ZYsuperhard may offer customization options regarding specific PCD grades, edge preparations, or minor dimensional adjustments upon request for large volume applications.

Please contact our technical support team to ensure you select the correct insert geometry (width, corner radius), PCD grade, and compatible tool holder for your specific grooving or parting application.