Our CBN (Cubic Boron Nitride) Oil Honing Stones are the definitive solution for the precision finishing of hardened ferrous materials. Engineered as the second-hardest material after diamond, CBN possesses a critical advantage: exceptional chemical and thermal stability when machining steels and cast irons. Unlike diamond, CBN does not react with iron at high temperatures, making it the superior abrasive for preventing metallurgical damage such as surface burns, micro-cracks, and undesirable changes in hardness.

Key Features & Benefits:

- Unmatched Thermal Stability: CBN’s ability to withstand high temperatures without chemical degradation ensures a cool, clean cutting action. This preserves the integrity of the workpiece surface, resulting in a finish free from thermal damage and with favorable compressive residual stress.

- Superior Performance on Hardened Steels: Specifically designed for materials with a hardness of HRC55 and above, our CBN stones maintain their sharp cutting edges far longer than conventional abrasives, leading to faster cycle times, consistent performance, and reduced tool wear.

- Exceptional Surface Quality and Integrity: Achieve precise dimensional tolerances and low surface roughness (Ra) values consistently. The clean cutting action of CBN produces a superior honed surface, ideal for high-stress, high-performance components where fatigue life is critical.

- Long and Predictable Tool Life: The inherent toughness and thermal stability of CBN translate into a durable, long-lasting honing tool, reducing downtime for tool changes and lowering the overall cost per part.

Applications:

Our CBN honing stones are the first choice for professionals in industries where hardened steel components require ultimate precision:

- Automotive: Honing engine cylinder bores (cast iron/steel), crankshafts, connecting rods, camshaft lobes, and hardened gears.

- Bearing Industry: Precision finishing of inner and outer bearing races made from high-hardness bearing steel.

- Wind Power & Heavy Equipment: Finishing large bores in planetary gears and other critical gearbox components.

- Hydraulics & Pneumatics: Honing hardened steel hydraulic cylinders, spools, and valve bodies.

- Tool, Die & Mold: Fine finishing of dies and molds made from high-alloy tool steels (e.g., D2, M2).

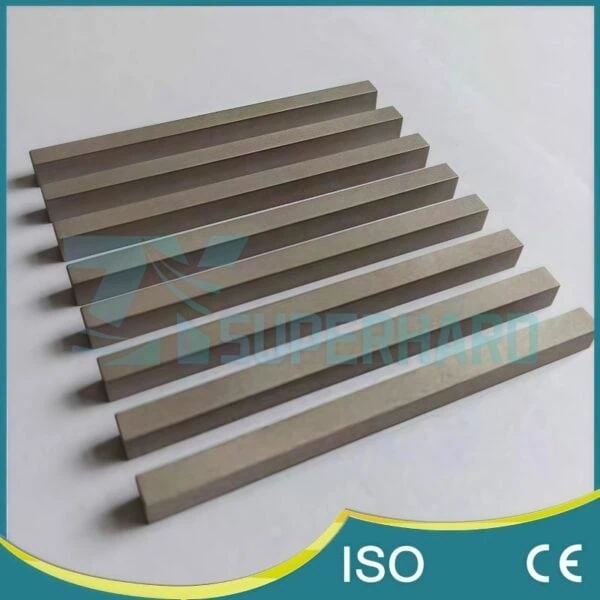

Technical Specifications:

- Abrasive Material: High-Grade CBN (Cubic Boron Nitride)

- Grit Sizes: A complete selection of grit sizes is available, from coarse grits for efficient stock removal to fine grits for polishing and superfinishing.

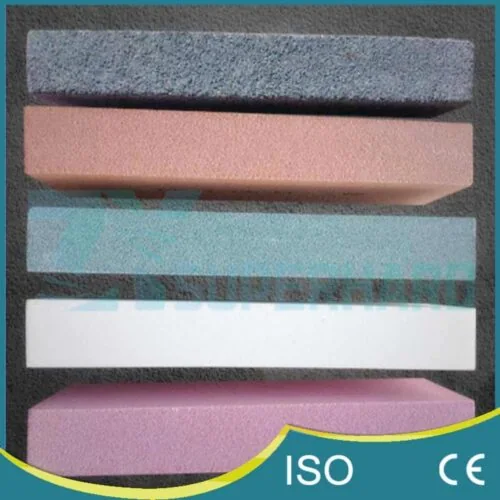

- Bond Type: A full range of bond systems are available to suit your application, including high-strength Metal, fine-finishing Resin, versatile Vitrified, and aggressive Electroplated bonds.

- Standard Dimensions: Offered in a wide variety of industry-standard square and rectangular cross-sections.

- Lubrication: Must be used with a high-quality honing oil to maximize performance, ensure surface quality, and extend tool life.

Customization Services:

We recognize that every honing application has unique requirements. We provide extensive customization to deliver the perfect tool for your process. Available customizations include:

- Custom Grit Sizes and Concentrations

- Non-Standard Dimensions (Length, Width, Height)

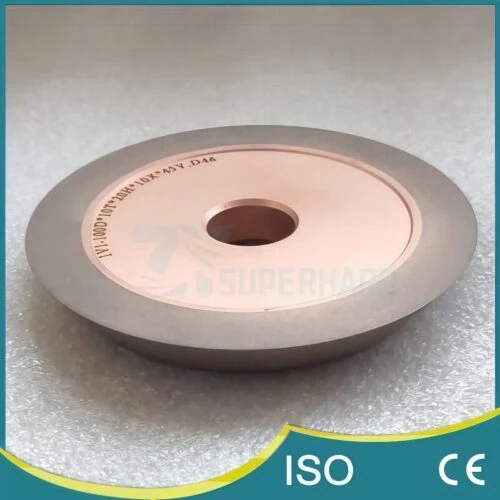

- Special Shapes and Profiles

- Application-Specific Bond Formulations

Contact our technical team with your specifications, and we will partner with you to engineer a CBN honing solution that meets your precise needs.