-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

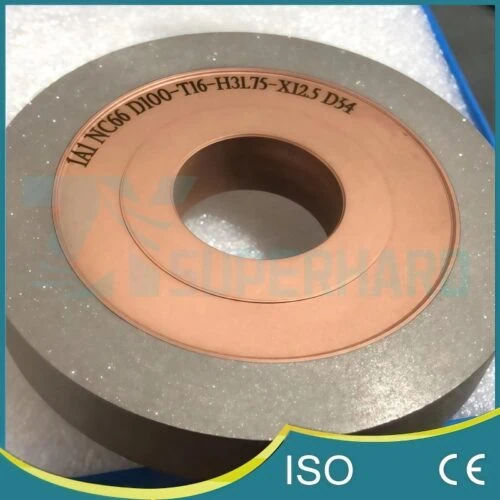

CBN Camshaft Grinding Wheels

High-speed (60-160m/s) Vitrified CBN wheels for precision camshaft & crankshaft grinding. Achieve tight tolerances (0.005 roundness, Ra0.4) & long life on steel/iron. Custom specs & cores.

High-Speed Vitrified CBN Wheels for Precision Camshaft & Crankshaft Grinding

Engineered for the extreme precision and high productivity demands of automotive engine component manufacturing, ZYsuperhard’s Vitrified CBN Grinding Wheels provide the ultimate solution for high-speed grinding of camshafts and crankshafts. Designed to operate reliably at peripheral speeds from 60 up to 160 m/s on dedicated CNC grinding machines (such as TOYODA, Landis, JUNKER, etc.), these wheels ensure exceptional dimensional accuracy, superior surface finish, and outstanding durability when machining critical hardened steel and cast iron components.

The Vitrified CBN Advantage for Engine Components:

The synergy between Cubic Boron Nitride (CBN) abrasive and our advanced vitrified bond system is paramount for meeting the stringent requirements of modern camshaft and crankshaft grinding:

- CBN for Hard Ferrous Materials: CBN, second only to diamond in hardness yet chemically stable with iron, is the ideal abrasive for efficiently grinding the hardened steels, tool steels, and cast irons typically used for these vital engine parts, ensuring sharp cutting and long life.

- High-Speed Optimized Vitrified Bond: Our specialized vitrified bond provides the exceptional rigidity, thermal stability, porosity, and form-holding capability required for stable operation at extremely high surface speeds (60-160 m/s). This structure facilitates effective coolant penetration for cool grinding, prevents wheel loading, maintains profile accuracy (especially on CAM lobes), and enables significantly faster cycle times compared to conventional wheels.

Key Features Tailored for Your Application:

- High-Speed Rated: Engineered and rigorously tested for safe and efficient operation at peripheral speeds ranging from 60 m/s to 160 m/s.

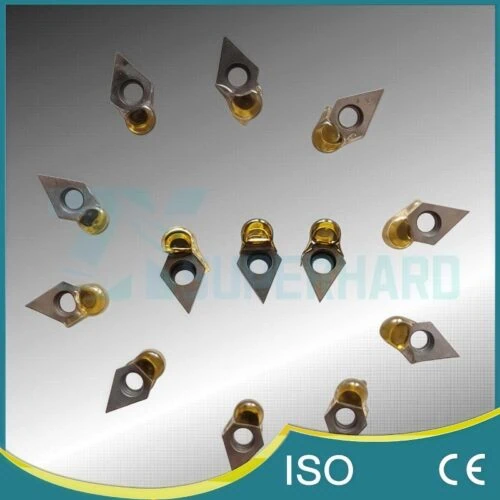

- Optimized CBN & Grit Selection: Offers a range of CBN concentrations and carefully selected grit sizes (typically 60 to 320 mesh) to suit various operations, from rough grinding of journals and pins to fine finishing of CAM lobes and thrust faces.

- Advanced Core/Body Materials: Available with different matrix/body materials including Aluminum, Steel, Carbon Fiber, or Titanium Alloy, allowing optimization of wheel weight, vibration damping characteristics, and overall rigidity based on the specific application, machine type, and performance goals.

- Precision Manufacturing & Balancing: Manufactured to the highest standards of dimensional accuracy and balance to ensure smooth, vibration-free performance, critical for achieving micron-level tolerances.

Achieving Critical Tolerances & Superior Surface Quality:

Our vitrified CBN wheels are designed to consistently meet and exceed the demanding technical requirements inherent in high-quality camshaft and crankshaft manufacturing, enabling you to achieve:

- Journal & Neck Precision: Grinding main bearing journals, camshaft journals, and connecting rod necks (pins) to exacting diameter tolerances (e.g., 0.021mm), exceptional roundness (e.g., 0.005mm), fine surface finishes (e.g., Ra 0.4 µm), and strict coaxiality/runout control (e.g., 0.04mm or better). Compatible with integrated on-line measurement systems.

- CAM Lobe Accuracy: Maintaining precise base circle dimensions and accurately grinding complex CAM profiles, ensuring correct lift characteristics and high coaxiality relative to bearing journals.

- Positional & Geometric Accuracy: Achieving tight tolerances on key slot dimensions and positions, as well as excellent perpendicularity of thrust surfaces relative to journal centerlines (e.g., width tolerance 0.08mm, runout 0.035mm).

- Enhanced Component Integrity: Producing high-quality machined surfaces with minimal residual tensile stress and a significantly reduced risk of grinding cracks, which can ultimately improve the fatigue strength and operational reliability of the finished camshaft or crankshaft.

Machine Compatibility:

These wheels demonstrate proven performance on leading high-speed CNC camshaft and crankshaft grinding platforms, including models such as TOYODA GF50Mi, GF16S; Landis LT2He; JUNKER DU1200, DU1600, CGP series; SCHAUDT CamGrind/ShaftGrind, and other machines capable of utilizing high-speed vitrified CBN grinding technology.

Customization:

ZYsuperhard provides fully customized vitrified CBN grinding wheels. We tailor specifications including diameter (typically 70mm to 700mm range), thickness, hole configuration, abrasive layer dimensions, specific CBN type and grit size, concentration, bond hardness, and core material to precisely match your machine capabilities, workpiece material, component geometry, stock removal needs, and surface finish targets. Welcome to inquire with your specific requirements.

Choose ZYsuperhard Vitrified CBN wheels for unparalleled precision, enhanced productivity, superior component quality, and overall economic benefits in your critical camshaft and crankshaft grinding operations. Contact us to discuss your high-speed grinding application.