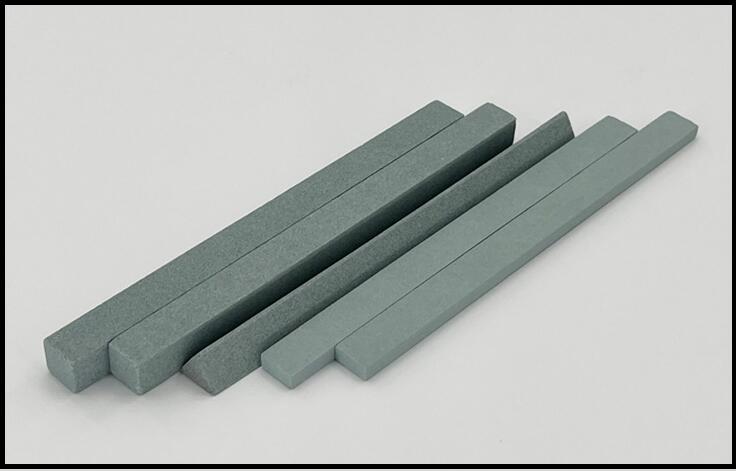

| Model | Features | Application |

| A | High hardness and toughness. | Suitable for grinding of medium and high tensile strength metal materials, such as general carbon steel, alloy steel, malleable cast iron, hard bronze, etc。 |

| WA | Hardness is higher than brown corundum, abrasive fragmentation, sharp edges and corners, good cutting, small grinding heat, etc. | It is suitable for grinding hard and heat-sensitive steel, such as quenched steel, high carbon steel, high-speed steel, alloy steel, etc. And we can use it to cut and form tools, tools, molds, gears, threads, thin-wall parts, etc. |

| PA | Hardness and white corundum are similar; toughness is higher than white corundum, abrasive cutting edge sharp, good angular retention, and increased durability. | Suitable for quenching steel, alloy steel tool and workpiece grinding, and precision grinding of measuring devices and instrument parts, also ideal for forming. |

| SA | Compared with brown and white corundum, it has high hardness, and toughness, a single particle spherical crystal with an excellent multi-edge cutting edge and crushing solid resistance. | Suitable for stainless steel, high alum high-speed steel, and other high hardness, toughness, and easy deformation, easy to burn as the workpiece grinding processing. |

| A/WA | It has the advantages of brown and white corundum. | Suitable for grinding ductile iron workpieces by the shaft, wheel shaft, and another grinding. |

| GC | It owns features of high hardness, brittleness, sharp abrasive, and good thermal conductivity. | Suitable for complex alloy tools, workpieces, and non-ferrous metal, non-metallic grinding. |

| C | It has high hardness, brittle, sharp abrasive, and specific thermal conductivity. | Suitable for grinding non-metallic materials for non-ferrous metals. |