-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

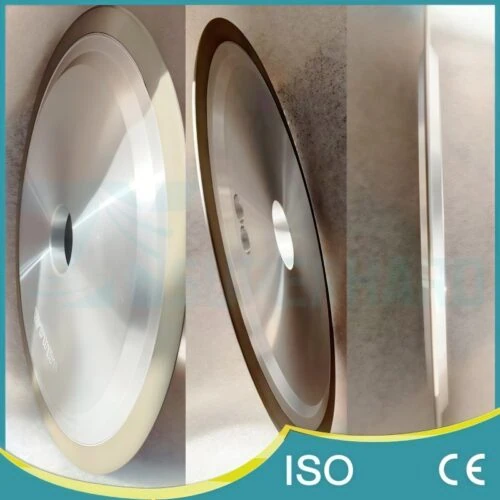

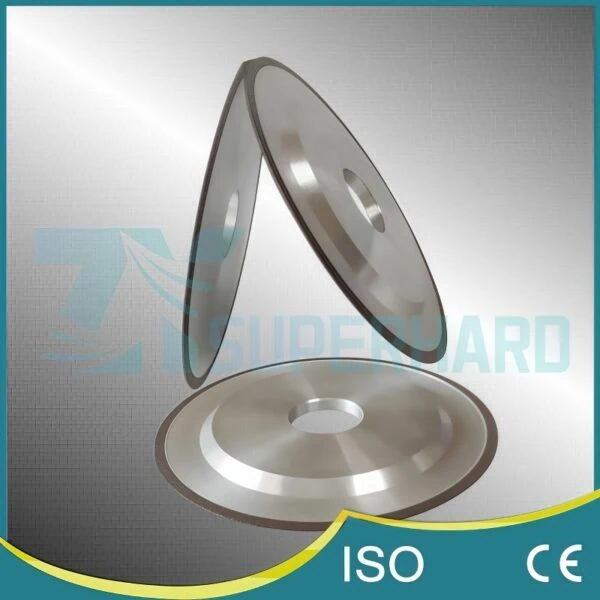

3A1 Resin Bond Diamond Grinding Wheels

High-speed 3A1 Resin Bond Diamond Grinding Wheels for Tungsten Carbide. Ideal for profile, conical & surface grinding, delivering precision & efficiency. Supports wet/dry use. Custom specs.

High-Speed 3A1 Resin Bond Diamond Grinding Wheels for Tungsten Carbide

Achieve high efficiency and precision when grinding Tungsten Carbide components with ZYsuperhard’s 3A1 Resin Bond Diamond Grinding Wheels. This specialized dish wheel shape (ISO Type 3A1), combined with a high-performance resin bond and premium diamond abrasive, is engineered for High-Speed Grinding (HSG) applications on various grinding machines. It excels in tasks requiring wheel clearance or specific profile engagement, such as surface, cylindrical, conical, and intricate profile grinding.

The Resin Bond Diamond Advantage for Tungsten Carbide Grinding:

- Efficient Carbide Removal: Diamond, being the hardest known material, provides exceptional cutting ability on ultra-hard Tungsten Carbide. When paired with our optimized resin bond, it allows for efficient stock removal while maintaining sharp cutting action.

- Superior Surface Finish & Cool Grinding: Resin bonds inherently offer a degree of resilience and promote a free-cutting action. This helps achieve good surface finishes on the workpiece and crucially minimizes heat generation, protecting the integrity of the Tungsten Carbide part, especially important in high-speed operations.

- High-Speed Grinding (HSG) Capability: Formulated with durable resins and quality diamond, these wheels are designed for stability and performance at higher peripheral speeds where applicable, enabling increased productivity and shorter grinding cycle times.

- Versatile Wet or Dry Operation: While wet grinding is strongly recommended for optimal cooling, chip flushing, surface quality, and extended wheel life when grinding Tungsten Carbide, specific bond formulations may allow for dry grinding in certain situations where coolant application is restricted.

Key Features:

- Functional 3A1 Dish Shape: The ISO Type 3A1 wheel, featuring the grinding face on the side/periphery of the dish rim, provides necessary clearance and accessibility for grinding complex geometries, conical surfaces, relief angles, or specific profile features on various tools and components.

- Premium Diamond Abrasive: Utilizes high-quality diamond grits specifically selected for effective grinding of Tungsten Carbide. Grit sizes are fully customizable to meet diverse requirements, from faster removal to fine finishing.

- Durable & Optimized Resin Bond: Engineered to provide an excellent balance between strong diamond grain retention (for long service life) and controlled wear (for consistent self-sharpening and cutting performance).

- Precision Manufacturing: Produced to ensure good wheel balance and dimensional accuracy for stable, reliable operation on grinding machines.

Core Applications:

Ideal for precision grinding operations on a variety of Tungsten Carbide parts, particularly where the 3A1 shape offers advantages:

- Cutting Tools: Grinding specific clearance angles, relief surfaces, or profile features on carbide tools like end mills, drills, reamers, or inserts (depending on the grinding machine and setup).

- Wear Parts: Performing surface, cylindrical, or conical grinding on carbide wear components such as nozzles, seals, bushings, guides, etc.

- Mold & Die Components: Grinding specific features, angles, or surfaces on Tungsten Carbide mold inserts, punches, or die components where the 3A1 wheel geometry is suitable.

- General Carbide Grinding: A versatile option for various precision grinding tasks on Tungsten Carbide requiring a dish-shaped wheel for access or profile generation.

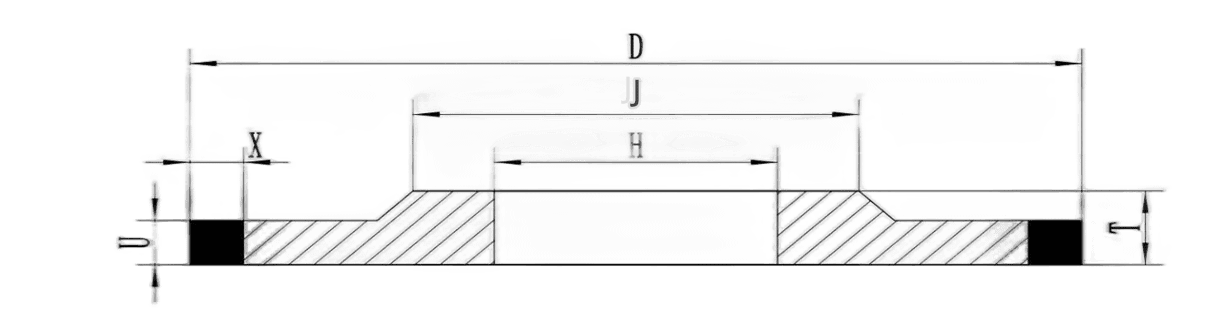

Drawing

3A1 Specifications (MM)

| Model | D | T | U | X | J | H |

| 3A1 | 150 | 5-20 | 1.5,2.0,2.5,3,5,6,10 | 6,10 | 100-350 | 12.7,16,20,25.4,

31.75,32,127,203 |

| 180 | 5-20 | 5,6,10 | 6,10 | |||

| 200 | 5-30 | 6,8,10 | 6,10 | |||

| 300 | 10-100 | 6,8,10 | 6,10 | |||

| 350 | 10-125 | 6,8,10 | 6,10 | |||

| 400,450,450,500 | 10-150 | 6,8,10 | 6,10 | |||

| Note:other specifications can be customized upon request! | ||||||

Customization:

ZYsuperhard specializes in customized 3A1 resin bond diamond wheels. We can precisely tailor the Diameter (D), Thickness (T), Hole (H), Rim dimensions (U, X, J), specific Diamond Grit Size, Concentration, and Bond characteristics to perfectly match your grinding machine capabilities and specific Tungsten Carbide application requirements.

Choose ZYsuperhard 3A1 diamond grinding wheels for efficient, precise, and versatile high-speed grinding of your Tungsten Carbide components. Contact us to discuss your requirements.