-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

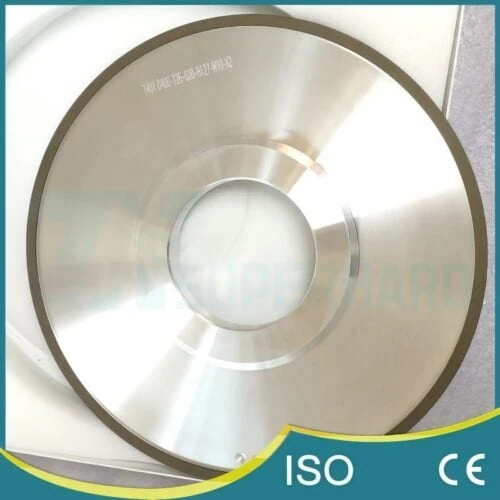

14F1 Resin Bond CBN Grinding Wheels

Precision 14F1 Resin Bond CBN wheels designed for deep slotting, gashing, and form grinding on HSS and hardened steels. Featuring a double-relieved profile (T>U), they offer superior side clearance and rigidity for grinding narrow grooves and precise radii without burning the workpiece.

Engineered for Precision Profiling & Deep Slotting

The 14F1 Resin Bond CBN Grinding Wheel is a specialized abrasive tool engineered for high-precision grinding operations on High-Speed Steel (HSS), Die Steel, and Hardened Alloy Steels (>50 HRC). Unlike standard flat wheels, the 14F1 is designed with a specific geometric profile that combines structural rigidity with deep-access capabilities, making it the industry standard for manufacturing and re-sharpening complex cutting tools.

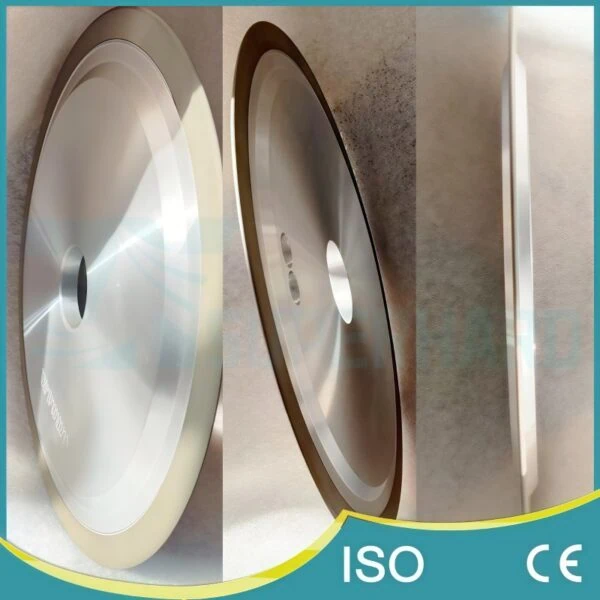

Intelligent Geometric Design: The 14F1 Advantage

The defining characteristic of the 14F1 shape is its “Double Relieved” profile, where the hub thickness (T) is greater than the rim thickness (U). This design offers two critical benefits:

- Maximized Rigidity: The thicker body (T) prevents wheel deflection under load, ensuring straight and accurate cuts.

- Side Clearance: The thinner abrasive rim (U) allows the wheel to enter deep slots, narrow flutes, or saw teeth gullets without the wheel body rubbing against the workpiece. This eliminates side friction and prevents thermal damage.

Optimized for Cool Cutting

We utilize a premium Resin Bond system tailored for hardened ferrous metals. The porous structure of the resin bond promotes a self-sharpening action, exposing fresh CBN particles continuously. This ensures a “cool cut” that minimizes heat generation—crucial for preventing surface burns or metallurgical changes in sensitive heat-treated components.

Versatile Industrial Applications

Thanks to its unique profile, this wheel is essential for:

- Deep Slotting & Grooving: Grinding precise slots in collets and machine parts.

- Tool Gashing: Creating initial flutes on end mills, reamers, and drills.

- Saw Sharpening: Grinding the tooth geometry (gullets) of circular and band saws.

- Spline Grinding: Profiling channels on splined shafts.

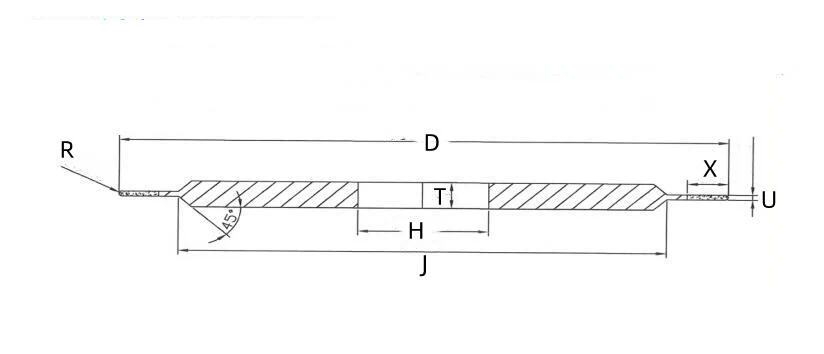

Fully Customizable Dimensions

While the 14F1 shape code defines the overall geometry, every critical dimension is custom-manufactured to match your specific drawing and machine requirements. You control the specifications:

- Outer Diameter (D) & Bore (H): To fit your specific grinding spindle.

- Rim Thickness (U): Customizable for ultra-narrow slots or wider profiles.

- Hub Thickness (T): Adjusted for necessary clearance and support.

- Profile Radius (R): The abrasive tip can be shaped with a specific radius (e.g., R0.5, R1.5) or full radius to match your workpiece requirements perfectly.

Ready to Optimize Your Grinding Process?

Contact our technical team today with your drawing or specifications (D, T, U, R) to receive a custom quotation and expert application advice.