-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

How Do You Select the Right Aerospace Grinding Tools to Overcome Key Manufacturing Challenges?

When it comes to making parts for airplanes and spacecraft, how do you really figure out which grinding tools are the right ones to handle all the tough challenges?

Selecting the right aerospace grinding tools requires a comprehensive understanding of the unique manufacturing challenges, including extreme precision and difficult materials. It involves choosing essential tool types like superabrasives (CBN and diamond) with appropriate bonds, considering specialized wheels and dressing tools, tailoring choices to specific materials like titanium, superalloys, composites, and ceramics, and recognizing that factors beyond the tool, such as machines, process parameters, coolant systems, and operator skill, are equally vital for success.

What Unique Grinding Challenges Does the Aerospace Industry Present?

So, what exactly makes grinding for the aerospace industry so uniquely demanding?

The aerospace industry presents a distinct set of grinding challenges stemming from its absolute need for parts with exceptionally tight precision tolerances, the use of advanced materials that are very hard to work with, the critical importance of maintaining the material’s internal quality at the surface, and the necessity to meet extremely strict safety and quality rules.

Precision Tolerances and Complex Geometries

Imagine trying to shape a piece of metal so perfectly that it fits with another part with almost no gap, thinner than a human hair. That’s the kind of precision tolerances aerospace parts often need. We’re talking about measurements that might be just a few micrometers off – a micrometer is one-thousandth of a millimeter! For instance, a turbine blade in a jet engine might require dimensional tolerances as tight as ±0.005 mm (or ±0.0002 inches). Achieving such exactness consistently is a major hurdle. Why is this so important? Even tiny errors in a part’s size or shape can affect how well an aircraft performs, how much fuel it uses, or even its safety.

Then, there are the complex geometries. Aerospace components are rarely simple blocks or cylinders. It’s like a sculptor trying to create a detailed masterpiece, but with super hard materials and the need for every copy to be identical down to the tiniest detail. Think about:

- Turbine blades: These have intricate curved surfaces and very thin edges. Grinding these without distorting them or creating weak spots is tough.

- Landing gear components: These often have deep pockets, internal bores, and complex load-bearing structures that require precise grinding in hard-to-reach areas.

- Fuel system components: These may feature tiny, precisely angled holes and channels.

Grinding these shapes accurately requires highly advanced machines and very skilled operators. The challenge is not just making the shape, but doing it repeatedly and reliably.

Difficult-to-Machine Materials (Superalloys, Composites, Ceramics)

The materials used in aerospace are chosen for their amazing properties: strength at high temperatures, light weight, or resistance to wear. However, these same properties often make them incredibly difficult-to-machine using grinding.

- Superalloys: These are metal mixtures, often based on nickel, cobalt, or iron, like Inconel® or Hastelloy®. They are designed to stay strong even when red-hot inside a jet engine. But this means they resist being cut or ground, leading to:

- High grinding forces: This can strain the grinding machine and the part.

- Rapid tool wear: The grinding wheels wear down quickly, making it expensive and time-consuming to keep replacing them.

- Heat generation: Lots of heat is produced, which can damage the part if not controlled. For example, grinding Inconel 718, a common aerospace superalloy, can generate significant thermal stress if not managed properly, potentially leading to surface defects.

- Composites1: Materials like Carbon Fiber Reinforced Plastics (CFRPs) are super strong and lightweight, perfect for aircraft bodies and wings. But grinding them is tricky. Instead of cutting cleanly like metal, they can:

- Delaminate: The layers can separate.

- Cause fiber pull-out: The reinforcing fibers can be ripped out instead of cut.

- Create hazardous dust: The fine dust needs careful management.

The cutting action is more like shearing and fracturing than the plastic deformation seen in metals.

- Ceramics and Ceramic Matrix Composites (CMCs): These are even harder and more brittle than superalloys. They are used in very hot sections of engines or for wear-resistant coatings. Grinding them requires special diamond wheels and very precise control because they can easily crack or chip. Think about trying to shape a very hard, brittle teacup with extreme precision – that’s the kind of care needed.

Dealing with these materials pushes the limits of current grinding technology. It’s not just about removing material; it’s about doing it without damaging these expensive and advanced substances.

Surface Integrity and Metallurgical Concerns

When a part is ground, it’s not just its shape that matters. What happens to the very top layer of the material – its surface integrity2 – is critically important in aerospace. Grinding is a machining process that involves chip formation at a micro-level, and this can introduce changes to the material’s surface and subsurface. If not done correctly, grinding can cause:

- Residual Stresses: Grinding can leave stresses locked into the surface of the part. If these are tensile (pulling apart), they can make the part weaker and more likely to develop cracks over time, especially under the repeated loads that aerospace components experience (fatigue). The goal is often to have compressive (pushing together) residual stresses, which can actually improve fatigue life.

- Micro-cracks: Tiny cracks, sometimes invisible to the naked eye, can form on the surface if the grinding is too aggressive or the wrong wheel is used. These can grow under stress and lead to failure.

- Thermal Damage: The heat generated during grinding can actually change the properties of the metal near the surface. This can include:

- Grinding burn: Discoloration indicating overheating and potential softening or hardening of the material.

- Phase transformations: The microstructure of the metal can be altered, affecting its strength and durability. For instance, in steels, overheating can lead to untempered martensite, which is very brittle.

- Alteration of Hardness: The surface hardness can be inadvertently increased or decreased, moving it outside the specified engineering limits.

Think of the surface of an aerospace part like its skin. If that skin is damaged, even slightly, it can compromise the health and strength of the entire part. Because aerospace parts are often pushed to their limits, ensuring excellent surface integrity after grinding is not just a preference, it’s a fundamental safety requirement. For example, a journal bearing surface in an engine requires a specific surface finish and integrity to ensure low friction and long wear life; improper grinding can lead to premature failure.

Regulatory Compliance and Quality Assurance

The aerospace industry is one of the most highly regulated in the world for obvious safety reasons. Every single component on an aircraft must meet incredibly strict standards set by bodies like the Federal Aviation Administration (FAA) in the U.S. or the European Union Aviation Safety Agency (EASA). This means that regulatory compliance and quality assurance (QA) are huge challenges in grinding operations.

What does this involve?

- Traceability: You need to be able to track every part and every process. Which batch of material was used? Which machine ground it? Who was the operator? What were the exact grinding parameters? All this information must be recorded and retrievable, sometimes for decades.

- Process Validation: Grinding processes often need to be formally validated. This means proving, with data, that your process consistently produces parts that meet all specifications. It’s not enough to make one good part; you have to show you can do it every single time.

- Strict Adherence to Specifications: Every dimension, every surface finish requirement, every material property has to be exactly as specified in the engineering drawings and standards (like AS9100, which is a quality management standard for the aerospace industry). There’s very little room for error.

- Non-Destructive Testing (NDT): After grinding, many aerospace parts undergo NDT, such as fluorescent penetrant inspection (FPI) to find tiny surface cracks, or magnetic particle inspection (MPI). If the grinding process has induced any defects, these tests will ideally find them, leading to costly rework or scrap. The challenge for grinding is to produce parts that pass these stringent tests the first time.

- Documentation: Extensive documentation is required to prove that all processes were followed correctly and that the parts meet all requirements. This adds a significant administrative burden to the manufacturing process.

Imagine every step of your work being watched, measured, and recorded, because if something goes wrong, the consequences could be catastrophic. That’s the level of scrutiny involved in aerospace grinding. This demanding QA environment means that grinding processes must be extremely robust, repeatable, and well-controlled.

Which Types of Grinding Tools Are Essential for Aerospace Applications?

So, when it comes to shaping super-strong aerospace parts with amazing precision, what kinds of grinding tools are actually up to the task?

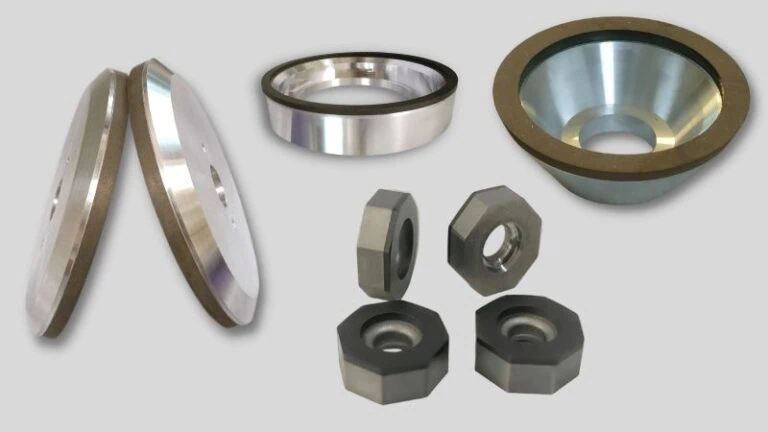

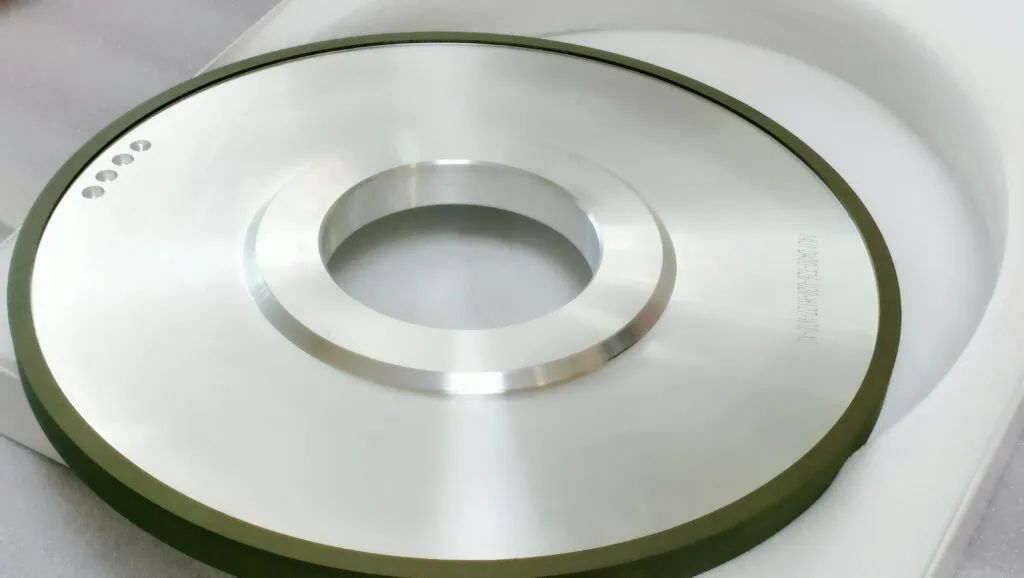

Essential grinding tools for aerospace applications include advanced superabrasive wheels, like CBN and diamond3, paired with specific bond types such as vitrified, resin, metal, or electroplated. Furthermore, specialized wheel designs for tasks like creep-feed or profile grinding, along with precision dressing tools, are crucial for achieving the required performance and accuracy.

Superabrasives: CBN vs. Diamond Wheels for Aerospace Materials

Imagine trying to cut something incredibly hard. You’d need something even harder, right? That’s where superabrasives come in. These are materials much harder than traditional abrasives like aluminum oxide or silicon carbide. In aerospace, the two main superabrasives you’ll hear about are CBN and Diamond. They are the superstars for grinding the toughest materials.

Applications for CBN (Cubic Boron Nitride)

Cubic Boron Nitride (CBN) is the second hardest material known, right after diamond. Its big advantage is that it doesn’t react chemically with iron-based materials, even at high grinding temperatures. This makes it perfect for grinding:

- Hardened Steels: Many aerospace components, like bearings or gears, are made from very hard steels.

- Nickel-based Superalloys: Think of materials like Inconel®, Waspaloy®, or René®, commonly found in the hot sections of jet engines (e.g., turbine disks, blades, and combustion chambers). CBN can grind these efficiently without excessive wear or thermal damage, thanks to its thermal stability.

- Cobalt-based Superalloys: Similar to nickel-based ones, these are also used for high-temperature strength.

Using CBN wheels means you can grind these tough metals faster, the wheels last longer, and you can get very precise shapes and smooth finishes. This is because CBN grains stay sharp for a long time and resist breaking down under the heat and pressure of grinding. For example, when grinding the fir-tree roots of turbine blades made from nickel superalloys, CBN wheels are often preferred for their ability to maintain form and achieve tight tolerances.

Applications for Diamond Abrasives

Diamond is the hardest material on Earth. This makes it incredibly effective for grinding materials that CBN can’t handle as well, or where its extreme hardness is a distinct advantage. Diamond is the top choice for:

- Composite Materials: Carbon Fiber Reinforced Plastics (CFRPs), Glass Fiber Reinforced Plastics (GFRPs), and other composites used for aircraft structures (fuselages, wings, control surfaces) are very abrasive. Diamond wheels can cut through these materials cleanly, minimizing issues like delamination or fiber pull-out if the correct diamond grit, concentration, and bond are selected.

- Ceramics and Ceramic Matrix Composites (CMCs): These are extremely hard and brittle materials used for thermal barrier coatings, engine shrouds, or exhaust components. Diamond is often the only abrasive that can effectively grind them to the required precision.

- Carbides: Tungsten carbide, often used for wear parts or tooling, is also ground with diamond.

- Some Non-ferrous Metals: While CBN is king for ferrous (iron-containing) alloys, diamond can be used for some non-ferrous materials like certain titanium alloys (though care must be taken to avoid excessive heat which can cause chemical reactions). For titanium, specialized diamond wheels with specific bond types are sometimes employed.

It’s important to remember that diamond typically isn’t used for grinding steels or iron-based superalloys because carbon (which diamond is made of) can react with iron at high grinding temperatures, causing the diamond to wear out quickly.

Here’s a quick comparison:

| Feature | CBN (Cubic Boron Nitride) | Diamond |

|---|---|---|

| Hardness | Second hardest material | Hardest known material |

| Best For | Ferrous materials (steels, superalloys like Inconel®) | Non-ferrous materials, composites, ceramics, carbides |

| Key Benefit | Chemically stable with iron at high temps | Extreme hardness for very hard/abrasive materials |

| Avoid With | Very soft, gummy materials | Most ferrous materials (steels, cast iron) |

The choice between CBN and diamond isn’t just about the material being ground; it also depends on the specific grinding operation, the machine tool, and the desired outcome. Specific abrasive grain size, concentration, and even coatings on the abrasives can vary significantly, so consulting with your grinding wheel supplier for the optimal specification for your aerospace application is always recommended.

Vitrified vs. Resin Bond vs. Metal Bond vs. Electroplated Wheels

The superabrasive grains (like CBN or diamond) are held together in the grinding wheel by a “bond.” Think of the bond as the glue that holds the cutting grains. The type of bond used4 dramatically affects how the wheel performs. The main types you’ll encounter for aerospace applications are:

Choosing the Right Bond for Your Application

Selecting the correct bond is just as important as selecting the right abrasive. Each bond type has unique properties:

- Vitrified Bonds:

- What they are: These bonds are made from glassy, ceramic materials. They are strong, rigid, and porous (they have tiny holes).

- Aerospace uses: Excellent for precision grinding of superalloys (often with CBN) and some ceramics. Their porosity helps with coolant delivery and chip clearance, which is vital for preventing heat damage. They hold their shape very well, which is key for tight tolerances on parts like turbine blade roots or bearing journals. One example is 3A1 Type Vitrified Bond Diamond Grinding Wheels5.

- Key features: High form-holding, good stock removal, long life, dressable for sharpness.

- Resin Bonds (Resinoid):

- What they are: These use synthetic resins (plastics) to hold the abrasive. They are generally softer and less rigid than vitrified bonds.

- Aerospace uses: Often used with diamond for grinding composites (like CFRPs) because the softer bond can help prevent excessive damage to the composite material. Also used for cut-off operations and some fine finishing on metals where a smoother surface is needed. They can provide a “softer” grinding action.

- Key features: Good surface finish, shock absorption, high material removal rates in certain applications.

- Metal Bonds:

- What they are: Abrasive grains are sintered (fused) within a metal matrix (e.g., bronze, steel). These are very tough and wear-resistant bonds.

- Aerospace uses: Primarily used with diamond for grinding very hard materials like ceramics, glass, and some composites where extreme durability and form-holding are needed. Also used in some profile grinding applications or for cutting tools where the wheel edge must last a long time.

- Key features: Extremely durable, excellent form-holding, long life, suitable for high production.

- Electroplated Bonds:

- What they are: A single layer of abrasive (usually diamond or CBN) is bonded to the wheel core using a layer of nickel plating.

- Aerospace uses: Very good for grinding complex forms and profiles in composites and some superalloys (e.g., specialized grooves or slots in engine components). Because there’s only one layer of abrasive, they offer very free cutting and can be made into very precise shapes. However, once the abrasive layer is worn, the tool is typically discarded or needs re-plating. More information can be found in the guide to Electroplated Diamond & CBN Grinding Wheels6.

- Key features: Aggressive cutting, excellent for complex profiles, no dressing needed (single layer).

Here’s a summary table for bond types:

| Bond Type | Key Characteristics | Typical Aerospace Uses | Abrasive Commonly Paired With |

|---|---|---|---|

| Vitrified | Strong, rigid, porous, good form-holding, dressable | Precision grinding of superalloys, some ceramics (e.g., turbine blade roots, bearings) | CBN, Diamond |

| Resin | Softer, shock-absorbing, good finish | Grinding composites, cut-off, some metal finishing | Diamond, CBN |

| Metal | Very tough, durable, excellent form-holding | Grinding ceramics, hard composites, some profile grinding | Diamond |

| Electroplated | Single abrasive layer, aggressive, precise complex forms | Grinding composites, intricate profiles in superalloys (e.g., slots, special forms) | Diamond, CBN |

The specific formulation of these bonds, including their hardness and porosity, can be tailored by manufacturers. Therefore, discussing your exact aerospace material and application with a grinding tool specialist is crucial to select the most effective bond.

Specialized Grinding Wheels (e.g., Creep-feed, Profile Grinding)

Sometimes, a standard flat or cylindrical grinding wheel just won’t do the job, especially with the complex parts found in aerospace. That’s where specialized grinding wheels come in.

- Creep-feed Grinding7 Wheels:

Imagine trying to remove a lot of material from a tough superalloy part in one go, instead of taking many small passes. That’s what creep-feed grinding does. It uses a large depth of cut but moves the workpiece very slowly past the wheel.- The Wheels: These wheels are often large and specifically designed with a highly porous structure (frequently vitrified bond) to allow lots of coolant into the grinding zone and to carry away chips effectively. This prevents burning and maintains precision.

- Aerospace Example: Grinding the “fir-tree” roots of turbine blades or slots in engine casings. Creep-feed grinding can significantly reduce cycle times for these types of operations compared to traditional multi-pass surface grinding.

- Profile Grinding Wheels (Form Wheels):

Many aerospace parts have intricate shapes or profiles that need to be ground accurately. Profile grinding wheels are made to the inverse (mirror image) of the desired shape on the part.- The Wheels: These can be made with vitrified bonds for dressing to a precise profile, or they can be electroplated superabrasive wheels where the diamond or CBN is plated onto a pre-formed core.

- Aerospace Example: Grinding the complex fir-tree root forms on turbine blades in a single pass, or specific grooves and contours on actuation system components. This ensures that the profile is consistent and accurate.

These specialized wheels often represent a significant investment, but they can provide huge benefits in terms of productivity and precision for specific aerospace components.

Precision Dressing Tools for Optimal Wheel Performance

A grinding wheel is like a very fine cutting tool with millions of tiny teeth (the abrasive grains). Over time, these teeth can get dull, or the wheel can get clogged with material (this is called “loading”), or it can lose its precise shape. Dressing8 is the process of re-sharpening the wheel, cleaning it, and ensuring it has the perfect geometry. For the superabrasive wheels used in aerospace, this is incredibly important.

What kind of tools do we use for this?

- Rotary Diamond Dressers: These are high-precision tools themselves – powered spindles with a diamond-impregnated roll that matches the profile needed on the grinding wheel. They are essential for dressing vitrified bond CBN and diamond wheels used in high-precision aerospace grinding. They can true the wheel (make it perfectly round and concentric) and condition its surface for optimal cutting. For instance, when grinding precise bearing races with vitrified CBN wheels, rotary diamond dressers are used to maintain the wheel’s profile and sharpness to achieve sub-micron tolerances.

- Stationary Diamond Tools: These are single-point or multi-point diamond tools that traverse across the wheel face. While more common for conventional abrasive wheels, specialized versions are used for some superabrasive applications, particularly for simpler forms.

- Dressing Sticks/Stones: These are handheld abrasive sticks used for manually cleaning the face of a loaded wheel or for slightly altering its sharpness. They are more for minor touch-ups than for precision profiling.

Without proper and precise dressing, even the most advanced grinding wheel will not perform as it should. It can lead to poor surface finish, inaccurate parts, and even damage to the workpiece. In aerospace, where every part has to be perfect, effective dressing is a non-negotiable part of the grinding process. The parameters of the dressing operation itself (speed, depth, traverse rate) are critical and specific to the wheel and application, and often require supplier consultation for best results.

What Are Key Considerations When Choosing Specific Aerospace Grinding Tools for Different Materials?

When you’re working with the advanced and often tricky materials used in airplanes and spacecraft, how do you pick the perfect grinding tool for each specific job?

Key considerations when choosing specific aerospace grinding tools for different materials involve matching the abrasive type (like diamond or CBN), its grit size, the bond system (such as vitrified, resin, metal, or electroplated), and the wheel’s geometry to the unique characteristics of each material—be it titanium, superalloys, composites, or ceramics—to effectively address challenges like heat generation, work hardening, or delamination and achieve the required precision and surface quality.

Grinding Titanium Alloys: Addressing Smearing and Heat Issues

Titanium alloys are fantastic for aerospace because they are strong and lightweight. You’ll find them in airframes, engine components like fan blades and disks, and landing gear. However, grinding titanium is quite a challenge. Why? Titanium alloys tend to:

- React chemically: Especially at high temperatures, titanium can react with the abrasive material in the grinding wheel.

- Generate a lot of heat: Titanium doesn’t conduct heat away very well. This means the heat stays right where you’re grinding, which can damage the part or wear out the wheel fast.

- Smear: Instead of forming a clean chip, the material can smear across the surface.

- Have a “gummy” nature: This can cause the grinding wheel to load up quickly, meaning the spaces between abrasive grains get clogged with titanium.

So, what kind of grinding tools do you need?

- Abrasive Choice:

- Silicon Carbide (SiC) wheels have traditionally been used for titanium due to their sharpness and lower chemical reactivity compared to aluminum oxide.

- Specialized Diamond Wheels: Some diamond wheels, particularly with certain bond types and used with specific coolants, can be effective, but care must be taken due to diamond’s carbon content and titanium’s reactivity at elevated temperatures.

- Ceramic Seeded Gel (SG) Abrasives: These advanced ceramic aluminum oxide abrasives can also offer good performance on titanium, providing a balance of toughness and friability (the ability of grains to fracture and expose new sharp edges).

- CBN: Generally, CBN is not the first choice for titanium due to chemical reactivity concerns, similar to diamond, but specific applications might exist with advanced CBN and bond formulations.

- Bond Characteristics:

- A softer grade bond is often preferred. This allows worn abrasive grains to pull out more easily, exposing fresh, sharp grains and reducing the chances of the wheel loading up or smearing the material.

- Porous bonds can help improve coolant delivery to the grinding zone, which is critical for managing heat.

- Grit Size: Using a medium to coarse grit size can help reduce friction and allow for better chip clearance, which also helps manage heat.

- Grinding Parameters: Lower wheel speeds (compared to grinding steels) are often necessary to reduce heat generation. Aggressive material removal rates should be approached with caution.

Crucial Element: Coolant

Effective cooling is absolutely vital when grinding titanium. A generous supply of high-quality coolant, precisely directed at the grinding zone, helps to reduce temperatures, flush away chips, and minimize chemical reactions. Specialized chemical coolants might be used to create a protective barrier on the titanium surface.

For instance, when grinding a Ti-6Al-4V landing gear component, selecting a SiC wheel with a friable vitrified bond, coupled with high-pressure coolant, can help prevent surface burning and achieve the required finish. However, the ideal abrasive, bond, grit size, and grinding parameters for titanium alloys can vary greatly depending on the specific alloy grade (e.g., Ti-6Al-4V vs. Ti-5553), the component’s geometry, and the machine capabilities. It is highly advisable to consult your grinding wheel supplier for precise recommendations tailored to your application.

Grinding Nickel-Based Superalloys (e.g., Inconel): Managing Work Hardening

Nickel-based superalloys like Inconel®, Waspaloy®, and Udimet® are the workhorses of hot sections in jet engines—turbine blades, disks, and combustion chambers. They are designed to be incredibly strong even at scorching temperatures. But this amazing strength makes them a real beast to grind. Key challenges include:

- Extreme Toughness and Strength: They resist cutting and cause rapid tool wear.

- Work Hardening: These materials get even harder very quickly as you try to cut or grind them. If your abrasive isn’t sharp or you dwell too long, the surface can become so hard that further grinding is almost impossible.

- High Heat Generation: Similar to titanium, a lot of heat is produced.

- Abrasiveness: They contain hard carbide particles that wear down grinding wheels.

What tools can tame these superalloys?

- Abrasive Choice: CBN is King

- Cubic Boron Nitride (CBN) is the go-to abrasive for nickel-based superalloys. As we learned earlier, CBN retains its hardness at high temperatures and is chemically stable with iron and nickel, preventing the rapid wear seen with other abrasives. This results in longer wheel life, better form holding, and more consistent part quality.

- Bond Characteristics:

- Vitrified bonds are very common for CBN wheels used on superalloys. They offer excellent rigidity for precision and can be engineered with specific porosity to aid cooling and chip removal. The bond’s “friability” (how easily grains pull out to expose new sharp edges) is carefully controlled.

- Electroplated CBN wheels can also be used for specific profiles or forms, offering a very sharp, aggressive cut.

- Grit Size & Concentration: This depends on the operation. Finer grits and higher CBN concentrations might be used for finishing operations requiring tight tolerances and smooth surfaces, while coarser grits might be used for stock removal.

- Wheel Design & Dressing:

- Maintaining sharp CBN grains is critical to minimize work hardening and heat. This means frequent and precise dressing of the grinding wheel, often using rotary diamond dressers.

- The wheel needs to be kept “open” (not loaded) to ensure efficient cutting.

For example, grinding the fir-tree roots of an Inconel 718 turbine blade requires a vitrified CBN wheel, often with a specialized profile, dressed meticulously to maintain the intricate shape. The grinding parameters, like wheel speed and feed rate, must be carefully optimized to cut efficiently without inducing excessive heat or work hardening. Tooling choices, including the exact CBN type, grit, concentration, and bond specification, are highly application-specific, so detailed discussions with your tooling provider are essential for success with these demanding materials.

Grinding Aerospace Composites: Preventing Delamination and Fiber Pull-out

Composite materials, like Carbon Fiber Reinforced Plastics (CFRPs), are prized in aerospace for their incredible strength-to-weight ratio. You’ll see them in wings, fuselages, empennages, and control surfaces. While they offer many benefits, grinding them presents unique problems quite different from metals:

- Abrasiveness of Fibers: Carbon and glass fibers are very abrasive and quickly wear down conventional tools.

- Delamination Risk: The layers of composite material can separate or peel apart if grinding forces are too high or the tool is dull. This is like trying to cut a stack of paper and having the edges fray and separate.

- Fiber Pull-out: Instead of being cut cleanly, fibers can be pulled out from the resin matrix, leaving a poor surface and weaker material.

- Edge Chipping: The edges of ground composites can be prone to chipping.

- Thermal Sensitivity: The resin that holds the fibers together can be damaged by excessive heat.

So, what tools are best for composites?

- Abrasive Choice: Diamond is Essential

- Diamond abrasives are almost exclusively used for grinding composites due to their unmatched hardness, which can effectively cut the abrasive fibers.

- Bond Characteristics & Tool Types:

- Electroplated Diamond Tools: These are very popular. A single layer of diamond is bonded to a core. They offer very sharp cutting edges, can be made into complex shapes (like router bits or specialized drills with grinding capabilities), and are good for minimizing delamination. They are often used for edge trimming, hole grinding, and creating contours.

- Metal Bond Diamond Wheels: For applications requiring longer life and more aggressive material removal, such as rough edge trimming or cutting thick composite sections, metal bonds offer excellent durability.

- Resin Bond Diamond Wheels: These can be used for finer finishing operations or where a slightly “softer” grinding action is desired to minimize subsurface damage.

- Brazed Diamond Tools: In this technology, diamond particles are chemically bonded to the tool substrate, offering strong grain retention and good chip clearance.

- Tool Geometry:

- Specialized tool geometries are often employed, such as “burr-style” grinders or routers with specific flute designs that shear the fibers cleanly.

- Wheels designed for low grinding forces are preferred.

- Grinding Strategy: The aim is to shear the fibers rather than push or tear them. This often involves higher speeds and lower feed rates. Dust extraction is also a major consideration due to the nature of composite dust.

Consider trimming the edge of a CFRP wing skin. An electroplated diamond router or peripheral grinding wheel, running at high RPM, would be used to create a clean, delamination-free edge. The specific diamond grit size (often finer for smoother finishes), concentration, and tool design (e.g., up-cut or down-cut routers) are critical and should be selected based on the exact composite material, thickness, and desired edge quality, with guidance from tool suppliers.

Grinding Ceramics and Advanced Coatings: Ensuring Precision and Finish

Aerospace uses advanced ceramics (like alumina, zirconia, silicon nitride) and ceramic thermal barrier coatings (TBCs) on components like turbine blades and combustors to withstand extreme temperatures and wear. These materials are incredibly hard, but also very brittle. The grinding challenges are:

- Extreme Hardness: Makes them very difficult to cut.

- Brittleness: Highly prone to chipping, cracking, and subsurface damage if grinding forces are not carefully controlled.

- Tight Tolerances and Fine Finishes: Often require mirror-like finishes and extremely precise dimensions.

What tools are needed for these demanding materials?

- Abrasive Choice: Diamond is the Only Way

- Given their extreme hardness, diamond is the only practical abrasive for grinding most engineering ceramics and hard coatings effectively.

- Bond Characteristics:

- Metal Bonds: Often chosen for their durability and ability to retain diamond grains when grinding very hard ceramics, especially in higher stock removal applications.

- Resin Bonds: Can be used for applications requiring very fine surface finishes and minimal subsurface damage, as they provide a softer, more forgiving Gcing action.

- Vitrified Diamond Wheels: These are also used for precision grinding of ceramics, offering good form holding and the ability to be dressed for specific requirements.

- Grit Size: This is a critical parameter. Grinding ceramics often involves a multi-stage process:

- Coarser diamond grits might be used for initial shaping or stock removal (if significant material needs to be removed).

- Progressively finer diamond grits (often down to micron or even sub-micron sizes) are then used to achieve the final dimensions, surface finish, and minimize any subsurface damage introduced by earlier stages. This is sometimes referred to as lapping or polishing with bonded abrasives.

- Machine Rigidity & Control:

- While the tool is vital, grinding ceramics successfully heavily relies on using highly rigid grinding machines with excellent vibration damping and precise motion control.

- Low grinding forces, shallow depths of cut, and controlled feed rates are essential to prevent fractures.

For example, finishing a yttria-stabilized zirconia (YSZ) thermal barrier coating on a turbine blade to a specific thickness and surface roughness requires fine-grit diamond wheels, often with a resin bond, on a highly precise grinding machine. The process must be carefully controlled to avoid chipping the coating or damaging the underlying superalloy. Achieving success with ceramics means every aspect of the grinding system – the tool, the machine, the parameters, and the coolant – must be perfectly optimized. Detailed consultation with diamond tooling specialists and machine manufacturers is invariably required.

Beyond the Tool Itself, What Else Impacts Aerospace Grinding Success?

So, you’ve picked out the perfect advanced grinding wheel for your aerospace part, but is that all it takes to guarantee success?

Beyond the grinding tool itself, achieving success in aerospace grinding critically depends on the capabilities and stability of the grinding machine, the precise control of grinding process parameters, the effective application and meticulous filtration of coolants, and, importantly, the deep knowledge and skill of the machine operators.

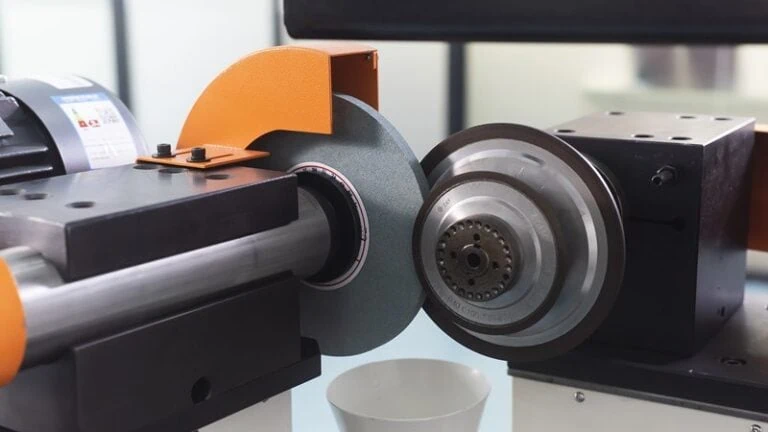

The Role of Grinding Machines and Process Parameters

Even the best grinding wheel can’t perform miracles if the supporting cast isn’t up to par. The grinding machine and the way it’s programmed (the process parameters) play a massive role.

Grinding Machines: The Unsung Heroes

Think of a grinding machine as the foundation of your entire operation. For aerospace parts, where precision is everything, this foundation needs to be rock-solid. Key machine characteristics include:

- Rigidity and Damping: A grinding machine must be incredibly stiff and able to absorb vibrations. Any tiny shake or flex in the machine during grinding can transfer to the part, leading to wavy surfaces, incorrect dimensions, or even tiny cracks. Aerospace tolerances are so tight that even microscopic vibrations can be a problem. High-quality machine tool builders use materials like cast iron or polymer concrete for machine beds due to their excellent damping properties.

- Spindle Power and Precision: The spindle is what holds and spins the grinding wheel. It needs enough power to grind tough aerospace materials without slowing down, and it must run with extreme precision (no wobble or runout) to ensure the wheel grinds true. High-frequency spindles are often used for small diameter wheels requiring high RPM.

- Advanced CNC Control: Modern aerospace grinding relies heavily on Computer Numerical Control (CNC). Multi-axis (e.g., 3-axis, 5-axis, or even more) CNC machines can guide the grinding wheel along complex paths to create intricate shapes like those found on turbine blades or landing gear components. This precise control is vital for repeatability and accuracy. For example, a 5-axis CNC grinder can simultaneously control the X, Y, Z linear axes and two rotary axes (A and C) to maintain the optimal wheel-to-workpiece orientation when grinding complex airfoil surfaces.

- Thermal Stability: Grinding generates heat, and machines can expand or contract with temperature changes. For long grinding cycles common in aerospace, the machine must be designed to remain dimensionally stable despite these temperature fluctuations to maintain accuracy. Some high-precision machines have built-in cooling systems for key components like the spindle and machine bed.

Process Parameters: Dialing in Perfection

Process parameters are the settings used for the grinding operation. Getting these right is a science and an art. Key parameters include:

- Wheel Speed (Surface Feet per Minute – SFPM, or meters per second – m/s): This is how fast the surface of the grinding wheel is moving. It affects the cutting action, heat generation, and surface finish. Too slow, and the wheel might not cut efficiently; too fast, and it could lead to excessive heat or even wheel damage.

- Work Speed / Feed Rate (Inches per Minute – IPM, or millimeters per minute – mm/min): This is how fast the workpiece is moving past the wheel, or how fast the wheel is fed into the workpiece. It influences how much material is removed and the quality of the finish.

- Depth of Cut (Inches or millimeters): This is how much material the wheel removes in one pass. A deeper cut removes material faster but also increases forces and heat.

- Dwell Time / Spark-out: At the end of a grinding pass, allowing the wheel to “spark-out” (grind with no additional infeed) helps achieve the final size and improve surface finish.

Optimizing these parameters is crucial. They are all interconnected, and a change in one can affect the others. For example, grinding a heat-sensitive nickel superalloy might require moderate wheel speeds, lower feed rates, and shallow depths of cut to minimize thermal damage and work hardening. The ideal process parameters are highly dependent on the specific grinding wheel, the material being ground, the machine tool’s capabilities, and the desired part quality. Aerospace manufacturers often develop these through careful experimentation and rely on recommendations from both machine tool and grinding wheel suppliers.

Coolant Application and Filtration Systems

Grinding generates a lot of friction and, therefore, a lot of heat. In aerospace, where materials are often sensitive to heat and surface integrity is paramount, managing this heat with coolant (also called grinding fluid) is essential.

Coolant Application: Getting It Where It Counts

Just having coolant isn’t enough; it needs to be applied effectively.

- Key Roles of Coolant:

- Cooling: Reduces the temperature of the workpiece and the grinding wheel, preventing thermal damage and maintaining dimensional accuracy.

- Lubrication: Reduces friction between the abrasive grains and the workpiece, which can improve surface finish and reduce wheel wear.

- Chip Flushing: Carries away the tiny chips of material (swarf) produced during grinding, preventing them from clogging the wheel or damaging the workpiece surface.

- Nozzle Design and Placement: The design of the coolant nozzles and where they are aimed is critical. The goal is to get a strong, steady stream of coolant directly into the grinding zone – the tiny area where the wheel meets the part. For some operations, like creep-feed grinding, specialized “shoe” nozzles are used to flood the entire contact zone. High-pressure coolant delivery systems can be very effective at penetrating the air barrier created by a fast-spinning wheel.

- Flow Rate and Pressure: You need enough coolant volume (flow rate) and pressure to do the job. Too little, and it won’t be effective.

Different coolants (water-soluble oils, synthetic fluids, straight oils) are used for different materials and operations, but the effectiveness of the application system is universally important.

Filtration Systems: Keeping It Clean

What happens to the coolant after it has flushed away those tiny metal or ceramic chips? If you just keep pumping dirty coolant back to the grinding zone, you’re essentially sandblasting your precision part with its own debris! That’s why coolant filtration is so important.

- Benefits of Clean Coolant:

- Improved surface finish on the part.

- Longer grinding wheel life (less loading).

- Extended coolant life (saves money and is better for the environment).

- More consistent grinding results.

- Types of Filtration Systems: There are many types, ranging from simple to very sophisticated:

- Paper Band Filters: Coolant flows through a disposable paper medium.

- Magnetic Separators: Used to remove ferrous (iron-containing) particles.

- Cartridge Filters: Offer finer filtration for critical applications.

- Centrifuges: Use centrifugal force to separate particles from the coolant.

For aerospace grinding, where surface quality is often critical, filtration systems that can remove very fine particles (e.g., down to 5 or 10 micrometers, or even finer for superfinishing operations) are often necessary. For example, when grinding high-precision bearings for an aircraft engine, ultra-fine filtration is key to achieving the required low-friction surfaces. The specific level of filtration and type of system will depend on the materials being ground and the finish requirements, and suppliers can offer guidance on the best fit.

Operator Skill and Training Requirements

In an age of advanced CNC machines and automation, you might think the human element is less important. But in aerospace grinding, a skilled and knowledgeable operator is still absolutely vital. They are the brains behind the brawn of the machine.

Why are they so critical?

- Deep Understanding of the Process: A skilled operator doesn’t just push buttons. They understand the grinding process itself – how different materials react, how grinding wheels wear, what the sounds of a good (or bad) grinding process are, and how to interpret the sparks.

- Precise Setup: Aerospace parts often involve complex setups on the grinding machine. The operator must be able to accurately mount and align the workpiece and the grinding wheel, which can be a very exacting task. An error of a few thousandths of an inch in setup can lead to a scrapped part worth thousands of dollars.

- Troubleshooting Prowess: What happens when something goes wrong? A skilled operator can identify problems early – perhaps a change in the sound of the grinding, a subtle difference in the surface finish, or an unexpected reading on a machine display. They can then make informed adjustments to the process parameters or alert engineering before a major issue occurs.

- Interpreting Complex Specifications: Aerospace drawings are filled with detailed information, including Geometric Dimensioning and Tolerancing (GD&T). Operators need to be able to read and understand these complex requirements to ensure the part is made correctly.

- Unwavering Quality Consciousness: Aerospace demands perfection. Operators must be meticulous, pay close attention to detail, and follow all quality procedures rigorously. There’s no room for “good enough.”

- Adaptability and Continuous Learning: Aerospace manufacturing is constantly evolving with new materials, new tool technologies, and updated machine capabilities. Operators need to be willing to learn and adapt through ongoing training and experience.

Think of an experienced grinding operator much like a skilled artisan or technician who combines deep knowledge with advanced technology. Their expertise, experience, and intuition allow them to produce components that meet the incredible demands of flight. Investing in thorough training and continuous development for operators is a key factor in achieving consistent aerospace grinding success.

Conclusion

Successfully grinding components for the aerospace industry is a highly demanding endeavor that goes far beyond simply selecting a grinding wheel. It requires a deep understanding of the unique challenges posed by exotic materials, complex geometries, and the absolute necessity for precision and surface integrity.

Choosing the right tools – from advanced superabrasives like CBN and diamond to the specific bonds that hold them, and specialized wheels for intricate tasks – is a critical first step. However, as we’ve seen, this must be complemented by careful consideration of the specific material being ground, whether it’s tackling the heat and reactivity of titanium, managing the work hardening of nickel superalloys, preventing damage in composites, or carefully shaping brittle ceramics.

Ultimately, aerospace grinding success hinges on a holistic approach. The grinding machine itself, the meticulously optimized process parameters, effective coolant delivery and filtration, and the invaluable skill and knowledge of the operator all form an interconnected system. Only by mastering each of these elements can manufacturers consistently meet the stringent quality and performance standards that define the aerospace sector, ensuring the safety and reliability of every component that takes to the skies and beyond.

References

- Composites1 – ZYDiamondTools blog post discussing the use of PCD tools for machining aerospace composites.

- surface integrity2 – ScienceDirect topic page providing a comprehensive overview of surface integrity in engineering.

- superabrasive wheels, like CBN and diamond3 – ZYDiamondTools blog post comparing CBN and Diamond grinding wheels.

- type of bond used4 – ZYDiamondTools blog post explaining different grinding wheel bond types.

- 3A1 Type Vitrified Bond Diamond Grinding Wheels5 – ZYDiamondTools product page for a specific type of vitrified bond diamond grinding wheel.

- Electroplated Diamond & CBN Grinding Wheels6 – ZYDiamondTools comprehensive guide on electroplated diamond and CBN grinding wheels.

- Creep-feed Grinding7 – United Grinding (grinding.ch) blog post explaining differences between creep-feed grinding and conventional traverse grinding.

- Dressing8 – ZYDiamondTools practical how-to guide on diamond wheel dressing.