-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

-

Whatsapp: +86 13526572721

-

Email: info@zydiamondtools.com

-

Address: AUX Industrial Park, Zhengzhou City, Henan Province, China

Grinding Wheel Bond Types Explained: Selecting the Right Bond for Optimal Performance

Ever wondered what makes one grinding wheel perfect for a job while another just doesn’t cut it, and how you can choose the right one every time?

The secret often lies in the grinding wheel’s bond type, the material that holds the abrasive grains together, which critically dictates its performance, suitability for various materials, and the results you can achieve. Understanding the defining characteristics of major bond types—like vitrified, resinoid, rubber, metal, and electroplated—and knowing how to match them to your specific application, material, and grinding objectives is key to selecting the optimal grinding wheel for peak performance and efficiency.

What Are the Defining Characteristics of Major Grinding Wheel Bond Types?

So, what exactly sets the major grinding wheel bond types apart from each other, and why should you care?

The major grinding wheel bond types are primarily distinguished by their material composition, which dictates their unique physical and chemical properties. These characteristics include varying degrees of hardness, strength, rigidity, elasticity, and resistance to heat or chemicals, directly influencing how the grinding wheel performs and its suitability for different tasks. For instance, vitrified bonds are celebrated for their unyielding rigidity and porous nature, making them excellent for precision work, whereas resinoid bonds provide more “give” or elasticity, rendering them suitable for operations involving higher stress or shock.

Understanding these differences is crucial because the bond is like the “glue” holding the abrasive cutting grains1 in place. If the glue is too weak, the grains fall out too soon, and the wheel wears down quickly. If it’s too strong, dull grains stay in place, and the wheel won’t cut efficiently. Let’s explore the key players.

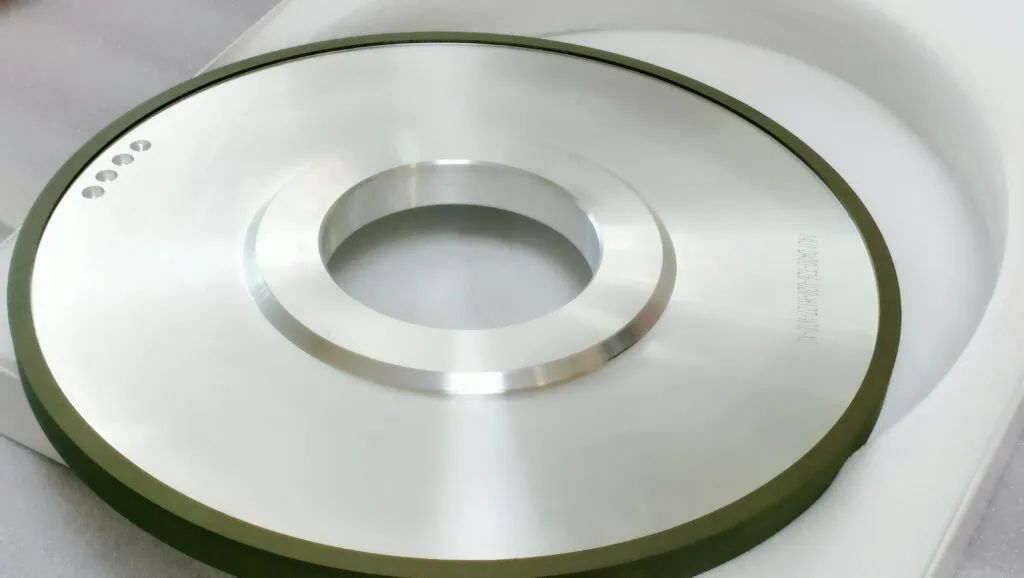

Vitrified (V) Bond: Key Properties and Strengths

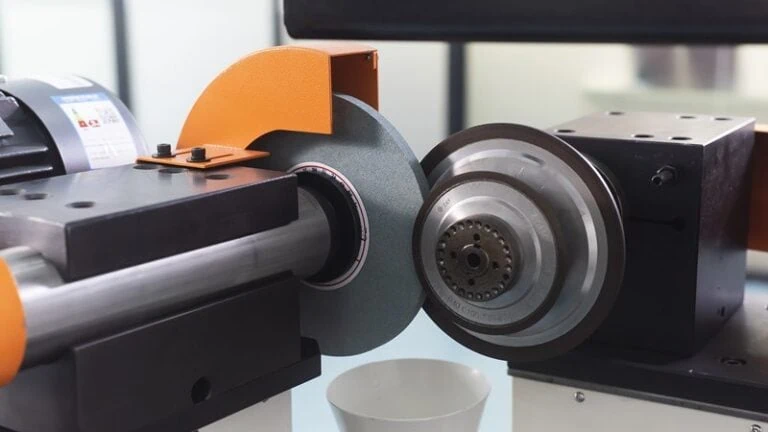

Vitrified bonds are among the most widely used in grinding operations, and for good reason. Imagine a very hard, glass-like material – that’s essentially what a vitrified bond is. It’s created by fusing clay and other ceramic materials at very high temperatures, typically between 1100°C and 1300°C. This process results in a strong, rigid, and porous structure.

Key Properties:

- High Rigidity and Strength: Vitrified bonds are very stiff and strong. This means they can hold the abrasive grains securely, allowing for aggressive material removal and precise grinding. They resist deformation under load, which is critical for maintaining accurate shapes and sizes on the workpiece.

- Porosity: The manufacturing process creates numerous tiny pores within the bond. Think of it like a sponge, but a very hard one! These pores are vital because they:

- Provide space for grinding swarf (the tiny chips of material being removed) to escape, preventing the wheel from “loading” or clogging up.

- Allow coolant to reach the cutting zone more effectively, reducing heat buildup.

- Chemical Inertness: Vitrified bonds are generally unaffected by water, oils, acids, or most common coolants. This stability ensures consistent performance over time and in various grinding environments.

- Excellent Form Holding: Due to their rigidity, vitrified bond wheels maintain their shape exceptionally well during grinding. This is essential for applications requiring tight tolerances and consistent profiles, such as grinding cutting tool flutes or precision aerospace components.

- Good Dressability: While strong, vitrified bonds can be effectively dressed (resharpened and reshaped) using appropriate dressing tools. This allows the operator to expose fresh, sharp abrasive grains and maintain the wheel’s geometry.

Strengths:

- Precision Grinding: Their rigidity and form-holding capabilities make them ideal for tasks demanding high accuracy, such as grinding bearings, gears, and tool surfaces. For example, in the automotive industry, vitrified CBN (Cubic Boron Nitride) wheels2 are used for grinding hardened steel crankshafts to very tight dimensional and surface finish specifications.

- High Stock Removal Rates (in suitable machines): When paired with a rigid, powerful grinding machine, the strong grain retention allows for aggressive cutting without premature wheel breakdown.

- Versatility with Conventional Abrasives: They work exceptionally well with conventional abrasives like aluminum oxide and silicon carbide for grinding a wide range of ferrous and non-ferrous metals, as well as some non-metallic materials.

- Long Life in Appropriate Applications: When used correctly, their wear resistance contributes to a longer usable life compared to softer bonds in similar precision tasks.

However, it’s worth noting that their rigidity also means they can be somewhat brittle and thus more susceptible to chipping or breaking under high impact or shock loads compared to more resilient bonds. Bond hardness grades (indicating the strength of the bond holding the abrasive) are available, and specific values can differ between manufacturers; always consult supplier data for precise specifications.

Resinoid (B) Bond: Key Properties and Strengths

Resinoid bonds, also known as organic bonds, are made from synthetic resins, such as phenolic or polyimide resins, acting as the bonding agent. These resins are mixed with the abrasive grains and then cured (hardened) using heat. Imagine a very tough, slightly flexible plastic holding the cutting particles.

Key Properties:

- Good Strength and Toughness: Resinoid bonds offer a good combination of strength and toughness. This means they can withstand higher mechanical stresses and shock loads than vitrified bonds, making them suitable for more demanding operations.

- Elasticity/Resilience: Compared to vitrified bonds, resinoid bonds have a degree of elasticity. This “give” helps absorb vibrations and impacts during grinding, which can be beneficial in rough grinding or when using portable grinding machines. For example, this resilience allows resinoid-bonded cut-off wheels to flex slightly without shattering when subjected to side pressures during a cutting operation.

- Heat Sensitivity (relative to vitrified): While tough, most resinoid bonds are less resistant to very high temperatures than vitrified bonds. Excessive heat can cause the bond to soften or char, leading to premature wheel wear or failure. However, specialized resinoid bonds are formulated for higher temperature applications.

- Variety of Formulations: Resinoid bonds can be formulated with various fillers and additives to tailor their properties for specific applications, such as improving heat dissipation or modifying the wheel’s cutting action.

Strengths:

- High-Speed Operations: Their strength and toughness make them suitable for grinding wheels designed to operate at high speeds, such as those used in cut-off applications, snagging (removing excess material from castings), and portable grinders. For instance, large resinoid-bonded wheels in steel mills operate at surface speeds exceeding 80 m/s to condition steel billets.

- Rough Grinding and Stock Removal: Ideal for applications where rapid material removal is more critical than achieving a perfect surface finish. Think of foundry snagging, where gates and risers are ground off castings.

- Cut-off Wheels: Resinoid bonds are the standard for thin cut-off wheels3 used for slicing through metals and other materials. Their ability to withstand flexing and side loads is crucial here. These wheels are often reinforced with layers of fiberglass for added safety and strength.

- Good for Superabrasives in Specific Applications: While metal and vitrified bonds are common for superabrasives (diamond and CBN), specialized resinoid bonds are also used effectively, particularly where a cooler cutting action or specific finish is needed.

- Can Produce Good Finishes: While often associated with rough grinding, certain resinoid bond formulations can also produce good surface finishes, especially when used with finer abrasive grits.

It’s important to choose a resinoid bond formulated for the specific grinding temperature and coolant being used, as their performance can be more sensitive to these factors than vitrified bonds. Different resin formulations offer varying degrees of hardness and heat resistance, so consulting supplier specifications for the specific application is advisable.

Rubber (R) Bond: Key Properties and Strengths

Rubber bonds, as the name suggests, use natural or synthetic rubber as the primary bonding agent. The abrasive grains are mixed with rubber and other modifying agents (like sulfur for vulcanization), then molded and cured under heat and pressure. The result is a wheel with a unique combination of properties.

Key Properties:

- Flexibility and Resilience: This is the hallmark of rubber bonds. They are more flexible and resilient than vitrified or even most resinoid bonds. This allows the wheel to conform slightly to the workpiece surface.

- Smooth Cutting Action: The inherent dampening effect of rubber contributes to a very smooth, chatter-free cutting action.

- Ability to Impart High Surface Finishes: Due to their smooth cutting action and ability to carry fine abrasive grits, rubber-bonded wheels are excellent for achieving very fine, almost polished, surface finishes.

- Heat Generation: Rubber is a poor conductor of heat. This means that grinding with rubber bonds can generate significant heat if not managed properly with appropriate coolants and light pressures.

Strengths:

- Producing Excellent Surface Finishes: Their primary strength lies in applications where a high-quality surface finish is paramount. They are often used in the final stages of grinding or for polishing operations. For example, they are used to achieve mirror finishes on rolls for the paper and steel industries.

- Centerless Grinding Regulating Wheels: In centerless grinding, the regulating wheel (which controls the rotation and feed of the workpiece) is often a rubber-bonded wheel due to its consistent grip and smooth control.

- Thin Cut-off Wheels for Burr-Free Cutting: For delicate cutting operations on thin-walled tubing or small components where minimizing burrs is critical, rubber-bonded cut-off wheels excel. Their flexibility helps prevent binding and breakage.

- Flute Grinding/Polishing: Used for polishing the flutes of cutting tools like drills and end mills to improve chip evacuation and tool life.

- Wet Grinding: Often used in wet grinding conditions, as the coolant helps manage the heat generated.

While flexible, they are not typically used for heavy stock removal due to their softer nature and heat sensitivity compared to vitrified or robust resinoid bonds. The specific rubber composition and cure can be adjusted to achieve different degrees of hardness and flexibility, and as with other bonds, checking supplier specifications for the intended application is recommended.

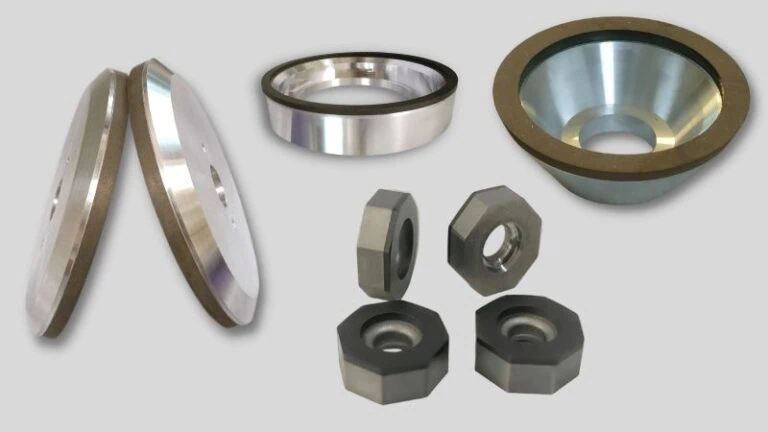

Metal (M) Bond: Key Properties and Strengths

Metal bonds use various metals and metal alloys (such as bronze, steel, tungsten carbide, or other specialized alloys) to hold the abrasive grains, which are typically superabrasives like diamond or Cubic Boron Nitride (CBN). The manufacturing process usually involves powder metallurgy, where the metal powder and abrasive are mixed, pressed, and then sintered (heated below the melting point to fuse the particles).

Key Properties:

- Extreme Hardness and Wear Resistance: Metal bonds are the toughest and most wear-resistant of all bond types. This allows them to securely hold superabrasive grains even under severe grinding conditions.

- Excellent Form Holding: Due to their rigidity and wear resistance, metal-bonded wheels maintain their profile exceptionally well over extended periods of use. This is critical for grinding complex forms or maintaining tight tolerances on hard materials.

- High Thermal Conductivity: Metals generally conduct heat well. This property helps dissipate heat from the grinding zone, which can be beneficial when grinding hard, heat-sensitive materials.

- Difficult to Dress: A consequence of their hardness and wear resistance is that metal-bonded wheels are more challenging and time-consuming to dress (true and re-sharpen) compared to other bond types. Specialized dressing techniques and tools are often required.

Strengths:

- Grinding Extremely Hard and Brittle Materials: This is their forte. Metal-bonded diamond wheels4 are used for grinding ceramics, glass, tungsten carbide, stone, and concrete. Metal-bonded CBN wheels are used for grinding hardened ferrous alloys, tool steels, and superalloys. For instance, in the construction industry, metal-bonded diamond blades are indispensable for cutting concrete and asphalt.

- Long Wheel Life: Their exceptional wear resistance translates into a very long service life, especially when grinding difficult-to-machine materials. This can offset their typically higher initial cost.

- Precision Form Grinding of Hard Materials: Ideal for applications like grinding carbide cutting tool inserts or complex ceramic components where maintaining an accurate profile for a long time is essential.

- Suitable for High-Force Applications: Their inherent strength allows them to be used in applications involving high grinding forces without rapid degradation.

Metal bonds are a significant investment, typically reserved for applications where the extreme properties of superabrasives are required and the long life can justify the cost. The choice of specific metal alloy for the bond will depend on the abrasive type (diamond or CBN) and the material being ground.

Electroplated (EP) Bond: Key Properties and Strengths

Electroplated bonds are unique in that they consist of a single layer of abrasive grains (usually diamond or CBN) held onto a pre-formed metal core (often steel) by a layer of electrodeposited nickel or other metal. Imagine sprinkling sugar onto a sticky surface – the grains are on the outside, very exposed.

Key Properties:

- Single Abrasive Layer: Only one layer of abrasive is present. Once this layer is worn, the wheel is typically considered consumed, though some specialized tools can be re-plated.

- High Abrasive Exposure: The abrasive grains protrude significantly from the bond layer, leading to a very aggressive, free-cutting action.

- Excellent Form Holding (Initially): The wheel is manufactured to a precise form, and because the abrasive is on the surface of this form, it holds that profile very well until the abrasive layer wears away.

- Good for Complex Profiles: Because the bond is applied to a pre-shaped core, electroplated wheels can be made in very intricate and precise shapes that would be difficult or impossible to achieve with other bonding methods.

- No Dressing Required: Since there’s only one layer of abrasive, dressing is not applicable.

Strengths:

- Aggressive Material Removal on Specific Materials: The high grain exposure allows for rapid cutting, especially in softer non-ferrous metals, plastics, composites (like Carbon Fiber Reinforced Polymer – CFRP), and some ceramics. For example, electroplated diamond tools5 are widely used in the aerospace industry for machining composite structures due to their ability to cut cleanly with minimal delamination.

- Grinding Complex Forms and Contours: Ideal for grinding or shaping intricate profiles, slots, and radii. Think of specialized tools for dental applications or molds.

- Small Diameter Wheels and Internal Grinding: Suitable for creating small grinding pins and wheels for internal grinding or deburring hard-to-reach areas.

- Relatively Lower Initial Cost for Custom Forms: For producing custom-shaped grinding tools in small quantities, electroplating can sometimes be more cost-effective than creating sintered metal or vitrified bond tools.

The primary limitation of electroplated bonds is their finite life, determined by the wear of the single abrasive layer. They are not suitable for continuous, high-volume production grinding in the same way as wheels with multiple layers of abrasives.

Other Specialized Bonds (Shellac, Oxychloride): A Brief Overview

While vitrified, resinoid, rubber, metal, and electroplated bonds cover the vast majority of grinding applications, a couple of other specialized types are worth a brief mention:

- Shellac (E) Bond:

- Key Characteristic: Uses shellac (a natural resin) as the bonding agent. These wheels are known for their ability to produce very fine, almost mirror-like finishes with a cool cutting action. They are not very strong and are typically used for light grinding and polishing operations.

- Strength/Use: Historically used for sharpening razors and fine cutlery, and sometimes for roll grinding to achieve exceptionally smooth surfaces. They are less common today due to advancements in other bond types but still find niche applications where an extremely gentle cutting action and high luster are required.

- Oxychloride (O) Bond:

- Key Characteristic: Employs magnesium oxychloride cement as the bond. This bond is known for its cool cutting characteristics, particularly in dry grinding applications.

- Strength/Use: Primarily used in some types of disc grinding and for embedding abrasive segments in specific grinding tools. They are not widely used for general-purpose grinding wheels but offer advantages in certain dry, low-pressure applications, such as grinding the faces of inserted tooth saw blades.

These specialized bonds serve very specific purposes and highlight the diverse material science involved in creating grinding tools tailored for almost any imaginable task.

Which Bond Type Is Best Suited for Your Specific Grinding Application and Material?

Alright, now that we know what these bonds are, how do you figure out which bond type is the right match for your specific grinding job and the material you’re working with?

Matching the correct bond type to your grinding application and material is crucial for achieving optimal results, efficiency, and wheel life. The ideal bond depends heavily on factors such as the material’s hardness and toughness, the type of grinding operation (e.g., roughing vs. finishing, cutting vs. shaping), and the desired outcome in terms of precision and surface quality. For example, rigid vitrified bonds are often preferred for precision grinding hard steels, while resilient resinoid bonds are better suited for high-speed cutting or rough grinding applications on various metals.

Choosing the right bond isn’t just about a single factor; it’s about how the bond’s characteristics (which we explored earlier) align with the demands of your task. Let’s break down where each major bond type typically shines.

Matching Vitrified Bonds to Applications and Materials

Vitrified bonds, known for their rigidity and porosity, are versatile but particularly excel in applications demanding precision and when working with specific material groups.

Typical Applications:

- Precision Surface Grinding: Creating flat, accurate surfaces on machine beds, die components, and other precision parts.

- Cylindrical Grinding (External and Internal): Grinding shafts, bearings, bushings, and internal bores to tight tolerances. For example, automotive crankshafts and camshafts are often precision ground using vitrified wheels with CBN or aluminum oxide abrasives.

- Tool and Cutter Sharpening: Maintaining the sharp edges and precise geometry of cutting tools like drills, end mills, and reamers. This is common in machine shops and manufacturing facilities.

- Form Grinding: Creating or maintaining specific profiles on workpieces, such as gear teeth or threaded components, where the wheel’s ability to hold its shape is paramount.

- Creep Feed Grinding: A specialized high-productivity surface grinding process where the full depth of cut is achieved in a single pass. The porosity of vitrified bonds is advantageous here for coolant delivery and swarf removal.

Suitable Materials:

- Hardened Steels: Tool steels, alloy steels, and case-hardened steels (typically >45 HRC). The rigidity of the bond helps in effectively grinding these hard materials.

- Cast Irons: Both grey and ductile cast irons.

- Ferrite and Some Non-Ferrous Metals: While less common than for steels, they can be used on harder bronzes or specific aluminum alloys.

- Superabrasives (CBN) for Ferrous Alloys: Vitrified CBN wheels are a standard for grinding hardened ferrous materials, offering long life and high precision. For instance, grinding high-speed steel (HSS) cutting tools.

- Superabrasives (Diamond) for Non-Metallics: Vitrified diamond wheels are used for grinding advanced ceramics, tungsten carbide (before sintering or for specific finishes), and some glass types.

When considering vitrified bonds, remember that while they offer excellent precision, their inherent brittleness makes them less ideal for applications with significant shock or vibration, or where the grinding machine lacks rigidity.

Matching Resinoid Bonds to Applications and Materials

Resinoid bonds, characterized by their strength and resilience, are the workhorses for a wide array of more rugged grinding tasks and high-speed operations.

Typical Applications:

- Cut-off Operations: Thin resinoid-bonded wheels, often reinforced with fiberglass, are universally used for slicing through metal bars, pipes, and sheets. Think of handheld angle grinders or larger stationary cut-off saws in fabrication shops.

- Snagging and Rough Grinding: Removing gates, risers, and flashing from castings in foundries, or smoothing weld beads. These are high-pressure, high-stock removal tasks.

- Portable Grinding: Used on handheld grinders for general-purpose grinding, deburring, and shaping in workshops and construction sites.

- Roll Grinding (specific types): While vitrified and rubber bonds are also used, certain resinoid bonds are employed for grinding large industrial rolls.

- High-Speed Grinding: Their ability to withstand high centrifugal forces makes them suitable for operations above standard speeds, often seen in specialized production environments. For example, conditioning steel billets in steel mills can involve resinoid wheels operating at surface speeds over 80 m/s.

- Centerless Bar Grinding: Used for through-feed grinding of bars and tubes where high productivity is key.

Suitable Materials:

- Steels (Soft to Medium Hardness): Carbon steels, structural steels, and some alloy steels.

- Stainless Steels: Widely used for cutting and light grinding of stainless steel components.

- Cast Irons: Effective for rough grinding and cutting.

- Non-Ferrous Metals: Aluminum, brass, bronze, and copper, especially for cut-off and general-purpose grinding.

- Superabrasives (Diamond and CBN) for Specific Tasks: Resinoid-bonded superabrasive wheels are used for grinding composites, ceramics (diamond), and tool steels or superalloys (CBN), especially where some shock resistance or a specific finish generated by this bond type is desirable. For instance, resinoid diamond wheels are common for grinding friction materials like brake pads.

Resinoid bonds offer versatility, but their performance can be affected by excessive heat. Ensuring proper coolant application (if used) and not exceeding the wheel’s recommended operating speed are important considerations.

Matching Rubber Bonds to Applications and Materials

Rubber bonds stand out due to their flexibility and ability to produce exceptionally fine finishes, making them ideal for specialized applications rather than heavy material removal.

Typical Applications:

- Fine Finishing and Polishing: Achieving very smooth, often reflective, surfaces on metals. This is crucial in industries producing precision components like hydraulic pistons or decorative parts.

- Regulating Wheels in Centerless Grinding: The “feed wheel” in centerless grinders is almost always a rubber-bonded wheel. Its consistent grip and controlled friction are essential for accurately rotating and feeding the workpiece through the grinding zone.

- Thin Slotting and Grooving: Creating narrow slots or grooves with minimal burrs, for example, in the manufacture of ball bearing races or fine electronic components.

- Cut-off Wheels for Delicate Parts: Producing clean, burr-free cuts on thin-walled tubing or small, delicate components where minimizing deformation is critical.

- Glass Edge Grinding/Polishing (Specific Formulations): Specialized rubber-bonded diamond wheels can be used for achieving smooth, polished edges on glass.

Suitable Materials:

- Hardened Steels (for finishing): After primary grinding with other bonds, rubber wheels can be used to achieve the final surface finish requirements.

- Stainless Steels (for finishing and burr-free cutting).

- Non-Ferrous Metals: Aluminum, brass, copper, especially when a high polish or delicate cut is needed.

- Glass and Ceramics (specialized diamond rubber bonds): For fine finishing and polishing rather than stock removal.

The key with rubber bonds is light pressure and, often, ample coolant to manage heat, given rubber’s insulating properties. Their flexibility is an asset for finish and conforming to slight irregularities, but they are not suited for hogging material.

Matching Metal Bonds to Applications and Materials

Metal bonds are the champions of durability and are almost exclusively paired with superabrasives (diamond or CBN) for tackling the hardest and most abrasive materials.

Typical Applications:

- Grinding Hardened Tool Steels and Superalloys (CBN): Metal-bonded CBN wheels are used for grinding high-speed steels (HSS), die steels, and heat-resistant superalloys found in aerospace components. Their long life makes them economical despite higher initial costs in high-volume production.

- Grinding Ceramics, Glass, and Quartz (Diamond): Manufacturing optical lenses, machining advanced ceramic components for electronics or wear parts, and cutting quartz for the semiconductor industry often rely on metal-bonded diamond wheels.

- Grinding Tungsten Carbide (Diamond): Shaping and sharpening carbide cutting tools, dies, and wear parts. For example, manufacturers of carbide end mills use metal-bonded diamond wheels for fluting operations.

- Concrete and Stone Cutting/Grinding (Diamond): Diamond blades and cup wheels with metal bonds are standard in the construction and stone industries for cutting concrete slabs, masonry, granite, and marble.

- Honing and Superfinishing (Specific Metal Bonds): While other bonds are also used, specialized metal bonds are employed in honing tools for achieving precise bore geometries and surface finishes.

Suitable Materials:

- Hardened Ferrous Alloys (>55 HRC) (CBN): Tool steels, high-carbon high-chromium steels, nickel-based and cobalt-based superalloys.

- Advanced Ceramics: Alumina, zirconia, silicon nitride, silicon carbide.

- Tungsten Carbide and Cermets.

- Glass, Quartz, and other Brittle Non-Metallics.

- Natural Stone (Granite, Marble) and Concrete/Asphalt.

Metal-bonded wheels are an investment. Their strength lies in their incredible wear resistance and ability to maintain form when grinding challenging materials. However, they typically require rigid machines and are harder to dress than other bond types. The specific metal matrix (e.g., bronze, steel, cobalt-based) is chosen based on the abrasive and the application’s demands for wear versus dressability.

Matching Electroplated Bonds to Applications and Materials

Electroplated bonds, with their single, highly exposed layer of superabrasive, offer an aggressive cutting action and are excellent for creating or maintaining complex forms.

Typical Applications:

- Form Grinding of Complex Profiles: Ideal for grinding intricate shapes, contours, and radii in a single pass. This is used in making molds, dies, and specialized tooling.

- Grinding Composites (Diamond): Carbon fiber reinforced plastics (CFRP), glass fiber reinforced plastics (GFRP), and other composite materials are effectively machined with electroplated diamond tools, often producing good surface quality with minimized delamination. Aerospace and automotive industries frequently use these for trimming and shaping composite parts.

- Internal Grinding of Small Bores (Diamond/CBN): Small-diameter grinding pins for internal grinding or jig grinding often use electroplated bonds due to the ease of manufacturing small, precise forms.

- Deburring Hard Materials: Removing burrs from machined or cast components made from hard metals or ceramics.

- Medical and Dental Instruments (Diamond): Manufacturing and shaping stainless steel or ceramic components for medical and dental tools often utilize the precision and form-holding of electroplated diamond tools.

- Abrasive Cutting Tools: Some specialized cutting tools, like routers or hole saws for abrasive materials, utilize electroplated diamond segments.

Suitable Materials:

- Composites (CFRP, GFRP).

- Plastics and Reinforced Plastics.

- Soft Non-Ferrous Metals (where high initial sharpness is beneficial).

- Some Ceramics and Glass (especially for shaping and intricate details).

- Graphite.

- Hardened Steels (CBN for specific form grinding or deburring).

Because electroplated tools have only one layer of abrasive, their lifespan is finite. They are not typically dressed. They offer excellent initial sharpness and can be cost-effective for custom forms or when the aggressive cutting action is a primary requirement for shorter production runs or specific profile work.

How Can You Systematically Choose the Ideal Grinding Wheel Bond?

So, with all this information about bond types and their uses, how do you actually go about picking the perfect one for your specific needs in a systematic way?

Systematically choosing the ideal grinding wheel bond involves a multi-step evaluation process. This begins with a thorough assessment of your workpiece material’s properties and a clear definition of your grinding objectives, such as desired finish, stock removal rate, and accuracy. Subsequently, you must consider your grinding machine’s capabilities, operating conditions, and how the bond will interact with your chosen abrasive and coolant to make an informed decision.

Making the right choice ensures your grinding operation is efficient, cost-effective, and produces parts that meet quality standards. Think of it as detective work, where each clue leads you closer to the optimal solution. Let’s break down the key factors to investigate.

Evaluating Workpiece Material and Its Properties

The first and often most critical step is to deeply understand the material you intend to grind. Different materials behave in vastly different ways when subjected to the forces and temperatures of grinding.

Key material properties influencing bond choice include:

- Hardness: This is a measure of the material’s resistance to indentation or scratching.

- Impact: Very hard materials (like hardened tool steels, ceramics, or tungsten carbide) typically require harder bonds (like vitrified or metal) that can securely hold superabrasive grains or very friable conventional abrasives. Softer materials might allow for softer bonds that break down more easily to expose fresh abrasive.

- Industry Example: Grinding a D2 tool steel hardened to 60 HRC would likely steer you towards a vitrified CBN wheel, whereas grinding soft aluminum might use a softer grade resinoid bond.

- Toughness: This refers to a material’s ability to absorb energy and resist fracturing.

- Impact: Tough materials can generate high grinding forces. Bonds need to be strong enough to withstand these forces. For instance, resinoid bonds are often favored for their toughness in applications like snagging tough castings.

- Tensile Strength: The resistance of a material to breaking under tension.

- Impact: Materials with high tensile strength may require bonds that allow for a sharper cutting action to avoid excessive heat or force.

- Thermal Conductivity: How well a material conducts heat.

- Impact: Materials with poor thermal conductivity (like many stainless steels or superalloys) are prone to overheating and thermal damage. A bond that promotes a cooler cutting action (e.g., more porous vitrified bonds for better coolant access, or sometimes rubber bonds for specific finishes if heat is managed) might be preferred.

- Chemical Reactivity: Some materials can react chemically with the abrasive or the bond at grinding temperatures.

- Impact: For example, carbon-based abrasives like diamond are not typically used to grind ferrous materials at high temperatures due to chemical reactions. This influences the abrasive choice, which in turn influences the bond. Vitrified bonds are generally very chemically stable.

Always refer to material specification sheets or engineering handbooks to get accurate data on these properties. This foundational knowledge will heavily guide your subsequent choices.

Clarifying Your Grinding Objectives (Finish, Stock Removal, Accuracy)

What do you need the grinding operation to achieve? Your goals will significantly narrow down the suitable bond types.

- Surface Finish6 (Ra, µm, or RMS, µin):

- Impact: If a very fine, almost mirror-like finish is the primary goal, softer and more flexible bonds like rubber or specialized shellac bonds (with fine abrasive grits) are often chosen. For good commercial finishes, vitrified and resinoid bonds with appropriate grit sizes are common.

- Industry Example: Grinding hydraulic cylinder rods often requires a very low Ra value, potentially leading to rubber-bonded wheels for the final pass.

- Stock Removal Rate (e.g., mm³/min or in³/min):

- Impact: When rapid material removal is the priority (e.g., in foundry snagging or rough grinding), tougher bonds that can withstand high pressures and hold coarser abrasives securely are needed. Resinoid bonds are a common choice here. Porous vitrified bonds can also offer good stock removal in precision applications with appropriate machine rigidity.

- Dimensional Accuracy and Form Holding:

- Impact: If maintaining tight tolerances (e.g., ±0.005 mm) and precise geometric forms is critical, a rigid bond that resists wear and deformation is essential. Vitrified bonds are excellent for this, and for extreme cases on very hard materials, metal bonds (especially with superabrasives) excel.

- Industry Example: Manufacturing precision ball bearing races requires exceptional dimensional and form accuracy, often relying on vitrified bond wheels.

Often, there are trade-offs. For example, achieving the highest stock removal rate might not yield the finest surface finish with the same wheel. You may need multiple operations with different wheels (and potentially different bonds) to achieve all objectives.

Factoring in Grinding Machine Capabilities and Operating Conditions

The grinding machine itself plays a huge role. A perfect wheel can underperform on an unsuitable machine.

- Machine Power and Rigidity:

- Impact: High-powered, rigid machines can effectively utilize harder bonds and enable more aggressive grinding parameters. Lighter, less rigid machines may require softer bonds that break down more easily to maintain a free-cutting action and prevent chatter or vibration. Using a very hard bond on a low-power or flexible machine can lead to wheel glazing and poor performance.

- Wheel Speed (Surface Feet Per Minute – SFPM, or Meters Per Second – m/s):

- Impact: Grinding wheels are designed and tested to operate safely up to a maximum rated speed. Resinoid bonds are generally preferred for very high-speed operations (e.g., above 60 m/s in some cut-off applications) due to their strength and toughness. Vitrified bonds also have high speed ratings but might have different limits. Always ensure the machine’s operating speed is compatible with the wheel’s maximum safe speed and the bond type. These speeds are typically marked on the wheel or provided in supplier documentation.

- Coolant Application (Wet or Dry Grinding):

- Impact:

- Wet Grinding: Most grinding operations benefit from coolant to reduce heat, flush away swarf, and improve wheel life and surface finish. Vitrified bonds are generally impervious to most coolants. Some resinoid bonds can be affected by certain types of coolants or prolonged exposure, so compatibility should be checked.

- Dry Grinding: If grinding dry, heat buildup is a major concern. Bonds that offer a cooler cut or are more heat-resistant are preferable. Open-structure (porous) vitrified wheels can help, or sometimes specialized bonds are used.

- Impact:

- Feed Rates and Depth of Cut:

- Impact: Aggressive parameters (high feed rates, deep cuts) demand bonds that can withstand higher forces without premature breakdown or excessive wear. This often points to tougher resinoid bonds or suitably graded vitrified bonds on rigid machines.

The machine’s condition (spindle bearing quality, overall stability) also affects performance and the suitability of different bond types.

Understanding the Interplay Between Bond, Abrasive, and Coolant

The bond is just one part of the grinding system. Its selection must be coordinated with the abrasive type and the coolant used.

- Abrasive Type Influence:

- Conventional Abrasives (Aluminum Oxide, Silicon Carbide): These are commonly used with vitrified, resinoid, and rubber bonds. The bond’s job is to hold these grains until they become dull, then release them to expose fresh, sharp grains.

- Superabrasives (Diamond, CBN): These much harder and more expensive abrasives require bonds that can hold them very securely and resist wear to maximize their long cutting life. This is why metal bonds are frequently used. Specialized vitrified and resinoid bonds have also been developed to optimize superabrasive performance7 in specific applications (e.g., vitrified CBN for hardened steels, resinoid diamond for composites).

- Bond’s Role with Abrasive Performance:

- A “harder” grade bond holds abrasive grains more tightly. This is good for soft materials that don’t dull abrasives quickly, or for maintaining form.

- A “softer” grade bond releases abrasive grains more easily. This is beneficial for hard materials that dull abrasives quickly, ensuring new sharp grains are always exposed (self-sharpening effect).

- Coolant Interaction:

- Coolant does more than just cool. It lubricates, reducing friction. It also helps flush grinding swarf from the pores of the wheel, which is particularly important for porous bonds like vitrified. The coolant must be compatible with the bond material to prevent degradation. For instance, highly alkaline coolants might affect certain resinoid bonds over time. Always check coolant compatibility with the wheel manufacturer’s recommendations.

Thinking of these three elements – bond, abrasive, coolant – as a team that must work together will lead to better grinding outcomes.

A Decision-Making Framework for Bond Selection

While every grinding application can have unique nuances, a structured approach can simplify the bond selection process. Consider the following questions and general pointers:

| Consideration Category | Key Question(s) to Ask | General Implication for Bond Choice |

|---|---|---|

| 1. Workpiece Material | What is the material? What is its hardness, toughness, and thermal sensitivity? | Hard/Brittle (e.g., >55HRC steels, ceramics): Vitrified (esp. with superabrasives), Metal. Soft/Ductile (e.g., aluminum, mild steel): Resinoid, softer grade Vitrified, Rubber. Heat Sensitive: Porous Vitrified, Rubber (with care), specific cool-cutting Resinoids. |

| 2. Grinding Objective(s) | What is the primary goal: high stock removal, fine surface finish, or tight dimensional/form accuracy? | High Stock Removal: Resinoid, porous Vitrified. Fine Surface Finish: Rubber, Shellac, fine grit Vitrified/Resinoid. Tight Tolerance/Form Holding: Vitrified, Metal. |

| 3. Machine & Conditions | What is the machine’s power, rigidity, and available spindle speed? Is coolant used (type)? | High Speed (SFPM/MPS): Resinoid. Low Power/Rigidity: Softer grade bonds. Precision Machine: Can utilize harder, more precise bonds like Vitrified. Dry Grinding: Bonds offering cool cut or higher heat resistance. |

| 4. Abrasive Type | Are you using conventional abrasives (AlOx, SiC) or superabrasives (Diamond, CBN)? | Conventional: Vitrified, Resinoid, Rubber. Superabrasives: Metal, specialized Vitrified, specialized Resinoid, Electroplated. |

| 5. Economic Factors | What is the required wheel life versus initial cost? What is the overall cost per part? | Long life on hard materials: Metal (higher initial cost, lower per-part cost in high volume). General Purpose/Cost-Effective: Vitrified, Resinoid. |

Final Step: Consult the Experts

After going through this evaluation, it’s always an excellent practice to consult with grinding wheel manufacturers or their technical representatives. They have extensive knowledge and can provide specific recommendations based on your detailed application parameters. They can also advise on the latest advancements in bond technology that might be beneficial. Remember that parameters like bond grade (hardness) within a bond type can vary significantly, and supplier data is key for these specifics.

Conclusion

Choosing the right grinding wheel bond is a critical step towards achieving your desired grinding results efficiently and effectively. By understanding the distinct characteristics of different bond types, recognizing their ideal applications and material pairings, and following a systematic approach to selection, you are now better equipped to make informed decisions that enhance productivity and part quality. Remember that the world of abrasives and grinding technology is continually advancing. Therefore, embracing ongoing learning and consulting with suppliers or industry experts will further refine your expertise and ensure your grinding operations remain at the cutting edge of performance and success.

References

- abrasive cutting grains1 – Britannica article explaining abrasives and their technological applications.

- CBN (Cubic Boron Nitride) wheels2 – ZYDiamondTools comprehensive guide to selecting and using vitrified bond diamond and CBN grinding wheels.

- cut-off wheels3 – ZYDiamondTools product page for resin bond diamond cutting discs.

- metal-bonded diamond wheels4 – ZYDiamondTools guide on why metal bond diamond/CBN grinding wheels excel and how to select them.

- electroplated diamond tools5 – ZYDiamondTools ultimate guide to electroplated diamond and CBN grinding wheels.

- Surface Finish6 – Get It Made UK article explaining surface roughness and its parameters.

- superabrasive performance7 – ZYDiamondTools blog post on choosing between CBN and diamond grinding wheels for optimal performance.